@ Jean Claude

Why not place your order at Mädler in Germany.

@ David

Yes, "Gedotec Drehbeschlag" will work and Pololu with 67 rpm also.

Regards

Heinrich

Why not place your order at Mädler in Germany.

@ David

Yes, "Gedotec Drehbeschlag" will work and Pololu with 67 rpm also.

Regards

Heinrich

Well, I have the,

- slewing ring (lazy susan w/gear)

- pinion gear

- circuit board

on order from Germany.

All I have to do now is settle on a,

- Motor

- Power Supply

- Jack for Power supply

- USB B male cable to a port of some type.

- slewing ring (lazy susan w/gear)

- pinion gear

- circuit board

on order from Germany.

All I have to do now is settle on a,

- Motor

- Power Supply

- Jack for Power supply

- USB B male cable to a port of some type.

@ Jean Claude

Why not place your order at Mädler in Germany.

@ David

Yes, "Gedotec Drehbeschlag" will work and Pololu with 67 rpm also.

Regards

Heinrich

Hello Heinrich,

Can you explain the math here, (cut and paste from another forum)

---

The phidgets encoder has 360 counts per rotation. In the following the calculation of the parameters:

sprocket = 176

pinion =11

Motor = 139.150696

Decoder = 360

factor = 2226.411

A = 1000

B = 2226411

@ Jean Claude

Why not place your order at Mädler in Germany.

Regards

Heinrich

Hi Heinrich,

Well It looks to me that Mädler does not have a webshop (or at least, I was not able to find it), but thanks for the link, they have a french rep who is willing to order the module for me !

Best regards

Jean Claude

Hello Heinrich,

Can you explain the math here, (cut and paste from another forum)

---

The phidgets encoder has 360 counts per rotation. In the following the calculation of the parameters:

sprocket = 176

pinion =11

Motor = 139.150696

Decoder = 360

factor = 2226.411

A = 1000

B = 2226411

Nevermind, I found the info, 🙂

The two scaling factors for the encoder determine the angular position of the turntable. The following information must be known for the calculation:

n = number of teeth of the pinion

N = number of teeth of the slewing ring

U = reduction of the geared motor

I = number of pulses of the encoder per revolution

The factor A is a pure scaling factor and can be freely selected. The calculation of the scaling factor B is as follows:

Scaling Factor B = N / n ∙ U ∙ I / 360 = Impulse / °

Example:

n = 11, N = 176, U = 131.25, I = 16

Scaling Factor B = 176 / 11 ∙ 131.25 ∙ 16/360 = 93.333 p / °

Since both factors can only be integers, A = 1000 should be chosen because of the better resolution (taking into account 3 decimal places).

Scaling factor A = 1 and B = 93 or for better resolution

scaling factor A = 1000 and B = 93333.

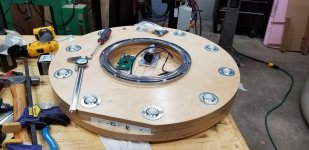

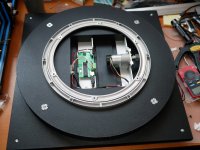

I will be doing the final wiring on my Arta turntable tomorrow and giving it a spin, but I could use some help with setting it up.

I am using,

- Hefter 330mm slewing ring

- Mädler 11 tooth gear

As shown in the Arta table documentation, but for a motor I am using the,

- Pololu 150:1 Metal Gearmotor 37Dx73L mm 12V with 64 CPR Encoder.

What parameters will I need to adjust in the following two windows?

- Parameters USB Rotary Table

- USB Rotary Table Parameter Fine Tuning

I expect Scaling Factor A and Scaling Factor B will need to be adjusted?

Any help would be appreciated.

Thank you, David.

I am using,

- Hefter 330mm slewing ring

- Mädler 11 tooth gear

As shown in the Arta table documentation, but for a motor I am using the,

- Pololu 150:1 Metal Gearmotor 37Dx73L mm 12V with 64 CPR Encoder.

What parameters will I need to adjust in the following two windows?

- Parameters USB Rotary Table

- USB Rotary Table Parameter Fine Tuning

I expect Scaling Factor A and Scaling Factor B will need to be adjusted?

Any help would be appreciated.

Thank you, David.

Attachments

Sometime in the 50's my father built an Xmas tree turntable - complete with slip ring commutators and AC sockets on the table. By the time I became conscious of it, its friction drive to the gear motor had worn out and it wouldnt turn anymore.

That's quite a piece of art you have there, David. I bet it still works 50 years from now~

Who knows what USB will be thought of after such passage of time.

That's quite a piece of art you have there, David. I bet it still works 50 years from now~

Who knows what USB will be thought of after such passage of time.

I have a motor with 131:1 / 64 CPR, so the scaling factor will be different with your.

I played around a bit with the Acceleration, Decelleration and Speed to get the turntable to behave as it should with the load i put on it.

Here's my config:

[Rotary Table]

RotaryTableType=2

[Application Setup]

AutoSaveSetup=True

[MotorUSBBoard]

P_Factor=90

I_Factor=0

D_Factor=0

MaximumPWMPower=90

MinimumPWMPower=10

AccSpeed=5

Speed=10

DeccSpeed=5

[EncoderUSBBoard]

ScalefactorA=1000

ScalefactorB=93863

UnitPosition=°

[Rotary Table Simulation]

PositioningTimeSec=1

I played around a bit with the Acceleration, Decelleration and Speed to get the turntable to behave as it should with the load i put on it.

Here's my config:

[Rotary Table]

RotaryTableType=2

[Application Setup]

AutoSaveSetup=True

[MotorUSBBoard]

P_Factor=90

I_Factor=0

D_Factor=0

MaximumPWMPower=90

MinimumPWMPower=10

AccSpeed=5

Speed=10

DeccSpeed=5

[EncoderUSBBoard]

ScalefactorA=1000

ScalefactorB=93863

UnitPosition=°

[Rotary Table Simulation]

PositioningTimeSec=1

Hi David,

the calculation for the Polulo 150:1 gear motor is as follows:

Scaling Factor B = N/n ∙ U ∙ I/360 = Impulse/°

N = 176

n = 11

U = 150

I = 64

B = 426.666

If A = 1000 --> B = 426000

Regards

Heinrich

the calculation for the Polulo 150:1 gear motor is as follows:

Scaling Factor B = N/n ∙ U ∙ I/360 = Impulse/°

N = 176

n = 11

U = 150

I = 64

B = 426.666

If A = 1000 --> B = 426000

Regards

Heinrich

Hi David,

the calculation for the Polulo 150:1 gear motor is as follows:

Scaling Factor B = N/n ∙ U ∙ I/360 = Impulse/°

N = 176

n = 11

U = 150

I = 64

B = 426.666

If A = 1000 --> B = 426000

Regards

Heinrich

My ring gear is 178 tooth (both my wife and I counted it 🙂 ) and here is the math I came up with,

N = 178

n = 11

U = 150

I = 64

B = 431.515

If A = 1000 --> B = 431515

Here is the thing, that number does not work!

For some reason, it is off by a factor of four.

Through trial and error, I am using B=107225.

I double checked that I received the motor I ordered, and it is indeed the correct one, as well as all the connections.

Pololu - 150:1 Metal Gearmotor 37Dx73L mm 12V with 64 CPR Encoder (Helical Pinion)

^This one.

Here is a short vid of the table moving from 0º-180º-0º

Arta Turntable 0 to 180 to 0 - YouTube

And some pictures of the motor, connections and software settings.

Any thoughts as to why Scaling Factor B is so wrong?

Thank you,

David.

Attachments

David,

I have just finished my table using the same Polulu motor as you (Polulu ref 2828 ) and I have the same problem : I have to divide by a factor of 4 to get the correct rotation.

I would really like to understand !

Any idea Heindrich ?

Jean Claude

I have just finished my table using the same Polulu motor as you (Polulu ref 2828 ) and I have the same problem : I have to divide by a factor of 4 to get the correct rotation.

I would really like to understand !

Any idea Heindrich ?

Jean Claude

Last edited:

David,

I have just finished my table using the same Polulu motor as you (Polulu ref 2828 ) and I have the same problem : I have to divide by a factor of 4 to get the correct rotation.

I would really like to understand !

Any idea Heindrich ?

Jean Claude

Well at least it was not just me!

Any pics of yours?

David.

For sure,

I use 30 x 50 mm aluminum corner with 3 mm thickness. I make my motor support in two parts to allow easy final adjustment and also add adjustable feet at the bottom.

table tournante auto jcg_2_low.jpg

I also place a 40 cm x 40 cm sheet of lead (7 mm thick) below the base plate to incease stability.

Here is the gear in situation

table tournante auto jcg_1_low.jpg

I use 30 x 50 mm aluminum corner with 3 mm thickness. I make my motor support in two parts to allow easy final adjustment and also add adjustable feet at the bottom.

table tournante auto jcg_2_low.jpg

I also place a 40 cm x 40 cm sheet of lead (7 mm thick) below the base plate to incease stability.

Here is the gear in situation

table tournante auto jcg_1_low.jpg

Attachments

Hi, Besides the Pololu I used this motor from Phidgets in my test setup (12V/8.4Kg-cm/28RPM 139:1 DC Gear Motor w/Encoder - 3264E_0 at Phidgets). Both worked as described in the application note.

The encoder seems to be the problem (factor 4 means 16 CPR). I will try to contact Wim.

Regards

Heinrich

The encoder seems to be the problem (factor 4 means 16 CPR). I will try to contact Wim.

Regards

Heinrich

Last edited:

Hi Heinrich,

Thanks for the answer, unfortunately the Phidgets motor is now discontinued !

And you are right, it seems related to the way the interface interpret the CPR

Hopefully, a solution could be found.

In the meantime, when the table rotate let's say from 0° to 180°, it accelerate, then slow down, then accelerate again and so on until it reach it's final position. It can be seen in the you tube link Davefred just posted a few post above:

Arta Turntable 0 to 180 to 0 - YouTube

Thanks for the answer, unfortunately the Phidgets motor is now discontinued !

And you are right, it seems related to the way the interface interpret the CPR

Hopefully, a solution could be found.

In the meantime, when the table rotate let's say from 0° to 180°, it accelerate, then slow down, then accelerate again and so on until it reach it's final position. It can be seen in the you tube link Davefred just posted a few post above:

Arta Turntable 0 to 180 to 0 - YouTube

Hello David, may i know how did you get the slewing ring and the pinion shipped in your contry ? Im from Mexico, and i can not find anywhere to get them here.

Regards!

Regards!

- Home

- Loudspeakers

- Multi-Way

- Polar measurements with automatic turntable