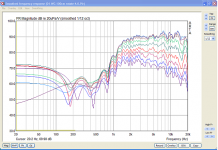

I'm considering a (partially) new build. Visually, it would be a clone of this old project, pictured. It would be for home use, multi amp, with DSP.

For the horn, I previously wanted to run a 4" or 5" driver from 400Hz-15kHz (ish). Since drivers this size have breakup <10kHz, I am considering keeping the horn essentially the same, but extending the throat to take a smaller wideband driver, or switch to a compression driver.

As well as making the cabinet pretty, I also wish to make a fairly light build, and to 'use up' existing bass and midbass drivers, so:

Subs would be SB Acoustics 12" mounted on opposing sides (sealed)

midbass: neo magnet Faital 12" (firing into short, stuffed line)

Horn to cover 1kHz (preferably lower) to 15kHz (ish)

Because the horn and baffle are continuous (and for aesthetics, I'd like to keep them this way), I'd like a HF driver that can easily be mounted from behind. I think this rules out bolt-on compression drivers.

idea 1) mount a threaded adapter permanently onto the horn & use a screw-on compression driver.

Problem: I don't think any cover a wide enough range - phenolic diaphragms don't go high enough, titanium diaphragms don't go low enough.

idea 2) something like this looks very good for the task:

Tymphany PLS Series 50F25AL01 2" Aluminum Full Range Speaker

Problem 1: it is open backed, which I'd have to build around, as pictured.

Problem 2: the low sensitivity. Even with horn loading, and sharp DSP filters, I wonder if they'd be the weak link - the raw driver is so much less efficient than anything I've ever tinkered with before.

Thoughts / suggestions?

Note: I still have the pictured cabinet to play with, so I can try out ideas before committing to a full build.

For the horn, I previously wanted to run a 4" or 5" driver from 400Hz-15kHz (ish). Since drivers this size have breakup <10kHz, I am considering keeping the horn essentially the same, but extending the throat to take a smaller wideband driver, or switch to a compression driver.

As well as making the cabinet pretty, I also wish to make a fairly light build, and to 'use up' existing bass and midbass drivers, so:

Subs would be SB Acoustics 12" mounted on opposing sides (sealed)

midbass: neo magnet Faital 12" (firing into short, stuffed line)

Horn to cover 1kHz (preferably lower) to 15kHz (ish)

Because the horn and baffle are continuous (and for aesthetics, I'd like to keep them this way), I'd like a HF driver that can easily be mounted from behind. I think this rules out bolt-on compression drivers.

idea 1) mount a threaded adapter permanently onto the horn & use a screw-on compression driver.

Problem: I don't think any cover a wide enough range - phenolic diaphragms don't go high enough, titanium diaphragms don't go low enough.

idea 2) something like this looks very good for the task:

Tymphany PLS Series 50F25AL01 2" Aluminum Full Range Speaker

Problem 1: it is open backed, which I'd have to build around, as pictured.

Problem 2: the low sensitivity. Even with horn loading, and sharp DSP filters, I wonder if they'd be the weak link - the raw driver is so much less efficient than anything I've ever tinkered with before.

Thoughts / suggestions?

Note: I still have the pictured cabinet to play with, so I can try out ideas before committing to a full build.

Attachments

...Because the horn and baffle are continuous (and for aesthetics, I'd like to keep them this way), I'd like a HF driver that can easily be mounted from behind. I think this rules out bolt-on compression drivers....

Many nice, suitable compression drivers are bolt-on, to rule them out will restrict you unnecessarily

Have you considered a simple plate adapter mount?

Attach the driver to the plate with countersunk bolts ("machine screws" if your fastener supplier is pedantic).

Then attach the plate via thru holes.

6 to 10mm Aluminium is cheap and easy to work.

You can even use the plate as a heat-sink, if you want to do impromptu rock concerts.😉

Best wishes

David

Have you considered a simple plate adapter mount?

Thanks, that's not a bad idea, particularly with thin(ish) alu plate.

I've previously had a hard time with a DIY adapter - but that was a thick layer of hardboard (which acted as an extension of the throat) and a very heavy driver. I had to use long bolts to get through the thick plate, and this meant the bolt heads wanted to hit the side of the horn flare.

I'd prefer to simplify the build, though - if I find a good (and reasonably priced) screw-on driver that does what I want, I can skip the hassle of a plate and bolts.

Hunting around a bit, I noticed the PRV Audio D290Py-S ...it looks OK for the range I want.

check this also[/URL]

Cheers. Similar to the little (low efficiency) driver I mentioned - but much more xmax.

- if I find a ...screw-on driver that does what I want, I can skip the hassle of a plate and bolts...

I don't know the screw-on drivers very well but all the ones I have seen are smaller, with consequent low frequency limitations.

Your requirements of <1kHz to ~15 kHz is in the middle of 3" voice coil compression driver specifications.

JBL does nice 3" units but all are bolt-on AFAIK.

There are also some suitable JBL 4" VC units (the 1.5" throat ones) but also all bolt-on AFAIK.

This is what I have used myself.

The newer, "latest and best" units all seem to be bolt-on mounts.

I would not compromise on an inferior driver when the plate is so simple to make.

I noticed in another thread that you are interested in cabinet vibration, so note that the aluminium has the additional benefit that it can be used as part of a constrained layer system to damp the enclosure too😉

I have just started to work on this, have the ally but not cut yet.

Best wishes

David

Your requirements of <1kHz to ~15 kHz is in the middle of 3" voice coil compression driver specifications.

JBL does nice 3" units but all are bolt-on AFAIK.

There are also some suitable JBL 4" VC units (the 1.5" throat ones) but also all bolt-on AFAIK.

This is what I have used myself.

I've also got JBL 4" VC units (older, 2" throats) and I like them - but I consider them overkill for home listening. I use them outdoors.

As curiosities, I picked up some vintage horns that are fitted with 3/4" throat screw-on drivers. They are pictured here:

hollowboy's albums - Imgur

At home, these play loud enough for me. They go down to 800Hz without problems. Therefore I think a more robust modern driver with a 1" throat is going to be big & bad enough for me 🙂

The pictured combo is very close to what I want. Easy mounting. $60 per channel. FR plot looks sweet. All good, but I'd prefer a driver that plays a little bit lower.

- the polar plot pictured is from Gainphile (Great Waveguide List)

- the driver + horn pic is from an ebay auction for these same parts

I'm leaning towards buying something like this. I'd simply shorten the plastic horn, and use it as the throat of my (slightly larger) wooden section.

I could use a foam insert, Geddes style, to conceal the non-wooden parts.

Attachments

There's some info on the SB65 on a horn here http://www.diyaudio.com/forums/multi-way/285030-bookshelf-multi-source-horn-125.html#post4644522

... JBL 4" VC units (older, 2" throats) and I like them - but I consider them overkill...

Yes, I wouldn't dispute that😉 I just wanted to match the top-of-the-line JBL studio monitor at the time.

I do think the 3" drivers are a nice fit for your specifications, dependent on how low you want to run them.

Still overkill for loudness, of course, but a bit of overkill never hurt anyone...

Reminds me of the classic JBL brochure copy "Steep wavefronts of explosive loudness are taken in stride..."

But a 1" throat should be more than adequate.

Nice woodwork by the way, where are you in 'straya?

Best wishes

David

Last edited:

How about a conventional tweeter? Horn loaded you could get to 1K. Something like the Wavecor TW030A05 comes to mind.

Nice woodwork by the way, where are you in 'straya?

Cheers. The 'nice' is mainly the result of using 19mm timber for the skin. This gives a lot of slop factor, so If I make a mistake, I can usually can grind / sand it back until it looks nice.

I want to make my next project a lot lighter, so I'll have to be a lot more precise.

I'm in Melbourne.

How about a conventional tweeter? Horn loaded you could get to 1K. Something like the Wavecor TW030A05 comes to mind.

Their own (mildly) horn loaded designs look pretty solid, so maybe.

Test Bench: Wavecor TW030WA12 30-mm Cloth Waveguide Loaded Tweeter

The Tymphany XT25TG30-04 is cheaper, and seem similarly robust, so I'd probably use something like that as a test mule if I tried this option 🙂

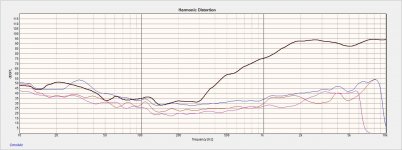

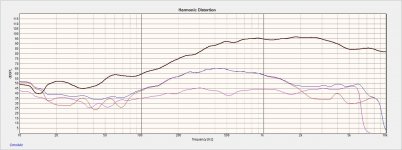

Measurements of the XT25 on a waveguide

Test Peerless / Tymphany XT25TG-30/04 (XT-300/K4) am Waveguide WG-300 / PCT-300 – Heissmann Acoustics

Test Peerless / Tymphany XT25TG-30/04 (XT-300/K4) am Waveguide WG-300 / PCT-300 – Heissmann Acoustics

NO need to extend the horn back, just do a new contour with the desired mouth and throat sizes.For the horn, I previously wanted to run a 4" or 5" driver from 400Hz-15kHz (ish). Since drivers this size have breakup <10kHz, I am considering keeping the horn essentially the same, but extending the throat to take a smaller wideband driver, or switch to a compression driver.

Because the horn and baffle are continuous (and for aesthetics, I'd like to keep them this way), I'd like a HF driver that can easily be mounted from behind. I think this rules out bolt-on compression drivers.

Problem: I don't think any cover a wide enough range - phenolic diaphragms don't go high enough, titanium diaphragms don't go low enough.

I mount my CD from the back, just use and intermediary plate. The hole in the center must be part of the waveguide, but that's not so hard to do. I started using aluminium, and then plexiglass and finally polycarbonate, which works great.

I think that you will find that no direct radiating driver on a horn is going to have as great a bandwidth as a compression driver matched to a good waveguide. Mine cover well over a decade and that is a lot of bandwidth for a HF device with complete pattern control.

PS. The system that you show looks a lot like all my designs. You might want to consider my experience over 20 years making nearly identical designs and seven different models brings to the party.

Last edited:

I used the XT in my synergy horn and I think it would be a great test. Recently I'm enamored with the quality of the Wavecor tweeters.

For now, I wish to continue using found objects* for the horn. In the photo, the majority of the horn is a Sekin bowl from Ikea. This sets a ~30cm mouth and 65 degree coverage angle. It isn't very deep, and the 'throat' of the bowl is about 12cm across, so I need some sort of extender if I want to mount any CD or small driver on it.NO need to extend the horn back, just do a new contour with the desired mouth and throat sizes.

I may eventually try something else - like making a full horn from wood petals, or maybe I'll give up on the wood aesthetic and simply use a prebuilt horn.

I think that you will find that no direct radiating driver on a horn is going to have as great a bandwidth as a compression driver matched to a good waveguide. Mine cover well over a decade and that is a lot of bandwidth for a HF device with complete pattern control.

Hmmm. Some people happily run robust tweeters / small direct radiators in horns / the apex of Synergy clones. They are obviously getting the bandwidth.

What's the difference? I'm honestly curious, not asking just to be difficult. Is it mostly a question of peak SPL capability, because the CD has a 44mm voice coil and the tweeter only 25-30mm?

PS. The system that you show looks a lot like all my designs. You might want to consider my experience over 20 years making nearly identical designs and seven different models brings to the party.

Yea, the experience is appreciated. Over the past few days, I've trawled through a stack of your posts and some of your formal writing.

The visual resemblance to your designs was not lost on me. The drivers are very different (lower efficiency, 4" and 12") but the layout + low diffraction cabinet has enough convergence to make them look alike. The changes I'm considering** would make it more so - particularly if I use a foam plug to hide the plastic-to-wood transition in the horn.

Hunting for more driver info, it seems that the the PRV Audio D290Py-S and similar units are all considered to be copies of the B&C driver that you've used. You previously said that some of these are good ('comparable' to the B&C). Is there any reason the PRV driver wouldn't be good too - is anything actually wrong with the screw-on format?

*I have a cache of random objects, that I've put aside as potentially useful to cast horn parts from.

**or some of them. I may try a few more options before I settle.

I used the XT in my synergy horn

Do you run it to 1kHz? Have you posted pix / measurements somewhere?

I didn't find your rig, John H, but I found the Parts Express 'official' Synergy clone (which uses the Tymphany XT25TG30-04):

Synergy Horn | Parts Express Project Gallery

I like the clean, industrial look. The builder seems to have cut a few corners (square throat, single flare), but is neat & seems well thought out.

This is the disappointing part: "Efficiency is about 86 dB at 2.83 V rms."

bwaslo's "Small syns" on this forum is essentially the same thing (driver layout and budget), except he uses a cheap compression driver on a prebuilt horn (with lots of filler, which is very much my style), and his system is 7dB more sensitive (which is also to my taste).

Synergy Horn | Parts Express Project Gallery

I like the clean, industrial look. The builder seems to have cut a few corners (square throat, single flare), but is neat & seems well thought out.

This is the disappointing part: "Efficiency is about 86 dB at 2.83 V rms."

bwaslo's "Small syns" on this forum is essentially the same thing (driver layout and budget), except he uses a cheap compression driver on a prebuilt horn (with lots of filler, which is very much my style), and his system is 7dB more sensitive (which is also to my taste).

Last edited:

The efficiency is for the entire design, which is a function of the woofer baffle step compensation. The XT for your test is a function of the tweeter, 90ish depending on the model.

Square throat was tested, http://www.diyaudio.com/forums/mult...e-bandpass-mid-unity-horn-44.html#post5163719

There's a build thread in tech talk here Synergy horn build - Techtalk Speaker Building, Audio, Video Discussion Forum.

Square throat was tested, http://www.diyaudio.com/forums/mult...e-bandpass-mid-unity-horn-44.html#post5163719

There's a build thread in tech talk here Synergy horn build - Techtalk Speaker Building, Audio, Video Discussion Forum.

Well there's bandwidth and there's bandwidth, my point was "well controlled" bandwidth, which you won't get from a non-compression device. The reason is the phase plug. Compression drivers have a sophisticated phase plug which allows for a much better controlled wave front than not having one allows. A direct radiating device into a waveguide will not have a very well controlled high end because of the lack of a phase plug. There will be lots of HOM and other frequency aberrations both on-axis and most notably off axis. Lots of things are factors here and so some situations are better than others, but the bottom line is that compression drivers are designed to be on waveguides and do this job best.Hmmm. Some people happily run robust tweeters / small direct radiators in horns / the apex of Synergy clones. They are obviously getting the bandwidth.

What's the difference? I'm honestly curious, not asking just to be difficult. Is it mostly a question of peak SPL capability, because the CD has a 44mm voice coil and the tweeter only 25-30mm?

Hunting for more driver info, it seems that the the PRV Audio D290Py-S and similar units are all considered to be copies of the B&C driver that you've used. You previously said that some of these are good ('comparable' to the B&C). Is there any reason the PRV driver wouldn't be good too - is anything actually wrong with the screw-on format?

I can't speak to individual units - I don't have any data - and I suppose it would be possible to do a proper screw-on format, I just don't like that kind of connection. I don't understand why saving a few dollars buying a second rate driver over the B&C is worth it. Is your time worth so little? That's where the real investment is.

In the old days with drivers with massive magnets, screw-on just didn't have enough strength. With neo I suppose it could be done, but still this is a weak point. The throat on my waveguides is about 6 inches across, a legacy I suppose, but still there isn't going to be any motion of the driver on that mount. A heavy driver on a small mounting just sounds too weak for my taste. Even the neo drivers have quite a bit of steel and some decent mass. Ceramic get pretty heavy. A DE250 on a screw mount would be way too flimsy.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- seeking rear mounted driver for front horn

![IMAG1170[1].jpg](/community/data/attachments/585/585179-8ae23b33f89bcc233626afb9679338c6.jpg?hash=iuI7M_ibzC)

![IMAG1174[1].jpg](/community/data/attachments/585/585192-841824e4578f23ec7e05b5c519fdece2.jpg?hash=hBgk5FePI-)