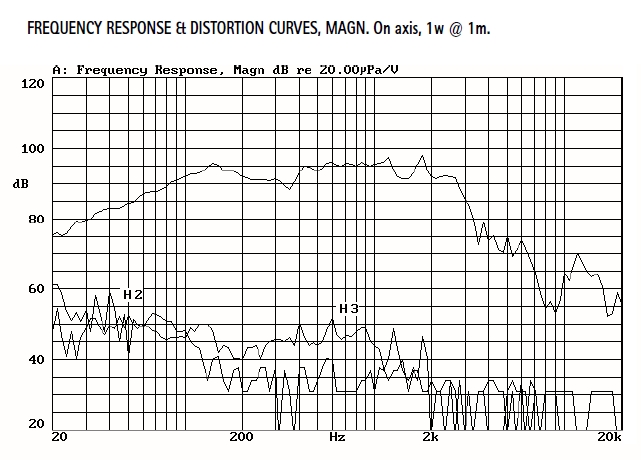

About the middle-treble frequency crossing, it's probably more difficult to move, due to the minimum requirement specified at 5KHz for the CP21/F.

Wait and See ! 😉

A+!

My friend used a Vifa midrange dome, no issues with 4.5kHz cross! The CP21 had a snappy sound, I liked it then, but it was 30 years ago🙄😉

Thanks @GM !

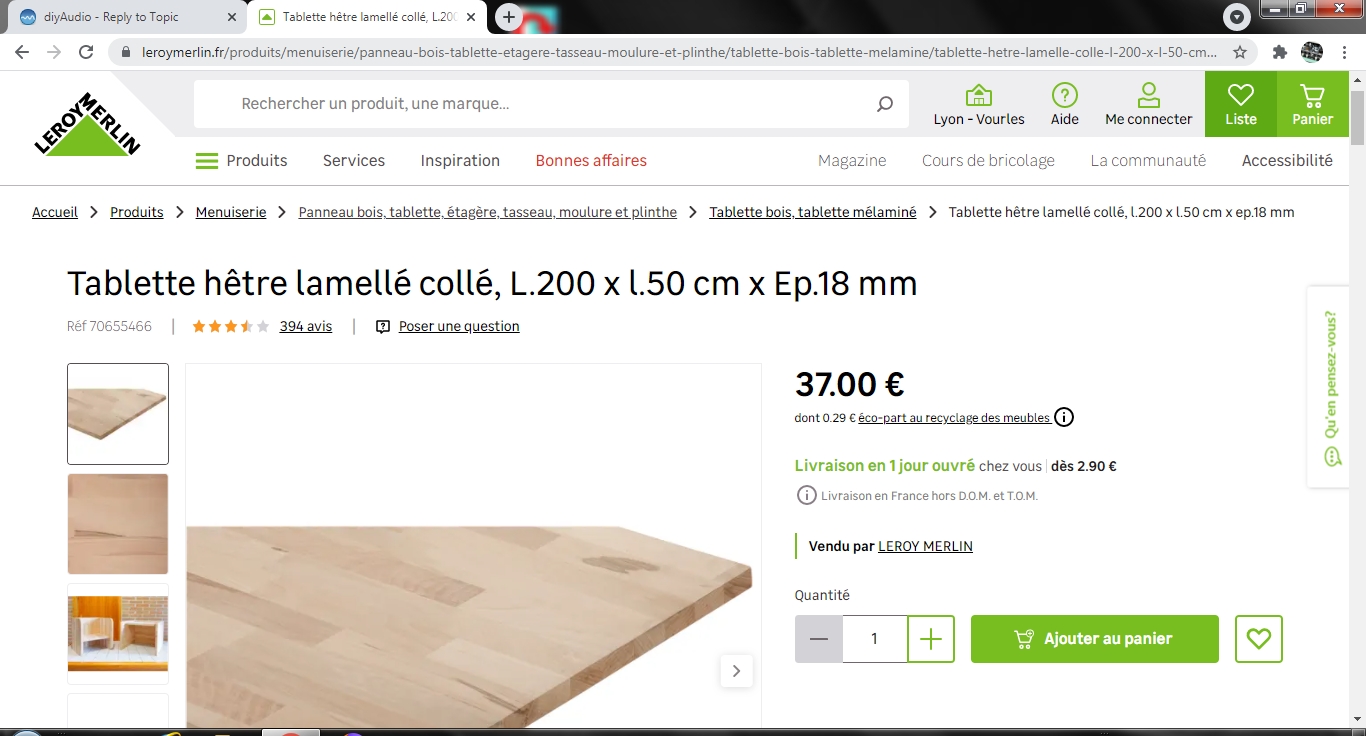

Looks great so far. That gluelam is interesting. I've never seen it in stores. Doesn't look cheap!

Surprisingly @mortron, it's not so costy here - I buy it and have that Beech wood glulam cut at the local DIY supermarket :

Typically available as kitchen worktops.

That's it, exacty @Charles Darwin.

I treat this wood with the same oil as for a kitchen workshop : sanding, oiling 1st layer, light sanding, oiling 2nd layer, then 3rd layer if needed.

Here the result on my CUBE bookshelf speakers, made from the same glulam Beech wood and treated accordingly :

Available in every IKEA store...

Yes, but much more costy there, then ! And I don't think they have a thickness under 25mm...

Here I use 18mm thick, and already this weight 13.5kg/m2, against 7.8kg/m2 for the Poplar plywood of the front and back panels !

I estimate that the mass of one 375L - finished and in working order - will be circa 45kg. You understand why I put lateral integrated handles... 😉

My friend used a Vifa midrange dome, no issues with 4.5kHz cross! The CP21 had a snappy sound, I liked it then, but it was 30 years ago🙄😉

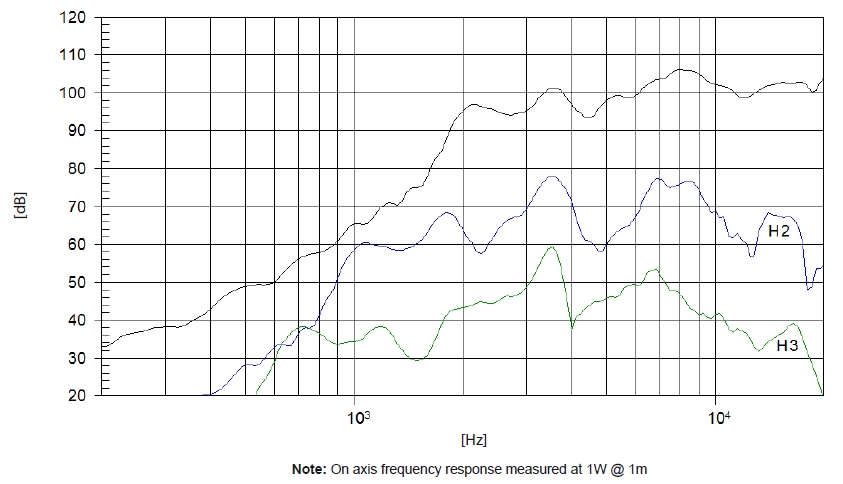

No issue with the 8M60N midrange as it can reach 7-8KHz at least in axis :

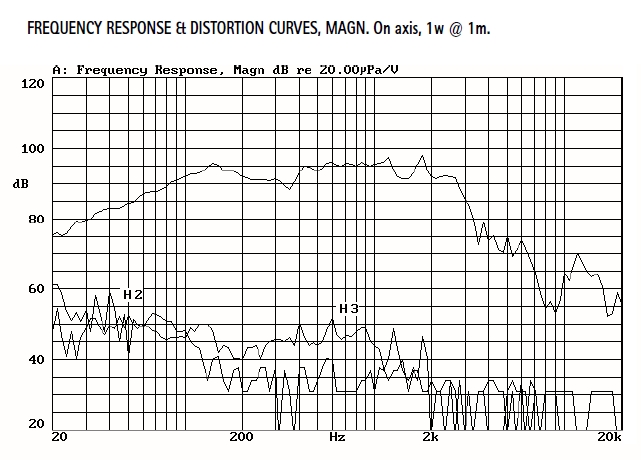

And yes, the CP21/F should widthstand even a circa 4KHz cut easlly, if the power stays reasonable, so I have some test possibilities :

Beyma cuts the 12B100R at 800Hz on the 3-way model kit B-27/9, so at 500He planned, I have some margin too :

As far as possible, I try to stay in the 2x-3x FR range for Xover FCs.

A+!

Work is on progress - slowly but surely :

Frontface covering :

PVC 100mm exhaust duct vent :

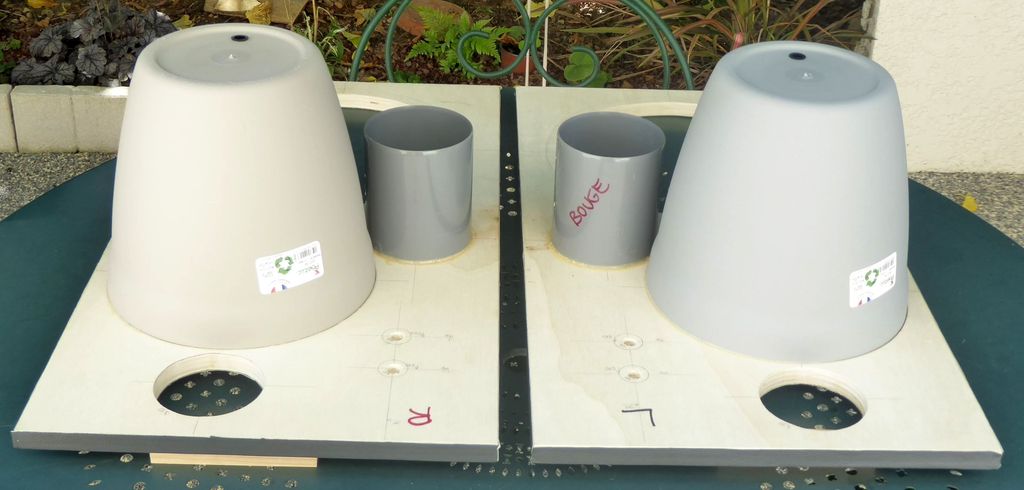

5mm recycled plastic resin flowerpot for 7.5L midrange back cover :

Wait and See...

A+!

Frontface covering :

An externally hosted image should be here but it was not working when we last tested it.

PVC 100mm exhaust duct vent :

An externally hosted image should be here but it was not working when we last tested it.

5mm recycled plastic resin flowerpot for 7.5L midrange back cover :

An externally hosted image should be here but it was not working when we last tested it.

Wait and See...

A+!

Those are gorgeous. Also, thanks for the links I will look for that gluelam here.

Thanks @mortron ! 🙂

Oh I'm sure that in your "Great Country Of Woods", you can find that kind of glulam wood, and even with wood species that cannot be found in France ...

Wait and See !

A+!

Last edited:

Do yourself a favour and oil inside also. It will prevent cracking of solid wood due to changes of humidity

Do yourself a favour and oil inside also. It will prevent cracking of solid wood due to changes of humidity

Really ? Moreover, it's as easy as fast to do, so yes : I'll do it.

Today : sanding 80 / 1st oiling / sanding 180 / 2nd oiling...

Tomorrow : final sanding and oiling, plus oiling the inside as you suggest, @peterbrorsson 😉

This evening, I was studying the possibility of a serial 6dB/oct 3-way crossover, whose merits are dithyrambically praised, just to see if that simpler design (than the classic 3-way parallel 12dB/oct) would work as expected :

FILTRE SERIE 6 dB 3 voies V4.0 : Partage d'experiences

Sorry, it's in French... 😱

Wait and See !

A+!

The last coat of oil is drying for the night... Tomorrow I'll start the final assembly 😎

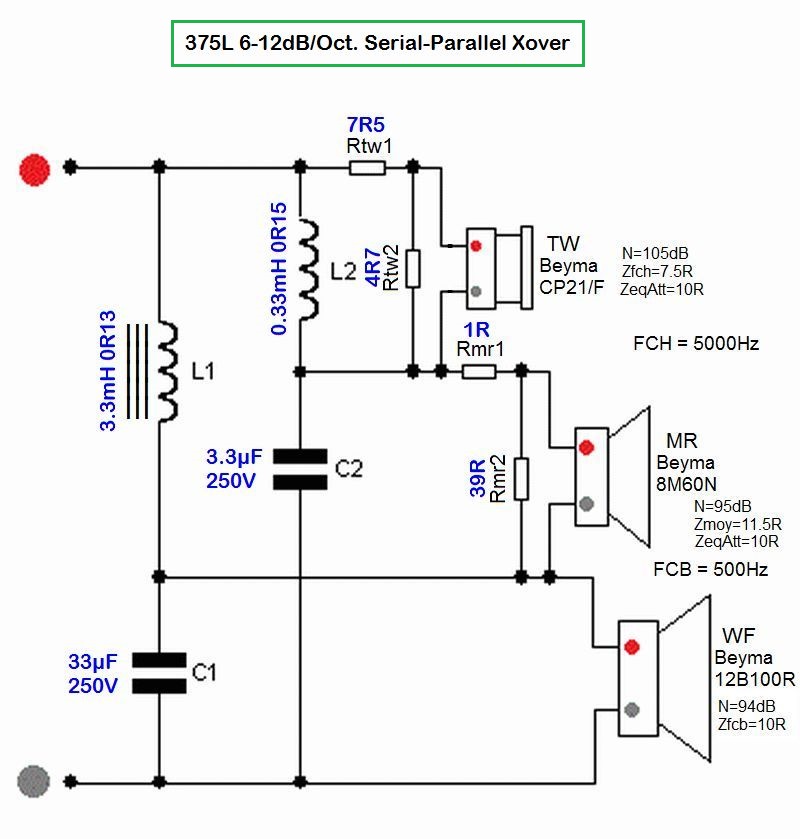

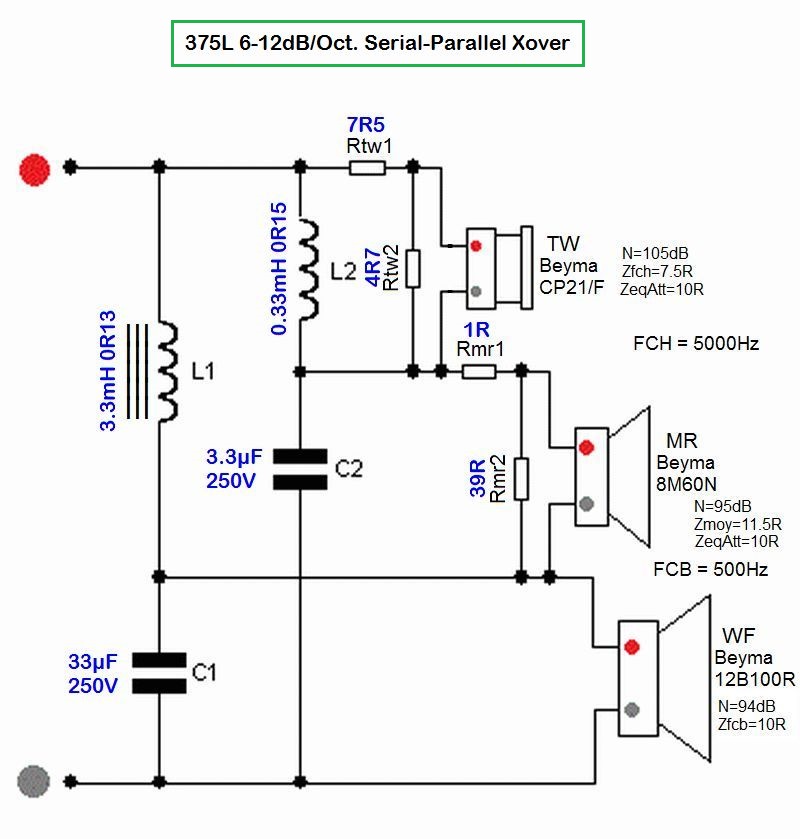

Here's the Serlal-Parallel 6-12dB/oct 3-way Xover I studied and will experiment, due to its simplicity and the fact that I had the required parts in my drawers...

Why not testing this, while waiting the elements for a conventional 3-way L-R 12dB/oct Xover ? 😉

In fact, this Xover is some kind of combination of 2 parallel 12dB/oct (TW and WF), "serialized" by the Midrange speaker placed in-between, which will receive the remaining frequencies that are in-between FCH (5KHz) and FCB (500Hz). Since it will "fill the gap" without additional LC element, I suppose that the slopes will be less than 12dB/oct for the Midrange, probably 6dB/oct...

Maybe it's an inconclusive idea... Wait and See ! 😱

Any experience of advice ? 😕

A+!

Here's the Serlal-Parallel 6-12dB/oct 3-way Xover I studied and will experiment, due to its simplicity and the fact that I had the required parts in my drawers...

Why not testing this, while waiting the elements for a conventional 3-way L-R 12dB/oct Xover ? 😉

In fact, this Xover is some kind of combination of 2 parallel 12dB/oct (TW and WF), "serialized" by the Midrange speaker placed in-between, which will receive the remaining frequencies that are in-between FCH (5KHz) and FCB (500Hz). Since it will "fill the gap" without additional LC element, I suppose that the slopes will be less than 12dB/oct for the Midrange, probably 6dB/oct...

Maybe it's an inconclusive idea... Wait and See ! 😱

Any experience of advice ? 😕

A+!

Last edited:

Cab assembly and finishing done...

Next step : speaker installation and stuffing.

Wait and See !

A+!

Next step : speaker installation and stuffing.

Wait and See !

A+!

With the speakers installed, it takes shape...

The empty cab weights 16.5kg, and with the speakers in, it reaches now 27.5kg...

A+!

The empty cab weights 16.5kg, and with the speakers in, it reaches now 27.5kg...

A+!

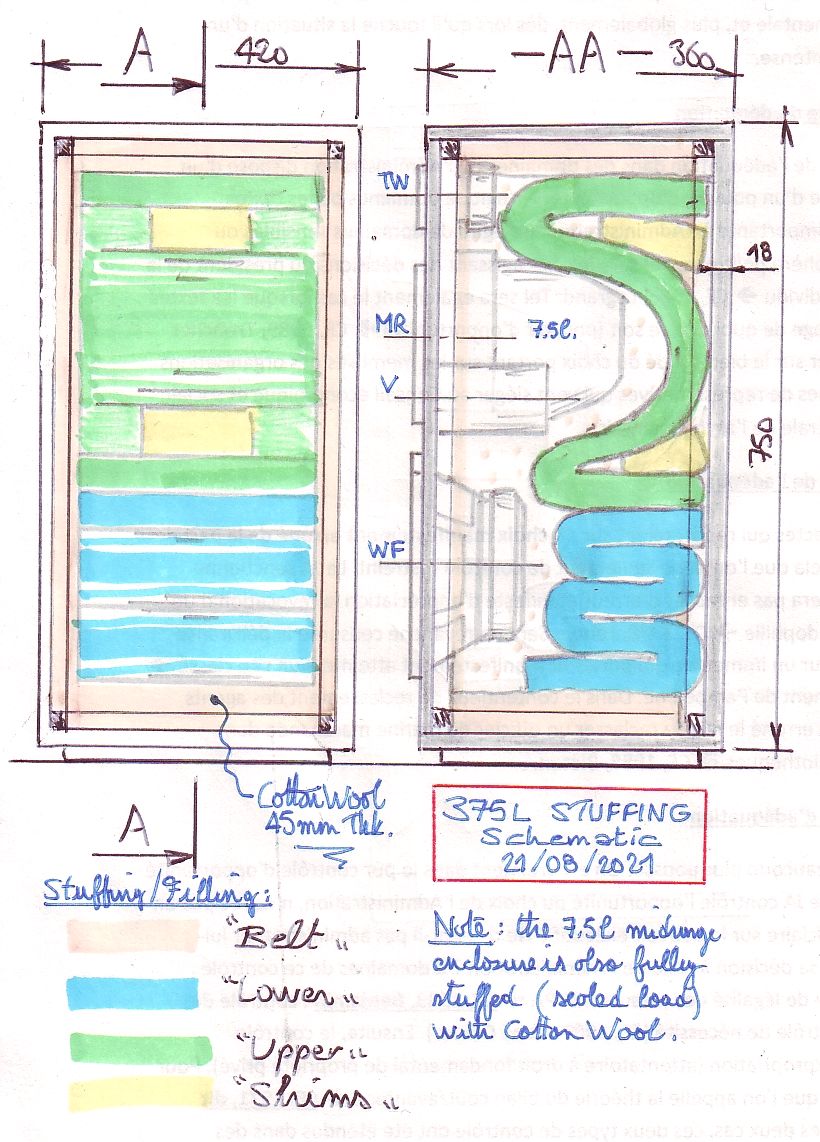

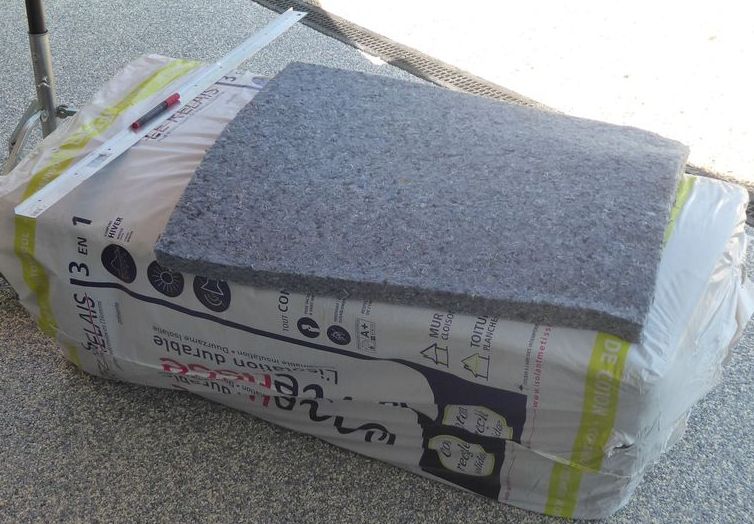

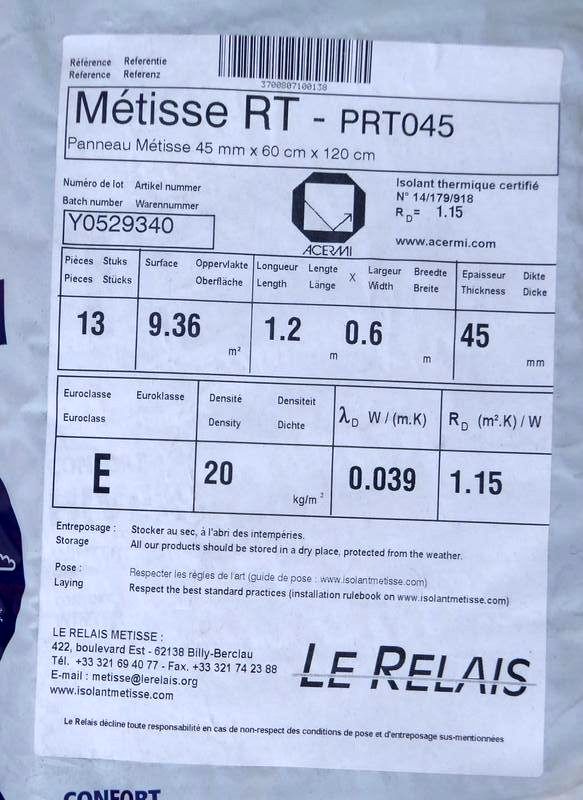

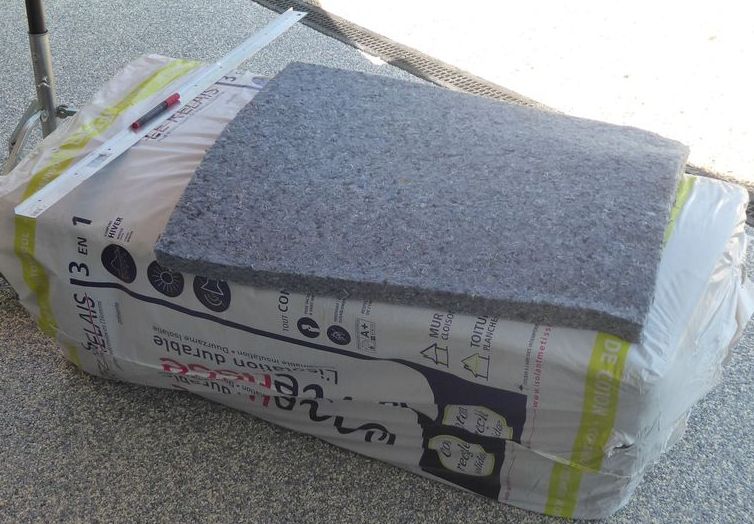

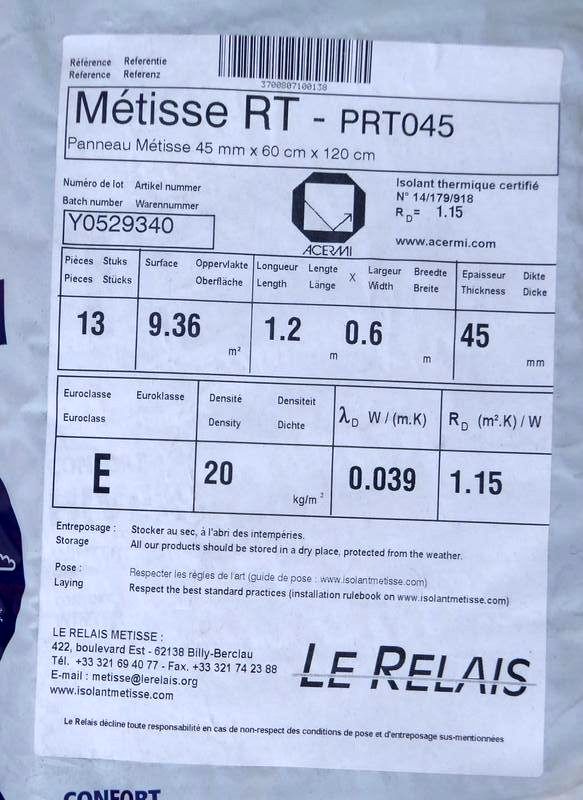

Stuffing operation...

0 - The material : cotton wool.

1 - Filling the midrange cavity.

2 - Filling the cab.

End of the construction work... I must confess that the lateral integrated handles proves to be very useful ! I calculated the gravity centre point of the finished enclosure to place them, and it proved to be exact : when lifted, the enclosure stays vertical and well balanced. 😎

It's a good point for weight that reaches now 29.5kg per unit... With the Xover, the total weight should reach 33-35kg, so less than the 38-40kg that I estimated. 🙂

Next step : crossover experimentations with the drawer's components. 😉

A+!

0 - The material : cotton wool.

1 - Filling the midrange cavity.

2 - Filling the cab.

End of the construction work... I must confess that the lateral integrated handles proves to be very useful ! I calculated the gravity centre point of the finished enclosure to place them, and it proved to be exact : when lifted, the enclosure stays vertical and well balanced. 😎

It's a good point for weight that reaches now 29.5kg per unit... With the Xover, the total weight should reach 33-35kg, so less than the 38-40kg that I estimated. 🙂

Next step : crossover experimentations with the drawer's components. 😉

A+!

Looks like too much stuffing to me.

How did you design the xovers? Did you measure the drivers in the box, on-axis and at various off-axis angles?

How did you design the xovers? Did you measure the drivers in the box, on-axis and at various off-axis angles?

Are you sure it is enough stuffing?

Kidding. Looks great.

Thanks @PCSoldaat ! 🙂

Yes, I prefer well damped cabinets... It's a matter of taste, but it has interesting benefits nonetheless.

Damped cabs sound more neutral in the midrange and bass-midrange region, offering a deeper low end thanks to the increase of acoustic volume due to the presence of the absorbent; moreover if it is placed in the middle of the cab - according to G.A. Briggs / Martin Colloms / Vance Dickason / John d'Appolito, and also after my personal experiments to check the effects of filling.

A+!

Fin de l'affaire... 😎

Matching riser bases :

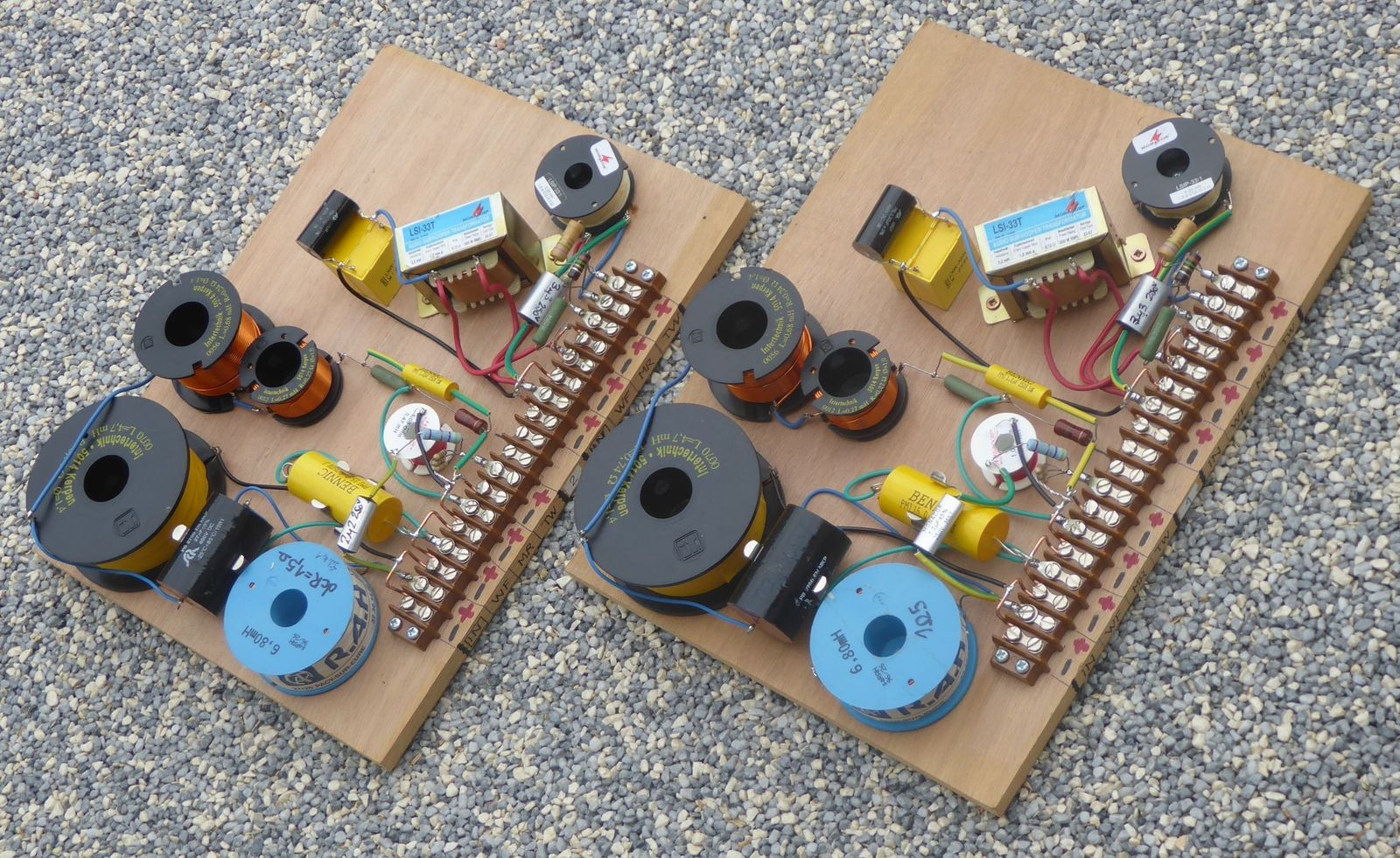

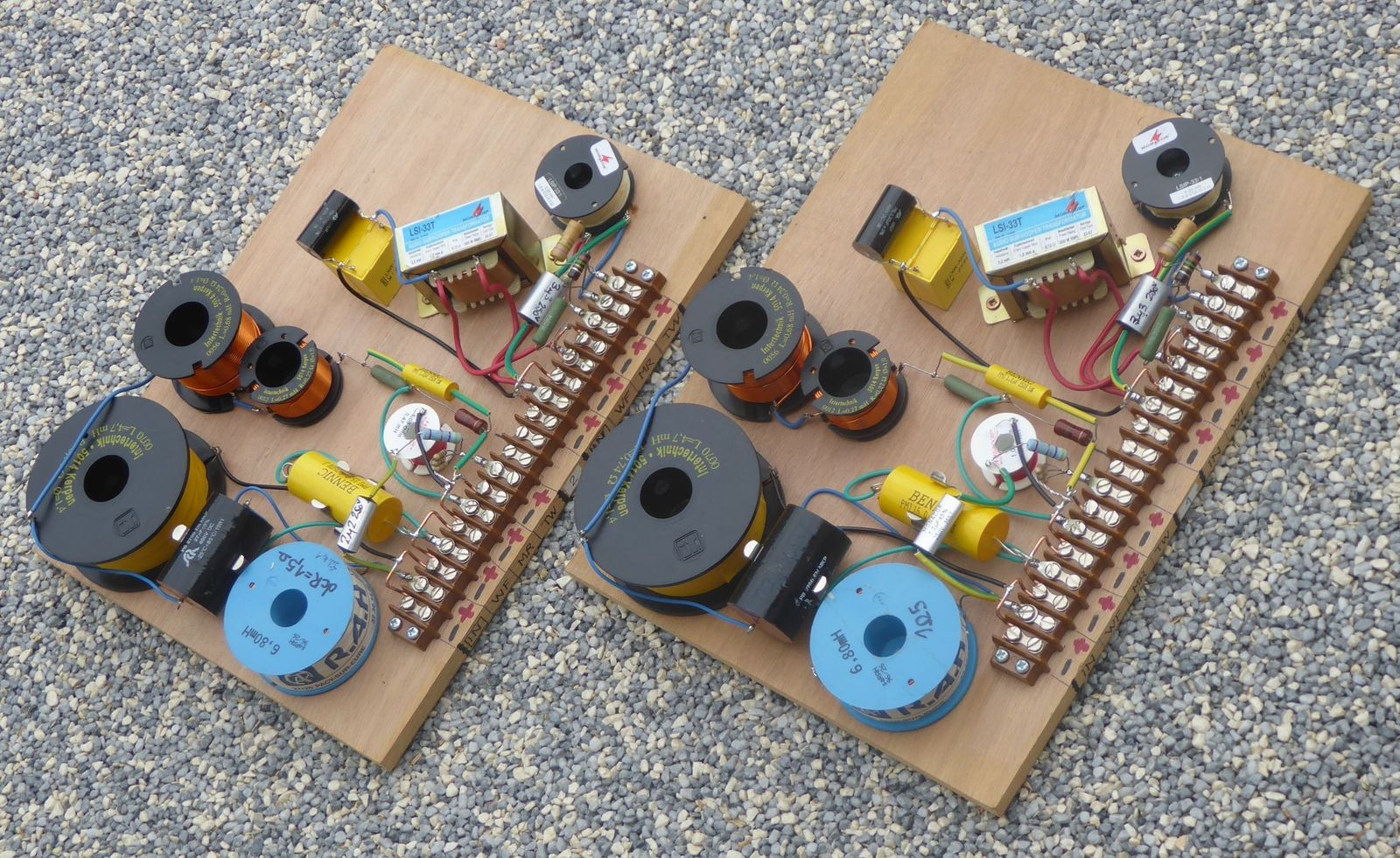

Dual version Xover prototypes :

Temporary installation in my gigantic auditorium :

The results are encouraging : no bad surprise, on the contrary ! 🙂

A+!

Matching riser bases :

Dual version Xover prototypes :

Temporary installation in my gigantic auditorium :

The results are encouraging : no bad surprise, on the contrary ! 🙂

A+!

Fantastic looking speakers. Amazing build. Quite similar to something I’m working on but I’m never going to reach this level of perfection. Inspirational for sure. 😀

Fantastic looking speakers. Amazing build. Quite similar to something I’m working on but I’m never going to reach this level of perfection. Inspirational for sure. 😀

Thanks @fabricadetabaco ! 🙂

It's not finished : I have to finalize the crossover and design the name / attenuator faceplate.

Good luck for your project... 😉

A+!

Last edited:

- Home

- Loudspeakers

- Multi-Way

- The 375L