Hey guys i need some help suggestion regarding my Technics SL-P 777 Cd player to bring it back to life!

i decided to clean and lube and toke it apart... before i did it was playing fine..

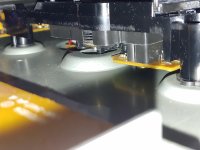

So after i assembled as it was before i followed the schematic the service manual for this player so the problem is i see the laser is lights up so its on but the disk wont spin and if i lift up gently the back of the servo unit as you can see in the picture with my fingure than its starts to spin and plays fine .

I have toke it apart like 3 times i cannot figure out what is the problem it seems like the disk is toouching/rubbing the tray i don't understand because everything is back as it was the servo/laser unit is installed with three bolts and springs underneet a picture attached i have all thoes rubber fittings installed correctly in the right direction as well.

Also what i noticed the the "yoke/magnet " what holds the disk while it playes its not centered , the clamping arm is installed correctly Pease see picure.

I thought maybe something happened to the laser but its lights up and when i lift the back of the floating laser assembly is starts to play , i have no parts left out i have checked many times using the schematics....

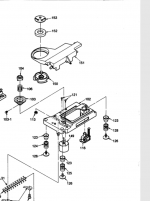

In the picture i am just showing the unit is installed back correctly with all the rubber washers under the feet.

In the picture you can see the spring that holds the laser unit with the screws there is no hight adjustement ....

This is a very nice player i really want to fix it it was playing fine before ...

If you have any suggestion please let me know!!

Thank you!!!

John

i decided to clean and lube and toke it apart... before i did it was playing fine..

So after i assembled as it was before i followed the schematic the service manual for this player so the problem is i see the laser is lights up so its on but the disk wont spin and if i lift up gently the back of the servo unit as you can see in the picture with my fingure than its starts to spin and plays fine .

I have toke it apart like 3 times i cannot figure out what is the problem it seems like the disk is toouching/rubbing the tray i don't understand because everything is back as it was the servo/laser unit is installed with three bolts and springs underneet a picture attached i have all thoes rubber fittings installed correctly in the right direction as well.

Also what i noticed the the "yoke/magnet " what holds the disk while it playes its not centered , the clamping arm is installed correctly Pease see picure.

I thought maybe something happened to the laser but its lights up and when i lift the back of the floating laser assembly is starts to play , i have no parts left out i have checked many times using the schematics....

In the picture i am just showing the unit is installed back correctly with all the rubber washers under the feet.

In the picture you can see the spring that holds the laser unit with the screws there is no hight adjustement ....

This is a very nice player i really want to fix it it was playing fine before ...

If you have any suggestion please let me know!!

Thank you!!!

John

Attachments

Last edited:

Hello,

I would re-check the ribbon cables/wiring (all ends on both main and servo pcb's)... I'm thinking of non-contact in stand-by/operate position and contact when you lift the mechanism.

Dónt look directly to the laser diode!

Best regards,

Cosmin.

I would re-check the ribbon cables/wiring (all ends on both main and servo pcb's)... I'm thinking of non-contact in stand-by/operate position and contact when you lift the mechanism.

Dónt look directly to the laser diode!

Best regards,

Cosmin.

Hello,

I would re-check the ribbon cables/wiring (all ends on both main and servo pcb's)... I'm thinking of non-contact in stand-by/operate position and contact when you lift the mechanism.

Dónt look directly to the laser diode!

Best regards,

Cosmin.

thank you for your reply!!

the motor works fine , what i have discovered is when i lift the mechanism with my fingure i take of pressure from the CD because its touching the loading tray that is why is not spinning after i do that the player works but i need to hold it in a upper position if i let it go back its stops with a scraping noise ....i have looked at it from every angle i cannot figure out why is it touching the tray "AKA" not enough clearance.

all the parts installed i checked many times ...😕 i have no idea!!😕

Hi,

Is SOAD60A servo? If so, I'll try tomorow to replicate your problem on SL-P770... If SOAD70A, I'll check on SL-PS900...

Regards,

Cosmin

Is SOAD60A servo? If so, I'll try tomorow to replicate your problem on SL-P770... If SOAD70A, I'll check on SL-PS900...

Regards,

Cosmin

Hi,

Is SOAD60A servo? If so, I'll try tomorow to replicate your problem on SL-P770... If SOAD70A, I'll check on SL-PS900...

Regards,

Cosmin

hi its SOAD70A

thank you

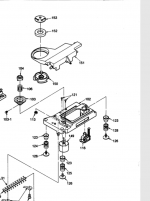

here is an other photo shows the rest of the parts

there is this rubber isolator rings goes into the case to that has a wider side as its shows in the photo so that i am sure i installed correctly and there is the springs and the bolts tight down the mechanism the only direction it can move is sideways and like i show in the photo i can pull it up after i relase it its goes back to its sitting position .

there is this rubber isolator rings goes into the case to that has a wider side as its shows in the photo so that i am sure i installed correctly and there is the springs and the bolts tight down the mechanism the only direction it can move is sideways and like i show in the photo i can pull it up after i relase it its goes back to its sitting position .

Attachments

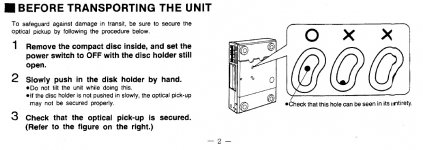

Hi, Johnyguy,

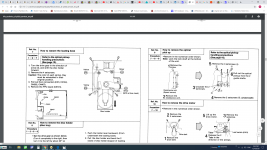

Don't get me wrong... I'm that kind of person trying to solve things from the simplest thing forward. So, have you checked this (from service manual of PS900):

View attachment 799681?

If you did, I'll open the player's lid tomorow to check out more.

Regards,

Cosmin

no problem i do apreacciate your time!!

my cd player has a different locking mechanism and yes its been open ...

Hey!

The loading unit chassis of PS900 is way different from your player, so I had to dismantle the entire unit. I must thank you because the belt waited more than an year to be changed...🙂

I tried to make photos from aprox. same angle as yours (is the third screw towards the back of the CD-player, right?):

It seems to me that you're right to suspect that screw beeng too tight, but I tried to tighten it myself and it doesn't go any further deep...

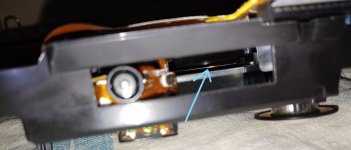

On the other hand, I recall a mistake I made when I changed the laser head on a SOAD60A unit: I didn't solder the the pins of spindle motor correctly and I had the same symptoms as you. Did you remove the spindle motor? If so, de-solder it, remove any solder excess and solder it back, making sure its pins are even.

I'll keep the CD-player open all day long in case you need more pictures.

Good luck,

Cosmin

PS: If necessary, I'll open the P770 too, because I think the loading unit chassis ('loading base' in service manual) is similar to your P777, allthought they don't have the same code.

The loading unit chassis of PS900 is way different from your player, so I had to dismantle the entire unit. I must thank you because the belt waited more than an year to be changed...🙂

I tried to make photos from aprox. same angle as yours (is the third screw towards the back of the CD-player, right?):

It seems to me that you're right to suspect that screw beeng too tight, but I tried to tighten it myself and it doesn't go any further deep...

On the other hand, I recall a mistake I made when I changed the laser head on a SOAD60A unit: I didn't solder the the pins of spindle motor correctly and I had the same symptoms as you. Did you remove the spindle motor? If so, de-solder it, remove any solder excess and solder it back, making sure its pins are even.

I'll keep the CD-player open all day long in case you need more pictures.

Good luck,

Cosmin

PS: If necessary, I'll open the P770 too, because I think the loading unit chassis ('loading base' in service manual) is similar to your P777, allthought they don't have the same code.

Hey!

The loading unit chassis of PS900 is way different from your player, so I had to dismantle the entire unit. I must thank you because the belt waited more than an year to be changed...🙂

I tried to make photos from aprox. same angle as yours (is the third screw towards the back of the CD-player, right?):

View attachment 799760 View attachment 799761

It seems to me that you're right to suspect that screw beeng too tight, but I tried to tighten it myself and it doesn't go any further deep...

On the other hand, I recall a mistake I made when I changed the laser head on a SOAD60A unit: I didn't solder the the pins of spindle motor correctly and I had the same symptoms as you. Did you remove the spindle motor? If so, de-solder it, remove any solder excess and solder it back, making sure its pins are even.

I'll keep the CD-player open all day long in case you need more pictures.

Good luck,

Cosmin

PS: If necessary, I'll open the P770 too, because I think the loading unit chassis ('loading base' in service manual) is similar to your P777, allthought they don't have the same code.

HI Cosmin

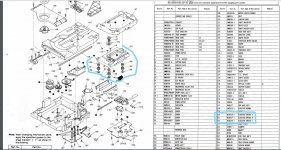

I think i have find the problem some of the CD players technics build the springs they used under the transport is color coded so the right spring goes to its right locations.... see below a photo shows this for the Technics SL-P530 ,, but for my 777 or i have looked at for the 999 the service manual don't show what spring goes where, when i toke apart mine mine has also color coded springs a black one a silver one and a gold one "see picture below".... i was thinking maybe they just use what they had available so try to keep them where they belongs but i must have mixed them up....

The springs dont feel much different from eachother but when i got them to the right location maybe they will make a different. they are responsible keeping that modul in line with the tray..

Yes i did unsolder the motor to be able to lubricate the shaft but that went back no problem the motor spinning fine

I also got a respond from a other forum that some models has different colored springs....

Can you please look at the springs on yours and let me know what color goes where

like you said i have one in the back in the middle and two on the front

i see the color of the back one is silver ...

yes be carefull tightening those screws because they are bottom out on those plastic stand offs dont brake them...at least that is how they are on mine ...

so facing the front of the cd player what is the color of the spring on the left and on the right ?

Thank you for taking the time helping me out !!!!

Attachments

Hey!

The loading unit chassis of PS900 is way different from your player, so I had to dismantle the entire unit. I must thank you because the belt waited more than an year to be changed...🙂

I tried to make photos from aprox. same angle as yours (is the third screw towards the back of the CD-player, right?):

View attachment 799760 View attachment 799761

It seems to me that you're right to suspect that screw beeng too tight, but I tried to tighten it myself and it doesn't go any further deep...

On the other hand, I recall a mistake I made when I changed the laser head on a SOAD60A unit: I didn't solder the the pins of spindle motor correctly and I had the same symptoms as you. Did you remove the spindle motor? If so, de-solder it, remove any solder excess and solder it back, making sure its pins are even.

I'll keep the CD-player open all day long in case you need more pictures.

Good luck,

Cosmin

PS: If necessary, I'll open the P770 too, because I think the loading unit chassis ('loading base' in service manual) is similar to your P777, allthought they don't have the same code.

This is a photo from the service manual of the sl-p777 and the 999 has the same manual i have looked at it also it does not say anything about spring color differences

Attachments

here is good website you can download service manuals for different cd players

https://[B]elektrotanya.com[/B] all you have to do is check the box that you not a robot and wait a few minutes while it processing .....

i just downloaded your service manual to see if that one is shows about the springs

https://[B]elektrotanya.com[/B] all you have to do is check the box that you not a robot and wait a few minutes while it processing .....

i just downloaded your service manual to see if that one is shows about the springs

Hey!

The loading unit chassis of PS900 is way different from your player, so I had to dismantle the entire unit. I must thank you because the belt waited more than an year to be changed...🙂

I tried to make photos from aprox. same angle as yours (is the third screw towards the back of the CD-player, right?):

View attachment 799760 View attachment 799761

It seems to me that you're right to suspect that screw beeng too tight, but I tried to tighten it myself and it doesn't go any further deep...

On the other hand, I recall a mistake I made when I changed the laser head on a SOAD60A unit: I didn't solder the the pins of spindle motor correctly and I had the same symptoms as you. Did you remove the spindle motor? If so, de-solder it, remove any solder excess and solder it back, making sure its pins are even.

I'll keep the CD-player open all day long in case you need more pictures.

Good luck,

Cosmin

PS: If necessary, I'll open the P770 too, because I think the loading unit chassis ('loading base' in service manual) is similar to your P777, allthought they don't have the same code.

its says A,B,C for the springs for your CD player

i know C is the silver spring....

Attachments

Hi, John.

Never thought the springs are colour coded. So, in your last attachement, A (right) is mat black in my CDplayer and B (left) is the same silver stainless steel as C (back). None is gold. Although I'm not the 1st owner of this player, I'm sure no one opened it before me.

About the turntable motor... if you soldered it tilted, the turntable on its axis will be tilted and the CD as well, touching/rubbing the laser head and when you lift the so called in service manual 'traverse base' from the back you're actually compensating the inclination angle, CD beeing kept straight by disc clamper assembly.

I have a good feeling we're on the right track, so keep me posted.

Regards,

Cosmin.

Never thought the springs are colour coded. So, in your last attachement, A (right) is mat black in my CDplayer and B (left) is the same silver stainless steel as C (back). None is gold. Although I'm not the 1st owner of this player, I'm sure no one opened it before me.

About the turntable motor... if you soldered it tilted, the turntable on its axis will be tilted and the CD as well, touching/rubbing the laser head and when you lift the so called in service manual 'traverse base' from the back you're actually compensating the inclination angle, CD beeing kept straight by disc clamper assembly.

I have a good feeling we're on the right track, so keep me posted.

Regards,

Cosmin.

Hi, John.

Never thought the springs are colour coded. So, in your last attachement, A (right) is mat black in my CDplayer and B (left) is the same silver stainless steel as C (back). None is gold. Although I'm not the 1st owner of this player, I'm sure no one opened it before me.

About the turntable motor... if you soldered it tilted, the turntable on its axis will be tilted and the CD as well, touching/rubbing the laser head and when you lift the so called in service manual 'traverse base' from the back you're actually compensating the inclination angle, CD beeing kept straight by disc clamper assembly.

I have a good feeling we're on the right track, so keep me posted.

Regards,

Cosmin.

Hi Cosmin

So i did relocate the springs i had the black in the back i placed that to the right front and i put the silver to the back and the gold one to the left .

It did improve alot the back is now floating on the spring like its suppose to!

How crazy that is if you would feel the springs by hand you would not feel much of a different its crazy engineering!!!!

So i installed back everything to try it out it worked i mean its playes the disk but you can hear a scraping so that is not right its still touches the right side if i face the cd player so i though ok let me swap the two front springs but that did not help it made it worst .

So what is means it is the right combination in my opinion.

What i also did was carefully looked at the motor you mentioned but what i see is the motor on my cd player is secured with two screws so the soldering is not there to hold it in position.

Anyhow i did desoldered it carefully and removed that back panel and i did lubricate that guide shaft and cleaned the laser positioning rail .

"see picture below"

If you decide to lubricate that guide shaft that is accessable on the side of the unit " see in picture" i would not remove that panel if i have to do it again to avoide problems .

Everything was put back correctly after all this ..

Oh i also try to rotate the spring if that would make a different "changing the tension or something" but that did not help, it is just hard to believe that after one gentle dissasemble and now the dics is rubbing? Does not make sense to me , i mean after all this thing is made to be serviced no? .

What i see the options here now is to raise the "turntable" where the disc sits on top of the motor shaft i could raise it but that is not good idea because that would change the aligment of the laser and of the entire mechanism so i am not doing that, also if i do that i think the laser would compansate for the change but that is not the way to go!!

Other idea is to install a small plastic ring /washer/spacer under that spring to bring it up ever soo slightly to avoide the rubbing....... i think this is a potencial but crude solution.

But after all i still think something is still not right and something is still off , i mean i did not have this issue before.

Note that i also included a picture for you to see the parallelism of the mechanism you can see its off! the unit was placed on cds so it wont touch the table just like its placed in the case..

Sorry for the long read!🙂

Attachments

Hey,

In your 1st post... 6th attach... is part 113 in place? Helps lifting or its role is to dump sledge's linear motion at the end? (Excuse my English, hope you understand).

You know what? Crazy thought: how about 'drawing' a ray onto a CD with something easy to clean and, after playing, checking where the 'marker' left traces on? It has to be extremly thin. Isopropyl alcohol?

Regards,

Cosmin

LE: it won't work; at that rotational speed it will be thrown away.

In your 1st post... 6th attach... is part 113 in place? Helps lifting or its role is to dump sledge's linear motion at the end? (Excuse my English, hope you understand).

You know what? Crazy thought: how about 'drawing' a ray onto a CD with something easy to clean and, after playing, checking where the 'marker' left traces on? It has to be extremly thin. Isopropyl alcohol?

Regards,

Cosmin

LE: it won't work; at that rotational speed it will be thrown away.

Last edited:

Here's a picture of an SOAD60A laser head. The black cap is easy to remove... Check yours if is in place.

View attachment 799925

you mean if.its rubs againts that?

- Home

- Source & Line

- Digital Source

- Please help me to fix my Technics SL-P777