Howdy,

I'm looking for a friendly member who is setup for SMD rework. I've got a small job that needs done - replacement of a 26-pin TSSOP. If you are willing to help out, please PM or email me.

Thanks in advance!

I'm looking for a friendly member who is setup for SMD rework. I've got a small job that needs done - replacement of a 26-pin TSSOP. If you are willing to help out, please PM or email me.

Thanks in advance!

It's easy enough to DIY.

Just don't try to remove the TSSOP intact.

The simplest way is to Dremel off all the legs and then remove them from the PCB with tweezers and a soldering iron.

Once the board is clean it is a simple job to solder on the new component.

Just don't try to remove the TSSOP intact.

The simplest way is to Dremel off all the legs and then remove them from the PCB with tweezers and a soldering iron.

Once the board is clean it is a simple job to solder on the new component.

You can do this yourself, particularly if you have something to practice on first (old remotes...)

Working with SMD. How to do it without specialised tools.

Working with SMD. How to do it without specialised tools.

Howdy,

I'm looking for a friendly member who is setup for SMD rework. I've got a small job that needs done - replacement of a 26-pin TSSOP. If you are willing to help out, please PM or email me.

Thanks in advance!

I just bought a SMD hot air tool and that removes most IC's.

Loads of cheapies on ebay.

Once removed, remove extra solder with copper braid.

Tack one corner of new IC then opposite corner then drag solder the pins.

Fix any shorts with copper braid.

I have managed TQFP 64 pin devices on 0.5mm pitch so its surprising what you can do by hand.

Thanks for the inputs. I may take a crack at it, my soldering skills are quite good - but my issue is hand tremors. Destructive (of the old IC) removal is definitely a good idea.

Fwiw, the victim is one of those $25 Chinese DAC kits. Build was a breeze, but the 4398 chip was found bad in testing - output stage for channel B / LH is dead. It ohms out at 95K vs, 3K3 for the good channel. It passes some signal, but very low level with heavy distortion.

Fwiw, the victim is one of those $25 Chinese DAC kits. Build was a breeze, but the 4398 chip was found bad in testing - output stage for channel B / LH is dead. It ohms out at 95K vs, 3K3 for the good channel. It passes some signal, but very low level with heavy distortion.

Last edited:

Get a $40 hot air pencil from Amazon. If the board doesn’t have anything on underside, a hot plate with frypan can bring heat up to about 130C for the board. Then hot air from pencil aimed at IC will melt it in 5 seconds. Lift off and clean pads with solder wick.

TSSOP is sufficiently fine that a hot air machine is needed - destructive removal can easily

lift the fine PCB traces, with a 26 pin device that's too likely to be worth the risk IMO.

With hot air you can have multiple goes at getting it right and you may not need any more solder, just add some rosin to keep the old stuff bright and surface tension does the rest.

More rosin, less solder, is the key to SMT work.

lift the fine PCB traces, with a 26 pin device that's too likely to be worth the risk IMO.

With hot air you can have multiple goes at getting it right and you may not need any more solder, just add some rosin to keep the old stuff bright and surface tension does the rest.

More rosin, less solder, is the key to SMT work.

If you run a 32 or 34 gauge wire under the pins on one side and attach the end to a handy solder point you can pull on it at an angle while desoldering 1 or 2 pins at a time. The wire lifts the pin up without lifting the trace. Hot air tools can remove nearby components too if not very careful and you hold it in one place a fraction of a second too ling.....

Reading back over these replies, I don't see much consensus.

Heh, yeah.. this is why I was looking for someone more practiced and better equipped than myself.

Heh, yeah.. this is why I was looking for someone more practiced and better equipped than myself.

The reality is that whatever method you use, you need to practice first.

Give a rank beginner just two wires to solder together, or some simple through hole parts to solder and although they will probably soon learn, the first attempts will most likely be dismal.

Give a rank beginner just two wires to solder together, or some simple through hole parts to solder and although they will probably soon learn, the first attempts will most likely be dismal.

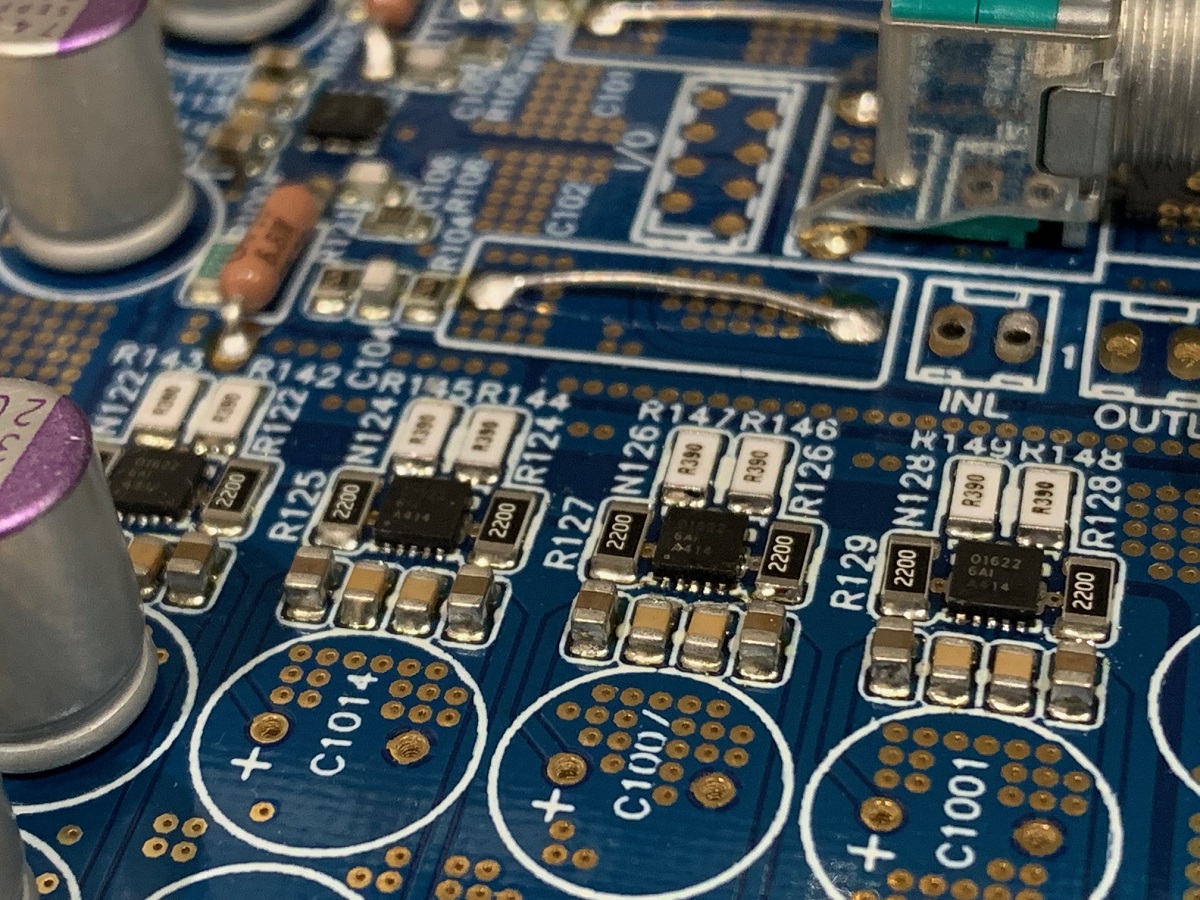

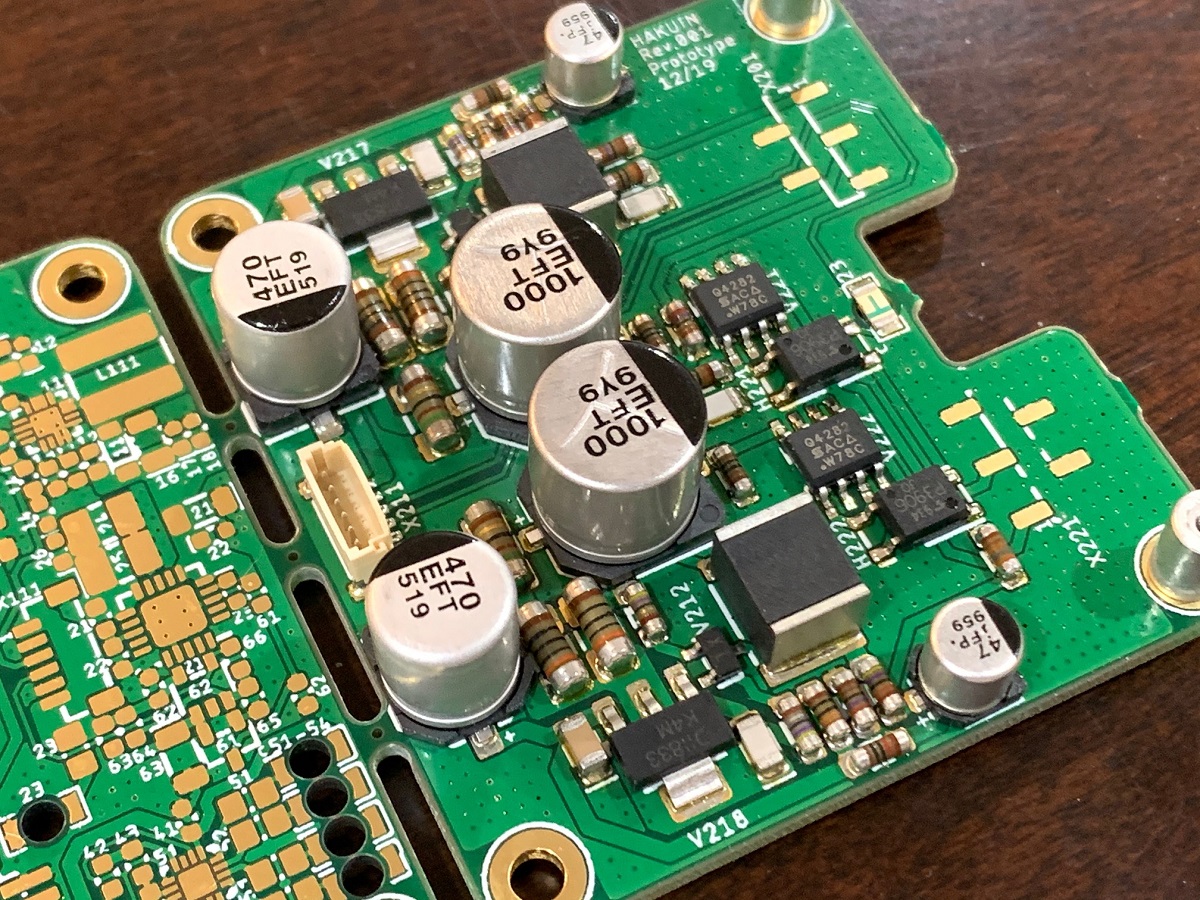

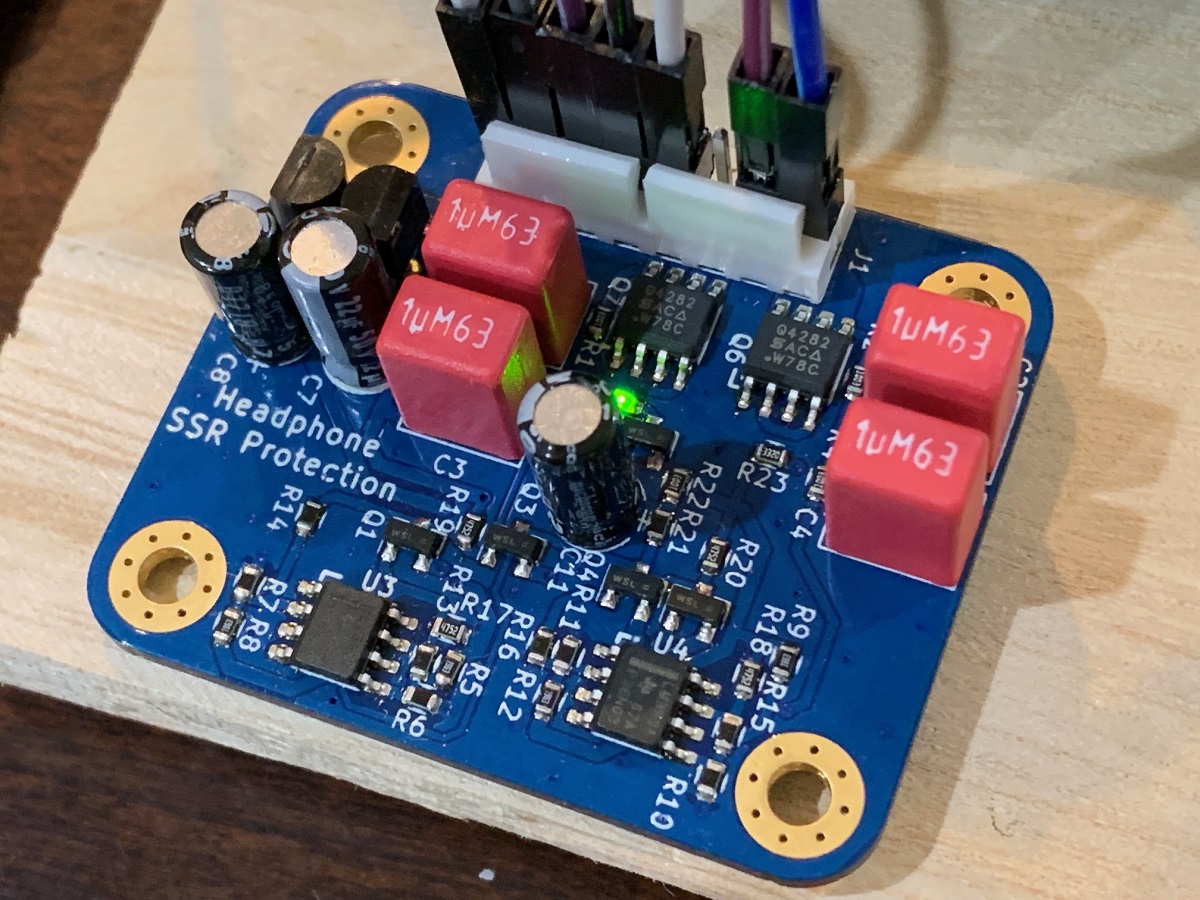

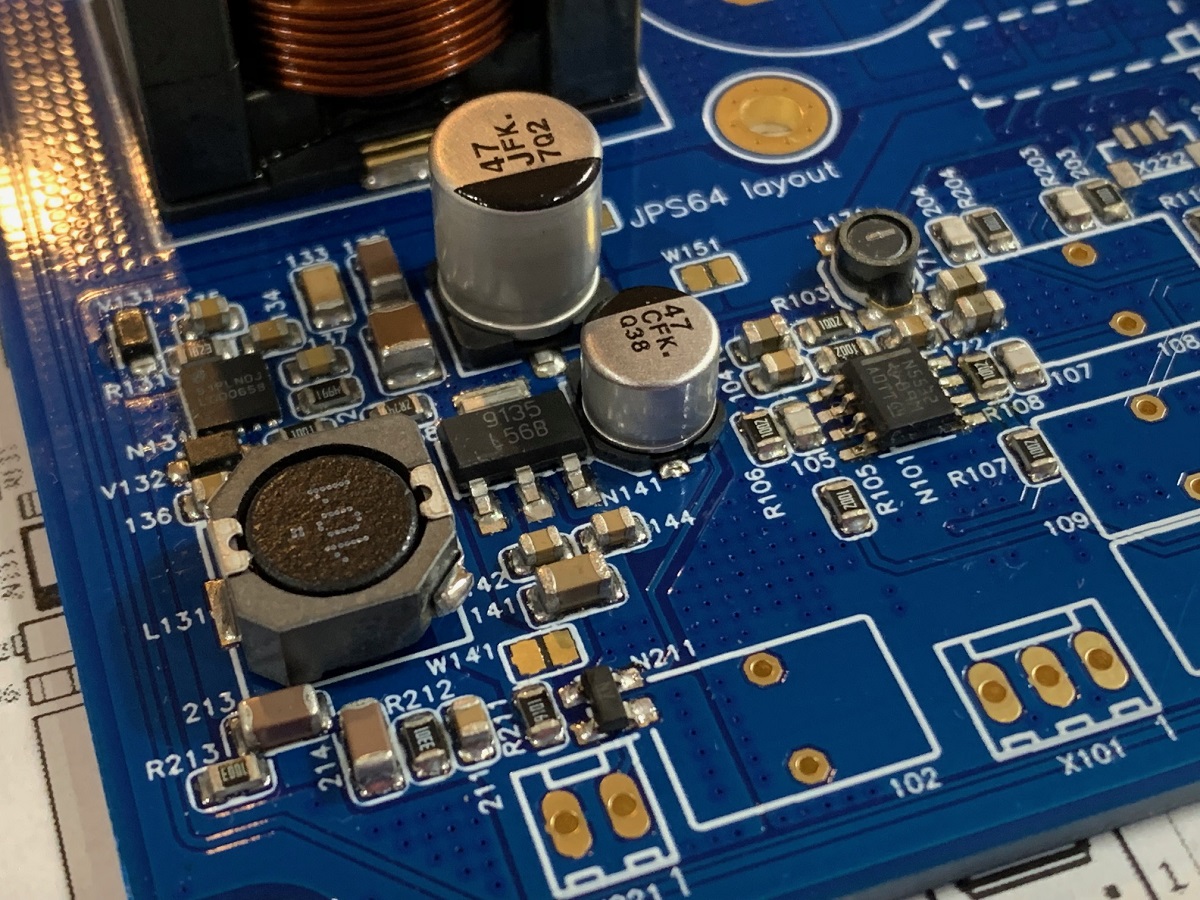

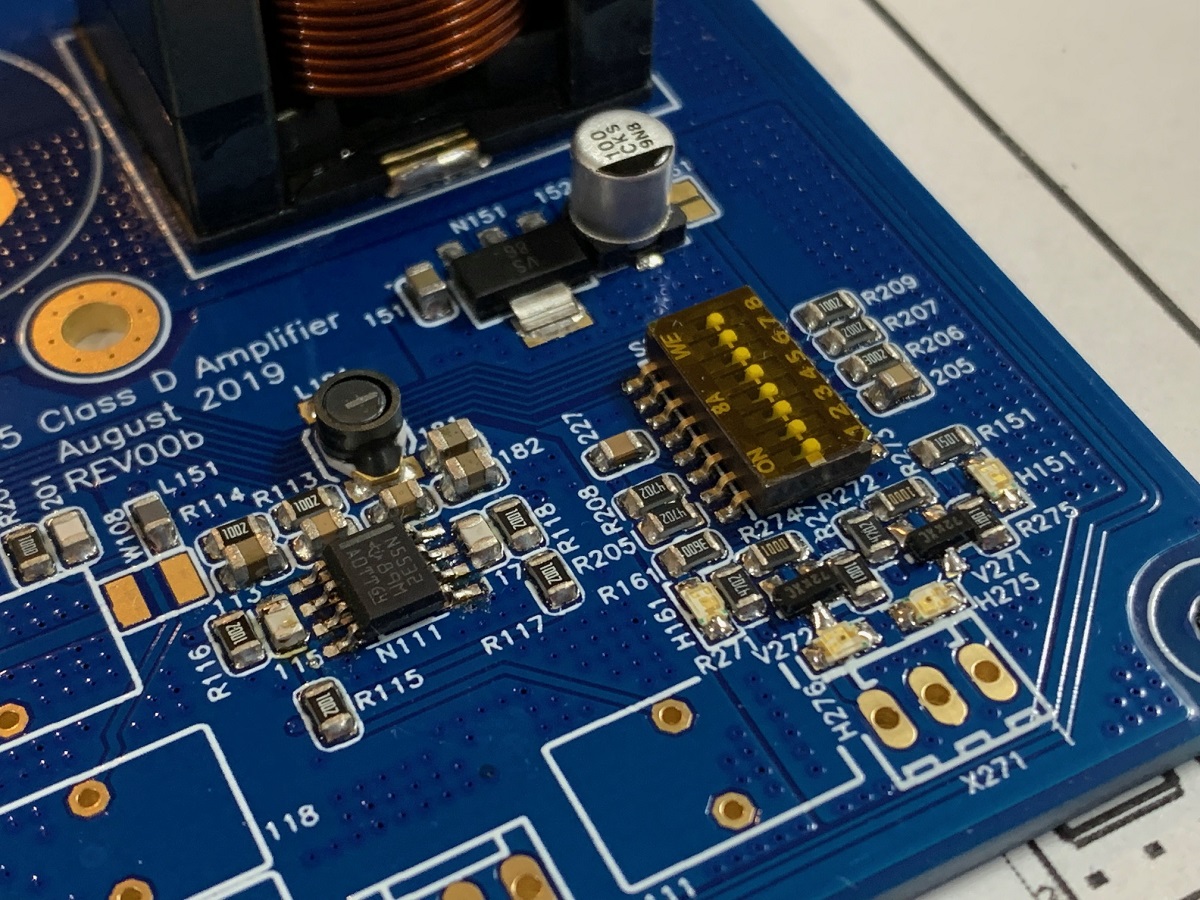

You may not get consensus, but you can believe that having a hot air pencil is important. Here is the sort of stuff I do with it.

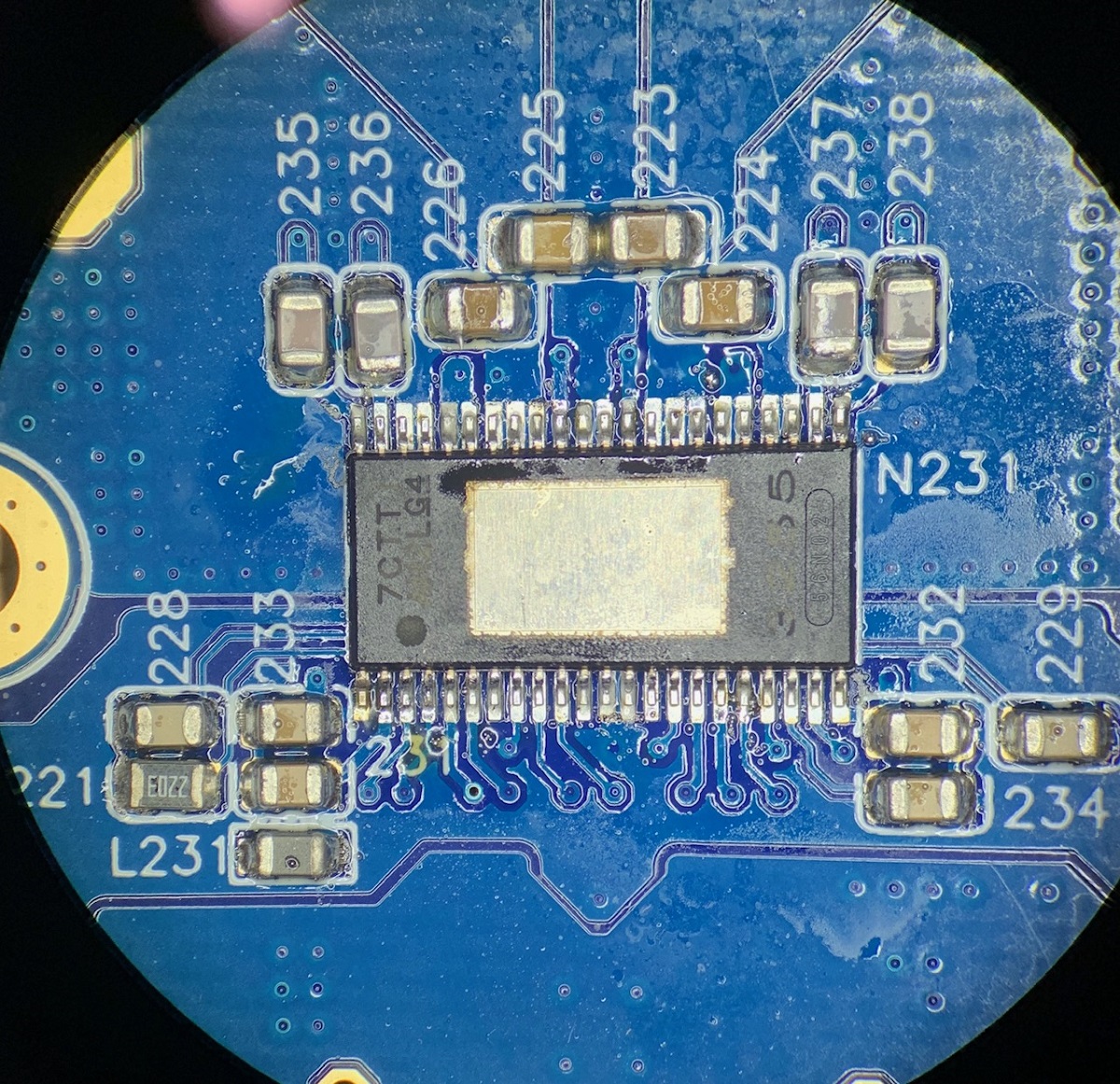

And I have actually used it to pull this TPA3255 out and replaced it with a new one. So desoldering works too:

It is always helpful to have some added heat from the bottom side to preheat the board to a temp below the melt temp. This reduces the heat needed from the hot air above.

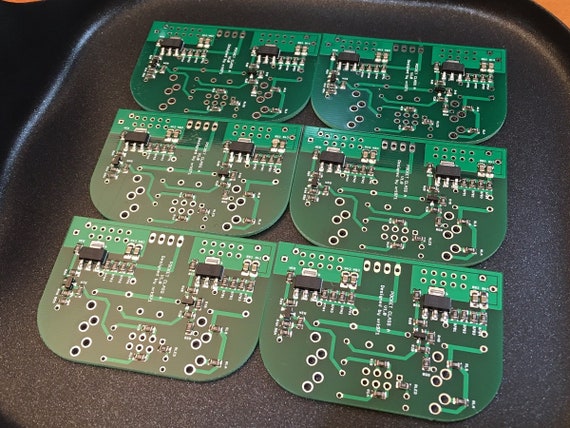

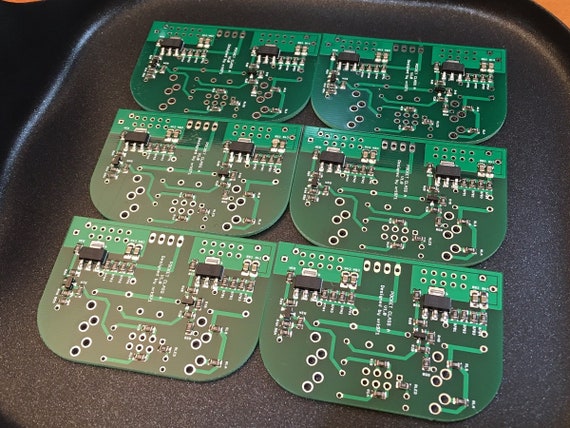

Edit - even a hot plate and skillet works for reflow or preheating the bottom:

Produces these:

And I have actually used it to pull this TPA3255 out and replaced it with a new one. So desoldering works too:

It is always helpful to have some added heat from the bottom side to preheat the board to a temp below the melt temp. This reduces the heat needed from the hot air above.

Edit - even a hot plate and skillet works for reflow or preheating the bottom:

Produces these:

Last edited:

Depending on what is on the back, if it is clean of components, protruding leads so it can sit flat, I have heard of one member use his skillet and stove burner element to reflow solder paste for assembly. So in theory, you can do the same for removal, have to be careful not to over do it and cause damage. Make sure you use some liquid flux on all the solder joints for the component you want to remove/replace.

Before removing the bad chip, I would try to touch up the leads on the current one with a fine tip iron. Good practice and you never know what might actually change.

I've found removing TSSOP chips, or any SO packages very easy with two soldering irons.

First solder a length of copper wire, cut from a resistor for example, across all pins on one side of the chip, with extra amount of solder. This wire will serve as a heat conductor and will encourage solder-bridging across all pins at a later step. Do the same to the pins on the other side of the chip. Apply generous amount of flux. Then with two soldering irons, heat up both side of the pins with good amount of solder. The chip will come off position in no time.

First solder a length of copper wire, cut from a resistor for example, across all pins on one side of the chip, with extra amount of solder. This wire will serve as a heat conductor and will encourage solder-bridging across all pins at a later step. Do the same to the pins on the other side of the chip. Apply generous amount of flux. Then with two soldering irons, heat up both side of the pins with good amount of solder. The chip will come off position in no time.

$40 is all it takes to make SMT rework (or first time installation) a breeze. When you have this, you can use solder paste, which is much neater than soldering iron and spool solder.

https://www.amazon.com/dp/B01MR2IWBN/ref=cm_sw_r_cp_api_i_F0eAEbTB1K61N

https://www.amazon.com/dp/B01MR2IWBN/ref=cm_sw_r_cp_api_i_F0eAEbTB1K61N

- Home

- Amplifiers

- Solid State

- Who can do SMD / SMT rework?