Luxman have a particular pitch in the market. This quote possibly sums them up nicely

So there you have it. Curved traces are the future!

We adopted a peel coat production technique for all of the audio circuit boards, to achieve lower circuit resistance, which can have a negative effect on sound quality. Also, the smooth curves of our non-angled circuit board trace pattern ease the flow of audio signals.

So there you have it. Curved traces are the future!

I should also add that Luxman appear to exclusively use the PCM1792 in their current range. This is a $7 part in 1k qty. But their DAC is still $5k. They know their market, which is not me 🙂

Arguing about why high-end stuff is ridiculously expensive, really?

Nope.

Arguing about if a certain statement _must_ be understood in a certain way or if the meaning could be a different one.

<snip>

So there you have it. Curved traces are the future!

Aren't they a bit late to the party? Afair DNM did it already roughly 25 years ago (other iirc as well) . 🙂

Luxman have also been doing this sort of thing for a while. They are one of the older companies still in the game.

IME the BOM on a transparent DAC should be no more than $100 or so translating into an MSRP of around $500.

Define transparent.

As I posted someone fixed the IMD hump an ESS design with maybe $2 and a little savvy.

No AKM hump to fix.

You would do your cause well to get some test equipment and do some bench engineering.

Sure. Expensive to measure some of the stuff that is audible. Like jitter noise (nondeterministic), for example. Donations gratefully accepted.

Perhaps wait for Scott to respond....................................................... 😉Nope.

Arguing about if a certain statement _must_ be understood in a certain way or if the meaning could be a different one.

I just went thru the costs for limited production. The electronic parts do not cost that much, is true. They are used in many other brands and total mfr is in the millions sometimes.

It is the chassis et al that is unique from brand to brand. And, with a limited production company, will be the major cost. If low volume milled alum, finished heat sinks et al, the cost at retail will be very high.

Then there is the distribution mark-up and retail mark-up and shipping costs.

To quote a 2$ part which is sold to many brands at high volume and imply the end product of a limited production brand should be really cheap.. it doesnt work out that way.

THx-RNMarsh

It is the chassis et al that is unique from brand to brand. And, with a limited production company, will be the major cost. If low volume milled alum, finished heat sinks et al, the cost at retail will be very high.

Then there is the distribution mark-up and retail mark-up and shipping costs.

To quote a 2$ part which is sold to many brands at high volume and imply the end product of a limited production brand should be really cheap.. it doesnt work out that way.

THx-RNMarsh

Last edited:

Learn something new everyday.Esperado,

Not as good as the following two. "You'll have to do better than that.", "Yep That must be the answer. What else could it be."Pretty much closes any discussion.

You sure did. Read further back than 1 hour and the answer will stare right at you.I didn't leave anything out.

You think? Well, if you say so.for me it is trying to avoid, means to start to get better at it over the time.

Given the number of times Mark has berated people (me) for having a 'cheap' DAC I feel he is certainly inferring something there. He has said that under $1000 is midrange for performance.

No intention to berate you, Bill. Just advising you of what I believe to be true.

No intention to berate you, Bill. Just advising you of what I believe to be true.

We already know how you measure performance.

I never would use Excel for anything, I tried to help someone here trying to use Excel's optimizer for IIR filters (what a nightmare).

It is becoming harder to use excel. Office 365 pushes updates every month or so, changing things, moving things, removing things. Visio, powerpoint, word, excel.. They force us to waste time re-learning how to do things again and again.

Jn

We already know how you measure performance.

Actually, you don't.

That explains a lot about the value, to people reading, of what you've been saying about it.Actually, you don't.

No intention to berate you, Bill. Just advising you of what I believe to be true.

A weird belief, thinking that sale price of anything correlates with quality.

It is frequently an inverse relationship....

I just went thru the costs for limited production. The electronic parts do not cost that much, is true. They are used in many other brands and total mfr is in the millions sometimes.

It is the chassis et al that is unique from brand to brand. And, with a limited production company, will be the major cost. If low volume milled alum, finished heat sinks et al, the cost at retail will be very high.

Then there is the distribution mark-up and retail mark-up and shipping costs.

To quote a 2$ part which is sold to many brands at high volume and imply the end product of a limited production brand should be really cheap.. it doesnt work out that way.

THx-RNMarsh

For a dac, the case doesn't need to be expensive at all. Even a custom case in small quantities is only a few tens of $$ max.

Of course you can spend crazy money if you want, but it's not necessary.

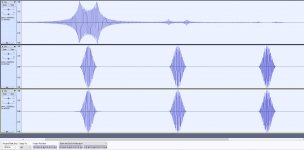

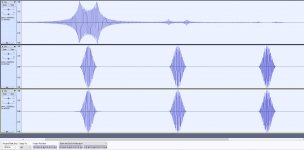

Further to the recent Cymbal posting, I made a 192Khz .wav file containing three frequencies, resp 22Khz, 25Khz and 30Khz, all contained in a 1Khz cosine envelope and separated by 5msec.

I then used a 20Khz Brick Wall FIR filter and subtracted the filtered from the unfiltered signal.

In the image below one can see resp. 1) the Brick Wall filtered signal, amplified by 40dB, 2) the original signal and 3) the difference between the two.

You can see that when having calculated the envelopes, that in that case Gibbs plus three 1Khz cosine signals would have been visible as a difference signal.

But apart from the addition of the Gibbs frequency, the envelopes around these 3 HF signals, do not take part in the sub 20Khz signal as you can see in the upper track.

In the 40dB amplified Brick Wall filtered signal, it's also obvious that the closer the HF signal is to the used Brick Wall frequency, the more violent the Gibbs amplitude.

This was all meant as a further explanation to my earlier posting, that when using just envelopes, a LF component within the Gibbs frequencies in the difference signal may be confusing, giving the impression that the LF part is affected by brick wall filtering, which is definitely not the case.

Hans

I then used a 20Khz Brick Wall FIR filter and subtracted the filtered from the unfiltered signal.

In the image below one can see resp. 1) the Brick Wall filtered signal, amplified by 40dB, 2) the original signal and 3) the difference between the two.

You can see that when having calculated the envelopes, that in that case Gibbs plus three 1Khz cosine signals would have been visible as a difference signal.

But apart from the addition of the Gibbs frequency, the envelopes around these 3 HF signals, do not take part in the sub 20Khz signal as you can see in the upper track.

In the 40dB amplified Brick Wall filtered signal, it's also obvious that the closer the HF signal is to the used Brick Wall frequency, the more violent the Gibbs amplitude.

This was all meant as a further explanation to my earlier posting, that when using just envelopes, a LF component within the Gibbs frequencies in the difference signal may be confusing, giving the impression that the LF part is affected by brick wall filtering, which is definitely not the case.

Hans

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part IV