When we discussed this earlier it was considered that a vibrating wall might do more radiating on its own than back through the cone.

A wall with a dimension large enough to give directivity to the midrange frequencies it was radiating, may not show up in a typical pressure measurement even though it radiates enough to have an effect in a room. It also has a larger diaphragm area than the cone itself.

A wall with a dimension large enough to give directivity to the midrange frequencies it was radiating, may not show up in a typical pressure measurement even though it radiates enough to have an effect in a room. It also has a larger diaphragm area than the cone itself.

That could be, and i wouldn't begin to try to say yea or nay.

But my gut says whether such radiation exists or not, spending much effort on it is bound to be deep in the range of diminishing returns.

But my gut says whether such radiation exists or not, spending much effort on it is bound to be deep in the range of diminishing returns.

A rig such as this might be more appropriate.

Test Your Speakers’ Performance with this DIY Measurement System | audioXpress

Test Your Speakers’ Performance with this DIY Measurement System | audioXpress

A rig such as this might be more appropriate.

Test Your Speakers’ Performance with this DIY Measurement System | audioXpress

Totally agree ! Would love to have a laser accelerometer to test this stuff.

I've come close to trying the ACH-01 approach.

But everytime i get serious thinking about it, i get the feeling i'm starting out on a witchhunt...😉

In the KEF LS50 whitepaper, there is an interesting finding. It saids the bracing works much better when they are held together by flexible damping glue, instead of a rigid bond. Kind of like CLD. See page 10 to 13.

https://www.shop.us.kef.com/pub/media/wysiwyg/documents/ls50/ls50_white_paper.pdf

https://www.shop.us.kef.com/pub/media/wysiwyg/documents/ls50/ls50_white_paper.pdf

Mainly straightforward transfer functions and impedance sweeps, before and after bracing changes.

After years of asking, I've never seen any measurement posted comparing bracing options (and twice-never for human tests). Never.... until today.

Will you be the world's first person to post findings (at least as far as I know)?

Or anybody else (inspirational YouTube videos from manufacturers don't count)?

Thanks.

B.

Last edited:

Mostly I would agree with Mark100, while bracing is important, it is not a big factor until all the much more important stuff is done correctly. I also agree with him that measurements of the effects are difficult to impossible - having tried many times to do this.

That said, I prefer damping to stiffness. I used 1" x 1" oak rods, which are infinity stiff when compared to the panels. Then I attached them in the center with a semi-resilient glue with high damping. I used a polyurethane impregnated with glass beads. This provided stiffness with some damping.

Later I made the actual connecting rods themselves less stiff and more damped.

I could not measure any of these differences and I would not comment on perceptual effectiveness other than to say that IMO my speakers just got better sounding. Was the damping key? There were so many other changes along the way that I can't be sure. It takes a lot of work to sort all this out.

That said, I prefer damping to stiffness. I used 1" x 1" oak rods, which are infinity stiff when compared to the panels. Then I attached them in the center with a semi-resilient glue with high damping. I used a polyurethane impregnated with glass beads. This provided stiffness with some damping.

Later I made the actual connecting rods themselves less stiff and more damped.

I could not measure any of these differences and I would not comment on perceptual effectiveness other than to say that IMO my speakers just got better sounding. Was the damping key? There were so many other changes along the way that I can't be sure. It takes a lot of work to sort all this out.

Last edited:

1x1 oak rods, eh. Sounds like discarded hockey sticks, my favourite, although I think they are maple.

When you say "difficult to impossible", do you actually mean "tried but no interpretable differences ever show up..." which is, outside of old science journals, reasonable evidence there is no effect?

B.

When you say "difficult to impossible", do you actually mean "tried but no interpretable differences ever show up..." which is, outside of old science journals, reasonable evidence there is no effect?

B.

You state that bracing isn't a big factor and then describe how bracing done in a particular fashion is. So, which is it?Mostly I would agree with Mark100, while bracing is important, it is not a big factor until all the much more important stuff is done correctly. I also agree with him that measurements of the effects are difficult to impossible - having tried many times to do this.

That said, I prefer damping to stiffness. I used 1" x 1" oak rods, which are infinity stiff when compared to the panels. Then I attached them in the center with a semi-resilient glue with high damping. I used a polyurethane impregnated with glass beads. This provided stiffness with some damping.

Later I made the actual connecting rods themselves less stiff and more damped.

I could not measure any of these differences and I would not comment on perceptual effectiveness other than to say that IMO my speakers just got better sounding. Was the damping key? There were so many other changes along the way that I can't be sure. It takes a lot of work to sort all this out.

When you say "difficult to impossible", do you actually mean "tried but no interpretable differences ever show up..." which is, outside of old science journals, reasonable evidence there is no effect?

B.

I would say that scientifically, that is correct. I could not measurably find any significant differences in individual tests. But, as I said, I believe, and measurements bore this out, that the speakers got better and better over time. I could not say what the resulting differences in the end from the beginning were due to specifically, say structural changes, driver changes, crossover changes, I don't know.

One would have to do very precise experiments to sort out the individual contributions, but my experience would lean on the side that some of this improvement was structural, but certainly not the dominant factor either.

You state that bracing isn't a big factor and then describe how bracing done in a particular fashion is. So, which is it?

I don't believe that I said it like that.

You mean "It was found that adding material with high mechanical resistance and low stiffness between the walls, baffle, driver and brace results in extremely effective suppression of the resonances."? I was thinking they meant pads so why do you think "flexible damping glue"? Not arguing, just wondering, since I've read and re-read that a couple times without quite grasping it. And what are some "flexible damping glues" or pads?In the KEF LS50 whitepaper, there is an interesting finding. It saids the bracing works much better when they are held together by flexible damping glue, instead of a rigid bond. Kind of like CLD. See page 10 to 13.https://www.shop.us.kef.com/pub/media/wysiwyg/documents/ls50/ls50_white_paper.pdf

Do you remember the actual product? When I see polyurethane it's either thin-coat stuff at Home Depot, or hardening stuff for auto body repair.That said, I prefer damping to stiffness. I used 1" x 1" oak rods, which are infinity stiff when compared to the panels. Then I attached them in the center with a semi-resilient glue with high damping. I used a polyurethane impregnated with glass beads. This provided stiffness with some damping...Later I made the actual connecting rods themselves less stiff and more damped.

Reading this thread I wonder if some kind of hard rubber connecting rods would work well...though it seems offhand you wouldn't want the connector TOO soft, or a whole other set of resonances could start up 🙁

Earl, is this similar to what you have done (CLD brace on left, solid oak control on the right):

I have two CLD braced boxes, one using Sikaflex 292i and the other Weicon Flex 310M Classic. I also have microspheres but waiting to test that when I settle on good adhesives. I'm wrapping up waveguide measurements today, then I'll be measuring the boxes for my box construction thread.

I have two CLD braced boxes, one using Sikaflex 292i and the other Weicon Flex 310M Classic. I also have microspheres but waiting to test that when I settle on good adhesives. I'm wrapping up waveguide measurements today, then I'll be measuring the boxes for my box construction thread.

....But everytime i get serious thinking about it, i get the feeling i'm starting out on a witchhunt...😉

Right.

If we can assesss dinosaur DNA after 100,000,000 yrs, and living covid19 on stainless steel after 5 days, we can certainly measure wall vibration.

But can you hear it?

Curiously, the KEF folks fine-tuned their crossover by ear (yup... you can find it in their paper) but didn't bother checking if their expensive bracing was worth a hearing test. Maybe their Marketing Department would complain endlessly if they published that it made no audible difference.

B.

Earl, is this similar to what you have done (CLD brace on left, solid oak control on the right):

I have two CLD braced boxes, one using Sikaflex 292i and the other Weicon Flex 310M Classic. I also have microspheres but waiting to test that when I settle on good adhesives. I'm wrapping up waveguide measurements today, then I'll be measuring the boxes for my box construction thread.

The damped one looks very similar to what I ended up with.

Do you remember the actual product? When I see polyurethane it's either thin-coat stuff at Home Depot, or hardening stuff for auto body repair.

Polyurethane comes in hundreds of different varieties see innovatives Solutions website for example.

In the KEF LS50 whitepaper, there is an interesting finding. It saids the bracing works much better when they are held together by flexible damping glue, instead of a rigid bond. Kind of like CLD. See page 10 to 13.

https://www.shop.us.kef.com/pub/media/wysiwyg/documents/ls50/ls50_white_paper.pdf

Thanks for the link to the white paper. Complete with measurements comparing the venerable LS3/5A to the new LS50. It would seem that KEFs attempts to beat their own legendary speaker was successful and people should just go and get a new commercially available LS50 for $1000 instead of $2500 on a used LS3/5A? But we see many threads chasing defunct B110 and T27 drivers and complex crossovers and special cabinets with beech wood battens. 🙂

I think that they should have put a downtilted Harman house curve instead of making it flat though. The LS3/5A has this tilt (before it was called the Harman curve) and the LS50 does not - might sound a bit too bright.

Last edited:

After years of asking, I've never seen any measurement posted comparing bracing options (and twice-never for human tests). Never.... until today.

Will you be the world's first person to post findings (at least as far as I know)?

Or anybody else (inspirational YouTube videos from manufacturers don't count)?

Thanks.

B.

Ben, i wish i had some measurements that could show some real bracing option changes, but i doubt i do.

The only ones that might are when i push subs to very high SPL levels, like 130dB @ 1m, and used REW's stepped sine capability to measure harmonic distortion. I'll look for those in the files of my PPSL sub project where i remember adding bracing after finalizing ports out in the driveway.

But as far as low signal measurements, say 2.83v etc....I can't say I've seen bracing make a noticeable difference in measurements...even for subs.

I guess if i thought there was a real need for bracing on smaller boxes , I'd try running stepped sine at high levels on them too . Otherwise, I don't know how regular measurements might show any changes.

I just can't see it's worth the trouble ......

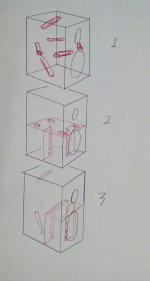

This is how I would brace a box, 1 is what I'd recommend, 2 is something I tried because I wanted to reduce reflections as well as stiffen the box, but the baffle with four holes caused a pronounced resonance ( although this could have been caused by the aperiodic tuning not quite right at first ) 3 is what I'd do if I was having another go at 2. After faffing about with speakers I'm starting to thing that the drivers transmit a certain amount of vibration to the box, and the only way to deal with it is to either isolate the driver ( like Eclipse td ) or have a very dead box.

- Home

- Loudspeakers

- Multi-Way

- A simple (but maybe not easy) bracing question.