Good day all.

I have a set of Ruark Crusader 2s, and the mid-range on the one speaker is giving distortion. It does not sound like mechanical distortion, so I believe it could either be a dry soldering joint, or bad capacitor in the cross-over.

I have attempted to open the speaker up by removing the driver(s), so I can get to the crossover, but are unable to get the drivers off, even after removing the driver screws. Are these drivers also glued onto the box by any means?

Any advice welcome.

I have a set of Ruark Crusader 2s, and the mid-range on the one speaker is giving distortion. It does not sound like mechanical distortion, so I believe it could either be a dry soldering joint, or bad capacitor in the cross-over.

I have attempted to open the speaker up by removing the driver(s), so I can get to the crossover, but are unable to get the drivers off, even after removing the driver screws. Are these drivers also glued onto the box by any means?

Any advice welcome.

Any advice welcome.

Hi,

try to remove the back panel where speaker terminal is,

then through the opening see if you can push the driver

through the front baffle while with the other hand you make

sure it doesn't fall out. I suppose they are not glued.

A very interesting speaker, worth keeping for all times.

Dynaudio tweeter and midrange with Vifa or Scan Speak

woofer, I suspect.

Last edited:

Hi,

try to remove the back panel where speaker terminal is,

then through the opening see if you can push the driver

through the front baffle while with the other hand you make

sure it doesn't fall out. I suppose they are not glued.

A very interesting speaker, worth keeping for all times.

Dynaudio tweeter and midrange with Vifa or Scan Speak

woofer, I suspect.

Thank you. I have tried that, but it seems there is some obstruction preventing me from pushing the terminal panel out of the way. Also afraid to push too hard in case I damage something. And the drivers are Unobtainium, in case I do damage them.

Hi henryve,

I recently upgraded the crossovers on a friends Crusader II's and the drivers are incredibly difficult to remove! The gasket tape used by Ruark is very sticky and you'll find the drive units, especially the woofers and mids are almost glued into place.

Eventually we did get the drive units out using some small hooked tools as Lojzek suggest but it two two of us pulling as hard as we could to get them to move!

When the adhesion of the gaskets finally let go and the drivers came out it unfortunately left a small amount of damage to the veneer although most of this damage was under the drive units and so not visible.

The circuit for the mids has two blue coloured Alcap electrolytic capacitors which I suggest you replace. The crossover itself is all point to point hard-wired with the components arranged on an MDF board and glued into place using hot melt glue. I can certainly believe that a bad solder joint might have happened.

In my friends speakers we replaced the two alcaps on the mids with Mundorf M-Cap films, the series cap on the tweeter circuit with a better Clarity Cap ESA (I think it was 4.7uF) and we also replaced all of the cement type resistors with Mills Wire Wounds. The improvement after doing these mods was very impressive!

When you put the speakers back together use some different (non sticky) gasket tape. I used the Monacor foam tape which worked well.

Good luck!

I recently upgraded the crossovers on a friends Crusader II's and the drivers are incredibly difficult to remove! The gasket tape used by Ruark is very sticky and you'll find the drive units, especially the woofers and mids are almost glued into place.

Eventually we did get the drive units out using some small hooked tools as Lojzek suggest but it two two of us pulling as hard as we could to get them to move!

When the adhesion of the gaskets finally let go and the drivers came out it unfortunately left a small amount of damage to the veneer although most of this damage was under the drive units and so not visible.

The circuit for the mids has two blue coloured Alcap electrolytic capacitors which I suggest you replace. The crossover itself is all point to point hard-wired with the components arranged on an MDF board and glued into place using hot melt glue. I can certainly believe that a bad solder joint might have happened.

In my friends speakers we replaced the two alcaps on the mids with Mundorf M-Cap films, the series cap on the tweeter circuit with a better Clarity Cap ESA (I think it was 4.7uF) and we also replaced all of the cement type resistors with Mills Wire Wounds. The improvement after doing these mods was very impressive!

When you put the speakers back together use some different (non sticky) gasket tape. I used the Monacor foam tape which worked well.

Good luck!

Thank you very much gents! You have provided me with more confidence to tackle this job. It is such a waste to have such beautifully crafted speakers which is not sounding quite right.

Drivers removed. Only on the bass driver did some veneer come off, but not much. 2 small patches, each less than 1 square cm.

I found a definite dry joint on the one terminal of the mid range driver.

Now trying to make sense of the mid-range crossover. Wondering if I can replace the 2 electrolytic caps. One is 8µF and the other 12µF. Both are parallel to the driver, so I don't really think it matters that they are electrolytic.

I found a definite dry joint on the one terminal of the mid range driver.

Now trying to make sense of the mid-range crossover. Wondering if I can replace the 2 electrolytic caps. One is 8µF and the other 12µF. Both are parallel to the driver, so I don't really think it matters that they are electrolytic.

Alas, seems I am screwed. I just tested the Dynaudio S-76AF mid-range, and it still has distortion. Seems I got shafted in a deal for these speakers second-hand.

So, unless someone knows where I can find this driver, I have a useless set of speakers. Most probably the previous owner mishandled these speakers.

So, unless someone knows where I can find this driver, I have a useless set of speakers. Most probably the previous owner mishandled these speakers.

Oh dear! I'm sorry to hear that henryve, I understand those Dynaudio mids are hard to find. It's always worth a try to post a wanted advert on here.

Well done getting the drivers out though.

What I would do is swap the mid drivers between the speakers to be absolutely sure that it's the driver which is the problem and not something you've missed on the crossover.

BTW: I seem to remember the mids are connected out of phase (red-to-black, black-to-red). Remember to take note of this when you are making the connections.

Well done getting the drivers out though.

What I would do is swap the mid drivers between the speakers to be absolutely sure that it's the driver which is the problem and not something you've missed on the crossover.

BTW: I seem to remember the mids are connected out of phase (red-to-black, black-to-red). Remember to take note of this when you are making the connections.

Yes, I noticed also they were connected out of phase. I did connect it to another source to remove the crossover from the equation.

Yes, they are impossible to find. Even more so when you live on the bottom of Africa. Now contemplating some options. Scrapping the speaker set and then selling off the remaining drivers might be one option, but it would be a tragedy.

Yes, they are impossible to find. Even more so when you live on the bottom of Africa. Now contemplating some options. Scrapping the speaker set and then selling off the remaining drivers might be one option, but it would be a tragedy.

Last edited:

I'm sure the friendly folk on here will help you find some suitable mid range drivers which could be used and advise on how you'll need to tweak the crossover to suit the new drivers. You never know you might be able to make something even better than the originals. Selling the remaining good mid could help fund the project.

Those mids do come up for sale occasionally but the last pair sold on ebay went for more than $400.

Those mids do come up for sale occasionally but the last pair sold on ebay went for more than $400.

Wait a second before you dismiss the mids as gone.

The voice coil is intact, that's what matters. Right?

Can you describe the issue more precisely. Could be

that the joint, where the voice coil lead out wire meets

the flexible wire, needs be reglued and resoldered.

The voice coil is intact, that's what matters. Right?

Can you describe the issue more precisely. Could be

that the joint, where the voice coil lead out wire meets

the flexible wire, needs be reglued and resoldered.

Good idea. Might as well see if I can find a suitable replacement mid-dome. Maybe the same or like it used in the ATC range. The crossover will need rebuilding then, but that is fine. I have a set of B&W Matrix Ones that is doing nothing at the moment while I tackle this project.

Wait a second before you dismiss the mids as gone.

The voice coil is intact, that's what matters. Right?

Can you describe the issue more precisely. Could be

that the joint, where the voice coil lead out wire meets

the flexible wire, needs be reglued and resoldered.

Looking at it now. I have the cap on the back off already to see if I can see anything glaringly obviously causing the distortion. One thing that concerns me is the DC resistance of the coil changing when I touch the dome and moving it a bit. That usually means, to me at least, that the voice coil is shorting out somewhere while moving, which could mean that it might have heated up sometime during it's life causing it to me deformed.

Perform all the measurements you can. DCR, impedance sweep,

FR, pull the VC-dome assembly out for visual inspection. I'd

like to see the photos if possible. Dynaudio charges insanely for

factory refurbished units. There were Vifa 3" domes on the

market, now they are called Scan Speak D7608-920010.

Ruark Crusader 3 has it, I think.

FR, pull the VC-dome assembly out for visual inspection. I'd

like to see the photos if possible. Dynaudio charges insanely for

factory refurbished units. There were Vifa 3" domes on the

market, now they are called Scan Speak D7608-920010.

Ruark Crusader 3 has it, I think.

Have it out. The dome/voice coil assembly. It seems that there was a manufacturing defect that eventually caused problems. The voice coil wire seems t be worn right at the point where it leaves the coil where it is connected to the braided wire going to the terminal. I will try to get a nice close up photo later tonight. Right now I have a headache and need to take a break.

Thanks for the info on the Scan Speak driver. I will investigate.

Thanks for the info on the Scan Speak driver. I will investigate.

OK, I think I can salvage this unit.

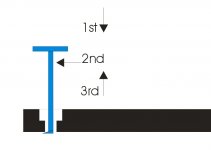

The problem was two-fold. Electrical distortion through a dry joint, as well as mechanical distortion through a malformed voice coil. Correcting the latter has proven difficult because of the tight magnetic gap. I have been dry assembling this unit a few times, using a tone sweep from 300Hz - 600Hz to get the unit buzz-free. Tonight I finally got it, but now I am scared that after I glue it back in place, the buzz will be back. I probably need something precisely round at 75mm diameter to verify roundness before final assembly. Any ideas? Tonight I printed a 76mm circle using a CAD package to verify, but I want it more precise.

Also, what type of glue is usually used to glue the dome fabric to the chassis? I guess normal fabric contact glue will be fine?

Also, how to I verify polarity after assembly? Using a DC pulse to see if the dome moves in or out?

The problem was two-fold. Electrical distortion through a dry joint, as well as mechanical distortion through a malformed voice coil. Correcting the latter has proven difficult because of the tight magnetic gap. I have been dry assembling this unit a few times, using a tone sweep from 300Hz - 600Hz to get the unit buzz-free. Tonight I finally got it, but now I am scared that after I glue it back in place, the buzz will be back. I probably need something precisely round at 75mm diameter to verify roundness before final assembly. Any ideas? Tonight I printed a 76mm circle using a CAD package to verify, but I want it more precise.

Also, what type of glue is usually used to glue the dome fabric to the chassis? I guess normal fabric contact glue will be fine?

Also, how to I verify polarity after assembly? Using a DC pulse to see if the dome moves in or out?

- Home

- Loudspeakers

- Multi-Way

- Advice needed on Ruark Crusader 2 Speakers