Was about to ask how narrow you can make it 🙂 It looks like the new formula is more versatile for sure.

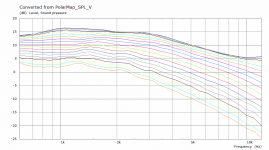

Interestingly this one happens to have lot nicer top end, and could have smaller mouth to meet 15" driver than the previous ones.

Interestingly this one happens to have lot nicer top end, and could have smaller mouth to meet 15" driver than the previous ones.

Last edited:

Seems like a trade off between a few HF wiggles and a developing trough at 1K.A one from another batch:

Frequencies above ~10 kHz are affected especially by the throat details and that is pretty independent of the rest of the waveguide (different 'k' values). So in these examples the behaviour above 10 kHz may not be directly related to anything below that and could be different with a different value of 'k'.

It seems there's nothing one can do to make the DI lower than about 15 dB at 20 kHz (for a simple open 1" throat, that is). So if it's already that high below that, it makes a "nicer" top end...

It seems there's nothing one can do to make the DI lower than about 15 dB at 20 kHz (for a simple open 1" throat, that is). So if it's already that high below that, it makes a "nicer" top end...

Last edited:

Refined R-OSSE equations - this could already be a final form:

https://www.desmos.com/calculator/12wg304nu2

Beaming like hell still possible: https://www.desmos.com/calculator/7nu1irzflt 🙂

https://www.desmos.com/calculator/12wg304nu2

Beaming like hell still possible: https://www.desmos.com/calculator/7nu1irzflt 🙂

Last edited:

😀Refined R-OSSE equations - this could already be a final form:

https://www.desmos.com/calculator/12wg304nu2

Beaming like hell still possible: https://www.desmos.com/calculator/7nu1irzflt 🙂

This is also possible, I'm only not sure it's the best way:

Above 3 kHz the DI (and the -6dB beamwidth) is as flat as possible but the frequency responses in the listening window are actually not (and I guess that's how it must be). I believe that better would be to let the DI rise gently with the listening window flat (which can be done).

More something like this:

Above 3 kHz the DI (and the -6dB beamwidth) is as flat as possible but the frequency responses in the listening window are actually not (and I guess that's how it must be). I believe that better would be to let the DI rise gently with the listening window flat (which can be done).

More something like this:

What's the size of this horn?

I assume you print each sector of the horn separately. Did you glue them together? How did you keep them in the appropriate place?

I assume you print each sector of the horn separately. Did you glue them together? How did you keep them in the appropriate place?

It's only around 10 - 12". I've done this before:

https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-6760729

https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-6752296

https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-6744458

This way it's printable without any supports and one can make quite big waveguide even on a small printer. It's glued and it's a lot of work, I'm not sure I would recommend it to everyone. For me it's certainly a way of testing these things.

https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-6760729

https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-6752296

https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-6744458

This way it's printable without any supports and one can make quite big waveguide even on a small printer. It's glued and it's a lot of work, I'm not sure I would recommend it to everyone. For me it's certainly a way of testing these things.

Last edited:

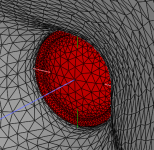

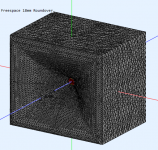

I put the Tritonia in a minimal baffle enclosure and simulated the freespace response with a dome tweeter as the original worked well with a spherical source.

I like it, within the listening window the responses are extremely similar to each other and fall off smoothly outside.

I like it, within the listening window the responses are extremely similar to each other and fall off smoothly outside.

Attachments

The final parametric equation, in case someone already wanted to explore it.

I write a paper on that but it will take some time...

I write a paper on that but it will take some time...

Code:

R = 180 # outer radius of the waveguide

a = 38.2 # nominal coverage angle

r0 = 12.7 # throat radius

a0 = 0 # throat angle

k = 0.88 # throat expansion factor

m = 0.85 # apex relative position

r = 0.31 # apex radius factor

b = 0.37 # bending factor

q = 3.00 # throat weighting factor

k1 = (k*r0)^2

k2 = 2*k*r0*tan(a0)

k3 = tan(a)^2

L = (sqrt(k2*k2 - 4*k3*(k1 - (R+r0*(k-1))^2)) - k2) / (2*k3)

x0 = L*sqrt(r*r + m*m)

b0 = (x0 - L*sqrt(r*r + (1-m)^2)) / (L*L)

y2(l) = sqrt(k1 + k2*l + k3*l*l) - r0*(k-1)

y0 = L + y2(L)

y1(l) = y0 - sqrt(L*L + k3*(l-L)^2)

w(t) = t^q

# t=<0,1>

x(t) = x0 - sqrt((r*L)^2 + L*L*(t-m)^2) - b*b0*(t*L)^2

y(t) = w(t)*y1(t*L) + (1-w(t))*y2(t*L)

Last edited:

Could someone advice wideband for STH 2-3" diameter? My friend (carpenter) would like to try STH in front and bent JMLC 80Hz on the back and install at home. He does not have experience to make multiway that's why a compromise.

Maybe the SB65WBAC25, it is used in this horn project with good results.

Though I doubt a driver that size will make a lot of bass...

Though I doubt a driver that size will make a lot of bass...

Would it be possible to have ATH output a set of kit stl files ready for 3D printing? Would be helpfull for guys like me that lack all the skills...

I wish I could be more helpfull. I try though. I ported (part of) MMM to python in order to try to utilize the GPU for the calculations. That succeeded after quite some hard work, but it is slower than the CPU version. Too bad, I dreamt of playing with some sliders for the OSSE parameters and getting some 'instant' feedback.

I wish I could be more helpfull. I try though. I ported (part of) MMM to python in order to try to utilize the GPU for the calculations. That succeeded after quite some hard work, but it is slower than the CPU version. Too bad, I dreamt of playing with some sliders for the OSSE parameters and getting some 'instant' feedback.

Jan Herich can implement ATH directly in his Java based nurbs slicer: https://www.spacedelta3d.com/

https://instagram.com/jan_herich?utm_medium=copy_link

https://instagram.com/jan_herich?utm_medium=copy_link

I can only recommend Autodesk Fusion 360 which I've learned myself just for this purpose (the few bits needed). It's really intuitive and easy to work with - to produce a STL model of an axisymemtric device takes a couple of minutes (see https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-6499437).Would it be possible to have ATH output a set of kit stl files ready for 3D printing? Would be helpfull for guys like me that lack all the skills...

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)