Vargas,

your boards are beautiful. I have home grown soft starts in half of the amps in my system. The other half use

AMP CONTROL BOARDS – Virtual Zero Audio Store

How to build a 21st century protection board

I'm glad to see Ostripper's latest designs being built and tested.

Evan

your boards are beautiful. I have home grown soft starts in half of the amps in my system. The other half use

AMP CONTROL BOARDS – Virtual Zero Audio Store

How to build a 21st century protection board

I'm glad to see Ostripper's latest designs being built and tested.

Evan

Nice PCB's that you have designed! Congratulations.

On the softstart PCB change the word Life to LIVE.

However it might be someone's life if they touch it😱

You might consider at getting rid of the relays on the speaker protection board and use a Vishay VOM1271 opto and low Rs Mosfets???

My preference is to have mono protection boards for each channel.

Looking forward to someone comparing all the input boards.

On the softstart PCB change the word Life to LIVE.

However it might be someone's life if they touch it😱

You might consider at getting rid of the relays on the speaker protection board and use a Vishay VOM1271 opto and low Rs Mosfets???

My preference is to have mono protection boards for each channel.

Looking forward to someone comparing all the input boards.

Nice PCB's that you have designed! Congratulations.

On the softstart PCB change the word Life to LIVE.

However it might be someone's life if they touch it😱

You might consider at getting rid of the relays on the speaker protection board and use a Vishay VOM1271 opto and low Rs Mosfets???

My preference is to have mono protection boards for each channel.

Looking forward to someone comparing all the input boards.

oh no don't tell me that? I just order the PCB today with that grammar error fick! well English is my second language so for us life is "vivo" that means alive like voltage alive active

ok about the relay I didn't know about

Vishay VOM1271 opto and low Rs Mosfets???

oh well too late is been ordered already

I just update the silkscreen and write to them I hope is not too late 🙁

Attachments

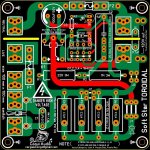

Greenamp twice

hey guys finally I put the Greenamp together with correct LED also I begin the build of the Arc Welder today first board 🙂

hey guys finally I put the Greenamp together with correct LED also I begin the build of the Arc Welder today first board 🙂

Attachments

Last edited:

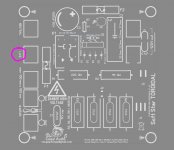

soft star for 120V toroid I need proper NTC part#

hello guys I need your advice and experience I have plan to build a new PCB soft star for a 600VA toroidal from AnTek part number AN-6445 - 600VA 45V and I been trying to find the proper part number NTC thermistor for my application and since this is my first time that I'm gonna used NTC devices and kind confuse if to use only one or two in series because the way I design the PCB I can do series or parallel connection, what is the best choice here one single NTC or two in series? also the proper part number? oh the outlet here in Puerto Rico is 117V AC 60Hz oh yes about my build project this is what I have so far on parts Greenamp IPS , power supply, speaker protection and two Arc Welder boards also the two Wolverine IPS options 🙂

Vargas

hello guys I need your advice and experience I have plan to build a new PCB soft star for a 600VA toroidal from AnTek part number AN-6445 - 600VA 45V and I been trying to find the proper part number NTC thermistor for my application and since this is my first time that I'm gonna used NTC devices and kind confuse if to use only one or two in series because the way I design the PCB I can do series or parallel connection, what is the best choice here one single NTC or two in series? also the proper part number? oh the outlet here in Puerto Rico is 117V AC 60Hz oh yes about my build project this is what I have so far on parts Greenamp IPS , power supply, speaker protection and two Arc Welder boards also the two Wolverine IPS options 🙂

Vargas

Attachments

Last edited:

I do not use NTC for a softstart, I do as Pioneer has done in many units.

Use a 3R3 - 4R7 20W resistor that sits on top of a thermal cutout, they are wired in series and a 15-16A relay contact to short them out after the big ecaps charge up, usually a 24 or 48V coil relay and its associated V drop power R. It is simple, effective and adds safety to the solution.

I used this resistor, A131149-ND & 317-1130-ND from Digi-key. The resistor you have to take off the metal chassis holder.

Use a 3R3 - 4R7 20W resistor that sits on top of a thermal cutout, they are wired in series and a 15-16A relay contact to short them out after the big ecaps charge up, usually a 24 or 48V coil relay and its associated V drop power R. It is simple, effective and adds safety to the solution.

I used this resistor, A131149-ND & 317-1130-ND from Digi-key. The resistor you have to take off the metal chassis holder.

Last edited:

thats a very beautiful board. and very nice assembly too.

Do you have a schematic of soft start?

Do you have a schematic of soft start?

yes here 🙂 PDFthats a very beautiful board. and very nice assembly too.

Do you have a schematic of soft start?

I just wanna to be sure that is why I posted today

Vargas

Attachments

yes here 🙂 PDF

I just wanna to be sure that is why I posted today

Vargas

Thanks Vargas,

Instead of the 4 resistors , I used 1 qty. MS15 40004 from ametherm.

Been working well on a 800VA trafo.

https://www.ametherm.com/datasheetspdf/MS1540004.pdf

Regards

Prasi

Last edited:

Thanks Vargas,

Instead of the 4 resistors , I used 1 qty. MS15 40004 from ametherm.

Been working well on a 800VA trafo.

Regards

Prasi

thank you so much for the info got it,

oh yes the resistors are just optional if NTC are not in use the layout have two options and I chose NTC instead thanks Prasi good day 🙂

oh yes the resistors are just optional if NTC are not in use the layout have two options and I chose NTC instead thanks Prasi good day 🙂Vargas

Last edited:

This is all about having a safe fault condition.

I do not like the idea of something sitting their boiling away indefinitely or eventually frying itself or something else under a fault condition. We have cleared out a whole factory with a burnt out pcb.

If left that way, it puts stress on the transformer and can be a fire hazard.

Have to ask yourself, under a fault condition what goes on, is it safe?

MS15 40004

I wonder if you have ever put a current probe on the line and watched/captured the inrush current on a storage/digital scope?

Max Steady State Current up to 65°c: 4.10 A

Tested in a fault condition. You design for worst case, not best case

can your pcb design handle "Body Temperature at 100% Max Current: 154.00 °c"

This what UL/CSA (or your insurance co) would be wanting you to show them in a cert 🙂

I am not talking out my back side here, I have done UL certs in my career.

Safety first!!

I do not like the idea of something sitting their boiling away indefinitely or eventually frying itself or something else under a fault condition. We have cleared out a whole factory with a burnt out pcb.

If left that way, it puts stress on the transformer and can be a fire hazard.

Have to ask yourself, under a fault condition what goes on, is it safe?

MS15 40004

I wonder if you have ever put a current probe on the line and watched/captured the inrush current on a storage/digital scope?

Max Steady State Current up to 65°c: 4.10 A

Tested in a fault condition. You design for worst case, not best case

can your pcb design handle "Body Temperature at 100% Max Current: 154.00 °c"

This what UL/CSA (or your insurance co) would be wanting you to show them in a cert 🙂

I am not talking out my back side here, I have done UL certs in my career.

Safety first!!

Last edited:

Hello rsavas,

I also use a close rated mains slow blow fuse. Wouldn't that be a primary protection under fault condition?

I also use a close rated mains slow blow fuse. Wouldn't that be a primary protection under fault condition?

The issue is can you rely on the fuse to blow under the fault condition? and is it fast enough to blow before there is a safety issue?

When it comes to the AC line, it is best to follow other mfg's examples, that have had international certs, that way you can feel secure about the design. It is best to follow UL guidelines that would be used in a cert. UL is a PITA and expensive but is necessary to ensure safety and be able to sell. I know this is DIY but we want to design and use it safely.

I have looked and worked on a few high power amps, I do not know of one I can point to that uses a MS15 40004 or similar part. If you find one, let me know so I can go over the service manual. If you find one, I suggest one follow those designs as close as you can.

When it comes to the AC line, it is best to follow other mfg's examples, that have had international certs, that way you can feel secure about the design. It is best to follow UL guidelines that would be used in a cert. UL is a PITA and expensive but is necessary to ensure safety and be able to sell. I know this is DIY but we want to design and use it safely.

I have looked and worked on a few high power amps, I do not know of one I can point to that uses a MS15 40004 or similar part. If you find one, let me know so I can go over the service manual. If you find one, I suggest one follow those designs as close as you can.

Last edited:

ok the thing here is to have a proper device for my application, oh no I don't have intencion to sell none of this diy PCB this are for personal use only and I know this is a dangerous and that is why I ask here cause you guys have more time experience than me, and I really don't want to mess this thing up you know with a fire hazard device

You can do the test of your design and find out for yourself. Real simple, disconnect the drive to the relay coil and power up with a line VAC and watch 🙂

You did ask for a magic wand part, now see what your wand can do for you 🙂 Can you answer,

If I leave the Ac power switch on indefinitely, will I need a fire extinguisher or can I sleep on it?

You did ask for a magic wand part, now see what your wand can do for you 🙂 Can you answer,

If I leave the Ac power switch on indefinitely, will I need a fire extinguisher or can I sleep on it?

Last edited:

You can do the test of your design and find out for yourself. Real simple, disconnect the drive to the relay coil and power up with a line VAC and watch 🙂

true you right, well I'm gonna open all the windows day I tested 😛

do it outside with the water hose tap on ready to go 🙂

It is an experience working with a UL EE getting a product certified. One time the boss had me do it for the first time, I had no idea, no one showed me the ropes, the UL EE just looked at me and laughed. A really nice guy born in Thailand, I remember. The UL process is expensive, the EE's get paid very well, so he took some time and showed me the ropes for that one testing class. It was a few models of HID ballasts, for 250-1000W, you see them each night, light up the planet. I saw another EE testing out a fluorescent ballast for a Panasonic bathroom fan/light fixture, they had thermal couples attached to every part that was potentially getting hot.

There a few ways to UL cert, one you get them to do it, most expensive, the one I did, we did all the tests, write the reports, submitt, they came in and witness some of the tests to verify the results.

Enlightenment.

I have an idea, utube your test so i can watch 🙂

It is an experience working with a UL EE getting a product certified. One time the boss had me do it for the first time, I had no idea, no one showed me the ropes, the UL EE just looked at me and laughed. A really nice guy born in Thailand, I remember. The UL process is expensive, the EE's get paid very well, so he took some time and showed me the ropes for that one testing class. It was a few models of HID ballasts, for 250-1000W, you see them each night, light up the planet. I saw another EE testing out a fluorescent ballast for a Panasonic bathroom fan/light fixture, they had thermal couples attached to every part that was potentially getting hot.

There a few ways to UL cert, one you get them to do it, most expensive, the one I did, we did all the tests, write the reports, submitt, they came in and witness some of the tests to verify the results.

Enlightenment.

I have an idea, utube your test so i can watch 🙂

Last edited:

oh man wow I mean there is a basement that I can do the test my home here in Puerto Rico is all concrete and there is not wood stuff around it sound funny but there is a tap water in the basement close by, cool man your UL EE thing that happen to you awesome ok I'm gonna documented with video if magic smoke come out I will posted here good or bad go or no go good day rsavas 🙂

Vargas

Vargas

- Home

- Amplifiers

- Solid State

- SlewMaster Builds