Second AMT Mk II B (201) is now finished.

A little bit more room infliction in LF due to shorter distance to the back wall.

But a little less distortion in HF.

But close enough in frequency response levels.

Next measurments will in the complete setup:

Partly in order to design a good wave guide but also to evaluate if there´s a need for any dampening or diffraction behind the AMT.

Started with a - 6 dB PEQ at 5 kHz, Q=1.

Listened to Ben Harper Gold To Me and decided to lower the output to the DACs that drives the amplifiers to the AMTs by 3 dB.

Some more music:

Sunrise — Norah Jones, perfects oooos

Revolving Door — Joyce Cooling, no vibrations during the sustained notes. For the first time I can now relax and really listen without any fear. And boy, that girl can play.

Detroit — Marcus Miller, Marcus' fingers really flies over the bass strings.

Never Let Me Go — Jeanette Lindström & Steve Dobrogosz, now I almost start to weep.

Patting myself on the shoulder...

A little bit more room infliction in LF due to shorter distance to the back wall.

But a little less distortion in HF.

But close enough in frequency response levels.

Next measurments will in the complete setup:

Partly in order to design a good wave guide but also to evaluate if there´s a need for any dampening or diffraction behind the AMT.

Started with a - 6 dB PEQ at 5 kHz, Q=1.

Listened to Ben Harper Gold To Me and decided to lower the output to the DACs that drives the amplifiers to the AMTs by 3 dB.

Some more music:

Sunrise — Norah Jones, perfects oooos

Revolving Door — Joyce Cooling, no vibrations during the sustained notes. For the first time I can now relax and really listen without any fear. And boy, that girl can play.

Detroit — Marcus Miller, Marcus' fingers really flies over the bass strings.

Never Let Me Go — Jeanette Lindström & Steve Dobrogosz, now I almost start to weep.

Patting myself on the shoulder...

Yes very well done - I would like to listen to these 🙂

Mold the baffles in concrete with integrated waveguide. 150 kg each.

All in now.

//

Mold the baffles in concrete with integrated waveguide. 150 kg each.

All in now.

//

Last edited:

Thank you Henry!Well done, enjoy!

Thanks. Whenever you are in the vicinity of Göteborg...Yes very well done - I would like to listen to these 🙂

Good idea. But I'd like to finish them this yearMold the baffles in concrete with integrated waveguide. 150 kg each.

//

.

.Fantastic job - congratulations🙂

Two questions:

1. What kind of efficiency have you achieved with the MkII version of the AMT?

2. How does the MkII version compare to the MkI version in subjective terms?

Thanks a lot and keep up the good work!!

Best regards

Peter

Two questions:

1. What kind of efficiency have you achieved with the MkII version of the AMT?

2. How does the MkII version compare to the MkI version in subjective terms?

Thanks a lot and keep up the good work!!

Best regards

Peter

Also curious what this ended up costing you in the end?

I was looking at using the Beyma TPL 150 but wished it could cross at around 700hz or lower. BUT now seeing this I am very interested is seeing if maybe I could build one that could serve my wants and cost less than the alternative.

Either way awesome job. I will have to go through this thread 10 more times to take everything in.

I was looking at using the Beyma TPL 150 but wished it could cross at around 700hz or lower. BUT now seeing this I am very interested is seeing if maybe I could build one that could serve my wants and cost less than the alternative.

Either way awesome job. I will have to go through this thread 10 more times to take everything in.

106-107 dBm @ 1 W and 1 meter. But with the needed PEQ of - 6 dB I'd say 100 dBm is a more realistic value.1. What kind of efficiency have you achieved with the MkII version of the AMT?

A lot more detail delivered effortless.2. How does the MkII version compare to the MkI version in subjective terms?

Thanks Peter. I will for sure continue with the development.Fantastic job - congratulations🙂

Thanks a lot and keep up the good work!!

Best regards

Peter

Well, the 32 custom made pole pieces costs about 20 SEK a piece.Also curious what this ended up costing you in the end?

The 64 magnets costs about 40 SEK a piece.

Then there's a lot of screws and bolts and some aluminium parts as well.

So lets say 4000 SEK in hardware parts for each AMT.

And then there's the membrane... The tape and the aluminium perhaps costs 50 SEK but then you would have to make it. And fold it.

The Silouette costs about 3000 SEK and the folding jigg 1000 SEK. Both these you could of course reuse.

I wanted a two way system and didn't like the sound of the TD15H above 400 Hz.I was looking at using the Beyma TPL 150 but wished it could cross at around 700hz or lower.

Cost less? Well perhaps for DIY. A retail price of the Mk II I think would be well above 20000 SEK if not more.BUT now seeing this I am very interested is seeing if maybe I could build one that could serve my wants and cost less than the alternative.

It all depends how many you manufacture and how well you can get it industrialized.

I'd say the TPL150 still is cheap.

I'll answer any question you will have.Either way awesome job. I will have to go through this thread 10 more times to take everything in.

Thanks a lot! I am really impressed🙂.

I have not heard your speakers (although I would really like to!), but I already have the Beyma TPL-150H as well as a pair of Bernd Lohmann's MT E500M's (Mid AMTs going down to about 300 Hz) and at least from a subjective point of view the AMT principle seems to really excell in some areas. To my ears, the the AMTs simply sound more natural, clear, and clean than anything else have heard. I think this is especially revealing in the 300-700 Hz range or so..

Best regards

Peter

I have not heard your speakers (although I would really like to!), but I already have the Beyma TPL-150H as well as a pair of Bernd Lohmann's MT E500M's (Mid AMTs going down to about 300 Hz) and at least from a subjective point of view the AMT principle seems to really excell in some areas. To my ears, the the AMTs simply sound more natural, clear, and clean than anything else have heard. I think this is especially revealing in the 300-700 Hz range or so..

Best regards

Peter

106-107 dBm @ 1 W and 1 meter. But with the needed PEQ of - 6 dB I'd say 100 dBm is a more realistic value.

A lot more detail delivered effortless.

Thanks Peter. I will for sure continue with the development.

If someone were manufacturing a giant 100 dB sensitive AMT that covered the 250-20,000 Hz range, and it sounded as good as I think it would, then I would buy a pair of these even if the retail price for a pair was 20,000 SEK!

Best regards

Peter

Best regards

Peter

A retail price of the Mk II I think would be well above 20000 SEK if not more.

It all depends how many you manufacture and how well you can get it industrialized.

I'd say the TPL150 still is cheap.

Last edited:

Trouble is that too few people have the digital setup (apart from the power amplifiers) required.

So the market is very small.

So the market is very small.

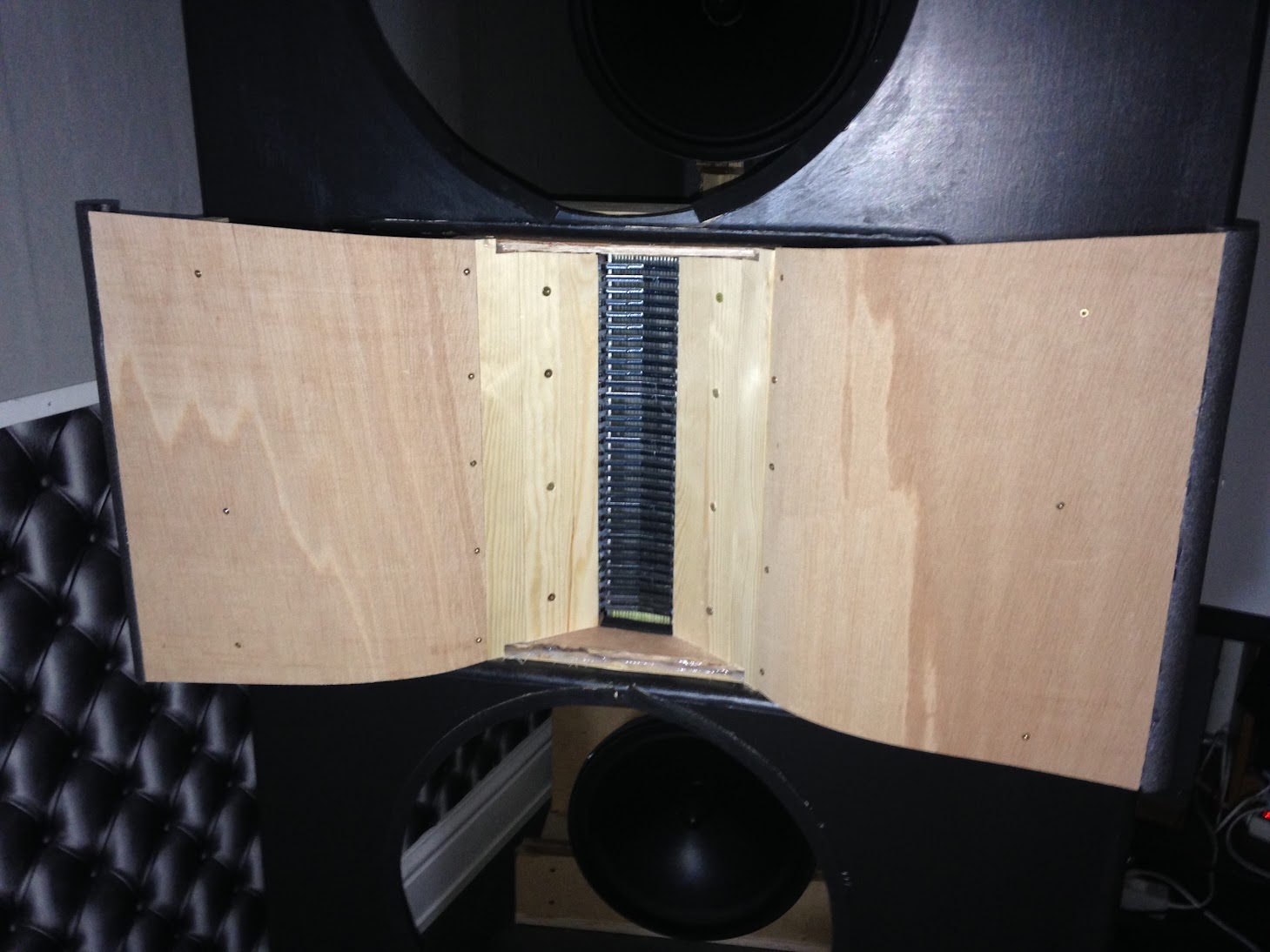

New waveguides in place in the baffel:

But when moving the last baffle onto the base elements I managed to rip one of the connection to the membrane.

Well, tomorrow is another day.

Measured on the remaining AMT in the baffle at 50 cm, 1 m and at sweet spot:

A little higher distortion in LF, I reckon dampening the back wave mitigates it.

But when moving the last baffle onto the base elements I managed to rip one of the connection to the membrane.

Well, tomorrow is another day.

Measured on the remaining AMT in the baffle at 50 cm, 1 m and at sweet spot:

A little higher distortion in LF, I reckon dampening the back wave mitigates it.

Aha your bass drivers are not attached to the baffle... clever clever clever.... 🙂

//

Yes, are mounted by the magnet to a pole completely free from the baffle.

Here's a picture showing the first attempt:

Nowadays both the pole and the baffle are made of birch plywood.

And space is made for the AMT of course.

So all mechanical forces are taken by the spine/pole. How much energy is imposed on the baffle by the bass drivers? Do they have mechanical contact or do the just hoover close to the baffle?

//

//

But I'm not that clever; got the suggestion from a member of the Swedish forum Hififorum.nu: Bernt Jansson.Aha your bass drivers are not attached to the baffle... clever clever clever.... 🙂

//

Yes. It weighs about 30 kg. Together with the TD15Hs that's more than 60 kg that have to counteract the moving mass of the three cones of the TD15Hs.So all mechanical forces are taken by the spine/pole.

//

So it is a 60 kg against 387 g, that a 1 to 155 relationship.

None.How much energy is imposed on the baffle by the bass drivers?

//

No contact. The cut outs in the baffle are a couple of millimeters wider.Do they have mechanical contact or do the just hoover close to the baffle?

//

The wavelengths of the frequencies the TD15H can reproduce are by far larger and thus doesn't gets inflenced by the gap.

Just to be sure though, I've put some acoustic foam in the gap.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- Yet another DIY AMT