BOM Questions for Kypton ND build

I am finally putting together a BOM for a Kypton-ND2 build. I've got the boards layout by jWilhelm 9/9/15.

Slewmaster boards were a group by from evanc and are marked ARC WELDER Edition 3.1 8/2/15.

The three files I'm looking at for part values are what I believe are OS's final schema for Kypton-ND marked as version 1.1.

Next I've got a CSV ... marked as Kypton-ND2 to which evanc referred me.

Last file I'm looking at for reference is "Kypton-ND resistor selection.pdf"

Now here is the question, between all these references resistance values are different for:

R10 / R11

R12 / R13

R14 / R15

R16 / R17

As examples between the 70V column of the "Kypton-ND resistor selection.pdf" and Kypton-ND2 CSV file. I believe OS modeled all these values based on 72V Rails so perhaps the values listed in the "Kypton-ND resistor selection.pdf" are to compensate for 70 volt rails instead of 72v ?

The only real difference I've noticed between the Kypton-ND v1.1 schema and the Kypton-ND2 CSV is R20/R21 are listed as R15 on the CSV and R47 on the schema.

Any advice on how to pick ideal values would be appreciated. As for my intent in terms of rails ... I have some 46V Transformers that create 67V Rails supply already.

Wondering if I'm after the ideal here if I shouldn't buy new ones that would create 72v on the dot ... I think a while ago I asked OS what he felt and he advised to go for the big time with 80V rails.

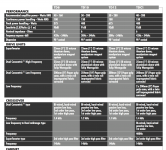

All of this is plenty of power for my speakers as I have Tannoy Dimension 8" and TDC. Specs attached. I also considered bi-amping with the Spooky for Mid and bass with kypton for high end.

Best Regards,

Theo

I am finally putting together a BOM for a Kypton-ND2 build. I've got the boards layout by jWilhelm 9/9/15.

Slewmaster boards were a group by from evanc and are marked ARC WELDER Edition 3.1 8/2/15.

The three files I'm looking at for part values are what I believe are OS's final schema for Kypton-ND marked as version 1.1.

Next I've got a CSV ... marked as Kypton-ND2 to which evanc referred me.

Last file I'm looking at for reference is "Kypton-ND resistor selection.pdf"

Now here is the question, between all these references resistance values are different for:

R10 / R11

R12 / R13

R14 / R15

R16 / R17

As examples between the 70V column of the "Kypton-ND resistor selection.pdf" and Kypton-ND2 CSV file. I believe OS modeled all these values based on 72V Rails so perhaps the values listed in the "Kypton-ND resistor selection.pdf" are to compensate for 70 volt rails instead of 72v ?

The only real difference I've noticed between the Kypton-ND v1.1 schema and the Kypton-ND2 CSV is R20/R21 are listed as R15 on the CSV and R47 on the schema.

Any advice on how to pick ideal values would be appreciated. As for my intent in terms of rails ... I have some 46V Transformers that create 67V Rails supply already.

Wondering if I'm after the ideal here if I shouldn't buy new ones that would create 72v on the dot ... I think a while ago I asked OS what he felt and he advised to go for the big time with 80V rails.

All of this is plenty of power for my speakers as I have Tannoy Dimension 8" and TDC. Specs attached. I also considered bi-amping with the Spooky for Mid and bass with kypton for high end.

Best Regards,

Theo

Attachments

Your transformer voltage is fine. With these inputs you are best to go dual power supply to eliminate ground loops though. The Kypton-ND VAS current will vary at different rail voltage and with different builds You need to adjust some of the resistance values to suit your actual build. The chart I put together was just a starting point. Once you have the input powered up, warmed up and burned in you will need to take some current flow measurements of the input board, and may need to change some of these resistance values to make yours operate properly.

Is there a process documented in the thread some place ?

Has someone called out the values of particular resistors that typically need adjustment?

I would rather exactly match up with what OS expected in his design then have to test around with different values.

If I had a 72V rails do you think I'd still have to adjust values? I suppose there will be differences in the Diodes and Q's.

I believe for the LED's 1.7v and 2ma type or expected.

Anything else I should read, think about etc before ordering parts?

Has someone called out the values of particular resistors that typically need adjustment?

I would rather exactly match up with what OS expected in his design then have to test around with different values.

If I had a 72V rails do you think I'd still have to adjust values? I suppose there will be differences in the Diodes and Q's.

I believe for the LED's 1.7v and 2ma type or expected.

Anything else I should read, think about etc before ordering parts?

Your transformer voltage is fine. With these inputs you are best to go dual power supply to eliminate ground loops though. The Kypton-ND VAS current will vary at different rail voltage and with different builds You need to adjust some of the resistance values to suit your actual build. The chart I put together was just a starting point. Once you have the input powered up, warmed up and burned in you will need to take some current flow measurements of the input board, and may need to change some of these resistance values to make yours operate properly.

Ostripper gives an explanation here on how to test and adjust these inputs. http://www.diyaudio.com/forums/solid-state/260268-slewmaster-builds-132.html#post4507148 In the following 20 pages there are more explanations.

I would use the transformers you have. There will be current flows that need to be adjusted for due to differences in transistors.

Trying to break it down a bit for the layman

Let me see if I can interpret what OS is saying in his K-ND-101 post:

Basically if you have 12v Zener you should see exactly 1ma of current across R4/7, if not the value of R4/7 can be adjusted up or down to achieve 1ma of current.

This in effect should set 2ma according to Kypton-ND 1.1 schema to 2ma across R10/11 ... these values can be played with if not.

The Section B state would be 1.5 x 2ma if 2ma is flowing across R10/11 and would result in 3ma feeding into section C potentially...which then gets knocked down by R18/19...

Need enough current at the end of stage C to be at 5.5ma at the base of Q11/12 and I've got the ratio of R18/22 and R19/29 respectively...the current consumption of the LEDs and the trimmer as methods of adjustment.

Based on this a few questions...

What is the best way to setup these sorts of current measurements in circuit?

Do I simply solder in some trim pots initially for a few of these key resistor adjustment points? Then figure out a nice way of dropping my multi-meter into the circuit?

It would seem that measuring transistor meta before using said transistors would be helpful to get close to the right values from the start.

What voltage should Q1/2 and Q3/4 be tested at? Would this be supply voltage or 12V?

How about hfe of the transistors...should I try and match up as close as possible to the schema for example BC550/560 seem to be C rated.

Q3 and Q4 seem k rated while Q10/11 are C rated...what is seen as ideal in hfe. I am aware it is important to match Q1/2 and Q3/4 ... both in terms of beta and hfe ?

Best Regards,

Theo

Let me see if I can interpret what OS is saying in his K-ND-101 post:

-section "A" is regulated +/- 12V. R4 and 7 set about 1ma current.

NO way to really change this current or the diamond's current (mirrors) -

Q1/2 - R10/11 will always have that same 1ma I.

If you put 9 or 15V zeners , you might have .7 - 1.3ma (Q1/2 diamond).

Basically if you have 12v Zener you should see exactly 1ma of current across R4/7, if not the value of R4/7 can be adjusted up or down to achieve 1ma of current.

This in effect should set 2ma according to Kypton-ND 1.1 schema to 2ma across R10/11 ... these values can be played with if not.

- Section "B" is the current feedback stage. It might develope 1.5X (or more)

the current of the diamond stage.

The Section B state would be 1.5 x 2ma if 2ma is flowing across R10/11 and would result in 3ma feeding into section C potentially...which then gets knocked down by R18/19...

- Then the "C" stage (VAS) will be the ratio between R18 and R22.

470/100 is 4.7X. 1.4ma (example) will be 1.4 X 4.7 = 6.53ma at R22.

1ma is "bled" off of this for the LED's/Cascode to equal 5.5ma final

current.

R18/22 and R19/29's ratio can be adjusted either by R18= 390-560R or

R22 = 68-100R to set this ratio.

If you are between 6.5ma and 8ma (R22/29) , the extra 1-2.5ma can be

"bled" by the trimmer + resistor (R24/25).

So , Q3's I X R18/22 - LED I (current through R24/25).

PS - Beta differences between Q1/2 and Q3/4 are the only things

that make the math "off". Or a non-12V diamond (Q1/2) supply.

Need enough current at the end of stage C to be at 5.5ma at the base of Q11/12 and I've got the ratio of R18/22 and R19/29 respectively...the current consumption of the LEDs and the trimmer as methods of adjustment.

Based on this a few questions...

What is the best way to setup these sorts of current measurements in circuit?

Do I simply solder in some trim pots initially for a few of these key resistor adjustment points? Then figure out a nice way of dropping my multi-meter into the circuit?

It would seem that measuring transistor meta before using said transistors would be helpful to get close to the right values from the start.

What voltage should Q1/2 and Q3/4 be tested at? Would this be supply voltage or 12V?

How about hfe of the transistors...should I try and match up as close as possible to the schema for example BC550/560 seem to be C rated.

Q3 and Q4 seem k rated while Q10/11 are C rated...what is seen as ideal in hfe. I am aware it is important to match Q1/2 and Q3/4 ... both in terms of beta and hfe ?

Best Regards,

Theo

My way was tedious. I hfe matched the transistors and built according to the schematic then used ohms law to figure the new resistor values one stage at a time. I found the front end very temperature sensitive. A small breeze and the current changed.

Gain isn't critical for the transistors. Input transistors should be matched though. HFE matching from a cheap multimeter or Ebay transistor will get you close enough.

Solder in the resistors listed on the chart that are closest to the voltage you plan to run. Warn up and burn in the input board, then measure the voltage drop across resistors and calculate the current flow from there.

As Evan says, these are temperature sensitive front ends. Wrap your transistor pairs in heat shrink to insulate the from air flow.

Solder in the resistors listed on the chart that are closest to the voltage you plan to run. Warn up and burn in the input board, then measure the voltage drop across resistors and calculate the current flow from there.

As Evan says, these are temperature sensitive front ends. Wrap your transistor pairs in heat shrink to insulate the from air flow.

Have your amps been stable since ?

interested to know your supply voltage and if you saved some of your hfe readings / resistors you used.

interested to know your supply voltage and if you saved some of your hfe readings / resistors you used.

My way was tedious. I hfe matched the transistors and built according to the schematic then used ohms law to figure the new resistor values one stage at a time. I found the front end very temperature sensitive. A small breeze and the current changed.

Have a look here what for thermal contact has been used.http://www.diyaudio.com/forums/solid-state/248105-slewmaster-cfa-vs-vfa-rumble-685.html

Thanks for the advice!

So I can use arctic silver 5 glue between TO-92 devices then heat shrink them?

Have you guys happened across little clips or holders that would allow you to say use a single board for testing by soldering in this "clip or holder" that one could jamb the legs of a transistor into ?

Then I could solder in some adjustable resistors for those locations that matter, jamb in the Transistors...get the resistors close ... let her burn in ... make the required tweaks ... once adjusted pull the transistors and solder in appropriate values for a final board.

Thanks for all the help guys.

So I can use arctic silver 5 glue between TO-92 devices then heat shrink them?

Have you guys happened across little clips or holders that would allow you to say use a single board for testing by soldering in this "clip or holder" that one could jamb the legs of a transistor into ?

Then I could solder in some adjustable resistors for those locations that matter, jamb in the Transistors...get the resistors close ... let her burn in ... make the required tweaks ... once adjusted pull the transistors and solder in appropriate values for a final board.

Thanks for all the help guys.

Gain isn't critical for the transistors. Input transistors should be matched though. HFE matching from a cheap multimeter or Ebay transistor will get you close enough.

Solder in the resistors listed on the chart that are closest to the voltage you plan to run. Warn up and burn in the input board, then measure the voltage drop across resistors and calculate the current flow from there.

As Evan says, these are temperature sensitive front ends. Wrap your transistor pairs in heat shrink to insulate the from air flow.

Yes just dab some heatsink compound between them and shrink tube them together. I'm not sure if Arctic Silver is the best choice though. Make sure it's not conductive. I've never used silver based compounds, but I've heard they can cause other issues too. I've always used Wakefield myself. 345-1007-NDThanks for the advice!

So I can use arctic silver 5 glue between TO-92 devices then heat shrink them?

Have you guys happened across little clips or holders that would allow you to say use a single board for testing by soldering in this "clip or holder" that one could jamb the legs of a transistor into ?

Then I could solder in some adjustable resistors for those locations that matter, jamb in the Transistors...get the resistors close ... let her burn in ... make the required tweaks ... once adjusted pull the transistors and solder in appropriate values for a final board.

Thanks for all the help guys.

You are overthinking things. Save yourself a lot of grief and just assemble the boards and test from there. Any sort of breadboarding isn't real world operating conditions so results are useless.

Yes I suppose I do tend to overthink...I just like to power on and have things work perfect.

What is the overall expected current consumption of this IPS when hooked up for test ?

Best Regards,

Theo

What is the overall expected current consumption of this IPS when hooked up for test ?

Best Regards,

Theo

Yes just dab some heatsink compound between them and shrink tube them together. I'm not sure if Arctic Silver is the best choice though. Make sure it's not conductive. I've never used silver based compounds, but I've heard they can cause other issues too. I've always used Wakefield myself. 345-1007-ND

You are overthinking things. Save yourself a lot of grief and just assemble the boards and test from there. Any sort of breadboarding isn't real world operating conditions so results are useless.

Good stuff I will then set my power supply to 30 - 40 ma.

The PCB is setup for BC550/560 in positions Q1/Q2 ... it it worth using the originial transistors speced by OS 2sc3423/2sa1360 ?

joshvi has these in stock.

The PCB is setup for BC550/560 in positions Q1/Q2 ... it it worth using the originial transistors speced by OS 2sc3423/2sa1360 ?

joshvi has these in stock.

The input board should run somewhere around 20mA.

The original transistors were BD550/560. Pete did some simulations with other transistors just to make sure there wouldn't be any issues. 2SC3423/2SA1360 but are TO126 devices and won't fit the board.

schema doubt

Thanks for the answer Jeff .. will move forward with BC550/560.

Thanks for the answer Jeff .. will move forward with BC550/560.

The original transistors were BD550/560. Pete did some simulations with other transistors just to make sure there wouldn't be any issues. 2SC3423/2SA1360 but are TO126 devices and won't fit the board.

I took a AAA size cell, and wound the wire (salvaged from computer SMPS) tightly on it (12 -13 turns) and although result was nowhere near perfect like JWilhelm does here, but works.

I took a M12 bolt and wound it around 18 turns, shrunk shrink tube on it, then 'unscrewed' it from the bolt, it can be a bit stuck, so be careful not to damage your new creation. I used some penetrating oil. Looks very professional.

- Home

- Amplifiers

- Solid State

- SlewMaster Builds