Honestly it was a huge thrill when Wayne Colburn and Bob Cordell listened to my HPA and gave their sonic impressions. As we were chatting away it turned out the three of us have mutual friends among our former colleagues -- very cool!

_

_

Last edited:

The part is questionable for audio purposes.

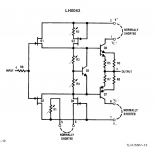

Why, is a standard Class A/AB (depending on the load) output stage. The output stage bias current and balance can be adjusted with the two pots.

This unity gain buffer, combined with a low distortion standard op amp fulfills one of the JC fetishes: an opamp that is not "current starved" at the output.

Did you work with it? I did, in the middle of eighties, quite enough. It was great, in those times, for fast impulse amplifiers driving a coax cable.

Did you work with it? I did, in the middle of eighties, quite enough. It was great, in those times, for fast impulse amplifiers driving a coax cable.

I did, after graduating from university, not for audio though. Then we got CFAs and this dinosaur got lost in the dust. So, what do you think it's the problem with it, for audio applications?

I think it looks cool and would definitely make for a good sales pitch 😉.

Last edited:

I think it looks cool and would definitely make for a good sales pitch 😉.

I don't remember if I put up a teardown of it at Burning Amp. I might have only put up the big TO power op-amp that was around then.

The LM12 was an 80 watt power amp. I used hundreds in subwoofers in the 1980s.Would that have been the LM12?

I think the hybrid opamp was the lh0032. I used those in an early Spectral power amp. Fantastic story in the early 1980s.

Bob,

You might think about some questions before starting:

What is the amp worth if you sell it now in working condition?

Are you willing to risk complete loss of the unit if things don't turn out well?

How much money are you willing to spend experimenting with it?

Mark. These amps are not that hard to fix, compared to something like a Crown

Ref 1A, they are fairly straight forward.

Having said that, we will assume Bob has at minimum a decent Cro to actually

see what it's doing and a basic level of electronics knowledge otherwise, leave

it alone.

Terry

WRT lead free solders, has anyone had any experience with these high

reliability varieties (REL61 and REL22) ?

High Reliability Alloys | AIM Solder

TCD

more stuff to fret over

all of the discussion re: different plating = different sound seems naive re: the literally hundreds of (usually) undocumented ways gold is applied electrolytically to electronic components. Kester has a brief article (more I'm sure) that hints at just a few of the problems soldering to various surfaces at various gold thicknesses, underplate, nickel, palladium, etc. etc.

https://www.kester.com/Portals/0/Documents/Knowledge Base/Soldering_Gold_over_Nickel.pdf

Seems that logically all of these undocumented variables should also have an effect on perceived sound quality, but noone seems to know or care about such things as grain size, deposit purity, surface morphology, the list goes on.

Yes, a few occasional references to grain oriented cables and such, but let's be serious and think for a moment. I made hundreds (if not thousands) of parts from all sorts of base metals for radio astronomy and DOD contracts, almost all of which required precision mil-spec gold plating, with various property modifications as functionally required (and verifiable thru testing). we rarely had problems with interface distortion, micro-diodes, etc. (and working in the THz range in some cases). Hard to believe there are issues at audio frequencies.

all of the discussion re: different plating = different sound seems naive re: the literally hundreds of (usually) undocumented ways gold is applied electrolytically to electronic components. Kester has a brief article (more I'm sure) that hints at just a few of the problems soldering to various surfaces at various gold thicknesses, underplate, nickel, palladium, etc. etc.

https://www.kester.com/Portals/0/Documents/Knowledge Base/Soldering_Gold_over_Nickel.pdf

Seems that logically all of these undocumented variables should also have an effect on perceived sound quality, but noone seems to know or care about such things as grain size, deposit purity, surface morphology, the list goes on.

Yes, a few occasional references to grain oriented cables and such, but let's be serious and think for a moment. I made hundreds (if not thousands) of parts from all sorts of base metals for radio astronomy and DOD contracts, almost all of which required precision mil-spec gold plating, with various property modifications as functionally required (and verifiable thru testing). we rarely had problems with interface distortion, micro-diodes, etc. (and working in the THz range in some cases). Hard to believe there are issues at audio frequencies.

Mark. These amps are not that hard to fix, compared to something like a Crown

Ref 1A, they are fairly straight forward.

I say this excellent design, especially that it has two identical (none of that mirrored layout rubbish) amp modules completely on connectors that easily drop out and can be operated out of the chassis position.

All other boards will also remove pretty easily....like I said it's good Taiwan design, easy for production and easy for servicing.

Mark, you are making serious implications that Bob is some kind of moron if he cannot cut and solder four wires successfully on rear panel connectors, nothing to do with active pcb's, and btw he has successfully rewired his loudspeaker crossovers.Having said that, we will assume Bob has at minimum a decent Cro to actually see what it's doing and a basic level of electronics knowledge otherwise, leave it alone.

And yes of course he has already considered the outcomes you describe, otherwise he would not be asking for advice so solve a problem that bugs him, ie he bought an amp that is not performing to his expectations.

I am encouraging Bob in several no risk /low risk steps to correct/improve a few elementary aspects of the design which will improve the coherency of the sound and should get the sound closer to what wants....and maybe some tips for the factory too.

Dan.

Mark, you are making serious implications that Bob is some kind of moron if he cannot cut and solder four wires successfully on rear panel connectors

No chance you are jumping to conclusions?

I spec'ed gold thickness for Monster connections/plugs/recept etc to be 60 u inch thickness to prevent corrosion of base metal. Those connectors were made to fit with a typical thin layer. Added gold made them a very tight fit.

High Thickness Gold Plated Connectors or Contacts (Greater than 50uin or 1.25um):

For applications where the highest corrosion protection and wear resistance are required, heavier gold deposits of 50uin (1.25um) or more are typically required. Depending on base material and surface finish of the connector, 100uin (2.5um) or more of gold plating is required to develop a fully pore-free layer that will provide the best barrier protection against corrosion of the base material. Gold plating of contacts or connectors greater that 50uin is common of mil-spec and Oil & Gas interconnect applications that are exposed to more aggressive environments as well as thermal and switching cycles. Heavier gold deposits in this range provide sufficient material to allow for very high cycle applications of 10,000 cycles or more when properly engineered with the proper underplate.

Gold Plating Thickness of Connectors - Advanced Plating Tech Blog

Porosity: Real World Concerns Part 2 | ConnectorSupplier.com

RJ45 Gold Plating Issues Causing Corrosion and Signal Loss

THx-RNMarsh

High Thickness Gold Plated Connectors or Contacts (Greater than 50uin or 1.25um):

For applications where the highest corrosion protection and wear resistance are required, heavier gold deposits of 50uin (1.25um) or more are typically required. Depending on base material and surface finish of the connector, 100uin (2.5um) or more of gold plating is required to develop a fully pore-free layer that will provide the best barrier protection against corrosion of the base material. Gold plating of contacts or connectors greater that 50uin is common of mil-spec and Oil & Gas interconnect applications that are exposed to more aggressive environments as well as thermal and switching cycles. Heavier gold deposits in this range provide sufficient material to allow for very high cycle applications of 10,000 cycles or more when properly engineered with the proper underplate.

Gold Plating Thickness of Connectors - Advanced Plating Tech Blog

Porosity: Real World Concerns Part 2 | ConnectorSupplier.com

RJ45 Gold Plating Issues Causing Corrosion and Signal Loss

THx-RNMarsh

Last edited:

Good heads up, thanks.I spec'ed gold thickness for Monster connections/plugs/recept etc to be 60 u inch thickness to prevent corrosion of base metal. Those connectors were made to fit with a typical thin layer. Added gold made them a very tight fit.

Good info, thanks.High Thickness Gold Plated Connectors or Contacts (Greater than 50uin or 1.25um):For applications where the highest corrosion protection and wear resistance are required, heavier gold deposits of 50uin (1.25um) or more are typically required. Depending on base material and surface finish of the connector, 100uin (2.5um) or more of gold plating is required to develop a fully pore-free layer that will provide the best barrier protection against corrosion of the base material. Gold plating of contacts or connectors greater that 50uin is common of mil-spec and Oil & Gas interconnect applications that are exposed to more aggressive environments as well as thermal and switching cycles. Heavier gold deposits in this range provide sufficient material to allow for very high cycle applications of 10,000 cycles or more when properly engineered with the proper underplate.

The Silver Plating Services page is interesting too.

Scroll to bottom of page for Silver Plating Services – AMS 2412 – Plating, Silver Copper Strike, Low Bake, looks interesting, no nickel undercoat.

Dan.

Hey, give Bob cred and encouragement I say, he is aware enough to do it right, he is just asking some questions along the way. 😉.

Bob has good ears, he will soon tell us of sonic changes, this is a good little project, maybe Bob can find the sound he likes. 😎.

And at least Bob is about to do actual experimenting, I haven't quite started the power isolator/conditioner box I have spoken about.

Dan.

Bob has good ears, he will soon tell us of sonic changes, this is a good little project, maybe Bob can find the sound he likes. 😎.

And at least Bob is about to do actual experimenting, I haven't quite started the power isolator/conditioner box I have spoken about.

Dan.

gold electrolytic coating

That's an unusually thick (for commercial applications) layer... typically 0.5 u or less (20 uinch) over nickel diffusion barrier is commonplace (if even measured). Note the last sentence re: ASTM standards

Everything I mfg.'d required 2.5 micron minimum (.0001") of mil spec 45204 type I or III, with various grades and classes depending on it's use, including electroformed Type 3 grade A Thz diffraction screens filters >25 microns ($$$$$) produced photolithographically with dimensional tolerances below 1/4 micron

Then there WAS rhodium... but that's a different subject

Here's a summary of the general mil spec

Types, Grades & Classes of MIL-DTL-45204 Gold Plating

There are three (3) different types, four (4) different classes, and eight (8) different grades of MIL-DTL-45204 mil-spec gold plating. The type refers to purity of the gold plating; the class refers to the hardness of the coating; and the grade of an electrolytic gold plating refers to its thickness. It should be noted that the type, grade, and class requirements are completely different for ASTM B488 gold platings and AMS 2422 gold platings.

Types of Mil-Spec Gold Plating

Type I: 99.7% minimum gold content (Grades A, B, or C)

Type II: 99.0% minimum gold content (Grades B, C, or D)

Type III: 99.9% minimum gold content (Grade A only)

Grades of Mil-Spec Gold Plating

Grade A: 90 Knoop maximum

Grade B: 91-129 Knoop

Grade C: 130-200 Knoop

Grade D: 201 Knoop and above

Classes of Mil-Spec Gold Plating

Class 00: 0.00002” minimum

Class 0: 0.00003” minimum

Class 1: 0.00005” minimum

Class 2: 0.00010” minimum

Class 3: 0.00020” minimum

Class 4: 0.00030” minimum

Class 5: 0.00050” minimum

Class 6: 0.00150” minimum

I spec'ed gold thickness for Monster connections/plugs/recept etc to be 60 u inch thickness to prevent corrosion of base metal. Those connectors were made to fit with a typical thin layer. Added gold made them a very tight fit.

THx-RNMarsh

That's an unusually thick (for commercial applications) layer... typically 0.5 u or less (20 uinch) over nickel diffusion barrier is commonplace (if even measured). Note the last sentence re: ASTM standards

Everything I mfg.'d required 2.5 micron minimum (.0001") of mil spec 45204 type I or III, with various grades and classes depending on it's use, including electroformed Type 3 grade A Thz diffraction screens filters >25 microns ($$$$$) produced photolithographically with dimensional tolerances below 1/4 micron

Then there WAS rhodium... but that's a different subject

Here's a summary of the general mil spec

Types, Grades & Classes of MIL-DTL-45204 Gold Plating

There are three (3) different types, four (4) different classes, and eight (8) different grades of MIL-DTL-45204 mil-spec gold plating. The type refers to purity of the gold plating; the class refers to the hardness of the coating; and the grade of an electrolytic gold plating refers to its thickness. It should be noted that the type, grade, and class requirements are completely different for ASTM B488 gold platings and AMS 2422 gold platings.

Types of Mil-Spec Gold Plating

Type I: 99.7% minimum gold content (Grades A, B, or C)

Type II: 99.0% minimum gold content (Grades B, C, or D)

Type III: 99.9% minimum gold content (Grade A only)

Grades of Mil-Spec Gold Plating

Grade A: 90 Knoop maximum

Grade B: 91-129 Knoop

Grade C: 130-200 Knoop

Grade D: 201 Knoop and above

Classes of Mil-Spec Gold Plating

Class 00: 0.00002” minimum

Class 0: 0.00003” minimum

Class 1: 0.00005” minimum

Class 2: 0.00010” minimum

Class 3: 0.00020” minimum

Class 4: 0.00030” minimum

Class 5: 0.00050” minimum

Class 6: 0.00150” minimum

Last edited:

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part III