Hi Antony,

From the picture of your TA I see the string seems well centred in the hole in the top of the arm wand

I suppose, mechanically speaking, the top bracket that hold the anti skating adjustment, the knob that rotate and adjust the anti skating, the screw that adjust the clearance of the 2 magnets, and the bottom magnet are perfectly inline and centred.

If so perhaps the diameter of the magnets of 5 mm might be too small and not enough attracting power.

By the way have your magnets of 5 mm diameter also a hole to let pass the thread?

How much is the clearance of the 2 magnets?

How flexible are the twisted TA wires near the magnets?

sorry for not being able to help more

Rgds

Adelmo

From the picture of your TA I see the string seems well centred in the hole in the top of the arm wand

I suppose, mechanically speaking, the top bracket that hold the anti skating adjustment, the knob that rotate and adjust the anti skating, the screw that adjust the clearance of the 2 magnets, and the bottom magnet are perfectly inline and centred.

If so perhaps the diameter of the magnets of 5 mm might be too small and not enough attracting power.

By the way have your magnets of 5 mm diameter also a hole to let pass the thread?

How much is the clearance of the 2 magnets?

How flexible are the twisted TA wires near the magnets?

sorry for not being able to help more

Rgds

Adelmo

Hi Adelmo

those are top and bottom the 2 part difficult to get exactly center and tie it down.

the gap maybe more than I like because around 1mm it's sliding when it's too close together. but when vta changes it will touch

I have some ideas in mind. but would like to hear your thoughts. before revisions.

Thank you

Anthony

Hi Antony,

My construction is a bit different from yours.

I have made the following parts from bottom to upper ward:

Bottom magnet and its pod, magnet pressed in the pod and pod bolted to the ground base of the TA, pod centred to the upper part.

Top magnet pressed in the bottom of the aluminium TA wand. The magnet have the small hole to let the thread pass by. The upper part of the aluminium TA wand has larger hole to let the thread pass by and no contact.

The thread pass through the small hole of the aluminium screw that adjust the mag clearance. I have put a drop of glue in the hole upper part of the screw so the thread do not turn while I adjust the anti skating.

top knob with the threaded for the above screw, turning it the screw keep the same height position, but twist the thread therefore adjust the anti skating force.

Therefore I do not have the top and bottom part as you do for the thread.

Rgds

Adelmo

My construction is a bit different from yours.

I have made the following parts from bottom to upper ward:

Bottom magnet and its pod, magnet pressed in the pod and pod bolted to the ground base of the TA, pod centred to the upper part.

Top magnet pressed in the bottom of the aluminium TA wand. The magnet have the small hole to let the thread pass by. The upper part of the aluminium TA wand has larger hole to let the thread pass by and no contact.

The thread pass through the small hole of the aluminium screw that adjust the mag clearance. I have put a drop of glue in the hole upper part of the screw so the thread do not turn while I adjust the anti skating.

top knob with the threaded for the above screw, turning it the screw keep the same height position, but twist the thread therefore adjust the anti skating force.

Therefore I do not have the top and bottom part as you do for the thread.

Rgds

Adelmo

Hi Antony,

Perhaps you may also try to use a more heavy counter weight and get it closer to the pivot.

Rgds

Adelmo

Perhaps you may also try to use a more heavy counter weight and get it closer to the pivot.

Rgds

Adelmo

Hi Adelmo

I had not fill up the back insert. that would bring the weight up some

meanwhile I found a possibly viable solution to centering problem using the 3d printer nozzle. ordered a bunch to try

also for the magnet alignment. I had ordered a sphere magnet.

so I would sandwich the sphere magnet with 2 magnets to find whichever is parallel. so I could pick the one with best alignment.

only problem I have is to lock the string on top.. I haven't thought of perfect idea.

BR

Anthony

Hi!

Centering the lower magnet is crucial for achieving a constant VTF and Azimuth over the usable radius of a record. Make the hole in the bottom plate of the "gallows" slightly larger than the diameter of the screw that is used to attach the bottom magnet "pod", so you can move/slide it sideways into perfect alignment before tightening the bottom screw. This can take some time/repeated attempts...

The magnet surface MUST be parallel with the mounting surface or, even better, ground slightly spherical with the highest point of the that sphere segment perfectly centered relative to the diameter of the magnet.

The upper attachment point of the thread must, likewise, be centered 100%, otherwise a change in antiskating setting will offset the Azimuth.

Recommended magnet sizes to start out with: 9x4 or 10x5mm, the first figure denoting the diameter...

Cheers,

Frank

Centering the lower magnet is crucial for achieving a constant VTF and Azimuth over the usable radius of a record. Make the hole in the bottom plate of the "gallows" slightly larger than the diameter of the screw that is used to attach the bottom magnet "pod", so you can move/slide it sideways into perfect alignment before tightening the bottom screw. This can take some time/repeated attempts...

The magnet surface MUST be parallel with the mounting surface or, even better, ground slightly spherical with the highest point of the that sphere segment perfectly centered relative to the diameter of the magnet.

The upper attachment point of the thread must, likewise, be centered 100%, otherwise a change in antiskating setting will offset the Azimuth.

Recommended magnet sizes to start out with: 9x4 or 10x5mm, the first figure denoting the diameter...

Cheers,

Frank

Hi Frank and thank you for the pointers

I will right all over it since it's lock down here due to Delta.

I got a problem how to secure the top string. since the new strings are quite slipery. and using a screw can damage the string.

also is it advisable to use ceramic as the inside wall of the ebony wood tonearm? to prevent long term warpage as well.

stay safe and best regards

Anthony

I will right all over it since it's lock down here due to Delta.

I got a problem how to secure the top string. since the new strings are quite slipery. and using a screw can damage the string.

also is it advisable to use ceramic as the inside wall of the ebony wood tonearm? to prevent long term warpage as well.

stay safe and best regards

Anthony

Hello,

I happen to use a knot to secure the upper end of the thread. I believe "hind knuckles" is the name for it, - but one side of a blood knot will do as well. Getting the knot to end up where it needs to be is tricky though...

If you are to use ebony that has been properly dried and stored for at least 5 years AND impregnate the wood after turning, you ought to be safe. The forces generated by "young" wood when subjected to humidity changes are quite high, likely enough to break a thin-walled ceramic tube, so don't go cheap on your choice of wood/supplier.

All the best,

Frank

I happen to use a knot to secure the upper end of the thread. I believe "hind knuckles" is the name for it, - but one side of a blood knot will do as well. Getting the knot to end up where it needs to be is tricky though...

If you are to use ebony that has been properly dried and stored for at least 5 years AND impregnate the wood after turning, you ought to be safe. The forces generated by "young" wood when subjected to humidity changes are quite high, likely enough to break a thin-walled ceramic tube, so don't go cheap on your choice of wood/supplier.

All the best,

Frank

OK, I can't take it anymore! I am NOT an audiophile nor do I play one on TV, I'm just a designer, modelmaker, woodworker, tinkerer (who needs a turntable). I have read every line of this blasted post up to page 129 and I can't take it, I had to jump to the end and say, I'm in.

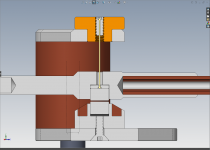

So, as I understand it, my humble version of the Schroder tonearm will look something like the attached.

3/8 x 1/4 - N52 magnets in aluminum TA section and lower “cup”, separated by ~.060” iron “wafer” one drilled and countersunk for the thread knot.

Does anything look really wrong to anyone?

Also, I would be remiss if I didn’t profusely thank Mr. Schroder (Frank) for his willingness to share his hard-fought knowledge, as well as his kindness to everyone that has commented in this forum. THANK YOU! Even if this becomes nothing more than a learning experience for me, I will be forever grateful for what I have learned here.

Muggs

So, as I understand it, my humble version of the Schroder tonearm will look something like the attached.

3/8 x 1/4 - N52 magnets in aluminum TA section and lower “cup”, separated by ~.060” iron “wafer” one drilled and countersunk for the thread knot.

Does anything look really wrong to anyone?

Also, I would be remiss if I didn’t profusely thank Mr. Schroder (Frank) for his willingness to share his hard-fought knowledge, as well as his kindness to everyone that has commented in this forum. THANK YOU! Even if this becomes nothing more than a learning experience for me, I will be forever grateful for what I have learned here.

Muggs

Attachments

HI Muggs,

Good drawing indeed but as per my understanding which by the way might not be 100%correct, the thread should pass through the top magnet too. If not in case it breaks you have to consider how to change it.

The bottom pod hole for the screw to lock it to the base of the TA I suggest to be a big bigger than the screw diameter allowing some adjustment to the top mag.

I recently resumed my tentative of a clone of the Ref 1 TA made 5 years ago and never really used before and despite by far in not close to a Ref 1 it sounded much better compared to my uni pivot TA that sounded better than the Jelco 750 L 12 inch. All the 3 TA are 12 inch with same 15mm overhang.

Ref 1 it is a really great TA, wonder how would sound the real one even with a cheap Denon DL 103 as I am using most on my TT.

Rgds

Adelmo

Good drawing indeed but as per my understanding which by the way might not be 100%correct, the thread should pass through the top magnet too. If not in case it breaks you have to consider how to change it.

The bottom pod hole for the screw to lock it to the base of the TA I suggest to be a big bigger than the screw diameter allowing some adjustment to the top mag.

I recently resumed my tentative of a clone of the Ref 1 TA made 5 years ago and never really used before and despite by far in not close to a Ref 1 it sounded much better compared to my uni pivot TA that sounded better than the Jelco 750 L 12 inch. All the 3 TA are 12 inch with same 15mm overhang.

Ref 1 it is a really great TA, wonder how would sound the real one even with a cheap Denon DL 103 as I am using most on my TT.

Rgds

Adelmo

Hi Muggs,

Looks fine, except for the countersunk screw for the bottom magnet. No matter how precise your tools are, you will need to align that lower magnet, - so go for a flat-headed screw...

@ Anthony: If you are to fit that ball-shaped magnet into the armwand, there is no way for the thread attachment point to end up as low as required for a near neutral balance character of the whole assembly. Put the ball on the bottom...

Have a relaxed weekend!

Frank

Looks fine, except for the countersunk screw for the bottom magnet. No matter how precise your tools are, you will need to align that lower magnet, - so go for a flat-headed screw...

@ Anthony: If you are to fit that ball-shaped magnet into the armwand, there is no way for the thread attachment point to end up as low as required for a near neutral balance character of the whole assembly. Put the ball on the bottom...

Have a relaxed weekend!

Frank

Last edited:

Hi Anthony,

Your (low center of gravity)counterweight will cause a restoring force and so any additional "support/stability" provided by the bearing just causes the VTF to change drastically when changing VTA(or just a 120gr pressing for a 180gr pressing).

To make that type of bearing bearing less stable, use a thinner upper magnet(lower the attachment point of your thread) or, while retaining thickness, increase the diameter of just the top - or both magnets.

And you can decrease the amount of eccentricity of your counterweight.

Don't worry, it'll work even when not executed ideally...

Cheers,

Frank

Your (low center of gravity)counterweight will cause a restoring force and so any additional "support/stability" provided by the bearing just causes the VTF to change drastically when changing VTA(or just a 120gr pressing for a 180gr pressing).

To make that type of bearing bearing less stable, use a thinner upper magnet(lower the attachment point of your thread) or, while retaining thickness, increase the diameter of just the top - or both magnets.

And you can decrease the amount of eccentricity of your counterweight.

Don't worry, it'll work even when not executed ideally...

Cheers,

Frank

hi Frank

yes you got me thinking..so I'm down to few option to play around..

I am going to try to tweak till the vtf is less variance so the damping is not that much. that should liven up the sound some.

BR

Anthony

yes you got me thinking..so I'm down to few option to play around..

I am going to try to tweak till the vtf is less variance so the damping is not that much. that should liven up the sound some.

BR

Anthony

Frank,

Thank you for the reply. DUH, yes I do remember you saying that somewhere in this VERY long thread. I will definitely put that into place.

Do you think that putting the TA in a "neutral" position and then letting the lower magnet "find a home" then tightening down the lower magnet cup would be the way to do that?

Also is there any benefit to rotating the lower magnet axially to find a good "happy" location as well, once I have found a good co-radial position?

Thanks again,

Muggs

Thank you for the reply. DUH, yes I do remember you saying that somewhere in this VERY long thread. I will definitely put that into place.

Do you think that putting the TA in a "neutral" position and then letting the lower magnet "find a home" then tightening down the lower magnet cup would be the way to do that?

Also is there any benefit to rotating the lower magnet axially to find a good "happy" location as well, once I have found a good co-radial position?

Thanks again,

Muggs

so the damping is not that much. that should liven up the sound some. Anthony[/QUOTE said:The restoring force has nothing to do with damping. Generally, it is the magnet diameter which determines the amount of lateral damping, - if magnet strength and distance between the magnets are the same for such a comparison.

Best,

Frank

- Home

- Source & Line

- Analogue Source

- DIY Schroeder Tonearm?