To prevent clogging another forum topic, I'll post my question in a separate topic. The question regards speaker isolation/stuffing.

The situation:

1. I've converted my B&W CM8 S2 (bass reflex port speakers) to active closed box loudspeakers. The drivers are powered by an FA-123 plate amp (hypex). I've done this because I liked the project and my speakers are relatively close to the walls.

2. I've (subjectively!) nailed it with the delay and crossovers of the speakers with a stunning mid- and high performance (thanks to this forum). But the lower end is perhaps as good as it gets, perhaps open to improvement. DIRAC live (full license of my NAD C658) can make de bass response of the speakers more than satisfactory for me, but I'm trying to find out if I should change the inner lining of my speakers. They originally came with 2 cm thick polyesterwool lining over the whole speaker.

3. After sealing the speaker I put a lot of polyester wool (Visaton Damping Material) in the place where the bass reflex port used to be.

4. After reading the 'burrito isolation' post, I removed all the isolation material and installed a burrito of polyester wool. I thinkt he bass got a bit more clear, but I wasn't very sure about the result.

5. I am trying to find out by reading forum post what the most logical inner lining of my speakers would be (floorstanders, relatively small, enclosed). I'm open to trying different amounts of isolation et cetera, but a theoretical guideline would help. I'm satisfied with the sound at the moment, but I would like to use the approach that is most logical.

6. Unfortunately, my understanding of physics is not sufficient to understand all arguments in this discussion, so a direction would be great.

Finally, the mid/tweeter are in a separate wooden cabinet within the floorstanders.

The options would be:

1. Burrito alone.

2. Inner lining alone (1 layer).

3 1 + 2.

4. Complete stuffing of the lower cabinet and no or limited upper.

5. Infinite possibilities...

Any suggestion as to what lining would be most logical?

Where to isolate an how thick? I have pleny of material in stock and can order more if needed.

The outer dimensions of the speaker is 960 mm (h) x 165 mm (w) x 277 mm (d)

The woodwork is approximately 18 mm thick.

Thanks for your help.

The situation:

1. I've converted my B&W CM8 S2 (bass reflex port speakers) to active closed box loudspeakers. The drivers are powered by an FA-123 plate amp (hypex). I've done this because I liked the project and my speakers are relatively close to the walls.

2. I've (subjectively!) nailed it with the delay and crossovers of the speakers with a stunning mid- and high performance (thanks to this forum). But the lower end is perhaps as good as it gets, perhaps open to improvement. DIRAC live (full license of my NAD C658) can make de bass response of the speakers more than satisfactory for me, but I'm trying to find out if I should change the inner lining of my speakers. They originally came with 2 cm thick polyesterwool lining over the whole speaker.

3. After sealing the speaker I put a lot of polyester wool (Visaton Damping Material) in the place where the bass reflex port used to be.

4. After reading the 'burrito isolation' post, I removed all the isolation material and installed a burrito of polyester wool. I thinkt he bass got a bit more clear, but I wasn't very sure about the result.

5. I am trying to find out by reading forum post what the most logical inner lining of my speakers would be (floorstanders, relatively small, enclosed). I'm open to trying different amounts of isolation et cetera, but a theoretical guideline would help. I'm satisfied with the sound at the moment, but I would like to use the approach that is most logical.

6. Unfortunately, my understanding of physics is not sufficient to understand all arguments in this discussion, so a direction would be great.

Finally, the mid/tweeter are in a separate wooden cabinet within the floorstanders.

The options would be:

1. Burrito alone.

2. Inner lining alone (1 layer).

3 1 + 2.

4. Complete stuffing of the lower cabinet and no or limited upper.

5. Infinite possibilities...

Any suggestion as to what lining would be most logical?

Where to isolate an how thick? I have pleny of material in stock and can order more if needed.

The outer dimensions of the speaker is 960 mm (h) x 165 mm (w) x 277 mm (d)

The woodwork is approximately 18 mm thick.

Thanks for your help.

Last edited:

I would use thick felt to line the walls, and use a burrito of fibreglass encased in polyester stuffing material. Fibreglass is much more effective than polyester (which is nigh on useless), but is nasty stuff which should be kept away from hands and drivers.

I have some concerns about the burrito, which I have illustrated here - Using sound absorption to reduce standing waves

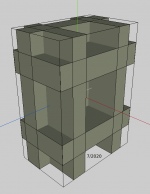

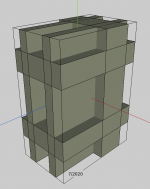

I've drawn what I believe is an effective starting point. Some improvements could be made with diminishing returns.

I've drawn what I believe is an effective starting point. Some improvements could be made with diminishing returns.

Attachments

Hi Allen,

Can you elaborate a little bit on your drawing? Is this where isolation should be placed?

Can you elaborate a little bit on your drawing? Is this where isolation should be placed?

Each of the three main pieces is positioned where the sound is moving between the walls, the pieces are sized to deal with wavelengths appropriate to each dimension, and the vertical is offset to give a little space to the woofer so it won't see direct resistance.

And this is isolation in the woofer cabinet only and below the woofers or also behind them?

And what would you use for material and what for the mid/tweet cabinet?

Many thanks!

And what would you use for material and what for the mid/tweet cabinet?

Many thanks!

That's another question, I think f/glass and rockwool have some useable properties.

There's no reason it wouldn't work in a midrange cabinet. It is effectively similar to stuffing the box. Some might prefer to dress a little around the driver.

There's no reason it wouldn't work in a midrange cabinet. It is effectively similar to stuffing the box. Some might prefer to dress a little around the driver.

It could also be split above and below the driver.and the vertical is offset

So I could make a rockwool (or fiberglass) 'cross' from the bottom op untill the driver and then insert seperate crosses between the drivers?

And is flaked foam also a possibility (since it's much easier to work with)?

And is flaked foam also a possibility (since it's much easier to work with)?

Last edited:

Yes, each of the three main pieces is positioned where the sound is moving between the walls

Oh, and the walls are soundproof 100% ??

I would invest in some lead sheets and cover the woofer box with them, internally or externally.

Attachments

This is a good topic, but this thread isn't about wall vibration. It is about damping sound inside the box. Fibreglass and rockwool aren't particularly effective against wall vibrations.Oh, and the walls are soundproof 100% ??

I would invest in some lead sheets and cover the woofer box with them, internally or externally.

The options would be:

1. Burrito alone.

2. Inner lining alone (1 layer).

3 1 + 2.

4. Complete stuffing of the lower cabinet and no or limited upper.

5. Infinite possibilities...

So you converted a vented box into a sealed one. It's a good choice.

But instead of stuffing / unstuffing the bass box repeatedly and hoping for a better outcome I would suggest you go a step further and convert it to an Aperiodic closed box.

Line the walls with felt and add a layer of poly insulation but not too dense.

Then stuff the former port with soft poly foam or felt and measure the impedance. Add or remove stuffing in the port until you get the lowest peak.

If you cannot or don't want to measure just listen, the bottom will be firm and extended but not like with a reflex alignment, more gentle and more pleasant IMHO.

Cheers

Hi Allen,

Thanks for your elaboration. I'll buy some rockwool and try to make the lineup you suggested. I'm still hoping that flaked foam can do the same thing since it's so much easier to use.

Should I invest in something to cover the walls of the speaker with? Is lead the way to go?

Thanks for your help.

Thanks for your elaboration. I'll buy some rockwool and try to make the lineup you suggested. I'm still hoping that flaked foam can do the same thing since it's so much easier to use.

Should I invest in something to cover the walls of the speaker with? Is lead the way to go?

Thanks for your help.

So you converted a vented box into a sealed one. It's a good choice.

But instead of stuffing / unstuffing the bass box repeatedly and hoping for a better outcome I would suggest you go a step further and convert it to an Aperiodic closed box.

Line the walls with felt and add a layer of poly insulation but not too dense.

Then stuff the former port with soft poly foam or felt and measure the impedance. Add or remove stuffing in the port until you get the lowest peak.

If you cannot or don't want to measure just listen, the bottom will be firm and extended but not like with a reflex alignment, more gentle and more pleasant IMHO.

Cheers

Thanks for your response. But see point two, I think I am fixed to a closed box.

So the steps you suggest is/my comments are

1. Line the (inner) walls with flet and polyester insulation on the walls (glued).

2. The former bass reflex port is sealed shut with wood of the same thickness as the driver, but's its mounted on the inside of the former port. It's sealed by glue & kit and completely airtight. So no stuffingin the former port. Skip this step then?

3. Am i clear to understand that you suggest only the port (not applicable) and the walls are lined with felt & polyester and the air inside the box is left untouched? Or do you mean with 'add stuffing': fill up the bottom step by step until you've reached the proper sound?

So would it be a plan to build the design by allen using flaked wool (for ease of use) + to cover the wall with something?

If so, what would be most wise to us?

Last edited:

OK, if you can open the port again then you can do what I suggested.

Otherwise you have to introduce another opening which is a bit of a hassle.

1. yes

2. see above

3. the walls are lined, the port is stuffed with some soft material, can be even a sock, the rest is air.

Aperiodic boxes are still closed alignments but with leaks.

Check Troels Gravesen's website for examples.

Jensen-1071

W1501/

JBL L26 restoration,

JBL L100 Century,

Acoustic Resistance, Secret Sauce for Speakers | audioXpress

Check also Dynaudio's variovent info.

Otherwise you have to introduce another opening which is a bit of a hassle.

1. yes

2. see above

3. the walls are lined, the port is stuffed with some soft material, can be even a sock, the rest is air.

Aperiodic boxes are still closed alignments but with leaks.

Check Troels Gravesen's website for examples.

Jensen-1071

W1501/

JBL L26 restoration,

JBL L100 Century,

Acoustic Resistance, Secret Sauce for Speakers | audioXpress

Check also Dynaudio's variovent info.

Thanks Stanislav for your elaboration.

Perhaps it's wisest for me to first explore the closed box options af if this does not give any results I'll convert to your suggestion.

What would be the proper steps for a closed design?

1. Line the walls (with what?)

2. Stuff speaker with rockwool using Allen's design? I've emailed a company if they can deliver rockwool in a way that I can cut it without dust flying everywhere.

Best regards,

Geert

Perhaps it's wisest for me to first explore the closed box options af if this does not give any results I'll convert to your suggestion.

What would be the proper steps for a closed design?

1. Line the walls (with what?)

2. Stuff speaker with rockwool using Allen's design? I've emailed a company if they can deliver rockwool in a way that I can cut it without dust flying everywhere.

Best regards,

Geert

It isn't necessary to remove the stuffing to go aperiodic, you can do both at once. However if you remove the stuffing you take away the box mode damping, regardless of the box type.

To first look at what aperiodic means, it's a way to make the box look bigger. It damps fs. Stuffing the box does this as well, to a small degree, so stuffing helps either way.

To first look at what aperiodic means, it's a way to make the box look bigger. It damps fs. Stuffing the box does this as well, to a small degree, so stuffing helps either way.

I buy it like roofing batts. It comes in the same sizes, behaves similarly to fibreglass and can be cut with scissors.rockwool in a way that I can cut it

https://www.diyaudio.com/forums/attachments/multi-way/859515d1594368054-stuffing-guideline-screenshot-2020-07-10-17-06-29-png

Now this begins to bring back memories of Bowers & Wilkins Matrix stuffing. Do NOT forget to fix the porous material, otherwise you will introduce nonlinear behavior.

Now this begins to bring back memories of Bowers & Wilkins Matrix stuffing. Do NOT forget to fix the porous material, otherwise you will introduce nonlinear behavior.

There is no right or wrong way, we all hear things differently.

I personally prefer aperiodic bass or OB bass, after playing extensively with vented boxes and MLTL.

I would say:

forget measurements and trust your ears.

What sounds good to you is what matters.

Have fun

Stan

I personally prefer aperiodic bass or OB bass, after playing extensively with vented boxes and MLTL.

I would say:

forget measurements and trust your ears.

What sounds good to you is what matters.

Have fun

Stan

I guess what I'm trying to say is making the box aperiodic is difficult because the plate amp is screwed to the wooden scructure used to seal of the speaker. Converting to an aperiodic speaker is a lot of work in terms of design and the way it will look and I'm not sure if I would like that.

I'd prefer to first try the sealed box (as the speaker is at this moment) and optimize the inner stuffing of the speaker. If I need to line the walls with something for other reasons than I'd happily do it.

So far I understand that I need to use dampening materials and I'll try and build something like the drawing you suggested and see what the results will be. However, if lining the walls (for other reasons) is wise, than I'd happily do that as well while I'm constructing the inner lining.

Would lining the wall with felt (or lead or whatever) be necessary in a closed speaker? If so I'm happy to try it. As long as it's material I can insert through the 5 inch woofer port.

I'd prefer to first try the sealed box (as the speaker is at this moment) and optimize the inner stuffing of the speaker. If I need to line the walls with something for other reasons than I'd happily do it.

So far I understand that I need to use dampening materials and I'll try and build something like the drawing you suggested and see what the results will be. However, if lining the walls (for other reasons) is wise, than I'd happily do that as well while I'm constructing the inner lining.

Would lining the wall with felt (or lead or whatever) be necessary in a closed speaker? If so I'm happy to try it. As long as it's material I can insert through the 5 inch woofer port.

- Home

- Loudspeakers

- Multi-Way

- Stuffing guideline