Guys

As you know, sometimes there is s a need to threading, to fix a threaded bolt or whatever it might be.

If there is only 1, 2, 3, 4 or may 5 holes to thread you have to make, then most of us with some mechanical background would do this easy.

But as soon there are more threadings needed, say 20 or more. it will become very time consuming.

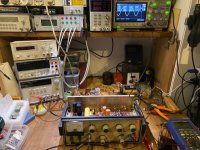

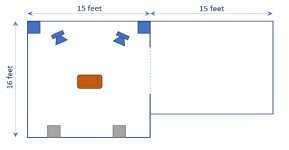

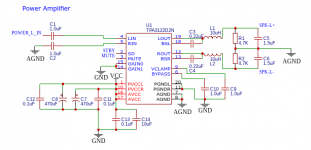

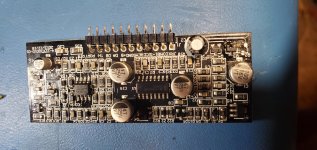

Now it happens that these day I need again tread some aluminium heatsink to hold 8 - T0264 Transistors, and also a large PCB with the size of 300x140 mm with a lot of component soldered to it.. So there are 8 Transistors that means 8 holes 8 times threading, and then also the stands for to hold the PCB fitted to the heat sink another 8. this makes 16 holes have to be drilled and 16 holes have to be threaded.

Take for one on hole a minimum time of 2.5 minutes to drill and to thread,

* any mechanic knows that this will not be enough time. * so then we have

16 x 2.5 minutes = 40 minutes, now we have two sides, left and rigth, so time doubles.. Again that would be fast, but I think 5 minutes for ome hole is average, so two pieces would take up 2.6 hours or 160 minutes. A lot of time..

This can be done faster. Go to a mechanical shop and have them done that.

You will need to draw them a layout, where the holes have to be. then may you have to wait because the shop has other customers which were first. And finally you have to pay them.

Do it by youself, get a Threading machine, for several hundred or even more Dollars. Or take this example and I can assure you that you will make one hole drilling and also threading under 2 minutes, neat and clean and of high quality.

There of course you will need a drilling machine, hand or standalone, and if possible brand new drills. HSS or better, make sure that the drill Cut Angle on top of the drill is correct for the material you are going to drill. that way you will get best results..

Till now no problem, anyone can drill a hole, but now threading, this is a thing for itself..

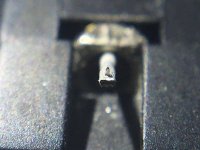

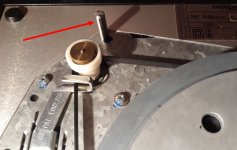

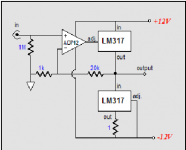

As threading will need forward and backward turning and also threading must be done on not to high speed most will use the manual way. Having a tool like to see in the picture..

But now there is the option ot have a threading machine made DIY, which works perfect on aluminum thin Stainless Steel plates and also copper.

I made a

VIDEO, just to show that this is real inexpensive and fast and can be done almost by everyone who has a hand for DIY..

The Tool I use is this small hand drill, battery driven, to drill or to fix screws or bolts; I just modified and Steel bolt removed from MAC PRO to hold the Threadingdrill. Insert into the Hand drill and there we go.!

The rest you will understand if you look at the picture. Of course you will need some Cutting solution to drill holes or threading, but also this is inexpensive.. Lenox is the Brand Name I use, not to advertise this here, but it's rather cheap and good quality. This Heat sink time to drill and threading was less than 20 minutes. The thread are good to screw in aans out bolt at least a 100 times without losing the grip of the Bolt. So migth the one or other can make use of this.

Regards

Chris Hess