Here's latest syn attempt that's a bit easier to build because the ports are simple circles, and not jammed into horn corners.

It follows the design pattern of syn7, where the ports are centered under the low-mid driver, with the drivers on the top and bottom horn panels. https://www.diyaudio.com/forums/multi-way/351670-synergy-7-a.html

This design came about primarily to reduce weight, and I've been pleased as punch with the syn7's so thought I'd stick with it.

The reason for this guy, i'll call it syn8, has been about trying to get the low/mids a little further into the horn towards the throat. I'm getting more and more convinced the tighter acoustic centers get the better.

So I dropped down from 10"s to a pair of 8" Beyma 8mc300nd's.

I also wanted a little tighter pattern than syn7's 90x60, so this one is 75x50.

It was impossible to go any tighter and keep the ports centered under the 8" drivers. Narrowing pushes the driver out into the horn away from the throat.

Centering under the cone simply measures better than ports under the outer periphery. I retried a bunch of different port locations including some crazy ones like this smiley face.

Since everything i build crosses to a sub at 100Hz, bass-reflex posts were needed to get the lower end response.

First time trying BR ports on a syn and had to prototype a few port sizes, locations, and lengths, once the driver location and its main port were set.

Uses the same bms 4594he or b&c dcx464 coax CD robbed from syn7's, to get down to 500Hz.

I know they are $$$ but they just solve too many syn issues and work so dang well. Highly recommend either ot them for a syn.

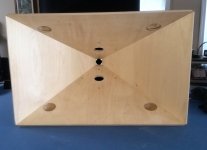

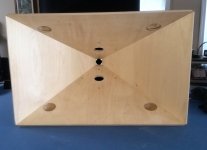

Anyway, here's the box without its yet unbuilt secondary flares.

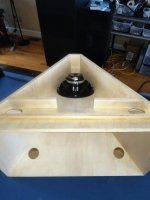

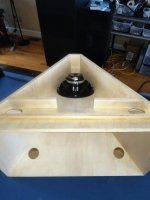

Here's a top view that shows the bass-reflex ports. Using the top and bottom cavities like this made for surprisingly easy BR port installation. One lid seals up both the driver and the reflex port ducts.

It's sounding so good i have the same dilemma as with other versions...whether or not to add secondary flares.

No doubt will though, just to see.....

Right now, without secondary flares, or a built in stand, or an an enclosure for the CD, it weighs 31 lbs. My guess is those parts will add about 12lbs, because I'll make the flares out of wood, not foam like syn7.

Otherwise I'll just copy what I did for syn7.

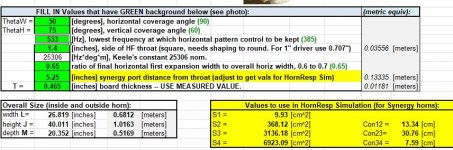

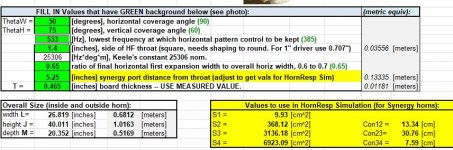

Here's the inputs for Mr Waslo's generous and excellent spreadsheet contribution given to us all.

Ports under the 8"'s are 2.125" dia, 6.25" from throat. Notch came in at 480Hz, which was a little lower than hoped, but CD's have no problem there matching all the SPL the 8"s can pull...which is alot 😀

BR ports are 2.25" dia, with centers 5" from mouth edge, and as close to horn walls as possible.

If there's further interest, ask and I'll give port duct dimensions.

It follows the design pattern of syn7, where the ports are centered under the low-mid driver, with the drivers on the top and bottom horn panels. https://www.diyaudio.com/forums/multi-way/351670-synergy-7-a.html

This design came about primarily to reduce weight, and I've been pleased as punch with the syn7's so thought I'd stick with it.

The reason for this guy, i'll call it syn8, has been about trying to get the low/mids a little further into the horn towards the throat. I'm getting more and more convinced the tighter acoustic centers get the better.

So I dropped down from 10"s to a pair of 8" Beyma 8mc300nd's.

I also wanted a little tighter pattern than syn7's 90x60, so this one is 75x50.

It was impossible to go any tighter and keep the ports centered under the 8" drivers. Narrowing pushes the driver out into the horn away from the throat.

Centering under the cone simply measures better than ports under the outer periphery. I retried a bunch of different port locations including some crazy ones like this smiley face.

Since everything i build crosses to a sub at 100Hz, bass-reflex posts were needed to get the lower end response.

First time trying BR ports on a syn and had to prototype a few port sizes, locations, and lengths, once the driver location and its main port were set.

Uses the same bms 4594he or b&c dcx464 coax CD robbed from syn7's, to get down to 500Hz.

I know they are $$$ but they just solve too many syn issues and work so dang well. Highly recommend either ot them for a syn.

Anyway, here's the box without its yet unbuilt secondary flares.

Here's a top view that shows the bass-reflex ports. Using the top and bottom cavities like this made for surprisingly easy BR port installation. One lid seals up both the driver and the reflex port ducts.

It's sounding so good i have the same dilemma as with other versions...whether or not to add secondary flares.

No doubt will though, just to see.....

Right now, without secondary flares, or a built in stand, or an an enclosure for the CD, it weighs 31 lbs. My guess is those parts will add about 12lbs, because I'll make the flares out of wood, not foam like syn7.

Otherwise I'll just copy what I did for syn7.

Here's the inputs for Mr Waslo's generous and excellent spreadsheet contribution given to us all.

Ports under the 8"'s are 2.125" dia, 6.25" from throat. Notch came in at 480Hz, which was a little lower than hoped, but CD's have no problem there matching all the SPL the 8"s can pull...which is alot 😀

BR ports are 2.25" dia, with centers 5" from mouth edge, and as close to horn walls as possible.

If there's further interest, ask and I'll give port duct dimensions.

Thanks for sharing it Mark, way cool project again!🙂

Did you try/consider reflex ports on the outside surface of the horn (enclosure)? There the port holes wouldn't affect the higher frequencies in the horn at all but you might have other reasons?

I'm wondering what kind of gluing jig you have for these large non boxy speakers? How you assemble these?

Did you try/consider reflex ports on the outside surface of the horn (enclosure)? There the port holes wouldn't affect the higher frequencies in the horn at all but you might have other reasons?

I'm wondering what kind of gluing jig you have for these large non boxy speakers? How you assemble these?

Thx tmuikku,

Yes, i did try pvc pipe on the outside, but i couldn't find anything that didn't get too awkward and unwieldy. Although the external pvc did help to get an idea of what to do with the inside ducts.

Tried pvc inside too, until i realized that ducts would have a correct cross sectional size, and length, underneath the lid up toward the mouth as shown.

The ducts in the top mounted cavity like that work out to be stupid simple easy! My kind of build 😀

I'm getting more convinced the ports don't mess with higher frequencies as much as common wisdom would say.

Mouth termination seems to be the biggest messer-upper,

when looking at measurements of the CD on the horn before any ports are put in, compared to measurements after the ports are added.

I think maybe the biggest reason to put ports in the corners is to tighten up C-to-C spacing to the CD.

Using the 'port under the mid cone center' like i do doesn't seem to mess with high freq any more than corner ports.

But it has the disadvantage of increasing distance to the CD, which makes getting the CD down to 500Hz pretty mandatory.

Although that said, if someone widens the horiz pattern to 90 degrees or greater, the cone driver can get close enough to raise to notch to maybe 700 Hz.

( Although I'm also not so convinced the 'notch', can't be EQed away. But that's another story...)

I don't have a glueing jig other than the tape and fold method, and fitting bar clamps however they may hold...which is usually means not lol

Final assembly typically just gets glue, tape and fold, and a brad nailer.

So far on the syn8 above, it's just screwed together with sheet rock screws.

I disassemble and reassemble alot, trying different ports etc...

The only glue used so far can be seen on the pic of the top, for the 3 pieces that make the bass-reflex ducts.

Yes, i did try pvc pipe on the outside, but i couldn't find anything that didn't get too awkward and unwieldy. Although the external pvc did help to get an idea of what to do with the inside ducts.

Tried pvc inside too, until i realized that ducts would have a correct cross sectional size, and length, underneath the lid up toward the mouth as shown.

The ducts in the top mounted cavity like that work out to be stupid simple easy! My kind of build 😀

I'm getting more convinced the ports don't mess with higher frequencies as much as common wisdom would say.

Mouth termination seems to be the biggest messer-upper,

when looking at measurements of the CD on the horn before any ports are put in, compared to measurements after the ports are added.

I think maybe the biggest reason to put ports in the corners is to tighten up C-to-C spacing to the CD.

Using the 'port under the mid cone center' like i do doesn't seem to mess with high freq any more than corner ports.

But it has the disadvantage of increasing distance to the CD, which makes getting the CD down to 500Hz pretty mandatory.

Although that said, if someone widens the horiz pattern to 90 degrees or greater, the cone driver can get close enough to raise to notch to maybe 700 Hz.

( Although I'm also not so convinced the 'notch', can't be EQed away. But that's another story...)

I don't have a glueing jig other than the tape and fold method, and fitting bar clamps however they may hold...which is usually means not lol

Final assembly typically just gets glue, tape and fold, and a brad nailer.

So far on the syn8 above, it's just screwed together with sheet rock screws.

I disassemble and reassemble alot, trying different ports etc...

The only glue used so far can be seen on the pic of the top, for the 3 pieces that make the bass-reflex ducts.

Looks like a great project. Only suggestion I have is perhaps the "towel mod" for the mouth termination. By all reports this will address sonic problems of your "messer-upper", the abrupt termination at the mouth, but what it gives in acoustic performance it takes away in appearance 🙂

Thx Soldermizer,

Yep, the towel mod is one of the first experiments i try on the various syn builds.

Then felt, then acoustic stick on,...i'll try anything...you name it lol.

But they all tend to whack up 5kHz and up in unpredictable ways.

So far, adding a secondary flare has made the most impact in smoothing on and off axis response.

But it also takes pattern control lower, so when sound changes a bit, it's hard to judge whether it's from better polars or lower pattern control.

Sometimes, room location depending, the non-flared, wobbly polars version, sounds best....😕

Did i ever flat state right out "i hate rooms"...worst damn component in our systems x100 !! lol

Yep, the towel mod is one of the first experiments i try on the various syn builds.

Then felt, then acoustic stick on,...i'll try anything...you name it lol.

But they all tend to whack up 5kHz and up in unpredictable ways.

So far, adding a secondary flare has made the most impact in smoothing on and off axis response.

But it also takes pattern control lower, so when sound changes a bit, it's hard to judge whether it's from better polars or lower pattern control.

Sometimes, room location depending, the non-flared, wobbly polars version, sounds best....😕

Did i ever flat state right out "i hate rooms"...worst damn component in our systems x100 !! lol

Hi Mark,

You don't stop building! It takes me ages to get a single box built 😀

Interesting about the 5k up being affected by the towel mods etc as a lot of stuff I've read says the highs are controlled by the CD exit and not so much by the actual horn. (I was planning to try some felt on the baffle front edge, running down into the horn a bit to see if it smooths the high end of my build. The raw measurement in REW looks a bit 'busy' above ~9K)

Cheers,

Rob.

You don't stop building! It takes me ages to get a single box built 😀

Interesting about the 5k up being affected by the towel mods etc as a lot of stuff I've read says the highs are controlled by the CD exit and not so much by the actual horn. (I was planning to try some felt on the baffle front edge, running down into the horn a bit to see if it smooths the high end of my build. The raw measurement in REW looks a bit 'busy' above ~9K)

Cheers,

Rob.

The way you have made the ports using the divider above the horn flare is very nice, I haven't seen it done that way before.

A neater version of the towel mod would be some acoustic foam around the mouth like the quadratic throat waveguide:

http://www.excelsior-audio.com/Publications/QTWaveguide/QTWaveguide_WhitePaper.pdf

A neater version of the towel mod would be some acoustic foam around the mouth like the quadratic throat waveguide:

http://www.excelsior-audio.com/Publications/QTWaveguide/QTWaveguide_WhitePaper.pdf

I had a thought with regard to further weight reduction, these speakers:

Soundgear - Speakers - Amplifiers - DSP

are available made from popular ply with some kind of impact resistant paint (I think if you search through soundgears facebook page there is a video of it withstanding a determined attack with a hammer). This is much lighter than normal plywood

Soundgear - Speakers - Amplifiers - DSP

are available made from popular ply with some kind of impact resistant paint (I think if you search through soundgears facebook page there is a video of it withstanding a determined attack with a hammer). This is much lighter than normal plywood

Hi Mark,

You don't stop building! It takes me ages to get a single box built 😀

Interesting about the 5k up being affected by the towel mods etc as a lot of stuff I've read says the highs are controlled by the CD exit and not so much by the actual horn. (I was planning to try some felt on the baffle front edge, running down into the horn a bit to see if it smooths the high end of my build. The raw measurement in REW looks a bit 'busy' above ~9K)

Cheers,

Rob.

Hi Rob,

Yep, most everything I've read says highs are controlled by CD exit and only a short distance thereafter. But's that simply not what I keep measuring.

Funny, but about the only thing that doesn't seem to make much difference in measurements is matching the CD exit to the throat. I thought it did back on syn5 or so, but continued work makes me question what was going on then.

So plain dunno here ......

Back to out in the horn...

I've found felt strips, or stick on foam like PE sells, can make quite a bit of difference.

Best results I've had with these are either strips or trapeziums, placed centered out in the end of the mouth. They seem to help best when on the top and bottom horn walls only. And wide pieces have yet to help.

This is when not using a secondary flare.

Have yet to try much when secondary's are on.

Hi kipman,

Yeah, i've tried putting foam all around the mouth when no secondary falers are involved.

Messed things up a bunch.

But I think i should revisit trying all around, putting foam on the secondary's, in similar fashion to the Charlie Hughes paper you linked.

I got lucky spotting the divider / BR duct / BR port idea. It's a byproduct of bashing my head in, trying to impossibly fit pvc pipe into the cavity.

Thx for the link on potential weight savings....always a big factor for me.

Yeah, i've tried putting foam all around the mouth when no secondary falers are involved.

Messed things up a bunch.

But I think i should revisit trying all around, putting foam on the secondary's, in similar fashion to the Charlie Hughes paper you linked.

I got lucky spotting the divider / BR duct / BR port idea. It's a byproduct of bashing my head in, trying to impossibly fit pvc pipe into the cavity.

Thx for the link on potential weight savings....always a big factor for me.

I had a thought with regard to further weight reduction, these speakers:

Soundgear - Speakers - Amplifiers - DSP

are available made from popular ply with some kind of impact resistant paint (I think if you search through soundgears facebook page there is a video of it withstanding a determined attack with a hammer). This is much lighter than normal plywood

There's an interesting resin based paint recipe on speakerplans that should be pretty tough. I haven't tried it myself though.

I think that could depend a lot on the exit and phase plug configuration of the driver itself as well as how accurately you can fabricate it by hand to make a solid comparison.Funny, but about the only thing that doesn't seem to make much difference in measurements is matching the CD exit to the throat. I thought it did back on syn5 or so, but continued work makes me question what was going on then.

So plain dunno here ......

mabat has shown some sims (I know "sims" 😉) of a conical expansion mated to an OS throat where there is a change in curvature causing an issue.

Some drivers have a zero degree exit angle which would mate quite differently.

In my own BEM simulations where the source is an ideal flat disc, changing the entry angle of the waveguide makes virtually no difference.

Thx fluid,

i really don't know what to think.....i discount my opinion to zero, about CD exit to throat matching.

Can only report what i measure, with no clue why or why not.......

You can see the aluminum plate corners around the CD in the front pict of this syn8 build...as so far I haven't found it worth the trouble to fix.

But I'll most likely end up filling in the corners when it's time to go to paint....just for the sake of because so many knowledgeable folks say to.

Oh, I have noticed in some Danley box picts, flat unblended corners...like said, 😕

Interesting your BEM sims don't show much difference.

i really don't know what to think.....i discount my opinion to zero, about CD exit to throat matching.

Can only report what i measure, with no clue why or why not.......

You can see the aluminum plate corners around the CD in the front pict of this syn8 build...as so far I haven't found it worth the trouble to fix.

But I'll most likely end up filling in the corners when it's time to go to paint....just for the sake of because so many knowledgeable folks say to.

Oh, I have noticed in some Danley box picts, flat unblended corners...like said, 😕

Interesting your BEM sims don't show much difference.

I've got this post by Tom D saved, seems relevant here.

"

If one starts with a source that is to small to produce any directivity on its own (less than about 1/3 wl across), it radiates into space as a spherical wave.

If one takes a straight sided conic horn and places that point source at the apex, it radiates a segment of a spherical wave.

There is no opportunity to produce or radiate higher order modes in this condition but when ever a curved wall horn changes wall angle, there is the chance of producing higher modes. The OS horn does this change in angle as slowly as possible to minimize / eliminate the effect.

In the real world, one finds that 20KHz has a wavelength of about 5/8 inch, already smaller than the one inch throat on compression drivers.

Also, all drivers are not equal, larger 1.4 inch and even more so 2 inch drivers have an internal geometry which produces a converging wavefront at its summation point, what one wants for a horn is a diverging wavefront.

The BMS driver mentioned (which I use in some of our products at work), has a different internal structure which does not involve multiple paths which sum in a converging wave but has one summation path ending at the center at about 3/8 inch dia.

From there forward inside the driver is a conical expansion which produces a diverging wavefront.

When coupling into a more rapid conical horn (then the inside of the driver), the idea is o do it quickly before the dimension get much larger.

In practice, if you make a square horn with a one inch driver, using a one inch pipe to spread the filler in the corner works well and forms a round shape.

"

"

If one starts with a source that is to small to produce any directivity on its own (less than about 1/3 wl across), it radiates into space as a spherical wave.

If one takes a straight sided conic horn and places that point source at the apex, it radiates a segment of a spherical wave.

There is no opportunity to produce or radiate higher order modes in this condition but when ever a curved wall horn changes wall angle, there is the chance of producing higher modes. The OS horn does this change in angle as slowly as possible to minimize / eliminate the effect.

In the real world, one finds that 20KHz has a wavelength of about 5/8 inch, already smaller than the one inch throat on compression drivers.

Also, all drivers are not equal, larger 1.4 inch and even more so 2 inch drivers have an internal geometry which produces a converging wavefront at its summation point, what one wants for a horn is a diverging wavefront.

The BMS driver mentioned (which I use in some of our products at work), has a different internal structure which does not involve multiple paths which sum in a converging wave but has one summation path ending at the center at about 3/8 inch dia.

From there forward inside the driver is a conical expansion which produces a diverging wavefront.

When coupling into a more rapid conical horn (then the inside of the driver), the idea is o do it quickly before the dimension get much larger.

In practice, if you make a square horn with a one inch driver, using a one inch pipe to spread the filler in the corner works well and forms a round shape.

"

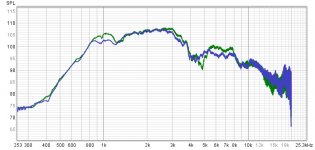

I tried both styles of throat on my 50x50 test box. Blue trace is Tom D style where the plate bolts to a 1"x1" square throat with a tiny bit of filler in the corners, green trace is the Bwaslo style from the spreadsheet.

The Tom D trace looks a little smoother above 10k. I overlayed the graphs so cannot be sure of exact spl as I measured them on different days, so cannot say whether the Bwaslo has higher sensitivity at 1k and 5k or lower sensitivity 1.4k to 3k.

Rob.

The Tom D trace looks a little smoother above 10k. I overlayed the graphs so cannot be sure of exact spl as I measured them on different days, so cannot say whether the Bwaslo has higher sensitivity at 1k and 5k or lower sensitivity 1.4k to 3k.

Rob.

Attachments

The BEM sims show no difference when the source is an ideal flat wavefront there is no inherent change in curvature or wall angle from a conic exit to an OS throat.Can only report what i measure, with no clue why or why not.......

Interesting your BEM sims don't show much difference.

Once you add a real driver things become more complicated.

With a conic exit and a conic throat an angle mismatch between them would produce diffraction.

So I think the type of horn matters, as to how an issue might present or be measured.

It could be very hard to measure without a very smooth mic barrel and mounting to avoid self diffraction.

- Home

- Loudspeakers

- Multi-Way

- A somewhat easier to build synergy...