I suppose you could build it either way, However, I think most of us have built it where the tonearm (wood) enters the aluminum tube and stops short of the magnet's placement.

That's how I built mine anyway..... end is not solid either on mine, I filled it with foam ear plugs (marshmallow type) in the theory it would help to quell any ringing/vibrations from the needle. No way to test if it worked though.

Ron

That's how I built mine anyway..... end is not solid either on mine, I filled it with foam ear plugs (marshmallow type) in the theory it would help to quell any ringing/vibrations from the needle. No way to test if it worked though.

Ron

Mgnet information

I Jeff,

Did yu use magnets with the tiny hole fo rthe upper one ? if yes where did you find them. <i have magnets with following dimension:

Diameter 12mm, thickness 5mm and i was planning to use it for a 12" arm while the othe rmagnets diameter 10mm , thickness 5mm for a 9" arm. Buth no holes in the center so the string pivoting point is behind the upper magnet.

Tks for any suggestion.

Best regrards and Happy New Year.

Adelmo

adelmor@libero.it

just the bottom side of the bottom, and the top of the top. Plan is to press fit the cylindical magnets into the arm tube and lower holder. Maybe a smidge of Loctite Green anaerobic retaining sealant around the magnet. Magnets from K&J Magnetics, N52 .375" diameter x .1875" thick.

JD

I Jeff,

Did yu use magnets with the tiny hole fo rthe upper one ? if yes where did you find them. <i have magnets with following dimension:

Diameter 12mm, thickness 5mm and i was planning to use it for a 12" arm while the othe rmagnets diameter 10mm , thickness 5mm for a 9" arm. Buth no holes in the center so the string pivoting point is behind the upper magnet.

Tks for any suggestion.

Best regrards and Happy New Year.

Adelmo

adelmor@libero.it

Just finished reading these 99 pages line by line (almost).

Mostly I understood, some, mmmmm not.

I salute Frank Schroeder for hi superb, superb help(s), suggestions, solutions.

Needless to say I want to build one with simpler (available) parts with my limited reach for things.

One question, what if I use top string on wand as most have done with inverted Y configuration yet do not use any magnet and use a rubber band (thin yet have useful high elasticity and quite lean in diameter) tie with lower base where lower magnet sits?

A rubber band actually increase it pulling strength when ever the wand moves or rotates away from its stable position. Whereas the magnet looses its strength when the above happens. Will it not be a better attribute?

I know friction from the rubber band (acting as bearing) will most probably be very poor comparing to zero contact bearing act of magnets. But it can give me a simpler build, less friction than a uni-pivot (depending on the elastic band).

Please comment.

I will try to make a drawing that's in my head right now and will upload later.

Mostly I understood, some, mmmmm not.

I salute Frank Schroeder for hi superb, superb help(s), suggestions, solutions.

Needless to say I want to build one with simpler (available) parts with my limited reach for things.

One question, what if I use top string on wand as most have done with inverted Y configuration yet do not use any magnet and use a rubber band (thin yet have useful high elasticity and quite lean in diameter) tie with lower base where lower magnet sits?

A rubber band actually increase it pulling strength when ever the wand moves or rotates away from its stable position. Whereas the magnet looses its strength when the above happens. Will it not be a better attribute?

I know friction from the rubber band (acting as bearing) will most probably be very poor comparing to zero contact bearing act of magnets. But it can give me a simpler build, less friction than a uni-pivot (depending on the elastic band).

Please comment.

I will try to make a drawing that's in my head right now and will upload later.

Hy guys

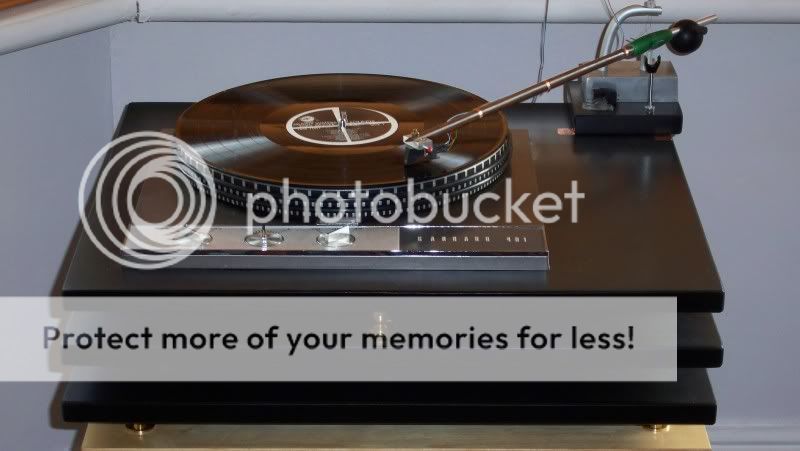

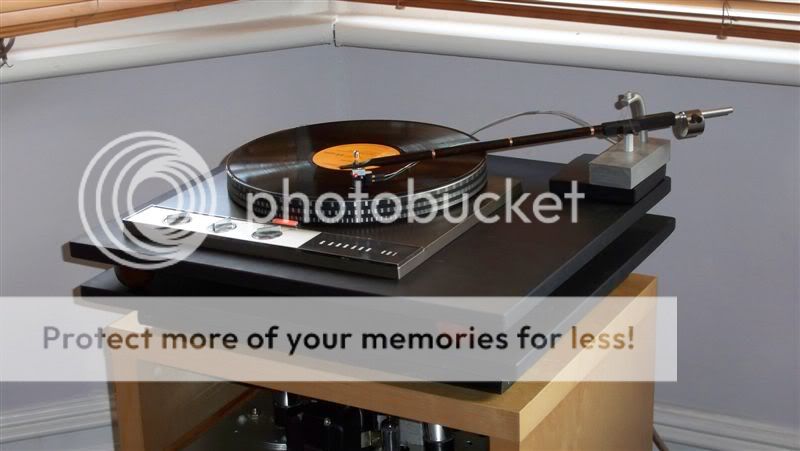

after spending the all winter in my workshop, finally I finished my Schroder tonearm and the diy turntable.

Really thanks to this forum for all the information, thanks to Frank Schroder who's sharing a lot of secrets of his amazing tonearm.

Here some picture of the finished turntable and the tonearm

Here the video of my work

https://www.youtube.com/watch?v=UXvz3y3JXw8

Thanks all

Luigi

after spending the all winter in my workshop, finally I finished my Schroder tonearm and the diy turntable.

Really thanks to this forum for all the information, thanks to Frank Schroder who's sharing a lot of secrets of his amazing tonearm.

Here some picture of the finished turntable and the tonearm

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Here the video of my work

https://www.youtube.com/watch?v=UXvz3y3JXw8

Thanks all

Luigi

Last edited:

Luigi,

Great work and an excellent presentation!

Congratulations on your achievement!

I hope it sounds just as good as it seems...

Great work and an excellent presentation!

Congratulations on your achievement!

I hope it sounds just as good as it seems...

Hi Sumanta,

"One question, what if I use top string on wand as most have done with inverted Y configuration yet do not use any magnet and use a rubber band (thin yet have useful high elasticity and quite lean in diameter) tie with lower base where lower magnet sits?

A rubber band actually increase it pulling strength when ever the wand moves or rotates away from its stable position. Whereas the magnet looses its strength when the above happens. Will it not be a better attribute?"

A rubber band is more of an energy storage device, rather than providing (velocity dependent)damping, such as the magnet bearing assembly. With a rubber band, you'll likely need an additional damping device.

It is also not the case that the magnets "loose" strength once the upper one is moved out of a perpendicular position. The restoring force increases because you're "raising" the entire wand/counterweight as well once the arm is moved laterally.

Magnet shape related, the fluxline distribution causes the bearing to become stiffer, then weaker again. But it takes waaaay more force than a tracking cartridge would ever create to notice any deflection.

But, why not try/build it and study the behaviour of a rubber band as a tensioning/positioning device? It'll sure provide valuable info for improving future designs.

Cheers,

Frank

"One question, what if I use top string on wand as most have done with inverted Y configuration yet do not use any magnet and use a rubber band (thin yet have useful high elasticity and quite lean in diameter) tie with lower base where lower magnet sits?

A rubber band actually increase it pulling strength when ever the wand moves or rotates away from its stable position. Whereas the magnet looses its strength when the above happens. Will it not be a better attribute?"

A rubber band is more of an energy storage device, rather than providing (velocity dependent)damping, such as the magnet bearing assembly. With a rubber band, you'll likely need an additional damping device.

It is also not the case that the magnets "loose" strength once the upper one is moved out of a perpendicular position. The restoring force increases because you're "raising" the entire wand/counterweight as well once the arm is moved laterally.

Magnet shape related, the fluxline distribution causes the bearing to become stiffer, then weaker again. But it takes waaaay more force than a tracking cartridge would ever create to notice any deflection.

But, why not try/build it and study the behaviour of a rubber band as a tensioning/positioning device? It'll sure provide valuable info for improving future designs.

Cheers,

Frank

Thanks guys for alI appreciations..

Anyway I want to give some info concerning my person.

I'm not an engineer, I dont have any electric or mechanical background, I dont have any friend or relative who help me in this project, I'm working in gastronomy environment, so no technical knowledge at all.

Untill last year i did not know how to use a lathe or milling machine, no background in painting, no knowledge about sharpening drill bits or create custom hss lathe's tools.

This turntable is all hand made by be, including painting, no one piece was machined or painted from an external factory, and most important, all is made from scrap metal.

I think, especially talking in a diy forum, that is really important to give the message that most people with a bit of craft skills, after a lot of internet studies and after hundreds of tutorials, can achieve its own target!

Luigi

Anyway I want to give some info concerning my person.

I'm not an engineer, I dont have any electric or mechanical background, I dont have any friend or relative who help me in this project, I'm working in gastronomy environment, so no technical knowledge at all.

Untill last year i did not know how to use a lathe or milling machine, no background in painting, no knowledge about sharpening drill bits or create custom hss lathe's tools.

This turntable is all hand made by be, including painting, no one piece was machined or painted from an external factory, and most important, all is made from scrap metal.

I think, especially talking in a diy forum, that is really important to give the message that most people with a bit of craft skills, after a lot of internet studies and after hundreds of tutorials, can achieve its own target!

Luigi

Hi Frank. I would just build a Unipivot. I seem to remember a BIC pen was where people started? The wood could be made in two halves then glued. It is almost impossible to fail doing this. Building a Schroeder clone should take 20 years for the fine tuning ? That is if you have gifted ears? To be honest the Scheoder arm like a Bumble Bee can not fly. If so like the celestial engineer you have to be very dedicated. The Harrier Jet comes to mind of the impossible made to work. Sceintists now think they understand the Bumble Bee. At first they estimated it only had 30 % the lift power it needs. Makes me wonder how much of sceince is guesswork and stong opinions ?

Frank I noticed April 30 th was completely forgotten by the BBC . And people say " lest we forget ". Sorry. A friend took me to the exact place when I was in Berlin. One could say the exact place where the EEC started for good or bad. Rather fancy traffic lights I remember that match vintage hi fi .

Frank I noticed April 30 th was completely forgotten by the BBC . And people say " lest we forget ". Sorry. A friend took me to the exact place when I was in Berlin. One could say the exact place where the EEC started for good or bad. Rather fancy traffic lights I remember that match vintage hi fi .

Hi Nigel!

Sure, a unipivot is an excellent starting point for a beginner. But since the thread is about Schröder arm-based DIY efforts(don't like the word "clone" ...), any variation, even with a rubber band as a substutite for the magnets, has a place here.

From the feedback people have left here and elsewhere, their efforts in building a Schröder "c#+&*" seem to have paid off. Anyone out there to better the original? I sure hope so...🙂

My arms may come across as bumble bees to some. But they're far less complicated than any of nature's creations. In fact, I strive for simplicity in any design.

There is certainly an over-abundance of guesswork and strong opinions on the net 🙂

Over here, the end of WWII has taken up a huge portion of the media. Fewer living witnesses left, so everyone is eager to hear it from a "true" source.

Ask me about the time right after the wall fell when I'm 85 and I will give you as personal(but definitely true in an absolute sense) an account of what it was like.

But that's a topic better discussed elsewhere 🙂

Keep up the great work!

Cheers,

Frank

Sure, a unipivot is an excellent starting point for a beginner. But since the thread is about Schröder arm-based DIY efforts(don't like the word "clone" ...), any variation, even with a rubber band as a substutite for the magnets, has a place here.

From the feedback people have left here and elsewhere, their efforts in building a Schröder "c#+&*" seem to have paid off. Anyone out there to better the original? I sure hope so...🙂

My arms may come across as bumble bees to some. But they're far less complicated than any of nature's creations. In fact, I strive for simplicity in any design.

There is certainly an over-abundance of guesswork and strong opinions on the net 🙂

Over here, the end of WWII has taken up a huge portion of the media. Fewer living witnesses left, so everyone is eager to hear it from a "true" source.

Ask me about the time right after the wall fell when I'm 85 and I will give you as personal(but definitely true in an absolute sense) an account of what it was like.

But that's a topic better discussed elsewhere 🙂

Keep up the great work!

Cheers,

Frank

A well thought out Uni-pivot would be a gift for the world. I dare say it could even be made with hand tools.

Professional people are greatly helped by freely available imformation on the net. It could not be a better smoke screen if caused by the old NKVD.

Professional people are greatly helped by freely available imformation on the net. It could not be a better smoke screen if caused by the old NKVD.

I liked Morgan Jones Tonearm very much. What criteria would make a unipivot tonearm almost perfect ?

Regards.

Regards.

If Frank wouldn't mind it is a Schroeder except pivot. I really think a BIC pen is OK for the point. For starters the cup could be a simple drill bit machined brass part. Have the mass of counterweight low down to assist the stability. Offset by simple clamp. Perhaps a 12 or 10 inch rather than 9 . The Hadcock was an OK design. It would outperform SME 5 to my ears. I would start with dowel wood and have the wires on the surface. Very quickly how good sounding will start to be known. Mass is the next step. If a Denon 103/110 I suspect it can be very much for another day as too high might be fine. This is not to say unimportant, it's an error that shouldn't kill the listening test. If the arm is of too low mass that could make you think the design is wrong when it isn't. Hard to say exactly how that sounds. A bit like cheaper CD players ? Try wood first.

I feel this is a more guaranteed route to use a uni-pivot. It's like you build a sportscar with an American V8 instead of a bespoke V12. The other 90 % of the design can be realised. The fact that the part that will almost certainly doom the project is not attempted will not stop the 90% being right. To be specific when a car the V8 it will not have the refinement. This will not be obvious without the other on hand. Time was when nearly all American cars were V8, even a Woody.

A Lenco 75 would be the turntable I would use.

I feel this is a more guaranteed route to use a uni-pivot. It's like you build a sportscar with an American V8 instead of a bespoke V12. The other 90 % of the design can be realised. The fact that the part that will almost certainly doom the project is not attempted will not stop the 90% being right. To be specific when a car the V8 it will not have the refinement. This will not be obvious without the other on hand. Time was when nearly all American cars were V8, even a Woody.

A Lenco 75 would be the turntable I would use.

If Frank wouldn't mind it is a Schroeder except pivot. I really think a BIC pen is OK for the point. For starters the cup could be a simple drill bit machined brass part. Have the mass of counterweight low down to assist the stability. Offset by simple clamp. Perhaps a 12 or 10 inch rather than 9 . The Hadcock was an OK design. It would outperform SME 5 to my ears. I would start with dowel wood and have the wires on the surface. Very quickly how good sounding will start to be known. Mass is the next step. If a Denon 103/110 I suspect it can be very much for another day as too high might be fine. This is not to say unimportant, it's an error that shouldn't kill the listening test. If the arm is of too low mass that could make you think the design is wrong when it isn't. Hard to say exactly how that sounds. A bit like cheaper CD players ? Try wood first.

I feel this is a more guaranteed route to use a uni-pivot. It's like you build a sportscar with an American V8 instead of a bespoke V12. The other 90 % of the design can be realised. The fact that the part that will almost certainly doom the project is not attempted will not stop the 90% being right. To be specific when a car the V8 it will not have the refinement. This will not be obvious without the other on hand. Time was when nearly all American cars were V8, even a Woody.

A Lenco 75 would be the turntable I would use.

Nigel,

Why are you trying to highjack the wonderfull Schroeder style thread into Unipivot???????????????😡😡😡

The place for your discussion is your own new thread.

Thank you.

That's a very strange thing to say. If only you knew the truth. That aside the basic things which make a Uni-pivot a good idea could be uprated. If you like drop the V12 in. To have the best chance of sucess keep it simple. If your Schroeder inspired arm sounds not as good as the Uni-pivot you will have to work at it. Over to you and the best best of luck. Antonio Stradivari comes to mind.

Last edited:

Antonio Stradivari comes to mind.

Troll comes to my mind.

Now where is that Tin of Spam smilie when you need it 😉

Dear Frank,

Thank you in tons for answering my questions and clarifying.

I will try use magnet first.

Rubber band isn't looking promising primarily from strength and replacement point of view. Instead having a strings for top hanging and bottom pull seems easier.

But, first I would like to follow your principle in my first trial.

As soon as a workable things stands, I will put photos here. Till then, back to work on my ironing table.

Thanks again.....

Thank you in tons for answering my questions and clarifying.

I will try use magnet first.

Rubber band isn't looking promising primarily from strength and replacement point of view. Instead having a strings for top hanging and bottom pull seems easier.

But, first I would like to follow your principle in my first trial.

As soon as a workable things stands, I will put photos here. Till then, back to work on my ironing table.

Thanks again.....

- Home

- Source & Line

- Analogue Source

- DIY Schroeder Tonearm?