You are the one that described it as being asymmetrical 😀. It's my favourite from all the graphs presented due to knocking down the impedance bump, moving it to the left the most and smoothing out the 200-400 Hz area.

There's nothing in that graph that would prevent me from running it like that. I've got to remember this is 5 drivers. Final impedance bump would be even lower.

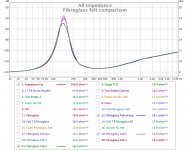

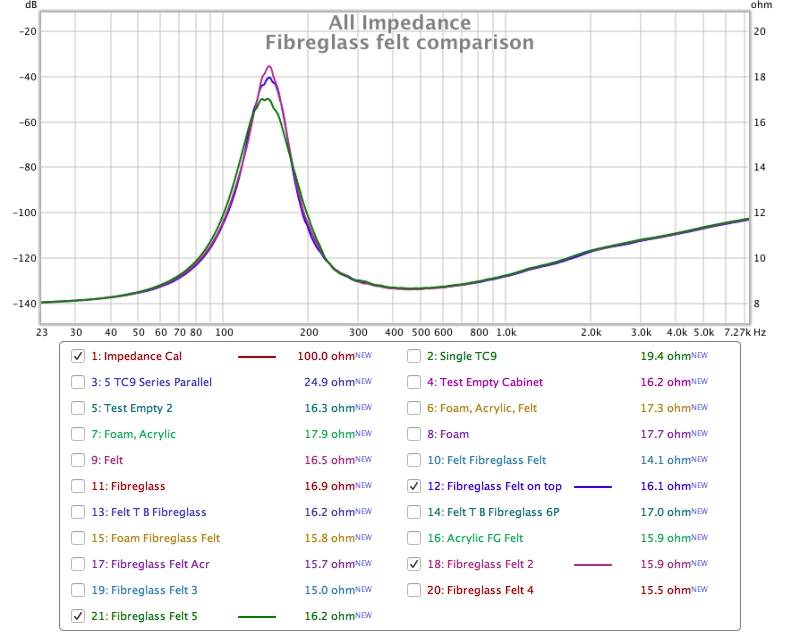

I was also eyeing the slight knee at 700-800 Hz (I remember having that) and the shape around 200 Hz. The blue one seems best overall.

There's nothing in that graph that would prevent me from running it like that. I've got to remember this is 5 drivers. Final impedance bump would be even lower.

I was also eyeing the slight knee at 700-800 Hz (I remember having that) and the shape around 200 Hz. The blue one seems best overall.

You are the one that described it as being asymmetrical 😀. It's my favourite from all the graphs presented due to knocking down the impedance bump, moving it to the left the most and smoothing out the 200-400 Hz area.

There's nothing in that graph that would prevent me from running it like that. I've got to remember this is 5 drivers. Final impedance bump would be even lower.

I was also eyeing the slight knee at 700-800 Hz (I remember having that) and the shape around 200 Hz. The blue one seems best overall.

Then I think we are talking at cross purposes and maybe it's the colours on my REW graphs that is the cause as they keep changing. I have made some new measurements so I will try again, maybe it will be easier to see what I am talking about this time 😱

The 5 drivers are wired differently so they have a higher impedance overall by an ohm or two, much peakier as well, the 25 should be much better behaved.

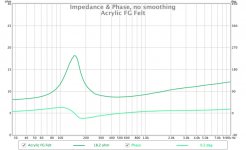

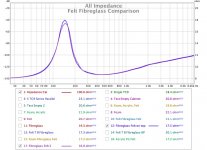

I tried a number of different materials behind the fibreglass and felt to see if it could be improved. It couldn't they were all worse.

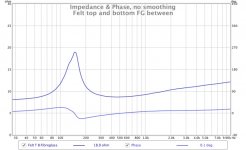

Felt on top and bottom of fibreglass

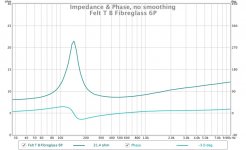

As above but with 6 pieces of fibreglass not 8

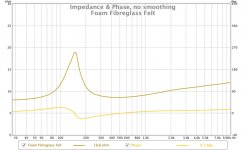

Foam behind fibreglass felt on top

Acrylic behind fibreglass felt on top

8 pieces of fibreglass felt on top, this was meant to be a confirmation of my previous result but it has depressed the peak more and moved it very slightly higher. I will need to check but it looks like before I must have had seven pieces of fibreglass not eight.

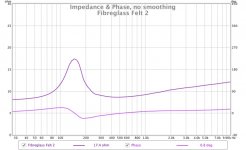

Comparison of the two felt and fibreglass measurements, I think the purple is more symmetrical when looking at phase, which one is better this time?

Attachments

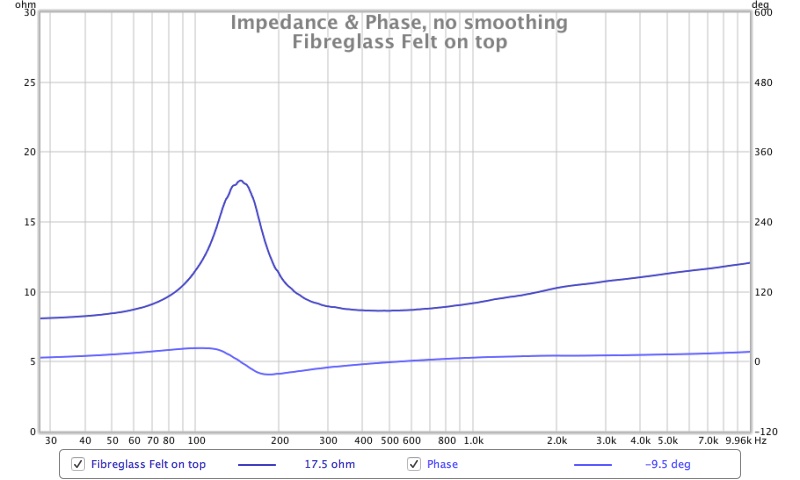

No 12, Fiberglass Felt on top. The purple has too much of a bend at ~250 Hz. The dark blue one seems smoother there?

Also seems true when looking at the smoothness of the phase curve:

Also seems true when looking at the smoothness of the phase curve:

No 12, Fiberglass Felt on top. The purple has too much of a bend at ~250 Hz. The dark blue one seems smoother there?

Also seems true when looking at the smoothness of the phase curve:

I agree that the No12 measurement is the smoothest in magnitude and phase, I was hoping for a greater reduction to the peak but it seems to come at a cost elsewhere.

Tomorrows job is trying to recreate that measurement repeatably 🙂

I also wanted to say thanks for prompting me to do this as the results have been helpful and different than I thought. The right amount and combination of damping materials that will give the smoothest impedance is more variable than I thought.

Well I found the reason why the fibreglass and felt 2 measurement didn't match well. I had left a piece of acrylic on the bottom of the cabinet!

I couldn't exactly replicate the No12 curve, the closest I could get was the same shape with with a slightly higher peak.

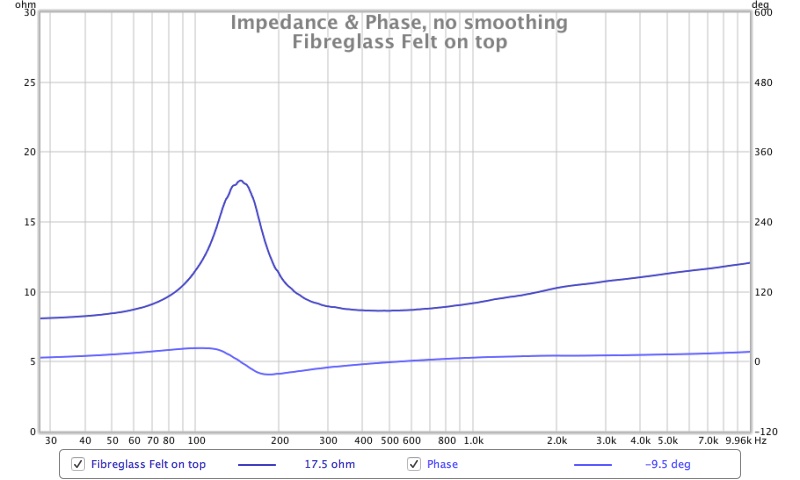

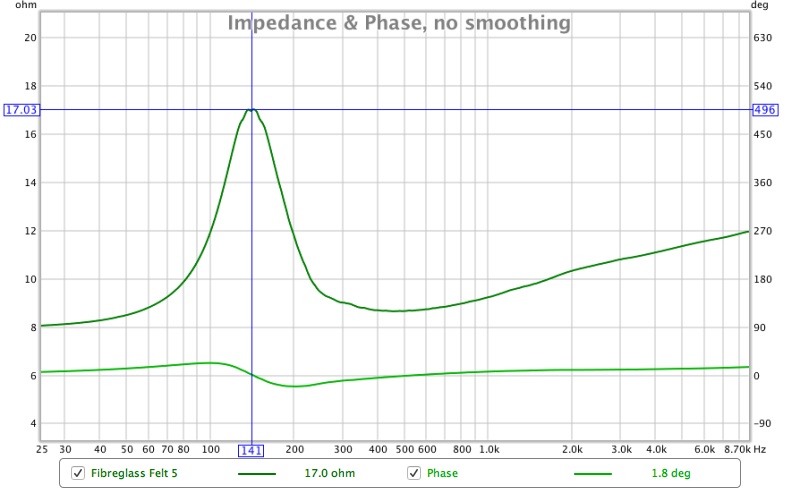

My favourite is actually with less pieces of fibreglass but with the layers stretched out a bit so it is a bit more fluffy and less compressed. The peak is lower in magnitude and frequency, looks smooth and very symmetrical.

Using pieces that were a slightly different size resulted in more change than I was expecting. For the final build I will make a template so the pieces are all much closer in size. I have made the separate spaces inside the cabinet exactly the same so I don't want to spoil that any more than necessary with inconsistent damping.

I have found something about the binding posts that annoys me. Why would you make a binding post that doesn't have a standard banana plug go all the way in?

I can fix the them in like this as an alternative, I'm not sure it's enough for me to use the speakon connectors but still...

I couldn't exactly replicate the No12 curve, the closest I could get was the same shape with with a slightly higher peak.

My favourite is actually with less pieces of fibreglass but with the layers stretched out a bit so it is a bit more fluffy and less compressed. The peak is lower in magnitude and frequency, looks smooth and very symmetrical.

Using pieces that were a slightly different size resulted in more change than I was expecting. For the final build I will make a template so the pieces are all much closer in size. I have made the separate spaces inside the cabinet exactly the same so I don't want to spoil that any more than necessary with inconsistent damping.

I have found something about the binding posts that annoys me. Why would you make a binding post that doesn't have a standard banana plug go all the way in?

I can fix the them in like this as an alternative, I'm not sure it's enough for me to use the speakon connectors but still...

Attachments

Fiberglass comes in different densities.

You could try to find lower density fiberglass, preferably the rigid type, then you would not have to average out the density by fluffing it out.

You could try to find lower density fiberglass, preferably the rigid type, then you would not have to average out the density by fluffing it out.

What speaks against Speakon?

Do you mean what is a Speakon?

It is a professional loudspeaker connector by Neutrik like this

Attachments

Fiberglass comes in different densities.

You could try to find lower density fiberglass, preferably the rigid type, then you would not have to average out the density by fluffing it out.

Nice thought but I will be using the stuff that I have. It was very cheap which is why I bought it and not at all easy for me to get hold of a different type. Again due to my location and the physical size of the stuff.

Awesome build fluid. I've been dabbling with the idea of building a line array but my current space and financial situation prohibits it. Good luck to you... 🙂

Those speaker posts are painted injection-molded zinc, the best attribute is the low price. They sound horrible and they will snap like chalk if you tighten them to the cabinet too tight. Then you can see the gray metal. For all the effort in your project, at least get some brass posts, or only use these to clamp wires directly together.

Do you mean what is a Speakon?

It is a professional loudspeaker connector by Neutrik like this

http://www.diyaudio.com/forums/attachment.php?[/QUOTE]

I believe GKH question was rather: what do have against Speakon?

Me personally I hate those banana plugs for speaker plugs. It's very easy to short your amp with those things.

With Speakon this is impossible. And they are build to carry very large currents. I use them in all my amp builds.

Thanks! I hope you find the funds to get started.Awesome build fluid. I've been dabbling with the idea of building a line array but my current space and financial situation prohibits it. Good luck to you... 🙂

I think we've been over this before, but I agree the fact that I have put a lot of effort is a good reason to make sure the connector is the right one.Those speaker posts are painted injection-molded zinc, the best attribute is the low price. They sound horrible and they will snap like chalk if you tighten them to the cabinet too tight. Then you can see the gray metal. For all the effort in your project, at least get some brass posts, or only use these to clamp wires directly together.

I believe GKH question was rather: what do have against Speakon?

Me personally I hate those banana plugs for speaker plugs. It's very easy to short your amp with those things.

With Speakon this is impossible. And they are build to carry very large currents. I use them in all my amp builds.

Then it must be a language barrier. I have nothing against speakons and they are the alternative I am considering using. I have a shoe box full of speakons they are very good connectors.

The safety of the connectors is one of their benefits but I'm very careful in how I connect and disconnect equipment so it's not an issue for me.

If you want to plug your amp into your speaker while it's turned on then use a speakon because they connect ground before power 😀

The main reason I am hesitating to use the speakons is that I will need to drill a fairly big hole in the cabinet to fit, then plug the other's. I can do it but it is harder now I have glued most of one cabinet together. The other is that I will have to have a bigger hole in the fabric sock at the back to fit the connector through.

I think we've been over this before, but I agree the fact that I have put a lot of effort is a good reason to make sure the connector is the right one.

Yup, and I promise not to harass you anymore! 😀

Looking good, fluid!

Yup, and I promise not to harass you anymore! 😀

Looking good, fluid!

Thanks 🙂

I have some spare binding posts that I used on my amplifier that I showed earlier on. These are gold plated brass and I have also considered using them. Their issue is the thread length. I tested them on a scrap piece of mdf last night but I'm not convinced I like that compromise either.

Do you mean what is a Speakon?

It is a professional loudspeaker connector by Neutrik like this

Working in pro audio since the early 80s, I have seen one or two of them 😀 Iwanted to say why don't YOU use Speakon?

I'm sure you have 🙂 Here is my box of spare speakons just to prove I like them too 😉Working in pro audio since the early 80s, I have seen one or two of them 😀 Iwanted to say why don't YOU use Speakon?

Reason:

The main reason I am hesitating to use the speakons is that I will need to drill a fairly big hole in the cabinet to fit, then plug the other's. I can do it but it is harder now I have glued most of one cabinet together. The other is that I will have to have a bigger hole in the fabric sock at the back to fit the connector through.

These are the other binding posts I have with the plastic taken off. I could counterbore a 17mm hole to sink them in a bit on the outside or counterbore on the inside to give more space for the nut and then put the bare wire into the post and use the grub screw to tighten. I would still need to drill out the holes as these are 8mm thread not 6mm.

If anyone has an opinion now is the time to share it 😀

Attachments

Must have missed the original post, sorry.

Nice heap of spares 😀

I'd opt for the Speakons; they're a PITA to drill, but then they're just great.

Nice heap of spares 😀

I'd opt for the Speakons; they're a PITA to drill, but then they're just great.

I have never even seen a Speakon connector in real life. It seems high end to mid tier equipment uses Banana plugs and low end to some mid teir equipment uses spring terminals. With binding posts, you can use either bare unterminated wire or banana plugs.I'm sure you have 🙂 Here is my box of spare speakons just to prove I like them too 😉

Reason:

These are the other binding posts I have with the plastic taken off. I could counterbore a 17mm hole to sink them in a bit on the outside or counterbore on the inside to give more space for the nut and then put the bare wire into the post and use the grub screw to tighten. I would still need to drill out the holes as these are 8mm thread not 6mm.

If anyone has an opinion now is the time to share it 😀

I understand Speakons have use in Pro audio for high power applications, but my opin is if some random person goes to hook up equipment and sees this, there will be a head scratching moment.

I would just go with 5-way binding posts myself. More secure than spring terminals for bare wires, and it accepts banana plugs too. Let's face it, you're not going to be hot plugging cables while the amp is live, so shorts are not an issue unless you're careless with your hookups, and a well designed modern amp will shut down or go into protect mode if this happens.

If you're planning on hot-plugging live cables, then by all means use a speakon. I wouldn't recommend doing it though since if there's a voltage differential across the filter cap to the terminal, you'll get a loud pop which could damage speakers, or even damage hearing when dealing with PA level signals.

As for drilling holes, I have found most "panel mount" accessories (especially from the 'shack) are meant for up to 1/8" (3mm) wall thickness. Some have threads that allow up to 1/4" (6mm). Just get a router and a 1/4" bit and set the depth such that the threaded portion of the part passes through to the other side, only far enough to allow secure connection. Then route around the hole until it's wide enough to accept the body of the part. That's how I connect hookups in thick panels anyhow.

Of course, you have an entire box full of Speakon terminals, might as well use them up.

Last edited:

- Home

- Loudspeakers

- Full Range

- Full Range TC9 Line Array CNC Cabinet