The trick is knowing what are the important elements to measure and there seems to be renewed doubt around what they are, for instance the relevance of THD has been questioned a fair bit lately. Then are there things that we really struggle with, measurement wise, like the dreaded psychoacoustics?

I have to say that I was wondering, those days, why in audio such issues were almost unknown and overlooked. People did not read and did not interpret the datasheets? Because every part has its optimal field of use. Even 40 years ago, I cannot imagine that I would put the X7R ceramics into active filters, that I used for instrumentation.

Higher educations still spits out so called "EE's" who haven't been drilled into paying attention to details, perhaps it's in some peoples nature and/or bad luck not having a real hands-on geeky teacher.

I can't claim having been fortunate enough being in an environment surrounded by datasheets, that's when I have to use a scope or other means to find out, curiosity is what makes us evolve.

Though things changed some times after mid 90's when internet matured enough to help us find information online.

Yes, correct. It looks like this:

Good Pavel, thanks for posting the mesaurement!

It's always refreshing "seeing" these anomalies with ones own eyes.

Really DPH? Where have the ceramic or tantalum distortion measurements changed in the last 40 years? Looks about the same to me! How about you, PMA?

By the way, I did most of my audio research between 35-45 years ago, so that's what I can easily cite from. Later, I was too busy making audio products, and putting out 'fires' running a company to do any 'free' audio research. What amazes me is how you guys can fight PMA today over his measurements, when he goes out of his way to show them in order to further audio design quality? Of course, the same thing happened 40 years ago to me, so it seems to be an expected response to doing a better job in audio design.

By the way, this is one of my later measurements with a ceramic cap measured at 10 Hz.

By the way, I did most of my audio research between 35-45 years ago, so that's what I can easily cite from. Later, I was too busy making audio products, and putting out 'fires' running a company to do any 'free' audio research. What amazes me is how you guys can fight PMA today over his measurements, when he goes out of his way to show them in order to further audio design quality? Of course, the same thing happened 40 years ago to me, so it seems to be an expected response to doing a better job in audio design.

By the way, this is one of my later measurements with a ceramic cap measured at 10 Hz.

Attachments

Last edited:

Of course, PMA has 'learned'

I have "learned" which parts are also used in audio even these days. I have not "learned" new knowledge about capacitors, because I also have my old measurements of their issues and since about 1980 I have only built direct-coupled amplifiers with just input coupling cap (or more often without it, because for measuring purposes they had to start at DC), which was always the foil type. So, only thing I have "learned", is how bad the audio design might be in commercial audio. And, frankly, in the past I disrespected commercial audio design and was not interested in audio schematics. I was fully involved in measurement, instrumentation and industrial automation solutions.

I have lousy recordings from the 20's that sound better through good equipment, I bother with them because I like the musicality of the performance and the musicality of the hi-fi does not detract from that.Code:

That can happen, though I've heard lots of lousy recordings not worth bothering with.

You might not like what the sound guy wanted to get from his studio system as well as yours.

Either way, it's just a preference, not high fidelity, since there is no original acoustical event.

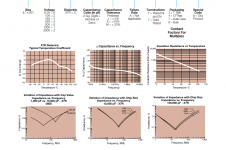

Here are some measurements from the past (40 years ago) that show the problem with ceramics and tantalum caps. When will we ever learn? '-)

What is the real application for a tantalum 4.7uF capacitor loaded with 68 ohm?? I would never see one reason to use it this way. I have shown a measurement, today, with 4.7uF tantalum loaded with 18k, which is quite realistic, and there is no distortion added. We have to compare apples to apples and investigate real life circuits. It is always possible to find an extreme. Load your JC-1 with 0.01 ohm load resistor and it would probably not behave very nicely, similar to that 4.7uF tantalum loaded with 68 ohm 😀

Today, we could have done it differently, BUT with the ST1700B with a 600 ohm output, I had to include the source with the load for the true loading. So the real load is 668 ohms. This is a low value, but not too low for some applications.

For everyone, I design my measurements with REASONABLE WORST CASE. Not typical, not midrange only, etc. And there is the factor of SCALING. If I load with 668 ohms, that could be similar to 6680 ohms at 1Hz. One Hz is what I would expect from a phono playback due to typical record warps.

The main thing is that the distortion mechanism exists, and it effects portions of the signal that passes through the audio stream.

The JC-1 comparison is silly, because we always have to trade the power dissipation limits for voltage vs current, so we design for a reasonable range of loads, not everything possible in the universe. For example, we can do 2 ohm loads, but discourage less impedance for practical reasons. In fact, the protection circuit would fire, opening the output relay, IF .001 ohm was the load, as it is designed to do.

For everyone, I design my measurements with REASONABLE WORST CASE. Not typical, not midrange only, etc. And there is the factor of SCALING. If I load with 668 ohms, that could be similar to 6680 ohms at 1Hz. One Hz is what I would expect from a phono playback due to typical record warps.

The main thing is that the distortion mechanism exists, and it effects portions of the signal that passes through the audio stream.

The JC-1 comparison is silly, because we always have to trade the power dissipation limits for voltage vs current, so we design for a reasonable range of loads, not everything possible in the universe. For example, we can do 2 ohm loads, but discourage less impedance for practical reasons. In fact, the protection circuit would fire, opening the output relay, IF .001 ohm was the load, as it is designed to do.

Really DPH? Where have the ceramic or tantalum distortion measurements changed in the last 40 years? Looks about the same to me! How about you, PMA?

By the way, I did most of my audio research between 35-45 years ago, so that's what I can easily cite from. Later, I was too busy making audio products, and putting out 'fires' running a company to do any 'free' audio research. What amazes me is how you guys can fight PMA today over his measurements, when he goes out of his way to show them in order to further audio design quality? Of course, the same thing happened 40 years ago to me, so it seems to be an expected response to doing a better job in audio design.

By the way, this is one of my later measurements with a ceramic cap measured at 10 Hz.

When you go to Mouser and you type in "tantalum capacitor" how many hits do you get?

When you go to Mouser and type in "ceramic capacitor" how many hits do you get?

Materials and manufacturing techniques haven't changed AT ALL since before I was born. That's absolutely correct. 🙄

And as PMA also noted, there's usage! So, no, you don't use a x7r or lesser rated capacitor as a coupling cap, but it's great for low inductance local psu bypass. Don't use a tantalum cap as a filter, but works well in coupling -- again provided it's sized to have essentially zero voltage drop across it. C0G are nice and linear, but as Jan noted, top out around 1 uF (and you pay for it). So, yeah, for a capacitor around 1-10 uF, a PS/PP works great. So also plenty of bipolar electrolytics (again in bypass as opposed to a filter). Whoop-dee-doo.

Code:

That can happen, though I've heard lots of lousy recordings not worth bothering with.

You might not like what the sound guy wanted to get from his studio system as well as yours.

Either way, it's just a preference, not high fidelity, since there is no original acoustical event.

Agree again.

//

Higher educations still spits out so called "EE's" who haven't been drilled into paying attention to details, perhaps it's in some peoples nature and/or bad luck not having a real hands-on geeky teacher.

I can't claim having been fortunate enough being in an environment surrounded by datasheets, that's when I have to use a scope or other means to find out, curiosity is what makes us evolve.

Though things changed some times after mid 90's when internet matured enough to help us find information online.

I'd invite any curmudgeon to go through a EE program at a decent school nowadays. Glass houses, stones, and all that.

People forget all the school of hard knocks they went to after getting out of school.

The term "high fidelity" can only refer to an acoustical sound.

Otherwise, it has no meaning.

Really? High fidelity - Wikipedia

You do know I could edit that Wiki to say what I said here? But I won't bother.

You do know that a huge portion of Wikipedia is well curated and edited such that your changes about what you say here would be quickly reverted, right?

But you wouldn't bother. 😉

But you wouldn't bother. 😉

Materials and manufacturing techniques haven't changed AT ALL since before I was born. That's absolutely correct. 🙄

Born yesterday????

Actually broadly they have not changed but the quality, uniformity have improved a lot as have manufacturing techniques. Where volume is high and competition is aggressive there have been significant improvements like electrolytic caps. Where the volume is small and getting smaller like film caps not a whole lot has changed and they are not a major component in cell phones so don't expect a lot. Also don't expect a lot for components that are too large for a cell phone. Follow the money.

Demian, I'm a youngster in relative comparison to most on this thread, but I was really really being sarcastic about John Curls use of "ceramic capacitor" as a catch-all phrase rather than identifying that there's now thousands upon thousands of different part numbers out there, and, well, it'd be really foolish to not know the big families of capacitor types (and their respective performance/usage).

I'd argue we've done a lot in the materials science of "electrolytic" and "ceramic" capacitors such that I'd call them new materials.

So you basically fleshed out what I was hinting at. 🙂

I'd argue we've done a lot in the materials science of "electrolytic" and "ceramic" capacitors such that I'd call them new materials.

So you basically fleshed out what I was hinting at. 🙂

Last edited:

Thank You ! .......No Carver just made the output impedance equal so that the speaker sounded the same on both amps.

Jan

My experiment was a ~ 20db line amp where I rolled lf357 vs lf356 ..... :

http://www.mit.edu/~6.301/LF155.pdf

It depends what you mean by "musical".... apparently [emoji57]

Engineers arguing the meaning of language seems much like the hifi reviewers using language to argue the meaning of engineering.

Kind of like playing the same album backwards.

Same circus, different monkeys.

Once again on datasheets. This shows what we can read from datasheets. No need to read Audio Amateurs or forum discussions. So it is only about designers competence or ignorance, if he uses class II ceramics for coupling or filters.

Attachments

You do know I could edit that Wiki to say what I said here? But I won't bother.

Yes I know (after 40 years of IT, developing OS's, Compilers and more I learned a few things) and you may use the opportunity to add some more 🙂

Last edited:

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part III