Hello, I was over at Parts Express and saw these new Planar speaker drivers that are on Sale the model is GRS PT6816-8 8 inch Planar Slim Tweeters , their Frequency Response is 320 to 20,000hz , I am thinking of using 7 or 8 of them in a Line Array as Tweeters .... and maybe 7 or 8 of the GRS PT6825-8 8 inch Planar Mid//Tweeters as the Midranges which are on Sale too ....... I was wondering if the tweeters can be mounted close enough to each other to avoid any major Lobing issues? -

GRS PT6816-8 Tweeters

- https://www.parts-express.com/GRS-PT6816-8-8-Planar-Slim-Tweeter-8-Ohm-272-128

-

GRS PT6825-8 Tweeter/Midranges

- https://www.parts-express.com/GRS-PT6825-8-8-Planar-Mid-Tweeter-8-Ohm-272-126

-

GRS PT6816-8 Tweeters

- https://www.parts-express.com/GRS-PT6816-8-8-Planar-Slim-Tweeter-8-Ohm-272-128

-

GRS PT6825-8 Tweeter/Midranges

- https://www.parts-express.com/GRS-PT6825-8-8-Planar-Mid-Tweeter-8-Ohm-272-126

-

Attachments

Hello,

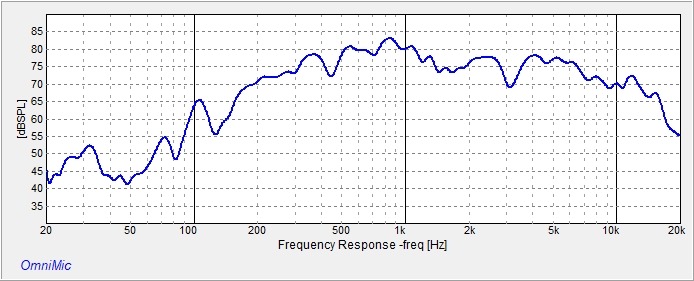

I am using a Chinese GRS PT6825-8.

Impedance curve.

Placed on a wall.

With a horn.

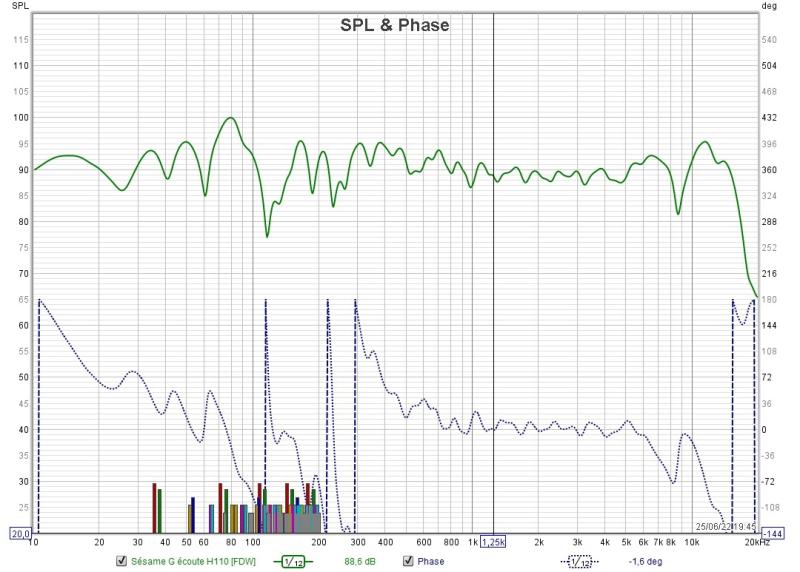

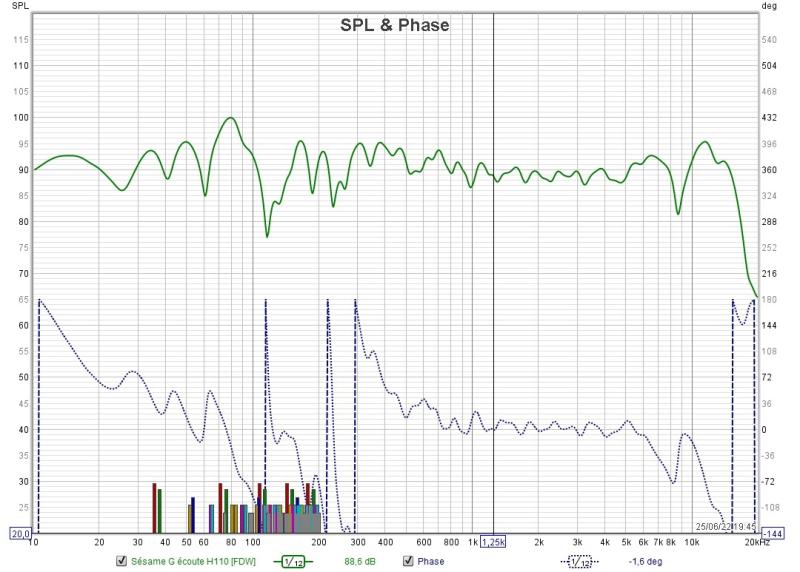

The green curve, with a cutoff of 48 dB / oct 250 Hz.

I am using a Chinese GRS PT6825-8.

Impedance curve.

Placed on a wall.

With a horn.

The green curve, with a cutoff of 48 dB / oct 250 Hz.

Hi sap2212, Very cool , the frequency response of the drivers in the horn looks better. It seems like you have been at this for a while, the horn is beautiful, hard to believe it is a diy speaker!

---- Do you have any pictures of how you made the Horns?

- It looks like you have some kind of lenses in front of the drivers , they make the installation look very professional, did you buy the lenses or make them?

- I noticed you have a Ripole subwoofer, I was looking into building one - I really like the concept, I was thinking of using two Woofers per Ripole to help cancel out any distortions., - not sure of the design yet though, I 'll put a couple of examples down below.

I was looking at your home page on diyaudio, and notice in another thread about Novacore planar tweeters that you mention your horns using the B&G Neo8 drivers , have you tried both? ,,, or are they maybe made by the same company that now makes the GRS PT6825-8 Planar drivers

Thank you for responding! -- been pretty quiet around this post - LOL ,

-- Ripole Ideas

---- Do you have any pictures of how you made the Horns?

- It looks like you have some kind of lenses in front of the drivers , they make the installation look very professional, did you buy the lenses or make them?

- I noticed you have a Ripole subwoofer, I was looking into building one - I really like the concept, I was thinking of using two Woofers per Ripole to help cancel out any distortions., - not sure of the design yet though, I 'll put a couple of examples down below.

I was looking at your home page on diyaudio, and notice in another thread about Novacore planar tweeters that you mention your horns using the B&G Neo8 drivers , have you tried both? ,,, or are they maybe made by the same company that now makes the GRS PT6825-8 Planar drivers

Thank you for responding! -- been pretty quiet around this post - LOL ,

-- Ripole Ideas

Last edited:

There is a description of my horns in a There is a description of my horns in a forum in French.

I think all the speakers are made in Asia.

The horns are made in Dibond®.

It is a material that can be found in billboard manufacturers.

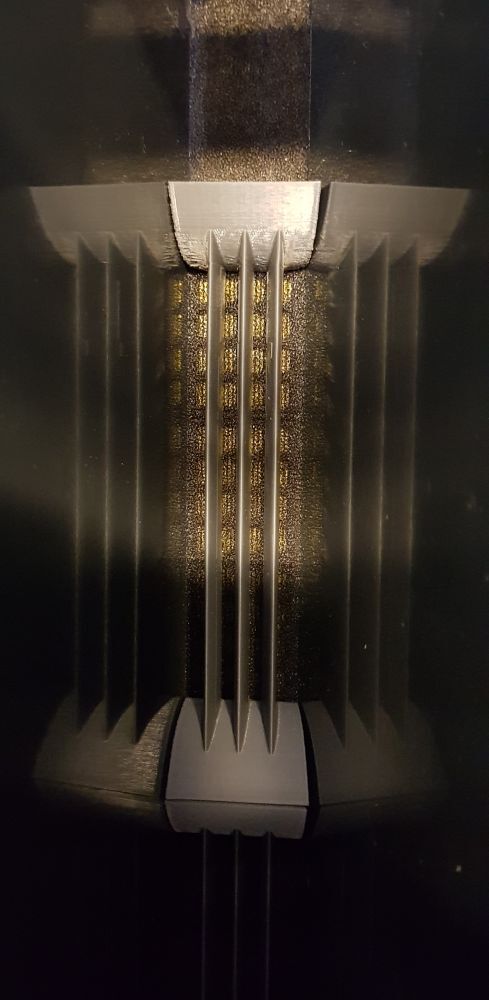

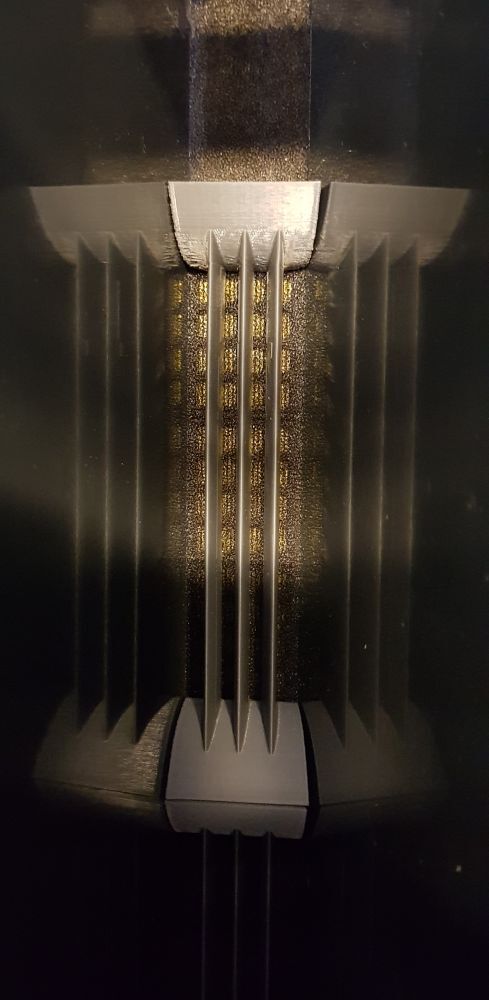

The other elements are created in 3D printing.

The Ripole uses a 24 "(61 cm) for the bass. Fane colossus 24 studio.

The QTS = 0.7 for 101 dB. The distortion is low because the diaphragm movements are small, even at 20 Hz. But not the floor.

I think all the speakers are made in Asia.

The horns are made in Dibond®.

It is a material that can be found in billboard manufacturers.

The other elements are created in 3D printing.

The Ripole uses a 24 "(61 cm) for the bass. Fane colossus 24 studio.

The QTS = 0.7 for 101 dB. The distortion is low because the diaphragm movements are small, even at 20 Hz. But not the floor.

Hi sap2212, thank you for the link! I enjoyed reading through the information on your speakers on the French Forum, it sounds like you have a really great audio community over at your forum.

- The Dibond® is a very interesting material, from what I could gather it doesn't sound like I could do a very good job of bending it, from my reading they use a special machine to do that, maybe I could cut and glue it at the right angle needed for the horn then maybe use some Aluminum to cover change of angles, But more likely I would probably have to build a horn out of mdf or some other material, eventually they could be built from Acrylic but maybe pretty expensive, but they would look nice and disappear into the room better.

- I looked around for a Fane Colosus 24 Studio but I couldn't find any.... maybe you got the last one ..... I don't don't think they make them any more ....

---

Thank you, for your encouragement !

- The Dibond® is a very interesting material, from what I could gather it doesn't sound like I could do a very good job of bending it, from my reading they use a special machine to do that, maybe I could cut and glue it at the right angle needed for the horn then maybe use some Aluminum to cover change of angles, But more likely I would probably have to build a horn out of mdf or some other material, eventually they could be built from Acrylic but maybe pretty expensive, but they would look nice and disappear into the room better.

- I looked around for a Fane Colosus 24 Studio but I couldn't find any.... maybe you got the last one ..... I don't don't think they make them any more ....

---

Thank you, for your encouragement !

PS. - I really like your 3D Printed Lenses , they make your speaker look as good or Better than any out there!

Hi sap2212 ,

- I was reading through the French Forum Link again I saw that your wife asked for a pair to be made for the living room - that's amazing she must really enjoy your new speakers! ......... As I was reading I realized you mentioned maybe making your new pair of Neo8 Horns Speakers out of Acrylic, and had several questions.

1. - I like how you used a hinge at the throat of you Horn Speaker to find the best angle to set the panels at, is that something you will use for the pair of speakers you want to make for your living room?

.... (or now that you have figured out the best angle, will you leave the hinge out of the pair for the Living room)?

2. - What do you think the best thickness of Acrylic panels should be for your new Neo8 Horn?

3. - Could you to tell me what degree that the fold is in the middle of each side panel?

-- Thank you, Dean

- I was reading through the French Forum Link again I saw that your wife asked for a pair to be made for the living room - that's amazing she must really enjoy your new speakers! ......... As I was reading I realized you mentioned maybe making your new pair of Neo8 Horns Speakers out of Acrylic, and had several questions.

1. - I like how you used a hinge at the throat of you Horn Speaker to find the best angle to set the panels at, is that something you will use for the pair of speakers you want to make for your living room?

.... (or now that you have figured out the best angle, will you leave the hinge out of the pair for the Living room)?

2. - What do you think the best thickness of Acrylic panels should be for your new Neo8 Horn?

3. - Could you to tell me what degree that the fold is in the middle of each side panel?

-- Thank you, Dean

An interesting idea. At the very low displacement an array would need, seems distortion may be tolerable. With one, it is not. I have a peculiar space problem in my HT, and this may be a viable way out. I was tempted by BG but they are gone.

As far as big horns, SOP for us woodworkers is "cold mold" plywood. Quite easy. I have bought sheets of oak veneer cheap and used it. Vacuum bagging.

As far as big horns, SOP for us woodworkers is "cold mold" plywood. Quite easy. I have bought sheets of oak veneer cheap and used it. Vacuum bagging.

Les haut-parleurs sont conçus pour fonctionner au mieux avec un petit amplificateur à tube. Sur la photo j'utilise un Yamamoto A08 équipé du tube 45 2 × 1,5 W dans une pièce de 600 pi².

Last edited:

I made my speakers in my cellar during confinement in France. The prototype is designed with panels for Wedi® tiles.

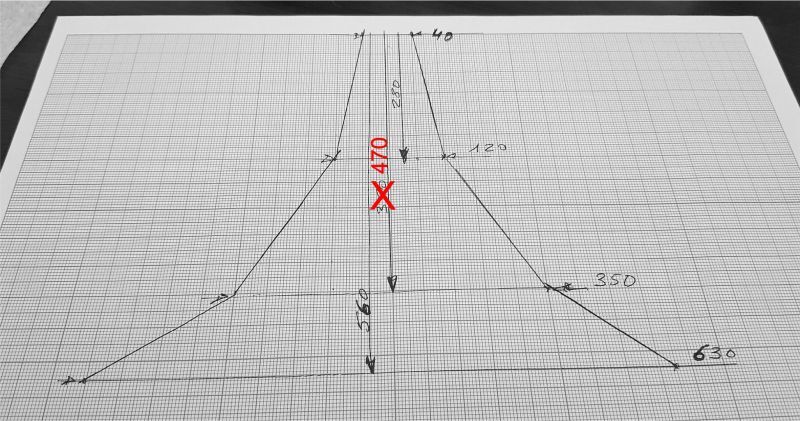

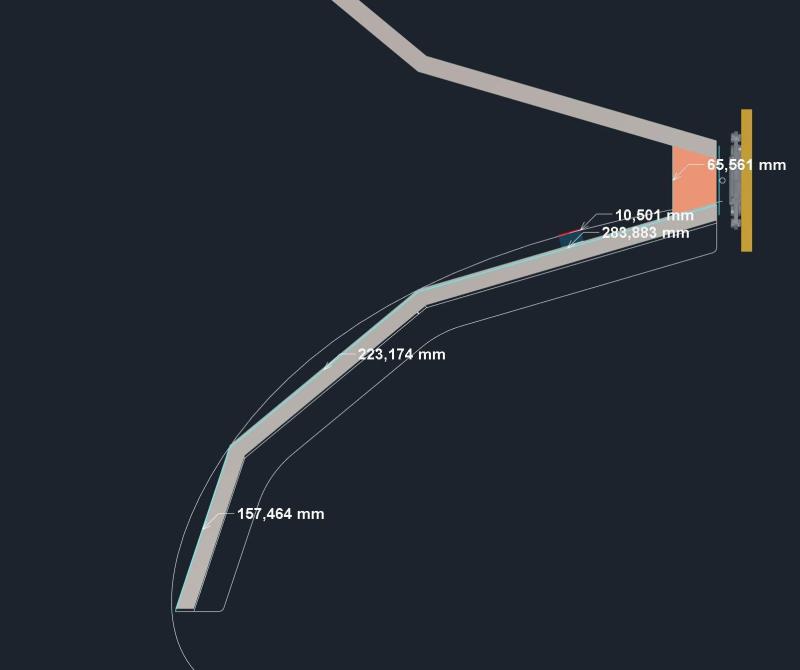

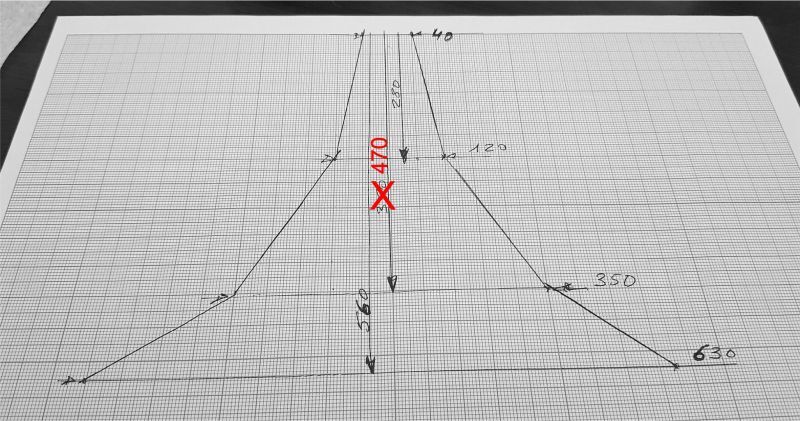

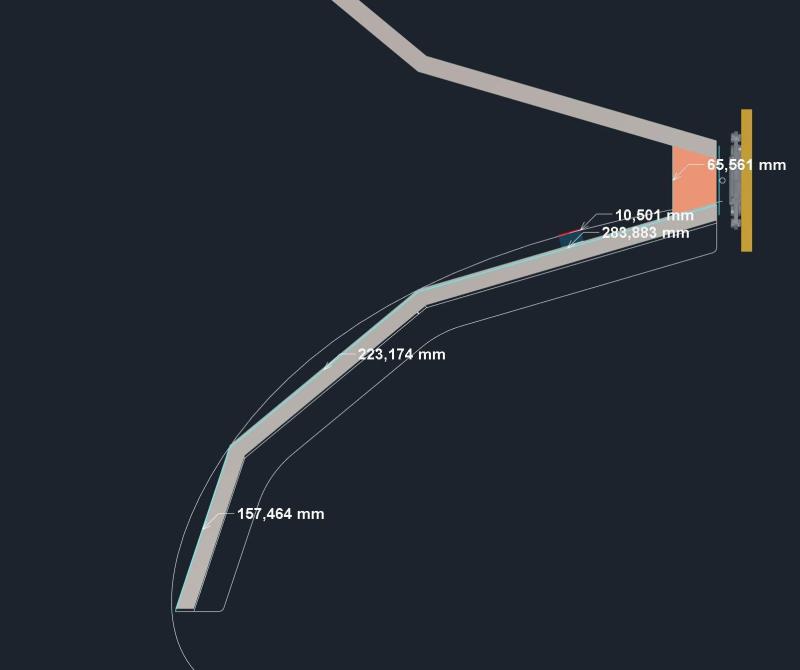

Here are the dimensions of the horn

Here are the dimensions of the horn

The loudspeakers have an efficiency of 101 dB / W / m.

They emit a cylindrical wave. The sound pressure will decrease by 6 dB when the distance is doubled with a conventional spherical source, and only 3 dB with a cylindrical wave.

At 12.5 ft (ca. 4 m) from the horn, it takes 4 times more power for a conventional system to achieve the same sound level.

The radiation takes place over a height of 6 ft (1.83 m). There is no difference in sound whether you are standing or sitting.

There is no longer any notion of distance from the speakers.

In the drawing, the conventional listening area is in blue. In gray, the listening area of my horns. Stereo is good from 2.6 ft (0.79 m) at the front of the horns.

They emit a cylindrical wave. The sound pressure will decrease by 6 dB when the distance is doubled with a conventional spherical source, and only 3 dB with a cylindrical wave.

At 12.5 ft (ca. 4 m) from the horn, it takes 4 times more power for a conventional system to achieve the same sound level.

The radiation takes place over a height of 6 ft (1.83 m). There is no difference in sound whether you are standing or sitting.

There is no longer any notion of distance from the speakers.

In the drawing, the conventional listening area is in blue. In gray, the listening area of my horns. Stereo is good from 2.6 ft (0.79 m) at the front of the horns.

Thank you for the great photos of your construction process!! --- that helps a lot.

Very nice Amplifier! - the Yamamoto A-08

----- If I can ask? - I have three questions :

1. - Am I right that the drawing shows that the length of Your horn is 560 mm? , and that the width of the mouth of your Horn is 630mm - is that correct ??

----- ( The reason I was asking is that I was comparing it to the size of your Yamamoto A - 08 Amplifier that it sitting next to it in the photo - (the SPECs for the Yamamoto say it is about 15 inches long) , but the horn mouth looks bigger than that in the Photos- 🙂 - thank you. )

2. - I was looking down into the mouth of the Horn in the -- Construction photos -- I don't see the Black frame that the Neo8 ribbons/ diaphragm drivers are inside of...... I can only see the gold color of the drivers . . . ?

- And then also the drivers are covered in your final pictures of your completed Horn Speakers by your very beautiful 3-D Printed Lenses... did you take off the front covers of the Neo8 drivers for final installation of the lenses? -- or are the drivers left intact behind your 3-D Printed Lenses?

3. - I saw the link you posted in the French audio Forum to the - Asian , Burmester Class 933 AB Amplifier clone ,

A. - Does it sound very good to you - ?

B. - Do you think it sounds close to the sound of the original Burmester 933 Amplifier - ??

--- I am looking for new amplifier ideas ,

- I did recently take part in a Class-D Amplifier Group Buy here at diyaudio and at first it went well and lots of folks got there Amplifiers sent out to them and were happy.... but after a couple months the guy running it - drMordor just stopped sending out the amplifiers and also stopped communicating with anyone at the group buy thread .... so myself and 20 or 30 other folks haven't received the Amplifiers we paid for........ Usually you can count on the people here, most of the time Group buys go well but it's not looking very good this time.

Very nice Amplifier! - the Yamamoto A-08

----- If I can ask? - I have three questions :

1. - Am I right that the drawing shows that the length of Your horn is 560 mm? , and that the width of the mouth of your Horn is 630mm - is that correct ??

----- ( The reason I was asking is that I was comparing it to the size of your Yamamoto A - 08 Amplifier that it sitting next to it in the photo - (the SPECs for the Yamamoto say it is about 15 inches long) , but the horn mouth looks bigger than that in the Photos- 🙂 - thank you. )

2. - I was looking down into the mouth of the Horn in the -- Construction photos -- I don't see the Black frame that the Neo8 ribbons/ diaphragm drivers are inside of...... I can only see the gold color of the drivers . . . ?

- And then also the drivers are covered in your final pictures of your completed Horn Speakers by your very beautiful 3-D Printed Lenses... did you take off the front covers of the Neo8 drivers for final installation of the lenses? -- or are the drivers left intact behind your 3-D Printed Lenses?

3. - I saw the link you posted in the French audio Forum to the - Asian , Burmester Class 933 AB Amplifier clone ,

A. - Does it sound very good to you - ?

B. - Do you think it sounds close to the sound of the original Burmester 933 Amplifier - ??

--- I am looking for new amplifier ideas ,

- eventually I would like a couple of nice little Tube amplifiers of some kind, and maybe a few others ..... something solid state maybe and maybe a Class - D Amplifier for the summer months ....

- I recently decided to sell my Tube amps , they were 350 watt VTL Monoblock Tube Amplifiers, I really liked them a Lot but we moved from California to Texas a few years ago, and it doesn't cool off much at night here during the summer months , so they were just to hot with 16 of the KT88 tubes so I had to let them go.

- I did recently take part in a Class-D Amplifier Group Buy here at diyaudio and at first it went well and lots of folks got there Amplifiers sent out to them and were happy.... but after a couple months the guy running it - drMordor just stopped sending out the amplifiers and also stopped communicating with anyone at the group buy thread .... so myself and 20 or 30 other folks haven't received the Amplifiers we paid for........ Usually you can count on the people here, most of the time Group buys go well but it's not looking very good this time.

Happy New Year!

1 - I confirm the dimensions of the horn. It is the photo which distorts the proportions.

2 - There is a three-millimeter layer of black acoustic foam in between.

3 - The clone is a great amplifier for its price. It is superior to my Ncore . I didn't listen to the 933. But I think the original is better. This amp made me sell an old Gryphon S100 and a First Watt F4.

These speakers are designed to get the most out of a 2A3 SE amplifier. The power is sufficient. At most each speaker receives 0.5 W and does not distort. At this power, there is no risk of destruction at 250 Hz. A simple Chinese clone of the Sun Audio 2A3 under $ 1000 ridiculed 90% of amplifiers above 100Hz. It is very easy to improve this clone without worrying about the mechanics and the paint. These horns with a 2A3 SE amplifier make a very high end set.

I will describe how the horns are made.

1 - I confirm the dimensions of the horn. It is the photo which distorts the proportions.

2 - There is a three-millimeter layer of black acoustic foam in between.

3 - The clone is a great amplifier for its price. It is superior to my Ncore . I didn't listen to the 933. But I think the original is better. This amp made me sell an old Gryphon S100 and a First Watt F4.

These speakers are designed to get the most out of a 2A3 SE amplifier. The power is sufficient. At most each speaker receives 0.5 W and does not distort. At this power, there is no risk of destruction at 250 Hz. A simple Chinese clone of the Sun Audio 2A3 under $ 1000 ridiculed 90% of amplifiers above 100Hz. It is very easy to improve this clone without worrying about the mechanics and the paint. These horns with a 2A3 SE amplifier make a very high end set.

I will describe how the horns are made.

To make the horn, I used 3 mm Dibond® plates. DIBOND® consists of two 0.3 mm thick aluminum facings and a polyethylene core. It is light and 3D transformable while being extremely stable and rigid.

To have four identical parts, I created a template.

The Dibond is grooved with a milling cutter, to be bent.

The core of the Dibond is made of polyethylene, which is the only thermoplastic that does not stick. Neither silicone nor epoxy will adhere to it. To mechanically block the angles, the solution is to glue with a 5 mm bead of glue on the aluminum surfaces.

I used gray polymer glue.

To have four identical parts, I created a template.

The Dibond is grooved with a milling cutter, to be bent.

The core of the Dibond is made of polyethylene, which is the only thermoplastic that does not stick. Neither silicone nor epoxy will adhere to it. To mechanically block the angles, the solution is to glue with a 5 mm bead of glue on the aluminum surfaces.

I used gray polymer glue.

Hi sap2212 , thank you the construction photos - I wasn't familiar with the Dibond material, but the photos really helped me understand how you made your panels. I am in the process of converting the numbers onto some graph paper for the design. And looking for a local source for the Dibond material.

Your template was a great idea.

-- that material that the template is made of is very interesting -- I don't remember seeing that before at any of the stores around here --

1- do you know what the name is of the material that your template is made out is?

-------------------

In post 13 you said - "The clone is a great amplifier for its price. It is superior to my Ncore . I didn't listen to the 933. But I think the original is better. This amp made me sell an old Gryphon S100 and a First Watt F4."

2- the clone amp - is that the amplifier that made you sell your Gryphon S100 and First Watt F4 ...... and is that the same as the Tube Amplifier in your pictures? - Is there a link that you can post where you found your clone amplifier?

thanks, Dean

Your template was a great idea.

-- that material that the template is made of is very interesting -- I don't remember seeing that before at any of the stores around here --

1- do you know what the name is of the material that your template is made out is?

-------------------

In post 13 you said - "The clone is a great amplifier for its price. It is superior to my Ncore . I didn't listen to the 933. But I think the original is better. This amp made me sell an old Gryphon S100 and a First Watt F4."

2- the clone amp - is that the amplifier that made you sell your Gryphon S100 and First Watt F4 ...... and is that the same as the Tube Amplifier in your pictures? - Is there a link that you can post where you found your clone amplifier?

thanks, Dean

Dear sap2213, I try to understand the drawing. But the length of 350 mm can't be correct- I guess it is 450mm - if I'm not wrong? Please confirm. Merci beaucoup! BernhardI made my speakers in my cellar during confinement in France. The prototype is designed with panels for Wedi® tiles.

View attachment 1009794

View attachment 1009795

View attachment 1009796

View attachment 1009802

Here are the dimensions of the horn

Hello Tangopaps

Sorry, you're right, I got the depth measurement wrong. The measurements are approximate, it is difficult to measure in position.

This image shows the reference curve and the horn profile.

This is the plan for the grooves on the Dibon before folding.

I'm not very good in English, I use a translator. If you want to make these horns, you will find a description in French on two sites:

http://www.forum-bleu.com/t2578-sesame-enceintes-diy-haut-de-gamme-pour-un-petit-budget

http://forum-hifi.fr/thread-23663.html

With planars, the line array does not need correction. The eight Neo8s are connected directly to the amplifier without a filter. I'm in the process of testing, and it doesn't seem necessary to me to make lenses, as I did, to correct the empty space between two Neo8s. It is to be confirmed.

Measured at 2.2 m at the listening position, the phase is good.

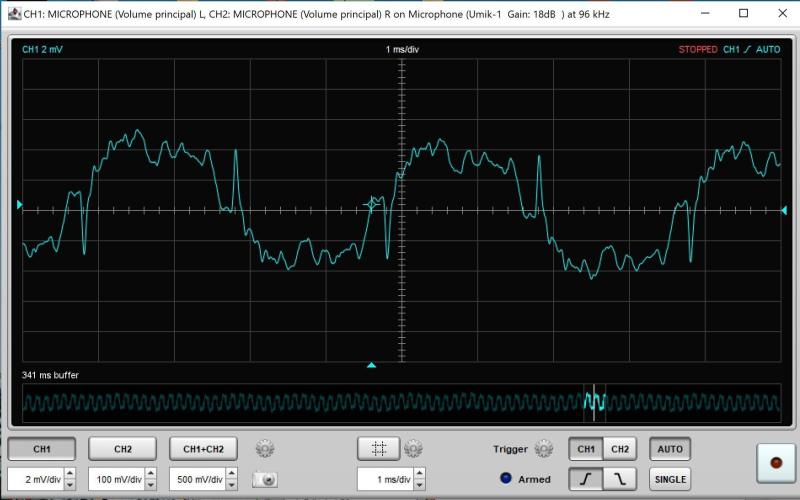

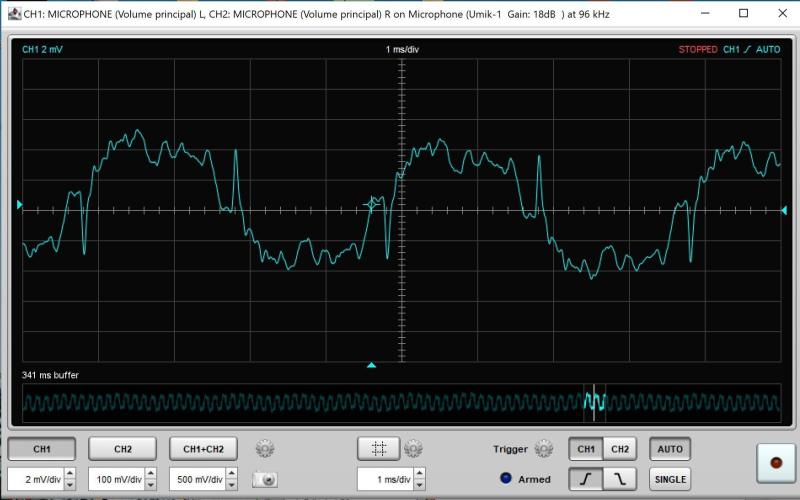

250 Hz square signal measurement at 1.60 m from the speakers in the listening room.

Apologies to hallcon83 I invaded his topic

Sorry, you're right, I got the depth measurement wrong. The measurements are approximate, it is difficult to measure in position.

This image shows the reference curve and the horn profile.

This is the plan for the grooves on the Dibon before folding.

I'm not very good in English, I use a translator. If you want to make these horns, you will find a description in French on two sites:

http://www.forum-bleu.com/t2578-sesame-enceintes-diy-haut-de-gamme-pour-un-petit-budget

http://forum-hifi.fr/thread-23663.html

With planars, the line array does not need correction. The eight Neo8s are connected directly to the amplifier without a filter. I'm in the process of testing, and it doesn't seem necessary to me to make lenses, as I did, to correct the empty space between two Neo8s. It is to be confirmed.

Measured at 2.2 m at the listening position, the phase is good.

250 Hz square signal measurement at 1.60 m from the speakers in the listening room.

Apologies to hallcon83 I invaded his topic

Hi Tangopaps , and sap 2212

Please no problem , Thank you for the invasion of the Topic ...... 🙂

- I understand your confusion ... I thought maybe one of the numbers was incorrect ..... but I was Really confused , I must have drawn the graphs/ design 15 times trying to figure out what I was doing wrong - LOL, LOL . . .

- Eventually I magnified sap2212's picture and counted all the little squares on the graph

paper .... trying to see what I was doing wrong - LOL

-- I am in the middle of dealing with cancer so I haven't had the money to build this yet...

- I'm not the biggest fan of the gray panels.... I think I would either paint them white , or Veneer them.

- I think the Ultimate would be to build this out of Acrylic . . . maybe 5/8 thick .

Please no problem , Thank you for the invasion of the Topic ...... 🙂

- I understand your confusion ... I thought maybe one of the numbers was incorrect ..... but I was Really confused , I must have drawn the graphs/ design 15 times trying to figure out what I was doing wrong - LOL, LOL . . .

- Eventually I magnified sap2212's picture and counted all the little squares on the graph

paper .... trying to see what I was doing wrong - LOL

-- I am in the middle of dealing with cancer so I haven't had the money to build this yet...

- I'm not the biggest fan of the gray panels.... I think I would either paint them white , or Veneer them.

- I think the Ultimate would be to build this out of Acrylic . . . maybe 5/8 thick .

Last edited:

- Home

- Loudspeakers

- Planars & Exotics

- Help Please, can 7 or 8 of these new tweeter/ Midrange planars be used in a Line Array?