Hi X,

Thanks for the valuable knowledge and information. Since I have no speaker measurement resources, software tools, and not much knowledge of acoustics, I think I will put this on the back burner for now. I think one of my first purchases will be a DATS V3 and mic , so I can start generating values, data files, plots, and also use the available free software that is compatible with the DATS to expand my knowledge base.

I will start out building a few published kit speakers, (modestly priced, maybe some karlsonators), take measurements, tweak, modify, experiment and learn as I go along. What an amazing journey this will be, along with building some of the amps that i have purchased from you.

Best regards

Thanks for the valuable knowledge and information. Since I have no speaker measurement resources, software tools, and not much knowledge of acoustics, I think I will put this on the back burner for now. I think one of my first purchases will be a DATS V3 and mic , so I can start generating values, data files, plots, and also use the available free software that is compatible with the DATS to expand my knowledge base.

I will start out building a few published kit speakers, (modestly priced, maybe some karlsonators), take measurements, tweak, modify, experiment and learn as I go along. What an amazing journey this will be, along with building some of the amps that i have purchased from you.

Best regards

Thanks Roundtoit.

I don’t use subwoofers for music. The Forte’s bass energy is overall stronger and more of it. It’s really not even a fair fight, double 12” cone surface area vs. single 8” cone. That being said, the bass response of the FAST TL’s seems to integrate in my room better. I don’t have any test equipment to back up my impressions, but the TL’s seem to dig almost as deep just with less volume, if that makes sense. The Forte’s would excite the room nodes and I’d hear vibrations. The TL’s do not have that effect and as a result have a smoother presentation. These two speakers are wildly different. If I use a car analogy, the Forte’s are the 1970 Chevy Chevelle LS6 454 Super Sport. The FAST TL’s are like a BMW M5 Dinan. Either would be a pleasure to own

I did think about laminating wood panels to the foamboard for a finished outside appearance, but I think I’d rather have a more rigid enclosure right from the start.

@angrypat,

Nice! A fellow LI’er

Are any projects ever done....

I don’t use subwoofers for music. The Forte’s bass energy is overall stronger and more of it. It’s really not even a fair fight, double 12” cone surface area vs. single 8” cone. That being said, the bass response of the FAST TL’s seems to integrate in my room better. I don’t have any test equipment to back up my impressions, but the TL’s seem to dig almost as deep just with less volume, if that makes sense. The Forte’s would excite the room nodes and I’d hear vibrations. The TL’s do not have that effect and as a result have a smoother presentation. These two speakers are wildly different. If I use a car analogy, the Forte’s are the 1970 Chevy Chevelle LS6 454 Super Sport. The FAST TL’s are like a BMW M5 Dinan. Either would be a pleasure to own

I did think about laminating wood panels to the foamboard for a finished outside appearance, but I think I’d rather have a more rigid enclosure right from the start.

@angrypat,

Nice! A fellow LI’er

Are any projects ever done....

Last edited:

I like the car analogy. Both the Chevelle SS and the M5 Dinan is from first hand knowledge as I recall.

That actually paints a vivid picture.

I think adding thin wood on the outside of the foam is an excellent way to keep them lightweight while being easy to build. If you have the shop and tools to make it all out of wood, that saves time because making it out of foam then cutting wood to cover might be like making it twice.

There is marine grade honey comb core plywood that is much lighter than 18mm BB ply and very strong.

That actually paints a vivid picture.

I think adding thin wood on the outside of the foam is an excellent way to keep them lightweight while being easy to build. If you have the shop and tools to make it all out of wood, that saves time because making it out of foam then cutting wood to cover might be like making it twice.

There is marine grade honey comb core plywood that is much lighter than 18mm BB ply and very strong.

Last edited:

Thx for the reply Vunce. I get the analogy. Can really rock the house with Forte's and an ACA, but then come the times lower levels must be tolerated due to family and WAF. I bet these will work.

X,

I'm down for cutting once. Have you measured the difference in, say, birch cabinet ply and foam/ply laminate? I have read a lot of you work, I just don't remember all of it (that's a compliment by the way... ). I would build in cabinet ply if there is not much audible difference. The design is well braced, but traditional mass and dampening seem unnecessary here in foam. My back would be better both building and moving these in a foam board system. That is really novel. Do you know of measurement differences in the high density foam board (for under concrete)? Might amount to nothing. I really need to set up some test equipment and answer my own questions...

). I would build in cabinet ply if there is not much audible difference. The design is well braced, but traditional mass and dampening seem unnecessary here in foam. My back would be better both building and moving these in a foam board system. That is really novel. Do you know of measurement differences in the high density foam board (for under concrete)? Might amount to nothing. I really need to set up some test equipment and answer my own questions...

X,

I'm down for cutting once. Have you measured the difference in, say, birch cabinet ply and foam/ply laminate? I have read a lot of you work, I just don't remember all of it (that's a compliment by the way...

I have found that a wooden BB ply cabinet needs the black butyl sound dampening sheets on large walls. Then add eggcrate foam on top of that.

The best cabinet would be to laminate a layer of rubber (butyl pond liner) between two sheets of ply or MDF/Ply on outside. Use 3M 777 or similar contact cement. This makes constrained layer damping boards.

But all this is not needed unless you are making much higher SPL speakers (like 300w 130dB) types. Here we are talking 105dB to 110dB speakers.

XPS covered in nice 3/16 in ply works and looks good. Have to be clever to cover ends so foam doesn’t show through. Transporting them is a breeze compared to 18mm birch plywood.

The best cabinet would be to laminate a layer of rubber (butyl pond liner) between two sheets of ply or MDF/Ply on outside. Use 3M 777 or similar contact cement. This makes constrained layer damping boards.

But all this is not needed unless you are making much higher SPL speakers (like 300w 130dB) types. Here we are talking 105dB to 110dB speakers.

XPS covered in nice 3/16 in ply works and looks good. Have to be clever to cover ends so foam doesn’t show through. Transporting them is a breeze compared to 18mm birch plywood.

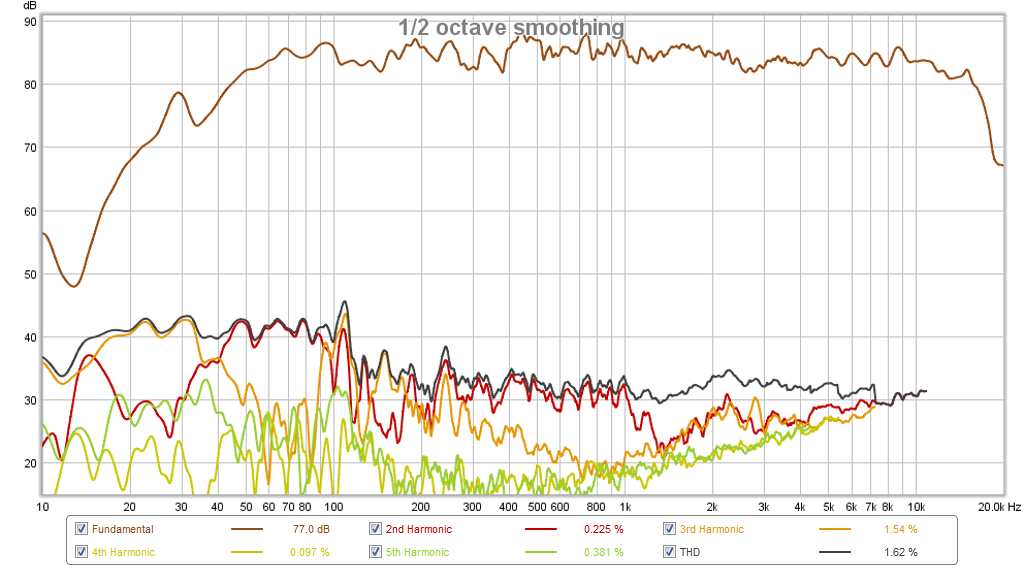

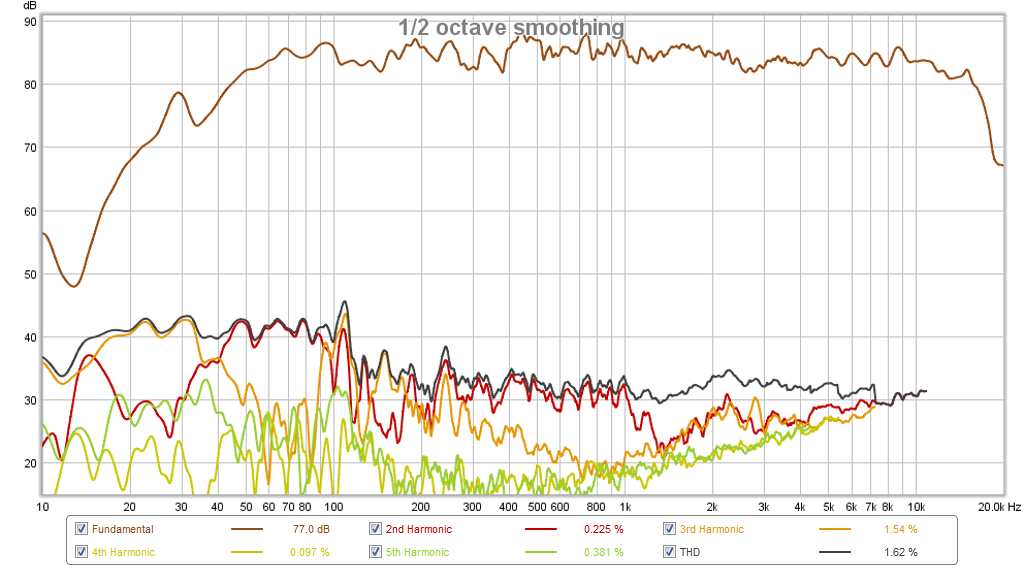

To answer your question if I have measured the difference between XPS foam cabinet vs an all BB ply cabinet treated with butyl rubber dampening sheets and eggcrate foam, yes. The data you want to look at is the harmonic distortion plot vs frequency.

Here is the XPS cabinet:

Here is internal construction of wood cabinet:

Here is the measured harmonic distortion vs frequency for the wooden box:l, you can see it is cleaner overall but that made a 2kHz distortion jump more visible:

I would say that the XPS did a better job of damping this out than the plywood.

Here is the XPS cabinet:

Here is internal construction of wood cabinet:

Here is the measured harmonic distortion vs frequency for the wooden box:l, you can see it is cleaner overall but that made a 2kHz distortion jump more visible:

I would say that the XPS did a better job of damping this out than the plywood.

Last edited:

Does anyone know if there is a difference between these 2 10F Thiel's, besides the obvious ferrite (DRVM-060-002) vs. neo (DRVM-060-001) magnet?

Speaking of Thiel... I just found out that there is a big difference between these 2 drivers. The DRVM-060-002 is a 4.5" woofer. It is not similar to the DRVM-060-001.

Attachments

Speaking of Thiel... I just found out that there is a big difference between these 2 drivers. The DRVM-060-002 is a 4.5" woofer. It is not similar to the DRVM-060-001.

Correct, I believe the Scanspeak model number for the 4.5” is 12W/8524G00.

FAST TL update

It’s been almost 1 week living with my new FAST TL’s and during this break-in period, there has indeed been improvement. The low bass has extended and tightened up. I think this can be attributed to the RS225 driver loosening up but also the foam cabinet “curing”. In my feverish haste to listen to the TL’s in stereo, the adhesive was still a bit rubbery, it was strong enough to handle the cabinets but was still pliable. After a couple of days the PL300 adhesive hardened which made the cabinets very solid (for foam ).

).

The Scanspeak 10F has opened up and the TL’s disappear. When seated, if you closed your eyes you would not be able to pick the placement of the TL’s. The sound is evenly across the front of the room. When standing, it’s easier to pick them out. Using them for A/V they are pinpoint accurate with on screen vocals and sound effects, offscreen sounds are limited only by the adjacent walls. Hey X, what about a center channel version, HeHe!

One of the tweaks I wanted to play around with was rolling XO capacitors, but not get crazy with price. The initial setup used 12 paralleled 5uF polycarbonate film caps for the 60uF value. All my thoughts so far were based on that setup. Tonight I swapped them out for a single 60uF polypropylene film cap made by ASC. I’ll give this some listening time.

This speaker is extremely satisfying, for what these cost to build I think every household should have a pair, Haha!!!

It’s been almost 1 week living with my new FAST TL’s and during this break-in period, there has indeed been improvement. The low bass has extended and tightened up. I think this can be attributed to the RS225 driver loosening up but also the foam cabinet “curing”. In my feverish haste to listen to the TL’s in stereo, the adhesive was still a bit rubbery, it was strong enough to handle the cabinets but was still pliable. After a couple of days the PL300 adhesive hardened which made the cabinets very solid (for foam

The Scanspeak 10F has opened up and the TL’s disappear. When seated, if you closed your eyes you would not be able to pick the placement of the TL’s. The sound is evenly across the front of the room. When standing, it’s easier to pick them out. Using them for A/V they are pinpoint accurate with on screen vocals and sound effects, offscreen sounds are limited only by the adjacent walls. Hey X, what about a center channel version, HeHe!

One of the tweaks I wanted to play around with was rolling XO capacitors, but not get crazy with price. The initial setup used 12 paralleled 5uF polycarbonate film caps for the 60uF value. All my thoughts so far were based on that setup. Tonight I swapped them out for a single 60uF polypropylene film cap made by ASC. I’ll give this some listening time.

This speaker is extremely satisfying, for what these cost to build I think every household should have a pair, Haha!!!

Attachments

Last edited:

I have rolls of that in every room. Super handy. I have even used it to hold up the frame of an open baffle speaker. Used it for months that way.

Anyone who gets boards from me now knows that I use Blue tape to package boards for shipping. It was Vunce’s idea - as my regular packing tape left nasty residue.

Anyone who gets boards from me now knows that I use Blue tape to package boards for shipping. It was Vunce’s idea - as my regular packing tape left nasty residue.

Update offset, measurements

Hi everybody,

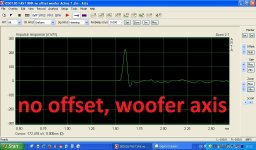

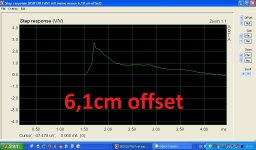

I have remade the offset listening outdoors, which I have described a couple days ago (https://www.diyaudio.com/forums/full-range/273524-10f-8424-rs225-8-fast-waw-ref-monitor-202.html#post6027366), and I have also done measurements. At the first try a couple weeks ago I was not very accurate concerning the listening position, I was too high with my ears, today I redid it, and the correct offset where it sounds best is 6,1cm = that is 2,4in. This is the horizontal distance from the front plate of one driver to the front plate of the other driver. The vertical distance center to center is around 7,5in in my case, but that is of minor importance, the listening point/ height was exactly between the drivers and in 1,2m distance.

Please find attached my measurements. They are worse than XRK's measurements. In the impulse response (IR) there is a kind of preringing, and in the step response (SR) the rise is not one constant slope, there is a bend.

Still I have to say, that outdoors it sounds way better with the offset, compared to no offset and the listening height = woofer axis. I assume that holds true for indoors too. I go with the offset. It sounds way more transparent and true 3D like.

For your interest: I have also tried no offset (a plane front baffle) and measured like 45° downwards (woofer down), so in order to get a similar offset again - and it measures similar to my setting with the offset. My concern was, that the edge of the enclosure/ front baffle might have something to do with the bad measurement, but obviously this doesn't seem to have anything to do with it.

Hi everybody,

I have remade the offset listening outdoors, which I have described a couple days ago (https://www.diyaudio.com/forums/full-range/273524-10f-8424-rs225-8-fast-waw-ref-monitor-202.html#post6027366), and I have also done measurements. At the first try a couple weeks ago I was not very accurate concerning the listening position, I was too high with my ears, today I redid it, and the correct offset where it sounds best is 6,1cm = that is 2,4in. This is the horizontal distance from the front plate of one driver to the front plate of the other driver. The vertical distance center to center is around 7,5in in my case, but that is of minor importance, the listening point/ height was exactly between the drivers and in 1,2m distance.

Please find attached my measurements. They are worse than XRK's measurements. In the impulse response (IR) there is a kind of preringing, and in the step response (SR) the rise is not one constant slope, there is a bend.

Still I have to say, that outdoors it sounds way better with the offset, compared to no offset and the listening height = woofer axis. I assume that holds true for indoors too. I go with the offset. It sounds way more transparent and true 3D like.

For your interest: I have also tried no offset (a plane front baffle) and measured like 45° downwards (woofer down), so in order to get a similar offset again - and it measures similar to my setting with the offset. My concern was, that the edge of the enclosure/ front baffle might have something to do with the bad measurement, but obviously this doesn't seem to have anything to do with it.

Attachments

Last edited:

florianderton

I would like to hear more about what you think of the 2.4" offset. I have all the parts for this build and am just planning the construction. If I do the 2.4" offset, I would probably add some MDF panels to the front of the cab that total 2.4" and those will follow the upper curve of the RS225, and square on the bottom. I would leave substantial breathing room around the RS225 inside.

Still debating whether I want to go 37litre tuned to 32hz or a TL of some sort. There is the Finalist TL design for the RS225 out there (pretty large at 56 litres internal) along with the foam one earlier in this thread. I have tried modelling the RS225 in hornresp but not having much luck.

But I would like to hear more of your listening impressions. I would MUCH rather have the Scanspeak on top.

I would like to hear more about what you think of the 2.4" offset. I have all the parts for this build and am just planning the construction. If I do the 2.4" offset, I would probably add some MDF panels to the front of the cab that total 2.4" and those will follow the upper curve of the RS225, and square on the bottom. I would leave substantial breathing room around the RS225 inside.

Still debating whether I want to go 37litre tuned to 32hz or a TL of some sort. There is the Finalist TL design for the RS225 out there (pretty large at 56 litres internal) along with the foam one earlier in this thread. I have tried modelling the RS225 in hornresp but not having much luck.

But I would like to hear more of your listening impressions. I would MUCH rather have the Scanspeak on top.

- Home

- Loudspeakers

- Full Range

- 10F/8424 & RS225-8 FAST / WAW Ref Monitor