Your tests seem to show that excess current draw is the issue and increasing the cap value is really just masking the fault (for now)... which knowing these things isn't going to get better, it will only get worse.

Look at which motors (if any) spin all the time. For example does the capstan motor rotate continually? If it does then that is not a main suspect.

Look which motors start up at the moment you press play.

You could try as a rough test loading the motors a little with a finger to make it harder for them to turn. Don't stall them, just make it harder for them to turn and see if that causes the noise. Try and find which is the cause.

If you can add an ammeter into each motor feed and watch the current on start up then that would be the best.

If you can remove the load from a suspect motor (such as slipping off a belt of holding an idler away from a pulley then you could also do that to see if the problem is mechanical friction on start up.

Try it with no cassette inserted.

Could the brakes be sticking and causing mechanical load?

Look at which motors (if any) spin all the time. For example does the capstan motor rotate continually? If it does then that is not a main suspect.

Look which motors start up at the moment you press play.

You could try as a rough test loading the motors a little with a finger to make it harder for them to turn. Don't stall them, just make it harder for them to turn and see if that causes the noise. Try and find which is the cause.

If you can add an ammeter into each motor feed and watch the current on start up then that would be the best.

If you can remove the load from a suspect motor (such as slipping off a belt of holding an idler away from a pulley then you could also do that to see if the problem is mechanical friction on start up.

Try it with no cassette inserted.

Could the brakes be sticking and causing mechanical load?

For example does the capstan motor rotate continually? If it does then that is not a main suspect.

The capstan motor is a 110/120VAC motor 😉

Not sure if I asked previously?..... when you press play, can you confirm there is a 0.5 ish second delay before the head plate actually moves?

Last edited:

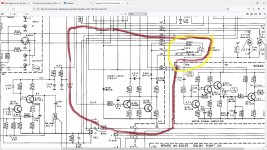

Thoughts: Here's where my head is being drawn towards.

The biggest current draw (relatively speaking) is the solenoid.... and the unusual thing is this deck has one solenoid but 4 connections on that solenoid .....

Is it mechanically latching somehow and there's a release coil within.? or is it feedback?

We've got:

Green - 23v (ever)

Black - ground.

Yellow - main control (decked when sol is actuated)

Blue - goes off to pause..........

And then theres MS2 mute switch (just above the solenoid) - what's weird about the depiction of that on the diag?.... the arrow in the middle to ground.... what's all that about😕

You did say it doesn't do the hum noise when you toggle pause when you're already in play mode didn't you? .... when in pause does the head plate fully drop back to stop mode position?.... or does it drop partially to just pull the pinch roller down a little?

I'm convinced the various switches (I'm calling MS1 into question too) are not operating when they should, to perhaps mask a perfectly normal heavy current draw when that solenoid kicks in before mute is released.

Maybe you could check the DC impedence of the solenoid .... and let's work out why there's four connections to it

The biggest current draw (relatively speaking) is the solenoid.... and the unusual thing is this deck has one solenoid but 4 connections on that solenoid .....

Is it mechanically latching somehow and there's a release coil within.? or is it feedback?

We've got:

Green - 23v (ever)

Black - ground.

Yellow - main control (decked when sol is actuated)

Blue - goes off to pause..........

And then theres MS2 mute switch (just above the solenoid) - what's weird about the depiction of that on the diag?.... the arrow in the middle to ground.... what's all that about😕

You did say it doesn't do the hum noise when you toggle pause when you're already in play mode didn't you? .... when in pause does the head plate fully drop back to stop mode position?.... or does it drop partially to just pull the pinch roller down a little?

I'm convinced the various switches (I'm calling MS1 into question too) are not operating when they should, to perhaps mask a perfectly normal heavy current draw when that solenoid kicks in before mute is released.

Maybe you could check the DC impedence of the solenoid .... and let's work out why there's four connections to it

Attachments

Q305 Q306 seem to be a monostable with time-constant 22uFd+68k, a bit over a second, similar to your half-second event.

L2 Blue goes off-stage at the top. To what?

L2 Blue goes off-stage at the top. To what?

Sorry for delay in getting back on this. I was figuring out how measure these currents as these wires are in inaccessible places. Luckily no soldering was required 🙂 I could pull the pins and measure the currents

To answer some of the questions

- Yes, the capstan (dual) motor runs all the time and its an AC motor

- There is One motor for Wind and another for Rewind

- Upon play click the Wind motor is turning on and the Solenoid is pushing the head towards the tape

- Yes, it doesn't do the hum noise when Pause is toggled

I will try to upload some video. There is a size limit so I might need to upload to YouTube.

Here are some tests I did

Motor Currents (Wind & Rewind motors)

Wind/Forward Motor:

On Play Click : 314mA (Max)

While playing: 314mA

On Forward click: 620mA (Max)

While forwarding: 233mA

Rewind/Reverse Motor:

On Play click: 50mA

While Playing: 20mA

On reverse click: 600mA (max)

While reversing: 230 mA

Solenoid ( Yellow wire):

On Play click: 550 mA

while playing: 0mA

Solenoid ( Green wire):

On Play click: 500 mA

while playing: 0mA

Not sure if I missed to answer any other questions

Thank you all again for trying to help me.

To answer some of the questions

- Yes, the capstan (dual) motor runs all the time and its an AC motor

- There is One motor for Wind and another for Rewind

- Upon play click the Wind motor is turning on and the Solenoid is pushing the head towards the tape

- Yes, it doesn't do the hum noise when Pause is toggled

I will try to upload some video. There is a size limit so I might need to upload to YouTube.

Here are some tests I did

Motor Currents (Wind & Rewind motors)

Wind/Forward Motor:

On Play Click : 314mA (Max)

While playing: 314mA

On Forward click: 620mA (Max)

While forwarding: 233mA

Rewind/Reverse Motor:

On Play click: 50mA

While Playing: 20mA

On reverse click: 600mA (max)

While reversing: 230 mA

Solenoid ( Yellow wire):

On Play click: 550 mA

while playing: 0mA

Solenoid ( Green wire):

On Play click: 500 mA

while playing: 0mA

Not sure if I missed to answer any other questions

Thank you all again for trying to help me.

First quick thought is that those currents sound sky high for the motors. Lets see what the others think to that. 314ma while playing sounds quite a lot. When rewinding and fast forwarding everything should be free and easy to turn... so why so high.

Brakes sticking? or back tension band sticking/incorrectly adjusted (does it have one of those 😀)

The solenoid looks like it could be a type that is just energised momentarily to pull and latch it one way or another and then the current is turned off rather than a type that needs to be continually powered.

Lets see what the others think to those currents.

Brakes sticking? or back tension band sticking/incorrectly adjusted (does it have one of those 😀)

The solenoid looks like it could be a type that is just energised momentarily to pull and latch it one way or another and then the current is turned off rather than a type that needs to be continually powered.

Lets see what the others think to those currents.

Thank you Mooly.

Forward and Reverse are running really fast and those spinners are not too tight. These two are direct drive motors and no belts on them. These spinning wheels are directly connected to the motor shafts

And the spike on Forward and Rev is for a very short period when the buttons touch the floor

They stop as expected when the tape reaches its end.

I heard one of these motors run as generator while forwarding/reversing and generate some voltage detected to stop the other motor when it reach the end of the tape. I am not sure

Forward and Reverse are running really fast and those spinners are not too tight. These two are direct drive motors and no belts on them. These spinning wheels are directly connected to the motor shafts

And the spike on Forward and Rev is for a very short period when the buttons touch the floor

They stop as expected when the tape reaches its end.

I heard one of these motors run as generator while forwarding/reversing and generate some voltage detected to stop the other motor when it reach the end of the tape. I am not sure

You are going to have to be creative in trying to locate this. Does it make the noise with no cassette inserted (and pressing play of course)?

Assuming it does then try the same ago but now isolate the motor/s and see if/which is responsible.

Assuming it does then try the same ago but now isolate the motor/s and see if/which is responsible.

Solved

Thank you all for guiding me to figure out the fix.

Replaced the bridge Rectifier and it has fixed the hum problem. Now the voltage is not dropping on pressing the play button.

thank you

Thank you all for guiding me to figure out the fix.

Replaced the bridge Rectifier and it has fixed the hum problem. Now the voltage is not dropping on pressing the play button.

thank you

Oh wow, well done. I know I mentioned the bridge back at the start but never really expected it to actually be that. That really would have been at the bottom of the list.

Very very rare indeed.

Very very rare indeed.

Thank you Mooly. Yes, you have mentioned about bridge in the initial post. The bridge was tested ok in and out of circuit and that is the reason we didn't focus on that. Thanks again for all your valuable suggestions. Learned a lot from this post

What a great find this thread is. Have the exact same problem with a TCD 310 I recapped earlier this year. It had so many faults before that, but couldn't nail this one and gave up. What kind of diodes did you replace the rectifier with?

Found an exact replacement on Amazon in here in USA. Its 2W10 rectifier. Exact physical size and will fit into the same holes. Got 30 of them for $7.41

https://www.amazon.com/gp/product/B07X9KXFBF/ref=ppx_yo_dt_b_asin_title_o05_s00?ie=UTF8&psc=1

https://www.amazon.com/gp/product/B07X9KXFBF/ref=ppx_yo_dt_b_asin_title_o05_s00?ie=UTF8&psc=1

Found an exact replacement on Amazon in here in USA. Its 2W10 rectifier. Exact physical size and will fit into the same holes. Got 30 of them for $7.41

https://www.amazon.com/gp/product/B07X9KXFBF/ref=ppx_yo_dt_b_asin_title_o05_s00?ie=UTF8&psc=1

Thanks mate! Have ordered one now.

- Home

- Source & Line

- Analogue Source

- Tandberg 300 cassette deck a brief loud hum on Play