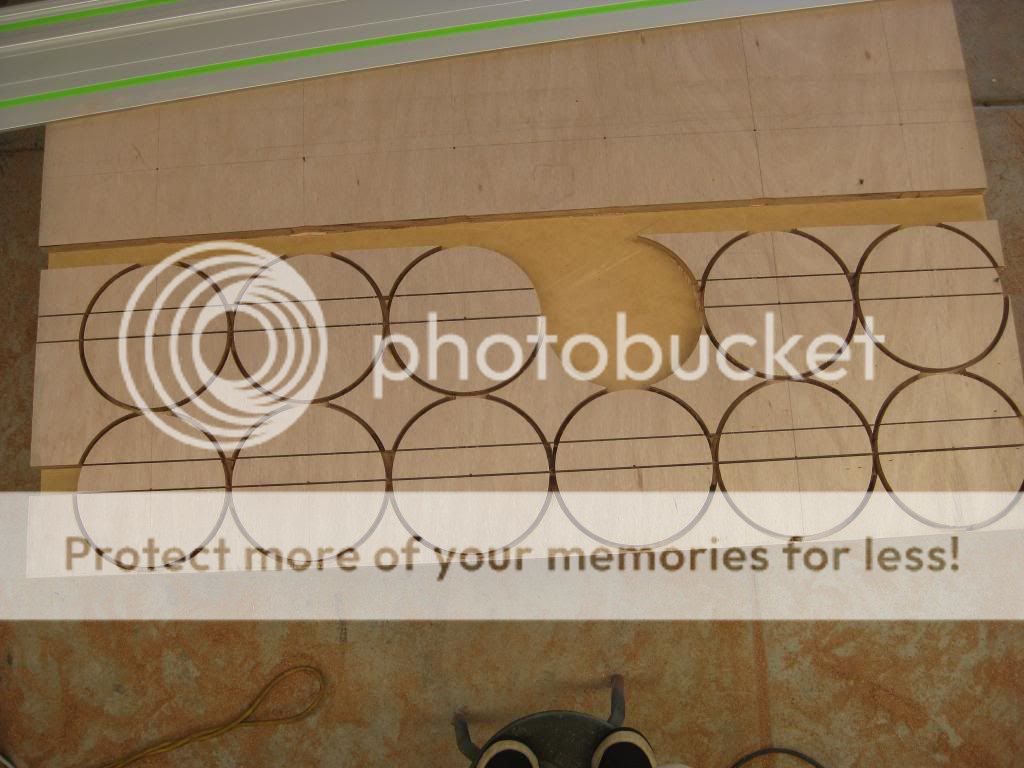

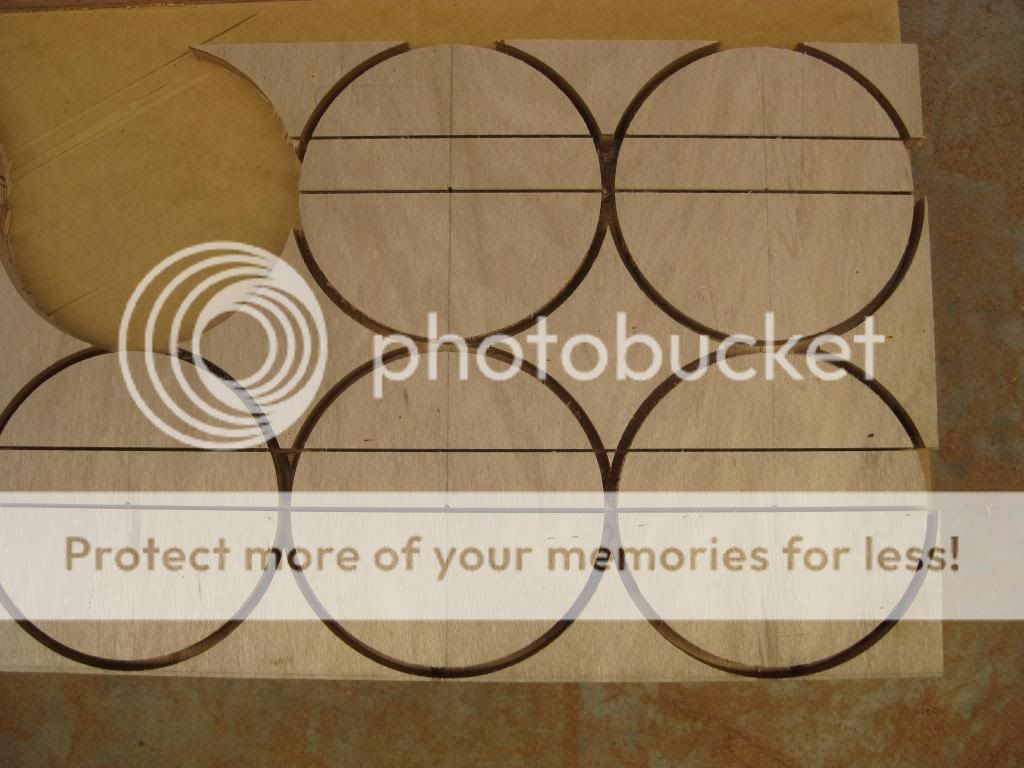

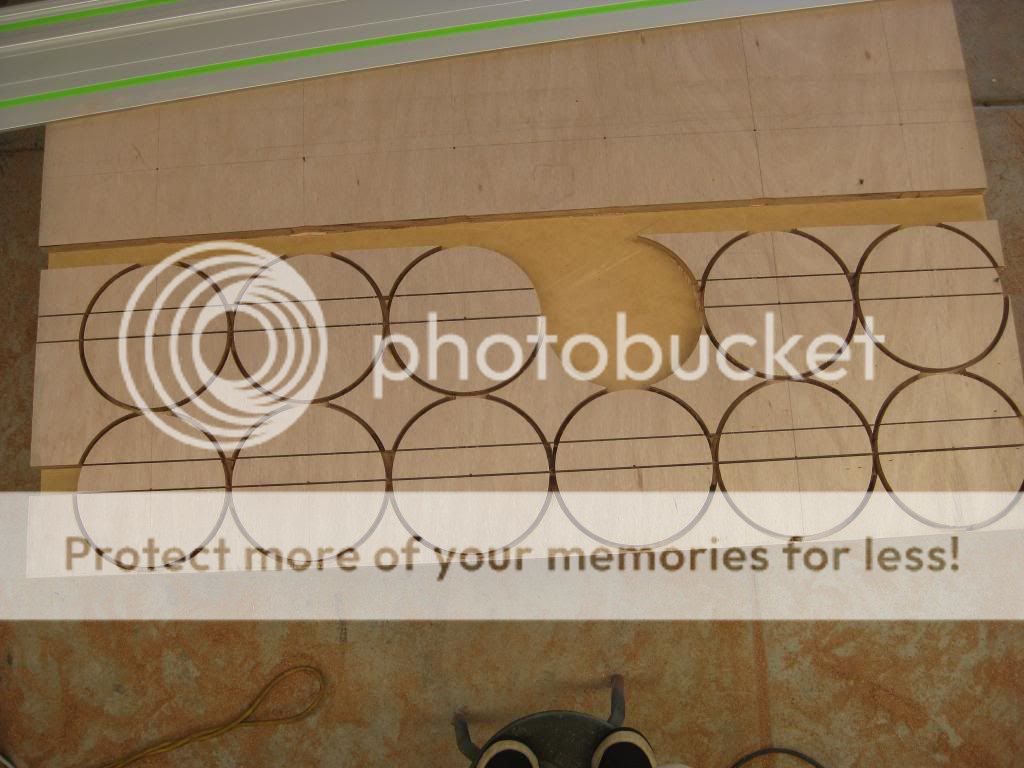

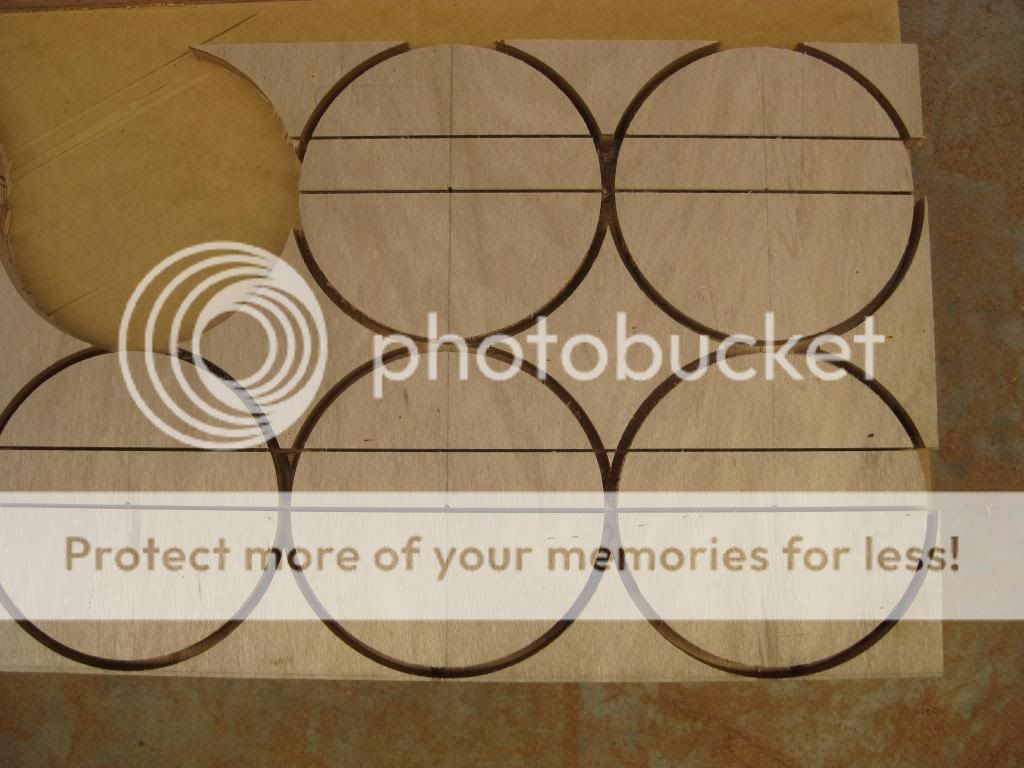

Working on the 1220mm side of the board makes it easier to router and the board needs to be supported .

Cheers

Cheers

you're not a short **** are you? Is that a stool I see you need to stand on??

Me noooooooooooooo , I made the bench to high 😛

I tried curfing a board ,what a pain in the **** that is .If the make each vein/section to wide ,when you curve it you end up with a faceted curve .

Last edited:

Geese that's heaps of routing, is that Russian birch B-B? l'm thinking of trying that out on my next build that will be stacked layer.

Geese that's heaps of routing, is that Russian birch B-B? l'm thinking of trying that out on my next build that will be stacked layer.

Hi Lusk

Its Pacific Maple Marine 2440x1220x25 $159.71 a sheet .

If your going to be showing the end grain after you stack them go with Russian or if you can get Finnish Baltic Birch .

CHeers

A spindle shaper would have made this a ton easier I'd think ... or a bandsaw if you're sanding anyway.

A spindle shaper would have made this a ton easier I'd think .

Now you tell puppet 🙄 ,whats a spindle shaper 😕🙂.

Anyway its down the corners are cut .Next glue them together then rabbit the ends for the side boards to fit into .

CHeers

gluing

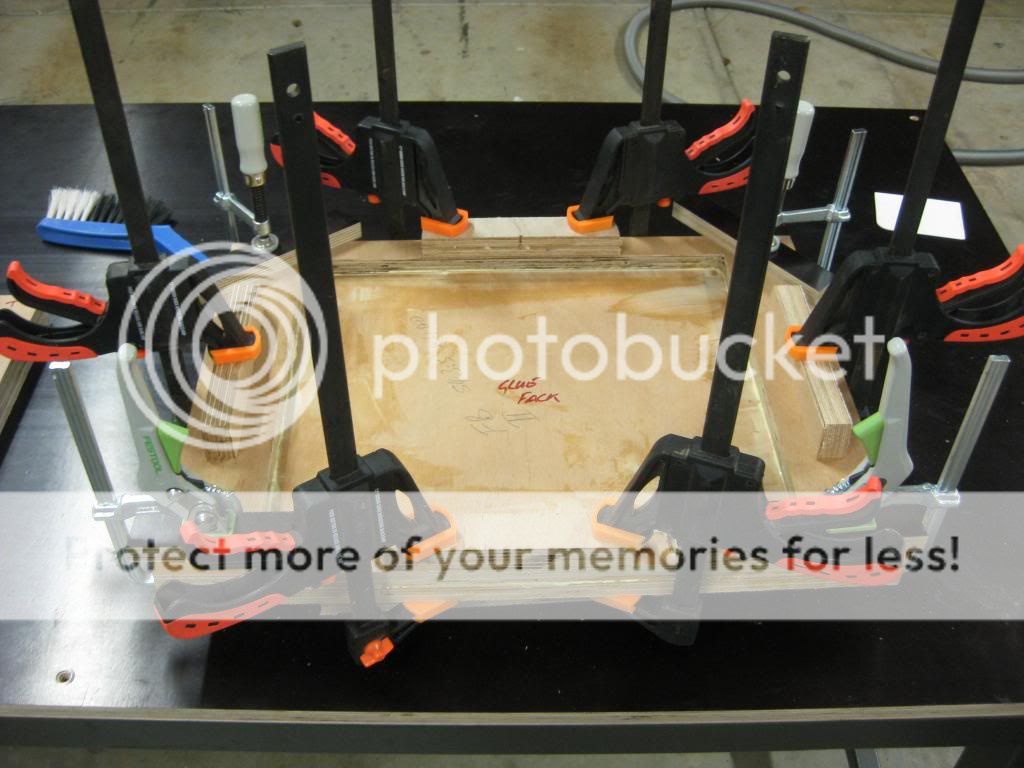

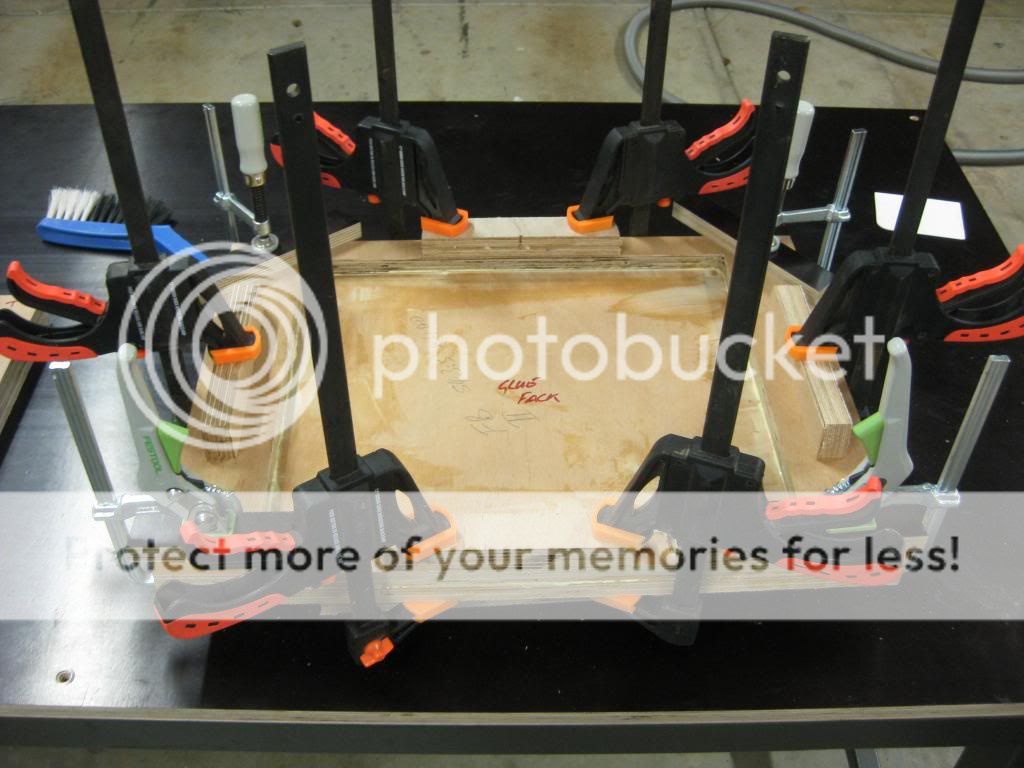

Made a simple jig up to hold the corners while being glued .Its much easier to glue layers together when you have dowel holes 😉🙂,like I did with the speaker cab's .

There's a little bit of variance between each layer which should be alright after sanding a hiFilling .

7 more to go 🙂

🙂

CHeers

Made a simple jig up to hold the corners while being glued .Its much easier to glue layers together when you have dowel holes 😉🙂,like I did with the speaker cab's .

There's a little bit of variance between each layer which should be alright after sanding a hiFilling .

7 more to go

🙂

🙂CHeers

What happened to the query:

"4 way active ,passive or what works best" ?!

Hi KM

I'm going to use all at hand ,share the load .

Cheers

Its good when you don't glue the job into the jig 🙂 . Good old cling wrap & baking paper .

CHeers

CHeers

Hi 56oval .... the bandsaw would have been ideal here ... if there's a next time, cut the sheet up into smaller squares.

Make a template for the bandsaw ... basically a flat piece of plywood that has a strip attached underside to ride the mitre gauge groove. Advance into the blade to establish the cut line halfway into the plywood template. Clamp a stop block on the aft side of the saw bed to keep the sled (plywood template) from going any farther forward while cutting all of the pieces ... (repeatability).

Off the cut line, right where it ends in the sled, scribe a 90* line. On this line you will locate a pin, nail, whatever at the desired final arch radius. Put your blank on the sled and advance it into the blade to the stop block ... turn the blank on the pin ... done.

Make a template for the bandsaw ... basically a flat piece of plywood that has a strip attached underside to ride the mitre gauge groove. Advance into the blade to establish the cut line halfway into the plywood template. Clamp a stop block on the aft side of the saw bed to keep the sled (plywood template) from going any farther forward while cutting all of the pieces ... (repeatability).

Off the cut line, right where it ends in the sled, scribe a 90* line. On this line you will locate a pin, nail, whatever at the desired final arch radius. Put your blank on the sled and advance it into the blade to the stop block ... turn the blank on the pin ... done.

HI puppet

NO more circles for awhile I hope 🙂.

Today the drivers arrived for the tapped horns .

Alpine SWR-12D4

Cheers

NO more circles for awhile I hope 🙂.

Today the drivers arrived for the tapped horns .

Alpine SWR-12D4

Cheers

Last edited:

accordion surround! thats rare.. in car audio, the only other sub ive seen using it was pioneer ODR

Do you have plans for the tapped horn using that driver? Did you go a car audio driver die to availability issues in Australia ?

3ggg the horn is the same with exodus anarchy TH by lilmike from avsforum and htguide forum as tested by patrick bateman here at diyaudio.

you will need to adjust the width of the horn to fit the eight rather than 6.5" of anarchy.

you will need to adjust the width of the horn to fit the eight rather than 6.5" of anarchy.

Do you have plans for the tapped horn using that driver? Did you go a car audio driver die to availability issues in Australia ?

3ggg the horn is the same with exodus anarchy TH by lilmike from avsforum and htguide forum as tested by patrick bateman here at diyaudio.

you will need to adjust the width of the horn to fit the eight rather than 6.5" of anarchy.

Hi Henry & 3GGG

Mine isn't the same design, Paul Spencer sim'd a different cabinet for the Alpine .The cabs over 600mm WIDE and 2400mm LONG the pair are going to be big 🙂.

Horns rep sims

Red Spade Audio

A mate showed me a build on AVS using these drivers but its a different build .

The drivers can be bought from a number of supplier's .I do have plans for the build which I payed for and there not up for grabs at the moment need to prove the design first .Need to make sure reality close to sims 😉🙂.

Cheers

Last edited:

Corners Glued

Today finished gluing the front and rear corners .Next thing to do is router the rabbets so the side panels fit up .

Glued up the front baffles reader for the alloy inner baffles .

CHeers

Today finished gluing the front and rear corners .Next thing to do is router the rabbets so the side panels fit up .

Glued up the front baffles reader for the alloy inner baffles .

CHeers

It's slowly coming together

Evening

The corners have had time to dry ,I've given a rough sand to smooth out the face's and square them up .The tops I've left to trim level with the sides.

I needed to rebate the ends so theres over lap with the side boards to bond to and seal .Couldn't find a router bit with enough width so I cut the rebates with the saw .Finally drilled the 20mm holes in the bench top for the clamps .

CHeers

Evening

The corners have had time to dry ,I've given a rough sand to smooth out the face's and square them up .The tops I've left to trim level with the sides.

I needed to rebate the ends so theres over lap with the side boards to bond to and seal .Couldn't find a router bit with enough width so I cut the rebates with the saw .Finally drilled the 20mm holes in the bench top for the clamps .

CHeers

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- 4 way active ,passive or what works best