Hi guys,

Just bought a pair of markaudio CHR 70 drivers. I was planning on making concrete enclosures for them, but I then thought how could I do it easier save making all the wooden moulds. Then it struck me how about a 1m 160mm pipe inside a 200mm pipe, then fill the void between them with concrete with the top and bottom being capped off.

Any advice on whether to do a MLTL or ported, I was looking at the Mark 8 design a ported 1m long floorstander with an internal size of 112 x 160, hence my choice of a 160mm pipe, should give about the same internal volume.

Any advice would be appreciated.

Neil

Just bought a pair of markaudio CHR 70 drivers. I was planning on making concrete enclosures for them, but I then thought how could I do it easier save making all the wooden moulds. Then it struck me how about a 1m 160mm pipe inside a 200mm pipe, then fill the void between them with concrete with the top and bottom being capped off.

Any advice on whether to do a MLTL or ported, I was looking at the Mark 8 design a ported 1m long floorstander with an internal size of 112 x 160, hence my choice of a 160mm pipe, should give about the same internal volume.

Any advice would be appreciated.

Neil

You can try with many tubes. In the post MDD3H240 you will find my prototype, I would like to try to redo it with the spiral sheath stuck in the concrete. Low frequency distortion should decrease.

Attachments

Thanks for the reply, but not really what I had in mind, to be honest when I first saw your picture, I thought what the hell is that. But I'm all for thinking out if the box, excuse the pun 😄

You could make a tube in tube folded TL. Add a rectangular baffle to the driver where it mounts to the tube to reduce circular diffraction (the worst kind) and to lower the baffle step frequency.

US6634455B1 - Thin-wall multi-concentric sleeve speaker

- Google Patents

You can simulate this in a number of programs as stepped area expansions. Hornresp or Akabak can do it. You will want to do at least 3 concentric tubes to get the bass to come out the back end. It will make it more compact too. You could do two and have it come out concentrically around the front (rectangular baffle). But it will be long and unwieldy as a speaker.

Suppose you want 50Hz bass extension. That’s 67in long 1/4 wave. Fold 3 times and it’s a reasonable 22in deep triple tube.

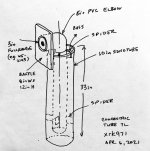

I suppose one could put a 90deg elbow at the top and have two 33in (up to 40in) long concentric pipe for a floor stander TL. Sort of like this:

I haven’t simulated it or anything, but you could tune it a bit with poly fill stuffing in the passages. W5-2143 is a great all around 5in driver with deep bass capability and nice highs. Add a BSC using 1mH inductor and 6.8ohm 10w resistor on parallel.

US6634455B1 - Thin-wall multi-concentric sleeve speaker

- Google Patents

You can simulate this in a number of programs as stepped area expansions. Hornresp or Akabak can do it. You will want to do at least 3 concentric tubes to get the bass to come out the back end. It will make it more compact too. You could do two and have it come out concentrically around the front (rectangular baffle). But it will be long and unwieldy as a speaker.

Suppose you want 50Hz bass extension. That’s 67in long 1/4 wave. Fold 3 times and it’s a reasonable 22in deep triple tube.

I suppose one could put a 90deg elbow at the top and have two 33in (up to 40in) long concentric pipe for a floor stander TL. Sort of like this:

I haven’t simulated it or anything, but you could tune it a bit with poly fill stuffing in the passages. W5-2143 is a great all around 5in driver with deep bass capability and nice highs. Add a BSC using 1mH inductor and 6.8ohm 10w resistor on parallel.

Attachments

Last edited:

From 1990, an article on a design that XRK’s mimics to give you more ideas; http://p10hifi.net/planet10/TLS/downloads/cylindrical-sonotube-TL.pdf

With a cylinder there is little to no point in doing concrete walls.

dave

With a cylinder there is little to no point in doing concrete walls.

dave

no point

By no point, do you mean a plastic tube wouldn't need deadening with concrete because it is none resonate?

The plan was to use a smaller pipe inside a larger one as a mould, affectively making a concrete pipe.

By no point, do you mean a plastic tube wouldn't need deadening with concrete because it is none resonate?

The plan was to use a smaller pipe inside a larger one as a mould, affectively making a concrete pipe.

No need to make a speaker out of concrete to dampen vibrations as it is heavy, brittle, immovable - when PVC pipe or Sonotube will do the job just fine and be portable low cost and robust. Add auto sound mass loaded foil faced sound dampener sheets to the tubing if you find resonance. But I don’t think a concrete tube is necessary. Also, concrete is hard and very resonant and will impart an echo for higher frequencies if not lined with felt or melamine foam.

By no point, do you mean a plastic tube wouldn't need deadening with concrete because it is none resonate?

Because it is a cylinder the box is inherently stiff (except the end caps).

4mm paper tube will probably perform as well as your concrete tube and your back will thank you.

dave

Hi guys,

Then it struck me how about a 1m 160mm pipe inside a 200mm pipe, then fill the void between them with concrete with the top and bottom being capped off.

Neil

Hi Neil,

If you really want a dead enclosure, sand filling the void between the concentric pipes wont be mechanically stiff like cured concrete. Wharfdale was big on that in-betwixt plywood panels.

Could even be a shippable comercial design, with the buyer responsible for getting some sand from HD and filling 'em up before use, via little Ikea style plugs in the base.

Then the fun starts in forums, where users discuss the sonic differences between cement sand, play sand, red/white sand, Diatomaceous earth, lead buckshot, gravel and packed sawdust - in various amounts and aggregates ;')

Jjasniew

Great minds think alike,,my initial post was to gauge the feeling on using a pipe.

But I also thought filling with sand has many advantages and probably result in a deader cabinet. If you were to go down the commercial route it would be perfect, light to post and end user could experiment with fillings.

Another idea I had was to use a 160 mm pipe then bend a piece of hardboard around it, Leaving a void between pipe and hardboard, then close off the hardboard with a wooden spine thus making a pear shape if looking from above.

The real question will a 1 m pipe with a radius of 160mm have the right volume for a markaudion chr 70 driver?

Great minds think alike,,my initial post was to gauge the feeling on using a pipe.

But I also thought filling with sand has many advantages and probably result in a deader cabinet. If you were to go down the commercial route it would be perfect, light to post and end user could experiment with fillings.

Another idea I had was to use a 160 mm pipe then bend a piece of hardboard around it, Leaving a void between pipe and hardboard, then close off the hardboard with a wooden spine thus making a pear shape if looking from above.

The real question will a 1 m pipe with a radius of 160mm have the right volume for a markaudion chr 70 driver?

Last edited:

Radius or diameter? The former would be approx 4x the volume of the latter, and much larger than the many smaller rectilinear boxes I can remember building for MA and Fostex drivers of the approx size class as the CHRs.

Being math challenged, I needed to double check myself, but I think those volumes would be circa 80 litres and 20 litres respectively?

Being math challenged, I needed to double check myself, but I think those volumes would be circa 80 litres and 20 litres respectively?

Last edited:

The real question will a 1 m pipe with a radius of 160mm have the right volume for a markaudion chr 70 driver?

Ok, so I'm playin' around too. I dropped a pair of Pluvia 7 HD atop two 3ft, 4" pipes, stuffed with polyfil. To get some break-in time while I figure out what I want to do cabinet wise, source build materials, etc.

It's a copy of a Japanese design called the "time-domain". I think they make a nice effect, particularly when you're not doing precision listening but just want something going in the background in a room, while your attention is on something else, like replying to a thread here. (Occasionally, they'll steal my attention away - even when I'm listening at >90 deg off axis, seated)

These are basically SL's "surround" design for the rear channels, different speaker, no EQ. He said he preferred the tubes stuffed, over a reflex ported or MLTL design - which of course leaves room for experimentation if the cabinet "hangover" of such designs is more tolerable to you, than it apparently was to SL.

If the 3' chamber volume is way too high, for an unstuffed approach, fill 'em with sand until the volume is right and plug the bottom of the circular chamber at that point. Lots of room for experimentation. I'm going to try a CHR50 in it as well.

Attachments

Neat, still not what I had in mind, could you not try a 90deg bend and mount the driver in that for more of a directional sound?

I have a give-away woofer ML-TL project that will look like a big version of that (8” pipe)

dave

Neat, still not what I had in mind, could you not try a 90deg bend and mount the driver in that for more of a directional sound?

These come to mind

the toobs Mk 1

Laying Pipe with Audio Lego

What about all the reflections from the close internal side wall? 😉I have a give-away woofer ML-TL project that will look like a big version of that (8” pipe)

dave

Perhaps less of an issue when operational bandwidth is restricted as would normally be intended for a woofer/sub woofer application? As I recall that was one of dozens of Dave’s thought experiments for which his symbiot builder never developed sufficient interest to execute.

What about all the reflections from the close internal side wall? 😉

In mine it is a 7” driver (5-6” cone) in an 8” pipe. Not so close to the walls as the example shown.

Note: i do have 2 PVC pipe woofer projects that i am happy to give away to anyone who can coe pick them up. The tall 8” pipes with Eastech 7” (x2 [like a mini el-Pipo]) and a much shorter 12” tube (2x), with 4 12” each isobarik push-push-push-pull.

dave

- Home

- Loudspeakers

- Full Range

- Tube with in a tube speaker