Hi 56oval. Any progress to report on the project?

HI Bon

All the best for Chrissy .

Project slowed down again lack of funds being diverted out side audio projects 🙂 .

The Alpine SWR 12D4 drivers have been ordered should arrive end of Jan .Worked out how much ply I need for the 15" bass cab's and Tapped Horns .6 sheets of Russisn BB 18mmx2440x1220 and 3 sheet's of furntiure grade ply 18mmx3050x1530 .

http://www.alpine-usa.com/product/view/swr-12d4/

A couple weeks aga went over to Pauls place with Roger to give a hand putting the S3 Synergy horns together . We didn't get them finished but Paul's managed to get more work done .

Red Spade Audio

Paul worked out the sims and drew the Tapped horn design for me . I'll be using a pair of them their 600x400x2400mm . It a dual opposed design where the drivers mount theres 2 end caps covering the driver magnets which add @ 300mm to the over all width .

Now to get them into the corners of the lounge without the wife noticing 😀

Go on leave mid Jan so hopefully get stuck into the cabs then .

Cheers

Mal

P.S The family has a new member so I've been a little bit distracted by he .

Last edited:

Update

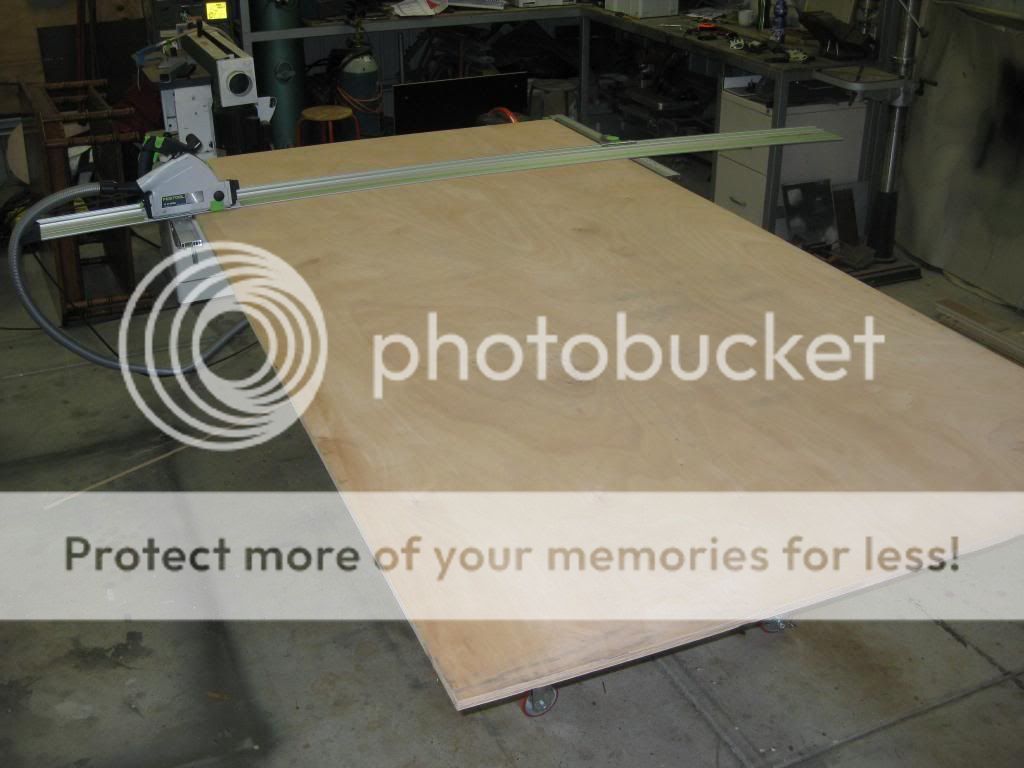

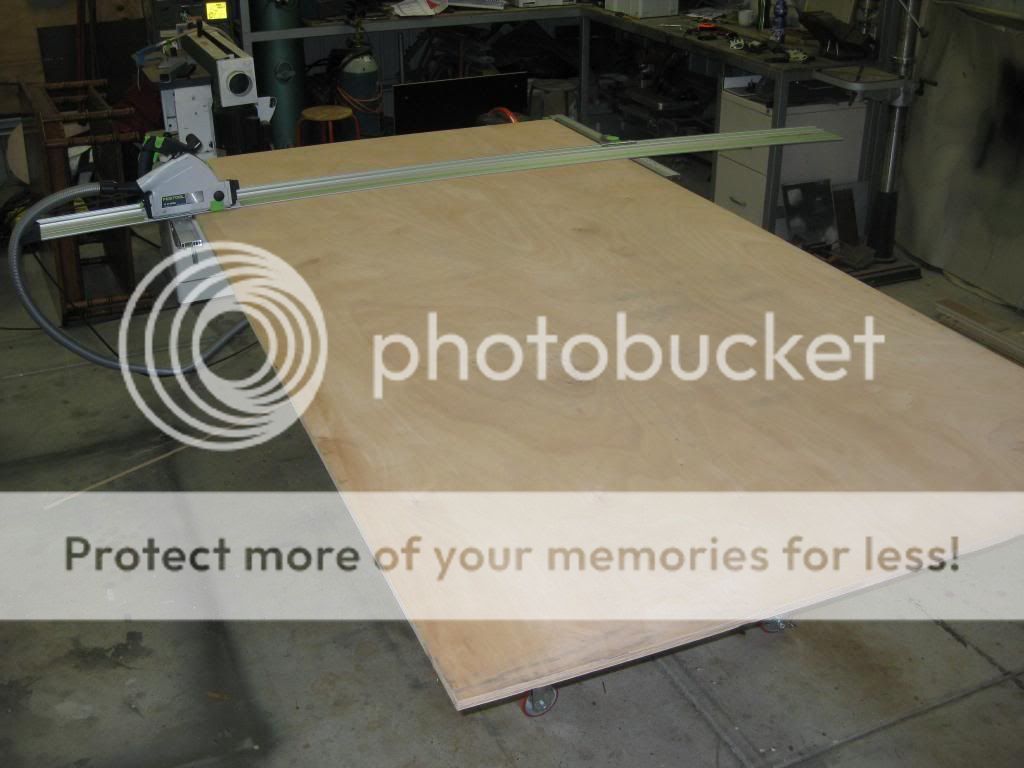

It been a while 😱 ,but today I received the ply for the bass 15" bass cabs and the Russian birch formply for the tapped horns .Bought myself a Festool TS55 saw and a number of their rails systems these should help me cut straight ,I hope 🙂 .

CHeers

It been a while 😱 ,but today I received the ply for the bass 15" bass cabs and the Russian birch formply for the tapped horns .Bought myself a Festool TS55 saw and a number of their rails systems these should help me cut straight ,I hope 🙂 .

CHeers

Each section divided up ,in white .

CHeers

Too late but i need to tell that there's no need to make separate section or division for tweeter, because tweeter is already a close back driver. You can make the tweeter and mid in the same room, or you can patch a small box at the magnet area of mid driver so that the whole volume of air in the total enclosure will be used by bass driver..'That will make a good response in the low section.

I don't drink bear ,so I'm left out in the open on cutting straight 🙂I've found that drinking light beer instead of heavy helps with making straighter cuts!

I might post a picture of the Festool in anger 😀 or a video of it flying across the shed .im more interested at the festool 😀, please show us ur latest tool

The divide acts as a brace and I've ended up with the volume needed .I was going to have the R1 sitting on an open baffle above the 6.5" mid but it looked like an add on . I feel the R1 looks better intergrated within the cabinet .Too late but i need to tell that there's no need to make separate section or division for tweeter, because tweeter is already a close back driver. You can make the tweeter and mid in the same room, or you can patch a small box at the magnet area of mid driver so that the whole volume of air in the total enclosure will be used by bass driver..'That will make a good response in the low section.

Cheers

Mal

CHeers

I don't drink bear

Mal

CHeers

fair enough..what about moose? (was gonna say beaver but thought I'd get into trouble...so lucky I did not say that eh?)

Oh, I remember now, cider was it not?

Guess that beats XXXX gold tho. Geez I hate it when people give me that.

fair enough..what about moose? (was gonna say beaver but thought I'd get into trouble...so lucky I did not say that eh?)

Guess that beats XXXX gold tho. Geez I hate it when people give me that.

😱 Bear bile is a required taste 😱🙂.

I told Nick not that one 🙄🙂.Hows the music theory going still tinkering on the ivorys .

Cheers

Mal

yeah, tbh the system simply does not get turned on any more. spend all my time on the music theory and tinkling the goanna.

that is required too!

that is required too!

Cutting update

Hi

Today a friend came to help me cut down the oversize ply sheets for the 15" bass cab's .We cut down to sheet's to make them easier to handle to cut them down further .

I used the Festo TS55 saw and parallel rail system ,made a couple of test cuts then adjusted the guides for calibration .Then tested the calibration making the bench top out of Birch form ply .Came up a treat diagonal measurements spot on .Next we moved onto cutting the cab's 14 cuts ranging from 400mm to 660mm .Making each piece individual would of been a real pain in the ar5e 🙂 .

Next to rip all the cuts down further .

Testing the widths

CHeers

Hi

Today a friend came to help me cut down the oversize ply sheets for the 15" bass cab's .We cut down to sheet's to make them easier to handle to cut them down further .

I used the Festo TS55 saw and parallel rail system ,made a couple of test cuts then adjusted the guides for calibration .Then tested the calibration making the bench top out of Birch form ply .Came up a treat diagonal measurements spot on .Next we moved onto cutting the cab's 14 cuts ranging from 400mm to 660mm .Making each piece individual would of been a real pain in the ar5e 🙂 .

Next to rip all the cuts down further .

Testing the widths

CHeers

Hi 56oval,

I think your doing very well, in driver choice and build quality of the enclosure.

I do want to warn you it will not be enough to make a nice sounding loudspeaker.

The tonal result is achieved by precise XO work and listing and improving, this also includes the right wire choice and capacitors and series resistance with the driver. This can take along time to tune the speaker to a level you say this is a near perfect cohered output.

I do not want to slow you down but want to motivate you to do much work on XO and components. I like passive but also active XO are influenced by capacitor sound quality. I experienced the level of bas to mid mid to high can make huge difference in how you the speaker sounds, even with small level shifts.

Keep on the good work I like the aluminium baffle I also had the same idea and wanted to do similar it in my own design.

I think your doing very well, in driver choice and build quality of the enclosure.

I do want to warn you it will not be enough to make a nice sounding loudspeaker.

The tonal result is achieved by precise XO work and listing and improving, this also includes the right wire choice and capacitors and series resistance with the driver. This can take along time to tune the speaker to a level you say this is a near perfect cohered output.

I do not want to slow you down but want to motivate you to do much work on XO and components. I like passive but also active XO are influenced by capacitor sound quality. I experienced the level of bas to mid mid to high can make huge difference in how you the speaker sounds, even with small level shifts.

Keep on the good work I like the aluminium baffle I also had the same idea and wanted to do similar it in my own design.

Last edited:

Morning HMHi 56oval,

I think your doing very well, in driver choice and build quality of the enclosure.

I do want to warn you it will not be enough to make a nice sounding loudspeaker.

The tonal result is achieved by precise XO work and listing and improving, this also includes the right wire choice and capacitors and series resistance with the driver. This can take along time to tune the speaker to a level you say this is a near perfect cohered output.

I do not want to slow you down but want to motivate you to do much work on XO and components. I like passive but also active XO are influenced by capacitor sound quality. I experienced the level of bas to mid mid to high can make huge difference in how you the speaker sounds, even with small level shifts.

Keep on the good work I like the aluminium baffle I also had the same idea and wanted to do similar it in my own design.

Thanks for the kind words 🙂

I have a couple experienced mates helping me out with the cross overs ,I don't have a clue about designing them .

When it comes to caps ,values first then maybe type latter ,build quality and reliablity .

Wire,required gauge then type .I'm not so hung up on it ,the room will dominate more than a correctly suited wire .

I have done the parts swapping thing for years and I thought it was time to do a complete build from scratch including room as part of the system .

The Raven R1 xovers are in the middle of the pic in post #12 😉🙂.Can you divulge and crossover info 56? Or is it top secret?

When I get to the xovers I'll post about there construction.

CHeers

Impressive

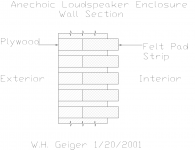

For best results, use an active crossover with dedicated amplifiers, particularly to drive the Raven Ribbon [2]. Also protect this driver with a series capacitor in the drive circuit. Borbely designed a FET, Class-A, Ribbon Amplifier [3] specifically for this driver type. Enclose the drive unit in its own back-box as well. Your salami-slice construction method presents an opportunity to implement an anechoic treatment [1] of internal enclosure wall surfaces using felt strips.

Hello Diy

This is my first speaker project ,I have a habit of biting of more than I can chew when it comes to projects🙂 .

This project has been going for a number of years now ,life just gets in the way more often than not . I'm also building the electronics from frontend to amps which doesn't help .Plus I have no real electronics knowledge 😱.Plus the room it self needs a bit of acoustic treatment .I was a its all about the front end ,but over the years I feel its more speaker ,xover room interaction .

Any here's a novice approache to speaker design and build 🙂 .

The design ,seperate bass cab's to the mid section so I can move them around and swap out the top section for a Synergy horn ,designed by Paul Spencer ,but thats another project 🙂.

>snip<

Drivers ,I've heard the Raven tweeters a number of times and I really like how they sound & they sound really nice with PHL's .Bought the drivers from Pat @ War Audio in Perth ,Australia . Pat has been very helpful over the years .

>snip<

CHeers

For best results, use an active crossover with dedicated amplifiers, particularly to drive the Raven Ribbon [2]. Also protect this driver with a series capacitor in the drive circuit. Borbely designed a FET, Class-A, Ribbon Amplifier [3] specifically for this driver type. Enclose the drive unit in its own back-box as well. Your salami-slice construction method presents an opportunity to implement an anechoic treatment [1] of internal enclosure wall surfaces using felt strips.

Attachments

For best results, use an active crossover with dedicated amplifiers, particularly to drive the Raven Ribbon [2]. Also protect this driver with a series capacitor in the drive circuit. Borbely designed a FET, Class-A, Ribbon Amplifier [3] specifically for this driver type. Enclose the drive unit in its own back-box as well. Your salami-slice construction method presents an opportunity to implement an anechoic treatment [1] of internal enclosure wall surfaces using felt strips.

Morning

I have dedicated amps for the drivers in post #12 .A 300B SET's for the Ravens and PHL's .For the R1 the OPT's are wound to suit the impedence load 2ohm's & -3db to 100K flat to 60K xover funtion built into the amp.

I bought the drivers from WarAudio based in Perth ,Australia . I'v known Pat for the number of years and have heard speakers he's built and he's used the PHL's and Raven's 1,2 &3 in combination .All the amps circuits and iron was designed and made by a mate , Lucas from BlackArt Audio these guys will be helping me out with the xovers ,as I said I don't have a good understanding of xover design 😱.

Like the idea of the felt ,I"ll be using Black Hole 5 in the cab's .But the strips of felt idea looks cool maybe I could use the BlackHole5 in the same way .

Thanks for the post ,thinking of decoupling the front baffle 😕 .

Cheers

Mal

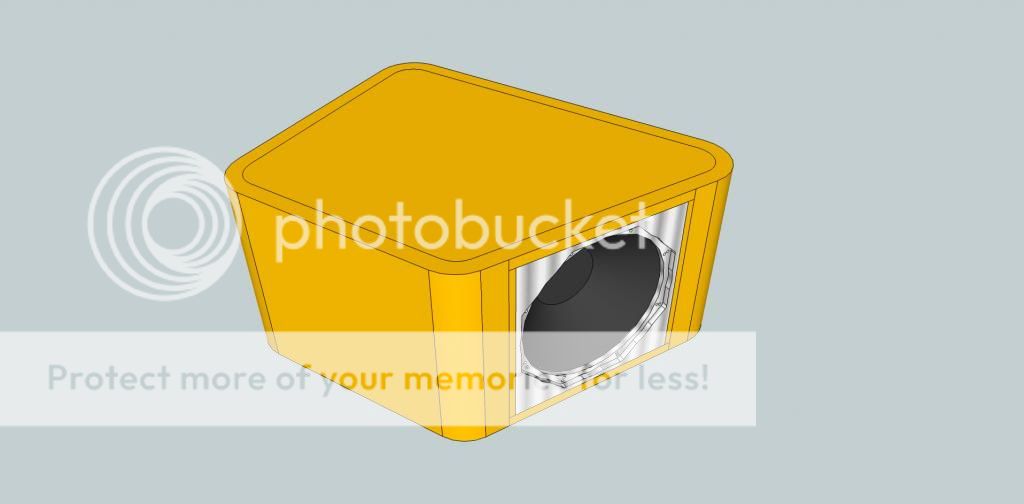

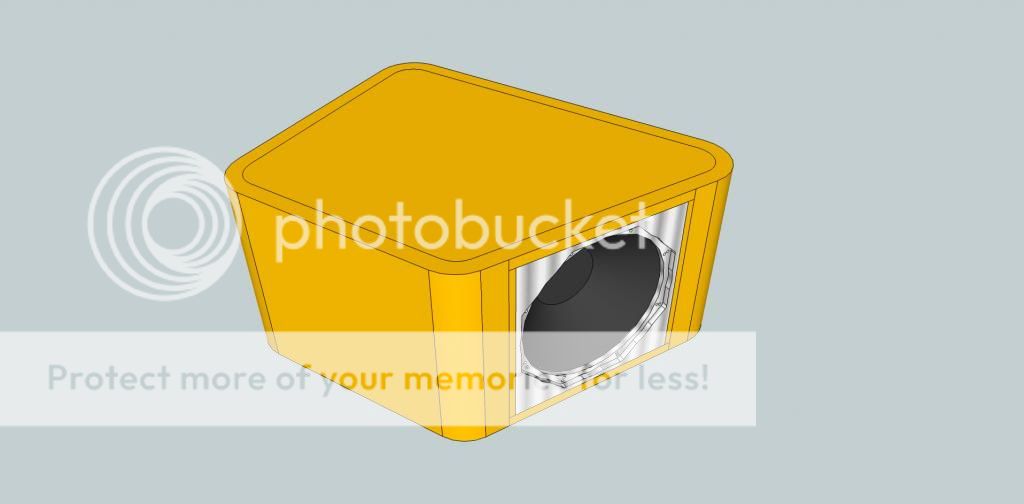

He's the bass cab for the PHL 15"

The tapped horn using the a pair Alpine 12D4 per cab .Building 2 of these .

How its going to fit in the room .

On the left the Synergy horn version

CHeers

The tapped horn using the a pair Alpine 12D4 per cab .Building 2 of these .

How its going to fit in the room .

On the left the Synergy horn version

CHeers

Rigid Mount Only

G'day,

Suspend the aluminum baffle from a wire and tap it with a hammer. What you hear should convince you not to attach it to an enclosure body using an elastic membrane or other such members.

Regards,

WHG

Morning

>snip<

Thanks for the post ,thinking of decoupling the front baffle 😕 .

Cheers

Mal

G'day,

Suspend the aluminum baffle from a wire and tap it with a hammer. What you hear should convince you not to attach it to an enclosure body using an elastic membrane or other such members.

Regards,

WHG

Hi WHGG'day,

Suspend the aluminum baffle from a wire and tap it with a hammer. What you hear should convince you not to attach it to an enclosure body using an elastic membrane or other such members.

Regards,

WHG

Looking at using one of Sika products ,used there products in the automotive trade.

Sika Australia | Sika Australia Pty. Ltd.

CHeers

Mal

More cutting down

My mate Roger came over today and we cut down the sheets further 28 pieces all up .I'm glad we didn't have to measure and mark each cut 🙁 .

Cut the angles for the top & bottom plates for the base cab with the 28 degree angles .

28 cuts

Cheers

My mate Roger came over today and we cut down the sheets further 28 pieces all up .I'm glad we didn't have to measure and mark each cut 🙁 .

Cut the angles for the top & bottom plates for the base cab with the 28 degree angles .

28 cuts

Cheers

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- 4 way active ,passive or what works best

.

.