I don't know if any of you chaps have heard of these guys, but I just took a punt on buying their PreAmp kit:

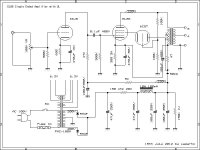

Classique – Phono Valve Preamp Amplifier With Passive RIAA Using 12AX7 / 12AU7 – DIY Kit – Caledonian Audio

Whilst Caledonian stuff gets great reviews, I don't have quite the same space as the standard enclosure needs, as you can see in the picture below (Top LH shelf is the deck, the highest shelf on the right is for my phono stage):

However, as this comes as a kit (without the enclosure) I figured I could look at making a custom enclosure so I dropped them an email. The owner came back to me and has been really helpful. After a number of emails back and forth, trying to find a way to fit all the components into the space, I came to the conclusion that there were two two options, both with issues:

1. Two Housings.

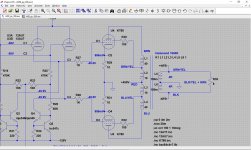

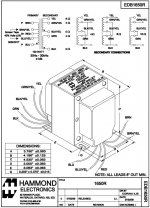

Separate the PSU PCB and Transformers (which are lovely, but big bu99ers), from the Amp PCB and valves and join the two with cables. However, I have some safety concerns around having a cable carrying HT DC and felt it will be neater if everything is in one case. So we discussed whether a single transformer could work, but I liked the purity of the CA design in using 2 transformers.

2. Use smaller transformers.

So, what about smaller transformers? After all, we are only driving three small tubes. To stay with the CA separate power supply design, and perhaps mitigate the chances of hum even more, use two toroidal transformers? And to minimise space, could the heater transformer be smaller too?

Perhaps a compact toroidal for the HT Anode supply, such as this:

240V/6.3V toroid power transformer – Amp Maker: Guitar amp kits and parts

Then a miniature toroidal for the heater supply, such as this:

60032 | Nuvotem Talema 115V ac, 230V ac, 2 x 12V ac Toroidal Transformer, 7VA 2 Output | RS Components

In the end, we decided that option 1 (two housings) could work if the PSU PCB was housed within the PreAmp housing.

I.E. A separate enclosure, housing the two transformers, building the enclosure from mild steel sheet with a central steel bulkhead, separating the two transformers. Then in the Preamp enclosure, I house both the preamp pcb and psu pcb, again with bulkhead between them. Then, all that is required between the two, is a 5-way cable linking the enclosures, comprising 2x twisted pairs (one for heaters and one for HT), each pair within its own shielded outer (e.g. shielded heat shrink), with shielding only grounded at the transformer enclosure, and a high-quality / low resistance grounding strap between the two enclosures.

However, space is still going to be tight in my application.

Height wise, the distance between the preamp shelf and the overlappling turntable shelf above, means I have 67mm of available height. Taking into account the 52mm for the 220uf 400v capacitor including the power supply board, that allows 15mm for the PCB mount, case and feet. Case top and bottom will total 3mm, feet about 5mm and if I use 5mm PCB mounts, I will have a couple of mm clearance. Tight as a gnat's chuff!

As far as width and depth are concerned, here are 1:1 scale cardboard representations of the 2x PCBs laid onto the original template I sent to the stonemasons who made the slate shelving for me:

As it happens, I was planning to copy the shape of the black slate shelf when creating the preamp case. As you can see; there is just enough room for the outer case (and a bulkhead between the PCBs to ensure EMF separation), with an area behind the amp pcb to site the input/output signal sockets and ground connection. There is also an area next to the power pcb, where I can site the power connections. Currently, all connections are hidden inside the shelving (power and signal in separate channels) so I should be able to also do this with the preamp.

So, I should be able to end up with a discretly powered Valve Preamp that is exactly the same teardrop (ish) shape as the slate shelf, and not a cable in sight!

Once everything arrives and I get started, I will Blog here about my build experience and the results

B