Hmm, I've been missing a lot of email notifications lately, yet when I check, it shows me as being subscribed and when I sent you the PM from here it sent me to some webpage I've never seen before rather than confirming it being sent, but when I hit the back button it had cleared out my text, so waited for a thread update which still hasn't come........

Anyway, I'll try again.

GM

Anyway, I'll try again.

GM

Glue,

Titebond II (traditional water based wood glue) or Gorilla (urethane based glue) ?

Well, I prefer PL400, but otherwise, Titebond III.

GM

Glue,

Titebond II (traditional water based wood glue) or Gorilla (urethane based glue) ?

application?

both are good, although Gorilla, etc is not without its own issues (messy clean up, longer cure times and penetrating staining amongst them)

The Titebond II is very strong; the pic was 2 end pieces glued together, then snaped a week later, it pulled the center of pieces shown; it took a good deal of force/weight to do this.

Remember to coat both sides, I use a 1" paint brush to float it around some, it doesn't hurt to let it soak in a while before setting pieces together.

Remember to coat both sides, I use a 1" paint brush to float it around some, it doesn't hurt to let it soak in a while before setting pieces together.

Attachments

No matter how carefully I plan I always seem to panic during glue-ups so I like to use glues with longer open times like Titebond Extend. Can be hard to find and may not be 'the strongest glue on earth' but plenty strong enough for speaker use.

GM, try an email if PM does not work.

With regards to the lower f3 compared to the traditional Fonken, the only way I see to move f3 up is to reduce the cab volume and re-tune the vents. When I sim this, it does not produce the nice sharp roll off unless I also accept a lot more peak below 100Hz. Since the size looks reasonable at 9L volume, I probably will go ahead with this design and see how it sounds.

With regards to the lower f3 compared to the traditional Fonken, the only way I see to move f3 up is to reduce the cab volume and re-tune the vents. When I sim this, it does not produce the nice sharp roll off unless I also accept a lot more peak below 100Hz. Since the size looks reasonable at 9L volume, I probably will go ahead with this design and see how it sounds.

Last edited:

Just out of curiosity I took the cab size up from 9L to 14L to see what would happen.

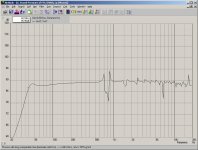

According to AkAbak, the f3 can be reduced to 40Hz with a 1dB dip (-2dB from 500Hz) before the peak around 45Hz. Is this model accurate, or have I done something stupid that is giving poor modeling accuracy?

According to AkAbak, the f3 can be reduced to 40Hz with a 1dB dip (-2dB from 500Hz) before the peak around 45Hz. Is this model accurate, or have I done something stupid that is giving poor modeling accuracy?

Attachments

I still use white glue for cabinets. ("Elmer's" or equivalent) Ultimate strength isn't an issue unless you plan on jumping up and down on the cabinets. Worried that the glue isn't waterproof? Don't throw them in the pool. I just like the working properties of white glue.

Jason fixed that, at least when i go there now... i'll alert hom that it is not universal.

dave

Just out of curiosity I took the cab size up from 9L to 14L to see what would happen.

According to AkAbak, the f3 can be reduced to 40Hz with a 1dB dip (-2dB from 500Hz) before the peak around 45Hz. Is this model accurate, or have I done something stupid that is giving poor modeling accuracy?

I would consider that an ungly tuning. The 1st derivative of the FR curve crosses 0 more than once.

dave

Isn't that true of any tuning that has a hump at the low end no matter how slight? Or is it a matter of degree as well?

The plot in post 115 has a very slight hump. Would it also suffer from the same problems?

The plot in post 115 has a very slight hump. Would it also suffer from the same problems?

Back on post #91, page 10, the center oak BR boxes are 10.5liter (maybe a bit more). They were not too bad, but I wouldn't go any larger.

Madisound said don't go larger than 9Liter. And the fostex BR box plans (also shown in the pic) is 9Liter.

*******

Yes white glue works fine, I'm trying to find a test report some friends did on glue.

Madisound said don't go larger than 9Liter. And the fostex BR box plans (also shown in the pic) is 9Liter.

*******

Yes white glue works fine, I'm trying to find a test report some friends did on glue.

The plot in 115 would pass muster. Remember that the somewhat aperiodic push given by skinny ports is going to lower the Q of the rolloff.

dave

dave

So far from the AkAbak simulations I've done (I'm new at it and still learning), 9L looks like a sweet spot. Above 9 the peak at the low end gets progressively worse no matter what I do with the port. Below 9L the low frequency f3 gradually increases as the volume decreases.

I haven't tried changing the aspect ratio of the cabinet yet, and there is a small chance that it may offer some additional latitude in tuning.

So having several skinny ports on both sides of the enclosure will impact Q more than a single less skinny port at the bottom.

Thanks Dave, oDougbo and everyone else.

I haven't tried changing the aspect ratio of the cabinet yet, and there is a small chance that it may offer some additional latitude in tuning.

So having several skinny ports on both sides of the enclosure will impact Q more than a single less skinny port at the bottom.

Thanks Dave, oDougbo and everyone else.

Last edited:

So far from the AkAbak simulations I've done (I'm new at it and still learning), 9L looks like a sweet spot. Above 9 the peak at the low end gets progressively worse no matter what I do with the port. Below 9L the low frequency f3 gradually increases as the volume decreases.

I haven't tried changing the aspect ratio of the cabinet yet, and there is a small chance that it may offer some additional latitude in tuning.

The side mounted port slots in the 3 layered wall panels of the 9L enclosures that Doug built offer a lot of latitude for tuning by adjusting the number and size of spacer blocks.

This particular design has been continually refined over a period of 6 years; net internal volume, cabinet and port dimensions have been optimized for drivers as wide ranging as CSS EL70, FR125, Fostex FE127E, FE167E, FX120, FF85K, FF85 /125/ 165WK, Mark Audio Alpair 7, 10 and 12 - plus probably a few makes/models that I haven't built.

Particularly when employing the large side chamfers, the challenge has often been getting the box wide enough to fit the large frames of say the Alpair models, while meeting the required smaller internal volumes.

As a general guideline, at what volume is it necessary to switch from 12mm to 15mm plywood?

I've got 12.5mm I can use for all but the front, and can pick up 17mm for it. Locally there are no options between 12.5 and 17.5mm

I've got 12.5mm I can use for all but the front, and can pick up 17mm for it. Locally there are no options between 12.5 and 17.5mm

GM, try an email if PM does not work.

With regards to the lower f3 compared to the traditional Fonken, the only way I see to move f3 up is to reduce the cab volume and re-tune the vents. When I sim this, it does not produce the nice sharp roll off unless I also accept a lot more peak below 100Hz.

I did, but didn't get a response initially, so posted here about the problems I'm [still] having.

F3 is lowest in a T/S max flat alignment. All others have a higher F3 regardless of box size, tuning. A sharp roll off with a higher F3 is always under-damped, so ideally its 'ringing' should be damped.

GM

Worried that the glue isn't waterproof? Don't throw them in the pool.

Down here in high humidity, Elmer's white hasn't held up all that well for me.

GM

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- New Fostex fullrangers are in at Madisound