Hello friends,

I have a Tandberg TCD 300 Cassette deck. It outputs a brief (~1 second) loud hum upon pressing the Play button and it continues to play normal from then onwards. It happens on every Play click. It doesn't do if I press Pause and un-pause it. It also doesn't do if I press and hold Stop button for the first second while pressing the Play button.

Attached recorded sound for your reference.

Tested all Caps and they are all looking good and have low ESR

Cleaned all the switches multiple times. Cleaned the head and demagnetized also

I saw an exact same issue reported on tapeheads.net but not sure what was the solution. Posted this on tapeheads on the same thread also but haven't received any response yet

I have a Tandberg TCD 300 Cassette deck. It outputs a brief (~1 second) loud hum upon pressing the Play button and it continues to play normal from then onwards. It happens on every Play click. It doesn't do if I press Pause and un-pause it. It also doesn't do if I press and hold Stop button for the first second while pressing the Play button.

Attached recorded sound for your reference.

Tested all Caps and they are all looking good and have low ESR

Cleaned all the switches multiple times. Cleaned the head and demagnetized also

I saw an exact same issue reported on tapeheads.net but not sure what was the solution. Posted this on tapeheads on the same thread also but haven't received any response yet

Attachments

Gotta say it sounds quite cool - I’d leave it as is 😛😛

I’d check the mech for dried up grease, this could be delaying actual operation of various switches as it slows levers and arms down…

It may not be obvious just watching the mech, you need to remove springs etc and check that stuff moves freely ..

I’ll put a £1 on it being this. 🙂

I’d check the mech for dried up grease, this could be delaying actual operation of various switches as it slows levers and arms down…

It may not be obvious just watching the mech, you need to remove springs etc and check that stuff moves freely ..

I’ll put a £1 on it being this. 🙂

Thank you Mike. Yes it sounds really good after that initial hitch. I am ok with it but just wanted to know what must be causing that and see if it can be easily fixed. This deck has all modular boards which can be lifted from pins and install them back again. I lifted them and detoxed all the pins as well

I checked the play head movement while engaging to play and its very smooth. There is no friction at all. May be I will try lubricating all mechanical sections

Thanks again for looking into this and sharing your thoughts

I checked the play head movement while engaging to play and its very smooth. There is no friction at all. May be I will try lubricating all mechanical sections

Thanks again for looking into this and sharing your thoughts

I would put a scope on the power supply. There might be an extra power requirement immediately after

pressing play that causes a regulator to drop out. A scope would rule that out in a few seconds.

G²

pressing play that causes a regulator to drop out. A scope would rule that out in a few seconds.

G²

Forget the electronics for now.... as said I doubt it will be there.

Just lubricating dried up grease will not sort the problem, you have to start stripping the mech , cleaning the dry grease, relubing and reassembling.

As you strip it down you will slowly realise if it was the problem.

Lube on top of dried up grease and dried up greased surfaces will not dilute the dried up grease.

A crucial lever only has to be a fraction of a second slower than original design and it can cause all sorts of problems.

Just lubricating dried up grease will not sort the problem, you have to start stripping the mech , cleaning the dry grease, relubing and reassembling.

As you strip it down you will slowly realise if it was the problem.

Lube on top of dried up grease and dried up greased surfaces will not dilute the dried up grease.

A crucial lever only has to be a fraction of a second slower than original design and it can cause all sorts of problems.

Dried up grease does make mech movement(s) very smoothI checked the play head movement while engaging to play and its very smooth.

Last edited:

It does sound rather cool 😉

Quick thoughts... could it be the motor drawing lots of current at start up. Might keep spinning in pause and holding the stop key might keep something in 'mute'.

Doesn't really sound like the ubiquitous Record/Play switches (assuming it has those) but would still be worth a look.

Quick thoughts... could it be the motor drawing lots of current at start up. Might keep spinning in pause and holding the stop key might keep something in 'mute'.

Doesn't really sound like the ubiquitous Record/Play switches (assuming it has those) but would still be worth a look.

Thank you all for sharing valuable suggestions.

Just FYI, I don't have any advanced equipment like scope etc., to test. I am kind of newbie and have a good multimeter and ESR meter 🙂. But I can definitely disassemble the transport and put it back after cleaning and greasing it 🙂. I will try that. There is a good youtube video on complete dismantling of this deck. I will follow that.

There are 3 motors in this deck. One for Dual Capstan and other two for supply and collect reels. Both forward and reverse are working fine without any issues

I will try cleaning up and post the results.

thanks again

Just FYI, I don't have any advanced equipment like scope etc., to test. I am kind of newbie and have a good multimeter and ESR meter 🙂. But I can definitely disassemble the transport and put it back after cleaning and greasing it 🙂. I will try that. There is a good youtube video on complete dismantling of this deck. I will follow that.

There are 3 motors in this deck. One for Dual Capstan and other two for supply and collect reels. Both forward and reverse are working fine without any issues

I will try cleaning up and post the results.

thanks again

update ..

As suggested I did dismantle the transport completely and cleaned up all old grease and applied new grease and lubricated all spinning & moving sections and put it back again. This hasn't make any difference on the issue

I did some voltage measurements based on Mooly and Status46 suggestions

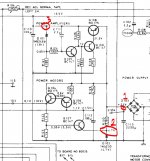

Attached a picture of my test points(TPs). I used Min/Max on my multimeter to measure min voltage when I press Play button

TP1: No Play - 21V. On Play click the Min goes down to 14V. While playing the Avg Voltage is 17.5V

TP2: staying at 4.7 V all the time

TP3: on Play click it goes down to 12.88 and it comes back to normal 13,5V while playing

TP1 Filter capacitor measuring ~2500 uf and ESR is 0.02 ohms. Cap is rated 25V

Is it something wrong with Power supply going down to 14V and staying at 17.V?

Any suggestions

thank you

As suggested I did dismantle the transport completely and cleaned up all old grease and applied new grease and lubricated all spinning & moving sections and put it back again. This hasn't make any difference on the issue

I did some voltage measurements based on Mooly and Status46 suggestions

Attached a picture of my test points(TPs). I used Min/Max on my multimeter to measure min voltage when I press Play button

TP1: No Play - 21V. On Play click the Min goes down to 14V. While playing the Avg Voltage is 17.5V

TP2: staying at 4.7 V all the time

TP3: on Play click it goes down to 12.88 and it comes back to normal 13,5V while playing

TP1 Filter capacitor measuring ~2500 uf and ESR is 0.02 ohms. Cap is rated 25V

Is it something wrong with Power supply going down to 14V and staying at 17.V?

Any suggestions

thank you

Attachments

The voltage on '1' needs to be a few volts higher than the 13.5v regulated voltage. So 14 volts will see the regulator 'drop out' and that may well introduce noise and so on onto the rail. The 13.5v DC voltage would also fall as well and this is what you have measured.

It would be worth checking the 10 volt line from Q104 is correct when it is playing. Just to be sure that the 10 v regulator is OK and not applying full unregulated voltage to the motors which could then pull the supply down.

The cap would appear to be OK but it would do no harm to tag another across it as a quick test. 1000uF or more would be suitable. I assume you unsoldered (isolated) the cap to test it.

Beyond that and other tests would involve checking motor currents at start up. One side of the bridge rectifier could also do this (but that is extremely unlikely as a fault) and would be checked in seconds with a scope across the unregulated rail.

It would be worth checking the 10 volt line from Q104 is correct when it is playing. Just to be sure that the 10 v regulator is OK and not applying full unregulated voltage to the motors which could then pull the supply down.

The cap would appear to be OK but it would do no harm to tag another across it as a quick test. 1000uF or more would be suitable. I assume you unsoldered (isolated) the cap to test it.

Beyond that and other tests would involve checking motor currents at start up. One side of the bridge rectifier could also do this (but that is extremely unlikely as a fault) and would be checked in seconds with a scope across the unregulated rail.

At least you've given the mech a freshen-up - it would have been my first choice but it's tricky when working at a distance sometimes .

That dip on the 21V is a bit severe to say the least

That dip on the 21V is a bit severe to say the least

Thank you Mike. Yes, it is running a bit quieter now after the fresh lube.

Thank you Mooly, Yes, I removed one end of the cap and measured. Tested both zeners also unsoldering one end. They are looking good. I just ordered some new 2200uf 35V caps. I will replace and test again. I will also test 10V line and see.

thank you.

Thank you Mooly, Yes, I removed one end of the cap and measured. Tested both zeners also unsoldering one end. They are looking good. I just ordered some new 2200uf 35V caps. I will replace and test again. I will also test 10V line and see.

thank you.

I've just realised I did one of threse for a customer only last year, I remember the layout now

I can't remember what I repaired on his unit though, but I remember having trouble getting those keys lined up when you put the top back on 🙄 especially the left one

EDIT: NO wait it was a TCD310 actually (for bulbs and tape path alignment. - I've just checked my emails)

I can't remember what I repaired on his unit though, but I remember having trouble getting those keys lined up when you put the top back on 🙄 especially the left one

EDIT: NO wait it was a TCD310 actually (for bulbs and tape path alignment. - I've just checked my emails)

Last edited:

Will you check something , that might be the cause of your ills......

Where the operation keyboard is there's a switchbank pcb below, and you might just find a couple of the infamous red ROE caps on there

Get 'em out , replace wth new and stamp on the old ones 😀

.... and retest 🙂

Where the operation keyboard is there's a switchbank pcb below, and you might just find a couple of the infamous red ROE caps on there

Get 'em out , replace wth new and stamp on the old ones 😀

.... and retest 🙂

Sure Mike. I will take that board out and try to replace these caps. I might not have them. I may need to order. I will update once it is done.

And as Mooly suggested I tested the 10V line from Q104. In stop mode its showing 0.52V and when I press Play its rolling up to 10V. Hope this is normal?

thank you

And as Mooly suggested I tested the 10V line from Q104. In stop mode its showing 0.52V and when I press Play its rolling up to 10V. Hope this is normal?

thank you

And as Mooly suggested I tested the 10V line from Q104. In stop mode its showing 0.52V and when I press Play its rolling up to 10V. Hope this is normal?

thank you

10v is fine but maybe what happens when you say it 'rolls up' to that value is a problem.

Does the 'roll up' correspond to the time when it makes the noise?

There is a time constant with C112 and the 4k7 resistor but that is only half a second or so. I just wonder if a motor is drawing excess start up current.

When you did the clean and relube, you did do the head plate didn't you ?

It 'slides' on three ball bearings , and this is a known dried up grease area..

When you press play, please watch the head plate movement - the speed of it, once the motors are ready the head plate should be very quick to respond (to move to playback position) as it's pulled up via a solenoid.

Ideally do a short video and post it, but ultimately this area needs a clean and regrease just like the other mech areas, it's crucial it moves at the speed when first manufactured.

Done properly you will not affect head alignment at all, but don't lose the ball bearings

It 'slides' on three ball bearings , and this is a known dried up grease area..

When you press play, please watch the head plate movement - the speed of it, once the motors are ready the head plate should be very quick to respond (to move to playback position) as it's pulled up via a solenoid.

Ideally do a short video and post it, but ultimately this area needs a clean and regrease just like the other mech areas, it's crucial it moves at the speed when first manufactured.

Done properly you will not affect head alignment at all, but don't lose the ball bearings

10v is fine but maybe what happens when you say it 'rolls up' to that value is a problem.

Does the 'roll up' correspond to the time when it makes the noise?

There is a time constant with C112 and the 4k7 resistor but that is only half a second or so. I just wonder if a motor is drawing excess start up current.

Yes, that timing is matching with the noise. Its coming a little slowly from .52 V to 10V. I will check the amount of current drawing by each motor and post it soon. I think this might be the reason. I will also check c112 and the resistor values again

When you did the clean and relube, you did do the head plate didn't you ?

It 'slides' on three ball bearings , and this is a known dried up grease area..

When you press play, please watch the head plate movement - the speed of it, once the motors are ready the head plate should be very quick to respond (to move to playback position) as it's pulled up via a solenoid.

Ideally do a short video and post it, but ultimately this area needs a clean and regrease just like the other mech areas, it's crucial it moves at the speed when first manufactured.

Done properly you will not affect head alignment at all, but don't lose the ball bearings

Yes, I did lift the head plate fully and cleaned up the grease in the pits of three ball bearings and applied new grease there. Cleaned all three balls also before putting the grease back. Also applied a bit of machine oil to the capstans and cleaned at cassette side tips. The head plate is bouncy and responding really well.

update

Received 2200uf 35V caps and tried adding one of these new in parallel to the existing cap and the hum has gone 99% on play click. I could hear if paid attention. The resultant capacitance was ~5000uf

Then I tried removing the old cap completely and replaced it with the one new one and the hum is back again 🙂 with just 2200uf

So its definitely electrical and not mechanical I think.

I haven't got a chance to measure the current drawing by motors on play click. I will do that.

May be just replace the filter cap with a higher capacitance like 6,000uf and leave it? Or that would cause any issues down the road as we are not fixing the actual root cause?

Received 2200uf 35V caps and tried adding one of these new in parallel to the existing cap and the hum has gone 99% on play click. I could hear if paid attention. The resultant capacitance was ~5000uf

Then I tried removing the old cap completely and replaced it with the one new one and the hum is back again 🙂 with just 2200uf

So its definitely electrical and not mechanical I think.

I haven't got a chance to measure the current drawing by motors on play click. I will do that.

May be just replace the filter cap with a higher capacitance like 6,000uf and leave it? Or that would cause any issues down the road as we are not fixing the actual root cause?

- Home

- Source & Line

- Analogue Source

- Tandberg 300 cassette deck a brief loud hum on Play