Just been left a pre and power CJ premier 3 and 4. I have repaired the 4 a couple of times for my friends in the past, but never opened the premier 3. It needs new valves and these diodes dont look happy, but I dont know what value and type they are, any help?

Cheers

Chris

Cheers

Chris

Attachments

I dont know what value and type they are.

These are 1N5257B, a 33V, 500mW Zener diode. They're part of the HV regulator.

Test them in circuit as a regular diode on your DVM for good/bad.

There are 12 of these in series, so the regulated HV supply voltage should be about 400V.

http://www.mccsemi.com/up_pdf/1N5221-1N5267(DO-35).pdf

Last edited:

Or measure voltage across each while it is powered. Zeners often dissipate heat, and that might explain the discoloration around them. They may be just fine. performance it their measure.

Thanks guys 🙂

Yes they are fine, but replacing them wont hurt as a preventative measure. Just need to replace the valves and hopefully I will be good to go 🙂

Cheers

Chris

Yes they are fine, but replacing them wont hurt as a preventative measure. Just need to replace the valves and hopefully I will be good to go 🙂

Cheers

Chris

May I suggest that before you change out working parts, make sure to fix all actual problems first. Once the amp is 100%, THEN go back and do any upgrades you may feel are warranted.

As an analogy, one would not tell the doctor doing open heart surgery to "go ahead and to the liposuction as long as you are in there."

As an analogy, one would not tell the doctor doing open heart surgery to "go ahead and to the liposuction as long as you are in there."

May I suggest that before you change out working parts, make sure to fix all actual problems first. Once the amp is 100%, THEN go back and do any upgrades you may feel are warranted.

As an analogy, one would not tell the doctor doing open heart surgery to "go ahead and to the liposuction as long as you are in there."

You have a point, but I had the pre amp on tonight it sounds amazing, but it has a hum. A bit of an odd issues in that low volume is high hum and high volume is high hum, but medium volume is still humming but much better. IMO it is either the diodes which are not well or a dodgy valve or two or the crackling volume pot has a bigger issue than I think as the hum is related big time to the volume pot. Re the diodes I want to restore this amp and I want problem free operation. The diodes may be ok, but they must be heat stressed and swapping them out is cheap ( about 4 bucks) and super easy.

My day to day preamp is a DNM so no slough, but even with a slight hum the CJ is amazing and I still dont have the valves for the CJ power amp I so have to hear this combo!! 🙂

Chris

Anytime there's an issue of hum, the first place you should look is the electrolytic capacitors in the power supply. These are notoriously failure-prone parts, especially in applications where there's heat. Your photo really reminds me of why I so hate the combination of vacuum tubes and printed circuit boards.

If you do change them,mount the replacements 1/4'' above the board to improve ventilation.

That may not be a good idea.

These diodes are designed such that the large bulk of the cooling is caused by the leads conducting the heat into the pc board. The size of the area of copper the diodes are soldered to will define the amount of cooling the diodes will see.

Longer leads can cause the diodes to overheat.

If there is a really good cooling airstream there, then your suggestion is good. Air against the pads on the other side may be more effective.

Another possibility is some kind of heatsink on the bodies.

John

That may not be a good idea.

These diodes are designed such that the large bulk of the cooling is caused by the leads conducting the heat into the pc board. The size of the area of copper the diodes are soldered to will define the amount of cooling the diodes will see.

Longer leads can cause the diodes to overheat.

If there is a really good cooling airstream there, then your suggestion is good. Air against the pads on the other side may be more effective.

Another possibility is some kind of heatsink on the bodies.

John

I like that idea, I need to have a think what I could use.

Cheers

Chris

Anytime there's an issue of hum, the first place you should look is the electrolytic capacitors in the power supply. These are notoriously failure-prone parts, especially in applications where there's heat. Your photo really reminds me of why I so hate the combination of vacuum tubes and printed circuit boards.

There are very few electrolytic's at all in the circuit. What is odd is how the hum is volume dependent not like normal ie high volume equals higher hum, but low volume equals high hum, middle volume is much less and high volume the hum get higher again. It is like the volume pot itself has something to do with the problem, any thoughts on why?

Cheers

Chris

There are very few electrolytic's at all in the circuit. What is odd is how the hum is volume dependent not like normal ie high volume equals higher hum, but low volume equals high hum, middle volume is much less and high volume the hum get higher again. It is like the volume pot itself has something to do with the problem, any thoughts on why?

Cheers

Chris

Is it doing this on both channels? Does this have a series pass transistor for a regulator?

Is it doing this on both channels? Does this have a series pass transistor for a regulator?

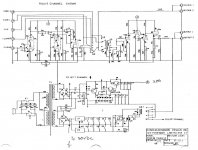

Yes on both channels, here is the circuit diagram, maybe give some ideas where to look.

Thanks again

Chris

Attachments

May I suggest that before you change out working parts, make sure to fix all actual problems first. Once the amp is 100%, THEN go back and do any upgrades you may feel are warranted.

As an analogy, one would not tell the doctor doing open heart surgery to "go ahead and to the liposuction as long as you are in there."

haha good advice, and better analogies

in this case, the cosmetic surgeon telling you he can also perform a triple bypass for a lil extra.

Last edited:

My reasoning is this: when you are chasing a problem, unless a part seems to be PART of the problem, by changing out a lot of other things, you greatly increase the potential for obscuring the problem cause or adding another. Every additional solder/un-solder you do is another potential bad joint.

And that means we have real evidence the diodes are involved. When we say something like it has to be either those diodes or maybe the (something else), we are clearly just guessing, and hoping to fall upon a bad component. A lesson every tech learns is that problems are not always a bad part. Open traces, open resistors, cracked solder, wire routing, etc, there are many sources of hum.

60/120Hz? Have a scope? Touch your finger to the scope probe, and get a waveform on the screen. Set the sweep so you have one complete cycle. It will not be a pretty sine wave, it will look distorted and buzzy. But it will be 60Hz, regardless of the shape. Your environment is full of 60Hz.

Now do not change the sweep speed, and probe your hum signal. Does it also now have one complete cycle on the screen? Or two? If one, it is 60Hz, and if two, it is 120Hz. Simple and quick

And that means we have real evidence the diodes are involved. When we say something like it has to be either those diodes or maybe the (something else), we are clearly just guessing, and hoping to fall upon a bad component. A lesson every tech learns is that problems are not always a bad part. Open traces, open resistors, cracked solder, wire routing, etc, there are many sources of hum.

60/120Hz? Have a scope? Touch your finger to the scope probe, and get a waveform on the screen. Set the sweep so you have one complete cycle. It will not be a pretty sine wave, it will look distorted and buzzy. But it will be 60Hz, regardless of the shape. Your environment is full of 60Hz.

Now do not change the sweep speed, and probe your hum signal. Does it also now have one complete cycle on the screen? Or two? If one, it is 60Hz, and if two, it is 120Hz. Simple and quick

There are very few electrolytic's at all in the circuit. What is odd is how the hum is volume dependent

not like normal ie high volume equals higher hum, but low volume equals high hum, middle volume

is much less and high volume the hum get higher again.

If the Zeners are ok, and the voltage seems right, and both channels are similar, this may be grounding or a bad connection.

The volume control is likely to be ok. Check for 120Hz ripple both on the HV supply and on the ground lugs of the volume control.

There will probably be ripple in both.

You mentioned "crackly" volume pot, see if there is DC on the pot. If so replace coupling caps.

Does the balance control affect the hum?

Does the balance control affect the hum?

hum could be anything from wonky cables, cracked connectors / joints to a bad device , use some trouble shooting skills to localize the problem, not sure I can train somebody to do that.

hum could be anything from wonky cables, cracked connectors / joints to a bad device , use some trouble shooting skills to localize the problem, not sure I can train somebody to do that.

I am no expert, but I have built my own amp in the past and the power amp a CJ premier 4 I rebuilt it for my friend after he blew it up, twice actually the second time he was a bit under the influence when he attempted to bias the valves and slipped with the screw driver. My friend very sadly passed away over Christmas and he left me the amps, knowing the preamp needed a good service and the power amp needed just valves.

The hum is strange, I have new valves coming as the ones in are going white they are so old so I suppose they could be causing the issue.. The volume pot is crackly (it is a dual 100k alps), it is not just crackly but it drops out too and it sounds scratchy too when you turn it. Oddly the pot affects the hum in a weird way ie high hum low volume and much less at mid volume and then higher again after that which is why I wondered if the pot was causing some odd problem?

I dont have a scope, but I thought I would start by testing the burned diodes then swapping them out as they are clearly heat stressed. I will then test all the components I can. The balance does not affect the hum at all.

Chris

Tested the bridge rectifier as the heat sink was loose and it tested fine so I put new grease on the heatsink and refitted it. The carbon on the rear of the board round the connections of the diodes was super thick so I scraped it off just in case it is causing a leakage ie maybe the carbon is shorting the diodes out. The diodes test fine too, but I have still ordered new ones.

One other thing that has me thinking is the relay for delayed switch on is not working correctly I wonder if this could be causing an issue? On switch on the sound is squeaky and thin, but no hum, then after maybe 15 seconds the relay clicks in and the sound goes loud and the hum starts, any thoughts on this?

Cheers

Chris

One other thing that has me thinking is the relay for delayed switch on is not working correctly I wonder if this could be causing an issue? On switch on the sound is squeaky and thin, but no hum, then after maybe 15 seconds the relay clicks in and the sound goes loud and the hum starts, any thoughts on this?

Cheers

Chris

- Status

- Not open for further replies.

- Home

- Design & Build

- Parts

- What are these components