Hello,

I ordered a mini passive radiator from Alibaba and i am thinking way to measure the stiffness (the definite value and not the curve of suspension creep), could you please suggest me the easiest and approximate method to find this. You should guess that since it is from Alibaba i am not looking fo very expensive solutions like Klippel System.

I was thinking of designing a box with a small loudspeaker to get the helmholtz resonance, then with the mass of the passive diaphragm along with airload subtraction to find the stiffness. Could you please let me know what do i need to update in this method to get the closely accurate stiffness.

Or using some kind of exciter/shaker to find the mechanical resonance by clamping the passive radiator.

Best Regards,

I ordered a mini passive radiator from Alibaba and i am thinking way to measure the stiffness (the definite value and not the curve of suspension creep), could you please suggest me the easiest and approximate method to find this. You should guess that since it is from Alibaba i am not looking fo very expensive solutions like Klippel System.

I was thinking of designing a box with a small loudspeaker to get the helmholtz resonance, then with the mass of the passive diaphragm along with airload subtraction to find the stiffness. Could you please let me know what do i need to update in this method to get the closely accurate stiffness.

Or using some kind of exciter/shaker to find the mechanical resonance by clamping the passive radiator.

Best Regards,

Attachments

I've done this by using a test speaker box with a woofer driver and a hole for passive radiator that can also be sealed with a piece of plywood or something solid.

Then I'll measure the woofer in sealed box and then install the PR and measure again.

woofertester.com

Woofertester 2 has capability to simulate sealed box and PR loaded box..

So one would use it first to model a speaker/box parameters so that the closed box simulation matches the measurement done. Then using the same speaker data / box size one would choose the PR box simulation and again tune the PR parameters until it matches the measured curves (some parameters like surface area of PR you'd have to measure and calculate manually of course).

Same could be done with LspCad for sure and probably with Soundeasy and maybe with VituixCAD.

Then I'll measure the woofer in sealed box and then install the PR and measure again.

woofertester.com

Woofertester 2 has capability to simulate sealed box and PR loaded box..

So one would use it first to model a speaker/box parameters so that the closed box simulation matches the measurement done. Then using the same speaker data / box size one would choose the PR box simulation and again tune the PR parameters until it matches the measured curves (some parameters like surface area of PR you'd have to measure and calculate manually of course).

Same could be done with LspCad for sure and probably with Soundeasy and maybe with VituixCAD.

I've done this by using a test speaker box with a woofer driver and a hole for passive radiator that can also be sealed with a piece of plywood or something solid.

Then I'll measure the woofer in sealed box and then install the PR and measure again.

woofertester.com

Then using the same speaker data / box size one would choose the PR box simulation and again tune the PR parameters until it matches the measured curves (some parameters like surface area of PR you'd have to measure and calculate manually of course).

.

Hello Ergo thank you for your reply, when you mention of making measurements is it the impedance measurements?

Thank you speaker doctor for the documents i will look into it, i am hesitant of purchasing the standard IEC 62459:2010 for stiffness measurement dont knw how much of importance it has

One of the true measures of a driver's stiffness is its compliance. Thiele/Small parameters include two measures of compliance. Cms meas. in units of micro-meters/Newton and Kms meas. in units of Newtons/meter. These have been around for many, many years. The numerical output of the WT2 test mentioned earlier includes those two T/S parameters.

Quick

The passive radiator comes with a set of weights for tuning. Weigh them. Then with the radiator face down, take displacement measurements with different amounts of weight added. The rest is just some math to get the compliance values which you may average if they fall on a materially linear path.

N.B., for best results, SD of the passive radiator should be 2 x the SD of the bass driver(s).

WHG

Hello,

I ordered a mini passive radiator from Alibaba and i am thinking way to measure the stiffness (the definite value and not the curve of suspension creep), could you please suggest me the easiest and approximate method to find this. You should guess that since it is from Alibaba i am not looking fo very expensive solutions like Klippel System.

I was thinking of designing a box with a small loudspeaker to get the helmholtz resonance, then with the mass of the passive diaphragm along with airload subtraction to find the stiffness. Could you please let me know what do i need to update in this method to get the closely accurate stiffness.

Or using some kind of exciter/shaker to find the mechanical resonance by clamping the passive radiator.

Best Regards,

The passive radiator comes with a set of weights for tuning. Weigh them. Then with the radiator face down, take displacement measurements with different amounts of weight added. The rest is just some math to get the compliance values which you may average if they fall on a materially linear path.

N.B., for best results, SD of the passive radiator should be 2 x the SD of the bass driver(s).

WHG

mh-audio.nl - Home

A passive radiator weight calculator.

H9944 SP18R

This is the Seas PR weight chart at this link for one model PR. You'll have to enterpolate for your radiator size.

A passive radiator weight calculator.

H9944 SP18R

This is the Seas PR weight chart at this link for one model PR. You'll have to enterpolate for your radiator size.

Last edited:

Hello,

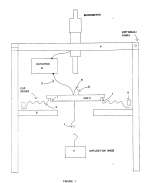

Thank you all for your reply and suggestion, i just want to clear that my concern is not to tune the passive radiator. i am looking for a 80/20 measurement method for the Kms/Cms of the surround mini passive radiator posted. I would like to get back to SpeakerDoctor about the standard you posted by ALMA for measuring the stiffness it was a great read. Thank you very much for that. I have a question regarding the added mass technique, first of all have you tried this method?. anyways could you please help me understand the relation between Cap 'C', Detector 'G' , E and the micrometer used. I am not being able to follow how can we hang the cap ' C 'in air less then a 1mm/2mm without causing much deformation to the surround. Is there a way around?

Best Regards,

Thank you all for your reply and suggestion, i just want to clear that my concern is not to tune the passive radiator. i am looking for a 80/20 measurement method for the Kms/Cms of the surround mini passive radiator posted. I would like to get back to SpeakerDoctor about the standard you posted by ALMA for measuring the stiffness it was a great read. Thank you very much for that. I have a question regarding the added mass technique, first of all have you tried this method?. anyways could you please help me understand the relation between Cap 'C', Detector 'G' , E and the micrometer used. I am not being able to follow how can we hang the cap ' C 'in air less then a 1mm/2mm without causing much deformation to the surround. Is there a way around?

Best Regards,

Attachments

Last edited:

Thank you whg for the suggestion but i need something quite precise to measure the displacement for the size of the passive radiator i am working withThe passive radiator comes with a set of weights for tuning. Weigh them. Then with the radiator face down, take displacement measurements with different amounts of weight added. The rest is just some math to get the compliance values which you may average if they fall on a materially linear path.

N.B., for best results, SD of the passive radiator should be 2 x the SD of the bass driver(s).

WHG

I was thinking if i ignore many points on the measurement setup(Cap) and just clamp the passive radiator, i have to find a way to attach the weight on its plate (use the weight of the plate and the additional weight as variable) and just need to find a clever way to make accurate displacement measurement as shown on the top half of the standard procedure. Could be a work around?

i found something very interesting for measuring displacement, let me knw what you think of it. Its called pepitas manufactured by Mitutoyo ,Japan and has accuraccy of 1/100 of mm and works with contact method. I could add weight measure displacement then subtract from the reference

Attachments

Hello Ergo thank you for your reply, when you mention of making measurements is it the impedance measurements?

Yes, my method is suggesting impedance measurements. Woofertester will allow extracting T/S parameters from those and simulate acoustic SPL also. So with that process you'll also get an idea what you acoustic SPL will be in end.

As for the dial indicator - thats a good option indeed. I bought one for

Indikaator 0-10 mm (0.01 mm) Diam. 58 mm INSIZE 2308-10A

23.44 eur

So don't buy too expensive brand for the casual hobby use.

Hello,

Thank you all for your reply and suggestion, i just want to clear that my concern is not to tune the passive radiator. i am looking for a 80/20 measurement method for the Kms/Cms of the surround mini passive radiator posted.

I posted how to get Vap. To get the compliance or stiffness, you just realize that Vap=Cmp*rho*Sp^2

Kmp = 1/Cmp

Relatively simple.

You can use displacement to get stiffness, it is kind of a trivial concept that should need no ALMA paper to dream up, but it is likely strongly nonlinear and the measurement is a bit more difficult to set up. Using a loudspeaker instead of a passive ( and an adjustable DC current source) you can use the micrometer rig to measure both Cms and Bl directly

I posted how to get Vap. To get the compliance or stiffness, you just realize that Vap=Cmp*rho*Sp^2

Kmp = 1/Cmp

If you want to measure Fp and Vap:

First measure (from a distance of a couple feet) the very low frequency response of the PR and woofer in a test box of volume Vb. Look for a minimum in frequency response. That is Fp, and it can be rather hard to measure. In that same box, measure teh impedance and find the frequency of the minimum in the saddle. Call that Fb.

The Vap of the PR is defined by:

Fb/Fp=sqrt(Vap/Vb+1)

so: Vap=((Fb/Fp)^2-1)*Vb

Hello Ron E, Thank you for your reply i added your prev meas method too, your idea of finding the Kmp could be the simplest but the only problem is only meas i can make is the very nearfield meas and from there i can find the accurate Fb by looking at the notch in NF meas of the driver, if i move couple feet away the whole meas is contaminated. The only method that i trust, would work for me would be the Hooke's law so more of mech meas then acoustical one. I have one idea i would like to confirm it here if it is really quite accurate after i make a meas but its again the disp meas in linear region.

Best Regards,

Yes, my method is suggesting impedance measurements. Woofertester will allow extracting T/S parameters from those and simulate acoustic SPL also. So with that process you'll also get an idea what you acoustic SPL will be in end.

As for the dial indicator - thats a good option indeed. I bought one for

Indikaator 0-10 mm (0.01 mm) Diam. 58 mm INSIZE 2308-10A

23.44 eur

So don't buy too expensive brand for the casual hobby use.

Hello Ergo,

Thanks for your reply, yes thanks for the impedance meas method and corelating with simulation i though of that but i just need to be sure of the air load which is affected by the dimension of PR because the saddle in the impedance curve is more of Fb then Fp, so i am little reluctant to try that.

Could you please send me the link of the dial indicator you are refering. I dont knw if that the dial indicator adds a force to the plate too while making a meas.

Best Regards,

Another way to obtain stiffness: tap the cone and measure the resonance frequency using a microphone and software like Audacity, while the basket is firmly secured to a baffle or something. Cone mass must be known.

omega = sqrt(k/m)

omega = angular frequency = 2*pi*frequency, k = stiffness = 1/compliance, m = cone mass.

This assumes damping is close to zero, which is a reasonable approximation for a passive radiator.

omega = sqrt(k/m)

omega = angular frequency = 2*pi*frequency, k = stiffness = 1/compliance, m = cone mass.

This assumes damping is close to zero, which is a reasonable approximation for a passive radiator.

Last edited:

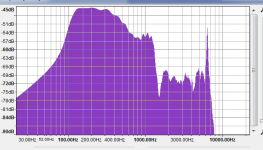

Another way to obtain stiffness: tap the cone and measure the resonance frequency using a microphone and software like Audacity, while the basket is firmly secured to a baffle or something. Cone mass must be known.

omega = sqrt(k/m)

omega = angular frequency = 2*pi*frequency, k = stiffness = 1/compliance, m = cone mass.

This assumes damping is close to zero, which is a reasonable approximation for a passive radiator.

Hello TBTL,

Thank you for your Reply, i tried this test quicky using the mic of laptop i would hold hand in the air in the name of physics if this worked. this is what i got.

BR

Attachments

Hello,

I ordered a mini passive radiator from Alibaba and i am thinking way to measure the stiffness (the definite value and not the curve of suspension creep)...

Best Regards,

Hi, what is the driver unit that you are working with? A single mini PR will probably translate into being too small to make an appropriate loading, so try using as many until you get better results by experimenting.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Measuring Surround of passive radiator.