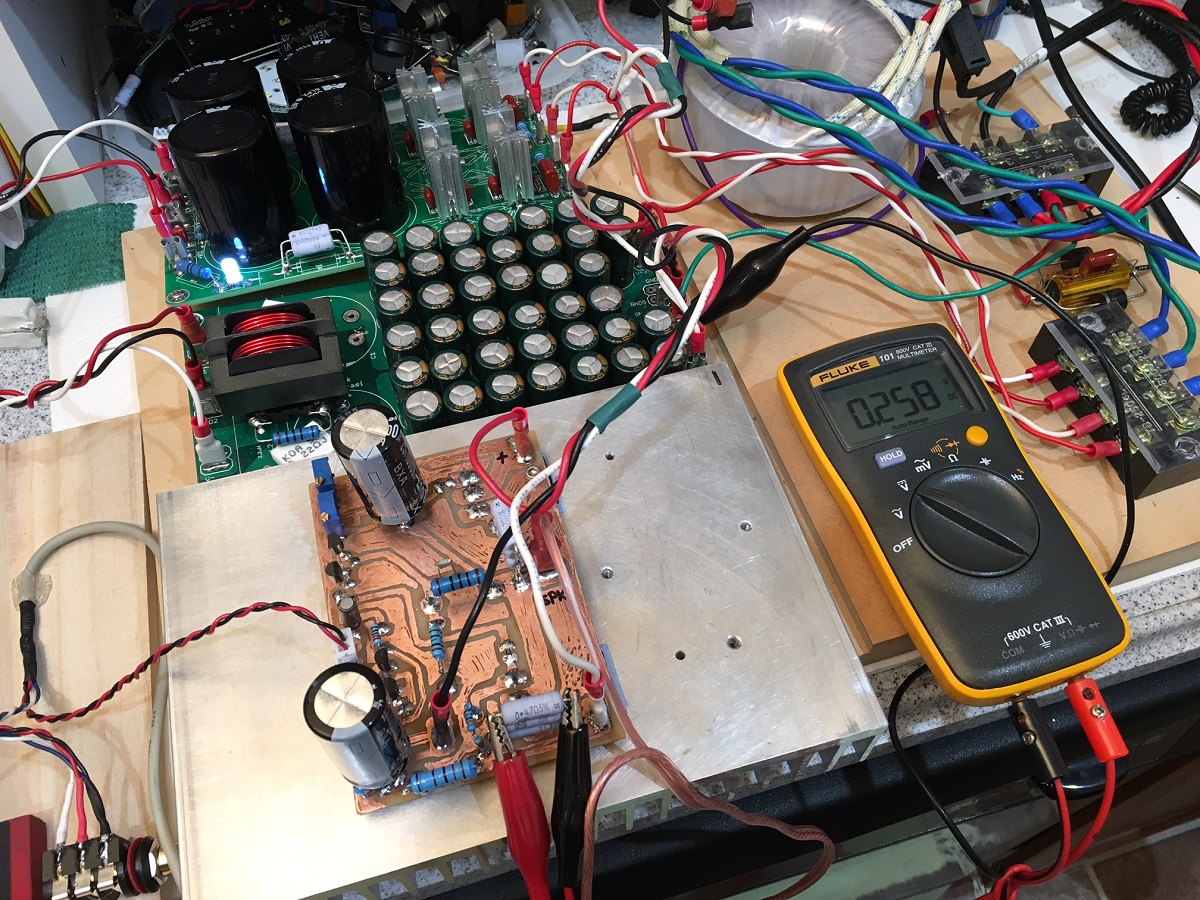

This PSU was used in time when I building this mosfet amplifier. There is PSU, DC and overload cut-out protect for each channel and soft-start for toroidal transformer. This circuit can be used with any amplifier.

how does overload cut-out protect works

thermal compensation

Actually , the thermal ~stability comes from D1,2,3,4, because the cross-over bias is dependent on VAS current which is a function of the diff-amp current, and one diode drop is across the current source(s) emitter resistor.

I'm not fond of completely symmetric front ends because there is so much bias dependency from one stage to the next and requires VAS emitter resistors. And according to some simulations I've done, there is no huge advantage in distortion that you would expect. And we know that symmetry cancels even order harmonics, which are "pleasant sounding", vs odd harmonics which are not. Harley Davidson sell a lot of motorbikes because the engine "defect" is very musical.

Years ago, Sinclair modules used a single resistor for cross-over bias and depended on the thermal compensation from the VAS current source, and that was a BJT circuit. Now, they blew up a lot because the output transistors were tiny and the system grounding critical, prone to oscillations. But they sounded great when they worked. That was my "previous life".

Ok, im not doubting you 😉 Q9 & 10 are effectively emitter followers though, if you mount them on the same heatsink as the output transistors surely they can't compensate for quiescent on the output stage?

Perhaps i'm having a stupid attack due to a few beers😀 My apologies if this is so...

Actually , the thermal ~stability comes from D1,2,3,4, because the cross-over bias is dependent on VAS current which is a function of the diff-amp current, and one diode drop is across the current source(s) emitter resistor.

I'm not fond of completely symmetric front ends because there is so much bias dependency from one stage to the next and requires VAS emitter resistors. And according to some simulations I've done, there is no huge advantage in distortion that you would expect. And we know that symmetry cancels even order harmonics, which are "pleasant sounding", vs odd harmonics which are not. Harley Davidson sell a lot of motorbikes because the engine "defect" is very musical.

Years ago, Sinclair modules used a single resistor for cross-over bias and depended on the thermal compensation from the VAS current source, and that was a BJT circuit. Now, they blew up a lot because the output transistors were tiny and the system grounding critical, prone to oscillations. But they sounded great when they worked. That was my "previous life".

This is my contribution to APEX HV250 amplifier, for those without prejudices about OP amp in front. Thanks Mr. Mile

Pozdrav

Pozdrav,

Thanks for giving me the link to this post from the main Apex thread. Did you switch to NE5532 as Djk suggested? Would you have Gerber files for this as I can’t home etch something this big.

Thanks,

X

Hello apex,

you can recommend your DIY 100Watt / 150watt stereo power mosfet amplifier.

I already have a PSU of +/- Vcc60

Thanks a lot..

Massimiliano

you can recommend your DIY 100Watt / 150watt stereo power mosfet amplifier.

I already have a PSU of +/- Vcc60

Thanks a lot..

Massimiliano

Pozdrav,

Thanks for giving me the link to this post from the main Apex thread. Did you switch to NE5532 as Djk suggested? Would you have Gerber files for this as I can’t home etch something this big.

Thanks,

X

I used the IC original one. Sorry, I dont have gerber files because I did it in corel draw, but this is not so big.

Ok, hand made layout - cool. I do those too using "Paint" and they work quite well but never something with this much power.

using "paint" is OK,but it is very painful... try to use China PCB Prototype & Fabrication Manufacturer - PCB Prototype the Easy Way program or such of free one. it is much easier to use than paint. I use sprint6 and it is very helpful when you get used to it. there is no need to do it hard way nowadays...

Also, forgot to mention that I use mostly PowerPoint for quick hand layouts. Anything more complicated I leave to experts like JPS64 or Prasi. 🙂

Thanks for the tip though.

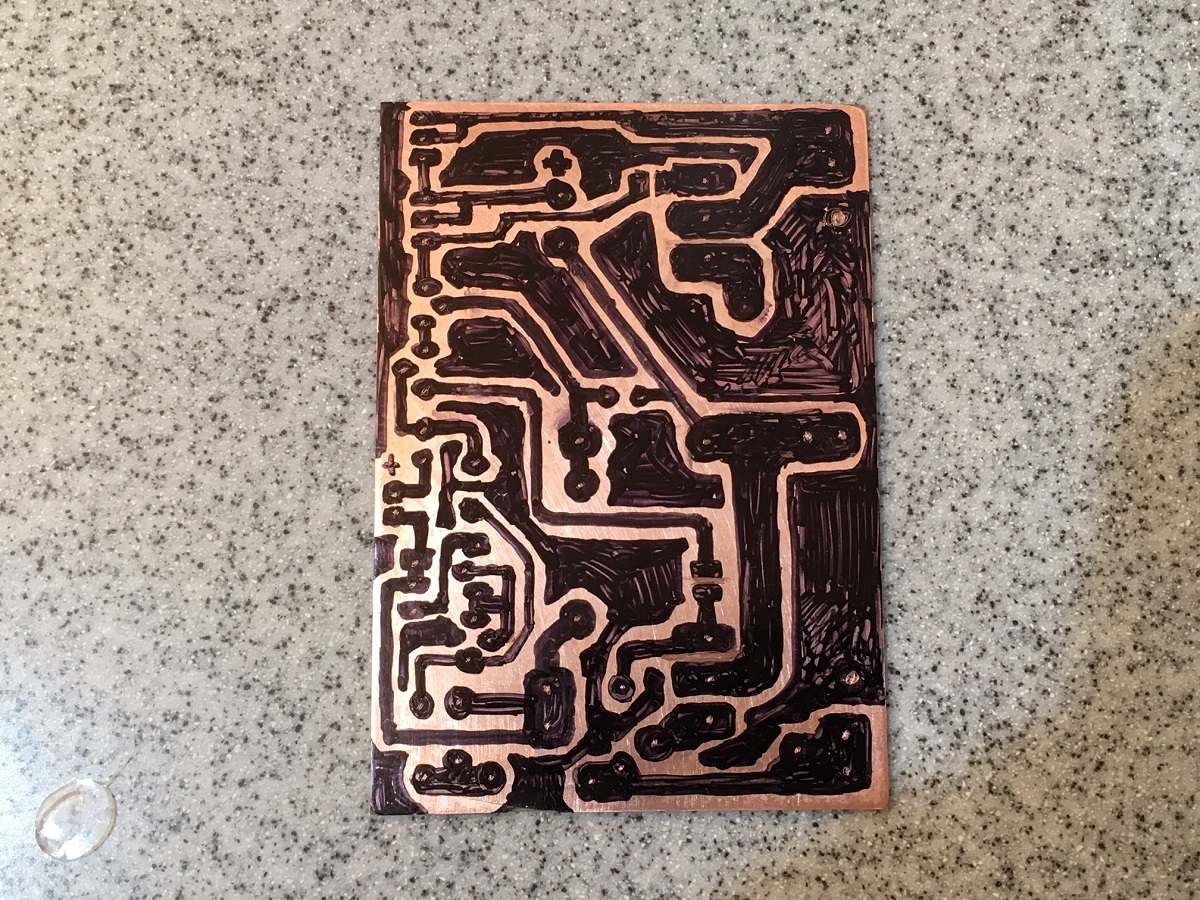

I also use Sharpie markers for very fast rough designs.

Here is the DLH Class A amp:

That amp was probably the highest bias current amp I have made with a Sharpie.

Thanks for the tip though.

I also use Sharpie markers for very fast rough designs.

Here is the DLH Class A amp:

That amp was probably the highest bias current amp I have made with a Sharpie.

Last edited:

like I have signed under my post :"chop your own wood and..." guess each one of us have our own wood, yours is quite good by the way! 🙂

RS Components don't seem to do IRFP240's any more.

They still do the IRFP9240 though.

However, the IRFP250 seems to work ok.

They still do the IRFP9240 though.

However, the IRFP250 seems to work ok.

using "paint" is OK,but it is very painful... try to use China PCB Prototype & Fabrication Manufacturer - PCB Prototype the Easy Way program or such of free one. it is much easier to use than paint. I use sprint6 and it is very helpful when you get used to it. there is no need to do it hard way nowadays...

With people giving away PCBCAD software there is little need for paint etc.

Also, with Chinese manufacturers giving away PCB's not much reason to make your own now.

JLCPCB $2 for 10 off 100mm by 100mm

PCBWAY $5 for 10 off 100mm by 100mm

Turn around time is usually just a few days, depends how much you want to spend on postage.

When you want to try the circuit in 2 hrs there’s no substitute to etch your own. I agree that for $2 plus $14 shipping from China, that’s what I resort to when not in a total hurry. In fact, my $2 JLCPCB order for some cap multipliers should be here in a few days. 🙂

- Home

- Amplifiers

- Solid State

- MOSFET Amplifier IRFP240/IRFP9240