No, the opposite; a speaker wall is like a bell, it will resonate until the energy is dissipated, either though radiating sound or through it's own damping. Making something stiffer just increases it fundamental resonant frequency, this may be a positive or negative. Don't forget that when you make a stiffer box by making it thicker, you're also making it heavier, making it more difficult for the driver to move it, and therefore more difficult to transfer energy to it ( if you're sat in a dingy and push on another dingy it will move, if you push on a battle ship you'll be able to push slightly harder but it will move a tiny, tiny amount - slightly more force, very much less movement much less energy transferred) ; it may by the extra weight is the cause of any improvement. An anvil would fulfil most peoples definition of " totally stiff " but they still resonate, just at a high frequency.

... thought the premise of bracing was to make a cabinet stiff enough to drive resonance/vibrations out of the range of audibility. Not sure why you'd engineer a box to resonate at an audible frequency as in your "Mids box" example?my takes is a simple irregular or triangled bracing will do fine. The most important point here is try to built the enclosure with resonance outside the passband of the driver. So for Woofers cabinet closer bracing will lift the box vibration above the driver operating range. Mids box will do well with a larger box with less bracing to ensure the resonance is at a lower frequency. All box should be irregular in shape with wedges to prevent standing waves. The BnW nautilaus speaker is actually a very good enclosure to copy.

Decoupling the driver from the rigid box will reduce the remaining noise. For damping If you don't mind the hassles CLD is best. You can also use MLV decoupled from the cabinet walls with foam. MLV tend very effective above 100hz and have next to no resonance except at a very low frequency .

An interesting video on tuned mass damping for gearheads.

Edd China explores: Vibration-damping technology by Sandvik Coromant - YouTube

Edd China explores: Vibration-damping technology by Sandvik Coromant - YouTube

Last edited:

I tend to agree with Mark100: a big wiggle on the impedance curve is probably audible, a small wiggle is probably not, and if there is no wiggle, there is probably no problem (Mark I hope I paraphrased you correctly)...

It is also my opinion that it is easier to make cabinet resonances a non-problem by making the cabinet stiff and well braced, rather than adding damping.

Hi hifijim, yeah, i do try to get rid of big impedance curve wiggles/breaks, as it does seem like the speaker gets a little better sounding. But like Earl Geddes mentioned, such changes are usually along with other adjustments also going on, so it's pretty hard to say anything definitive about bracing cause and effect.

I very much support the idea of simply building a strong cabinet, reasonably braced and letting go of thinking we need to do a lot of work at dampening.

To me, all the dampening analysis and such, like in the KEF white paper, is more about commercial marketing differentiation, than anything worth DIY time and effort.

Sure it might make some improvements down at the very lowest levels of audibility..... but who cares ? ......it's like fishing for minnows .......

Just an idea, how about using a cork sanding block as a bracing strut, it would both stiffen and damp at the same time, suitably placed they could also deflect the internal sound waves.

@cracked case ... I'd think that would be considered a "soft" connection which would reduce the effectiveness of the brace. The idea of a stiff bracing scheme is to move the panel into a higher modal region which provides for lower resonances through diminished vibration. Soft connections, from what I've read on the subject, act similarly to using thicker panels. Thicker panels are not as effective as a stiff bracing scheme would be.

Granted, the larger the panel, the more important adequate bracing would be. I'd describe adequate bracing as braces stiff enough to not allow the panel to deflect at the point of connection. A soft connection or less stiff braces would allow deflection.

Granted, the larger the panel, the more important adequate bracing would be. I'd describe adequate bracing as braces stiff enough to not allow the panel to deflect at the point of connection. A soft connection or less stiff braces would allow deflection.

Just wondering, if one mounted an exciter on a panel with stiff braces vs a panel with soft braces vs a panel with high damping, which panel would sound the loudest?

aurgerpro is doing some testing on here. Not sure how much territory he intends to cover though.

Throw some cash his way celef! 🙂

Throw some cash his way celef! 🙂

Just wondering, if one mounted an exciter on a panel with stiff braces vs a panel with soft braces vs a panel with high damping, which panel would sound the loudest?

My opinion is that the high damping would radiate the least. That is certainly true in noise control work. Is this significant? As stated nothing conclusive.

hi Puppet, ok when i refer to mid speaker i am refering to freq range of 500 to 5khz. An unbraced box will probably resonant around 300 to 500 hz. When u add damping like cld n MLV with fibres into it u will drive the resonance below 500hz . It is also the reason why u need to add a torturous path like a natulius within the box to eliminate standing wave n guide the unwanted backcone sound gently to nowhere n dissipates as heat. We don't try to move the mountain but to work around the obstacles. Its also the reason why I say 3 way speaker sound best as we can isolated and work around the insurmountable conflicting requirements of the different frequency bands.

Go look around the big long establish speaker mfg and u see their most expensive premium speakers....mostly 3 ways with big box . Of course many will say they are not good but let be honest it is generally very good. KEF BnW Tannoy JBL etc

Go look around the big long establish speaker mfg and u see their most expensive premium speakers....mostly 3 ways with big box . Of course many will say they are not good but let be honest it is generally very good. KEF BnW Tannoy JBL etc

aurgerpro is doing some testing on here. Not sure how much territory he intends to cover though.

Throw some cash his way celef! 🙂

well i think we can reason our way to a valid result without any physical tests 🙂

Thanks for the tip, is there an alternative to green glue as I'm not sure I can obtain any in small amounts and without having to get an applicator gun. I'm thinking of " gluing " hard board to the outside, then painting them gloss white.cracked case, CLD is the best solution for your box. Get some viscoelastic adhesive or best greenglue as it have published application notes to follow. Cover above 70% of flat surface with a sandwich of a thinner plywood.

Bracing have to be wood to be effective n viscous glued in placed. I never like the sound of a seal box playing loud and it have to do with the backwave from speaker cone muddling up the sound. Go TL or Bass reflex and the cabinet resonaces and box coloration will become less an issue.

sorry but even I cannot get it here. I use CLD as enclosure wall in my car front door to act as an encloure mainly bcos of space contrain. you can use any highly viscous glues and spread it thinly as sanwich then roughly check it by knocking on it. Hahaha... I try with many type of glue. Result varies but it will definately will be a big improvement over any pc of untreated panel.Just use a thinner plywood on the inside. For the mids you can stick CLD in the interior and stuff some wools. For my car 3 ins mids I use a plastic pine cone enclosure totally lined n damped with CLD and then another layer of loosely held and roll like a spring CLD inside the chamber with wools. The loosely held CLD acts as a torturous path for the sound absorption. It actually sound pretty good with no boxy coloration at all. For Subwoofer It just a generic 10 in woofer in a 2 sf seal box with some obliatory stuffings xo at 80 hz. Tweeter is a planar ribbon mainly bcos i like it for its limited vertical dispersion ..less reflection to worry about .

My opinion is that the high damping would radiate the least. That is certainly true in noise control work. Is this significant? As stated nothing conclusive.

thank you, based on all braced boxes out there i guess most would think otherwise. braced boxes seems almost mandatory but methods that works better does not, we seems to do what others do, we are copy cats, and we choose to do what pleases our eyes, a well braced box do looks fancy

My statement had nothing to do with boxes. It was talking about radiation from a panel, completely different. Box bracing is absolutely necessary, but what about adding damping as well? That's what I have always done.

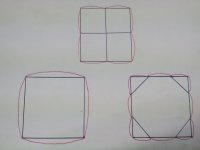

This is how I braced my box in a box speakers, I was limited to what I could do by the construction ( the internal boxes ). I decided to use diagonal braces because I wanted to connect the panels to a panel with a different resonant frequency. When I first gave them the knuckle test it sounded like it hadn't made a lick of difference, however after a day and the glue ( PVA ) had hardened the resonant frequency seemed to have doubled, but they didn't sound any deader. This should be an improvement because the box in a box design reduces the transition of vibration from the mid/bass driver so the only thing exciting the cabinet is the low frequency bass pressure.

Crack case your bracing will not work.

I suggest you google "triangulation for stiffness or rigidity" for further info or just look at B&W internal partitions for a guide to do bracing. The idea is to make the panel resonance higher which makes it easier to damp and dividing it into different apparent size panel which resonance in different frequencies.

I suggest you google "triangulation for stiffness or rigidity" for further info or just look at B&W internal partitions for a guide to do bracing. The idea is to make the panel resonance higher which makes it easier to damp and dividing it into different apparent size panel which resonance in different frequencies.

...This is how I braced my box in a box speakers..

As icwin says, you need to have mechanical engineering intuition or at least eyeball what others have done.

Assuming you have something stuck in the middle of your cab that prevents the simple approach of a strut side-to-opposite-side, I'd get L-shaped (say, 2x2 inch) or box shape (say 1x1 inch) steel rod from big-box hardware store and just screw one to each larger side - perhaps diagonally for the longest length possible and several spaced screws.

Or old hockey sticks.

Or if you are really, really patient, you could wait for anybody to post evidence that cab vibration is audible. I'm not denying that some amount of totally terrible vibration is audible but where is the data?

B.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- A simple (but maybe not easy) bracing question.