Hello everyone

Has been a long time since I have posted here, but been super busy away from here working and improving on what I can do from a driver design perspective. Today I want to share with you all Tenacious 7 as it is getting closer to completion.

Tenacious 7 is a 50.2cm2 full range driver, placing it at the same size as the Mark Audio Alpair/Pluvia 7 series, along with stuff like the Visaton FR 10. I still have work to do, especially on the high frequency response, but lets start with the T&S Data:

This is specifically Tenacious 7 PW and running my strongest motor design that it supports. Tenacious 7 CF is slightly heavier and so is likely low 85/ high 84dB region. Testing was done in my own TL design which was originally for the Mark Audio Alpair 7.2 some 10 years ago. This was used simply because I still use them and it isn't far of the suited design for these or the Pluvia 7.

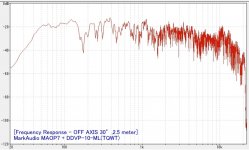

Next is a look at the upper frequency response of Tenacious 7 CF against Pluvia 7 Gen 1. Results where indoors gated to 3ms @ 1M distance, but I am in a overcrowded housing situation so some noise is possibly present:

White is Tenacious 7 CF

Red/Pink is Mark Audio Pluvia 7 Gen 1

You can see mine is a big rough and the top end rolls off to quickly. I have some ideas on fixing this, so this is where most of the final work will be focused on.

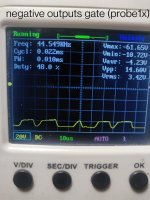

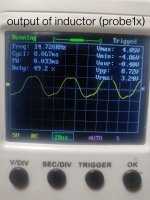

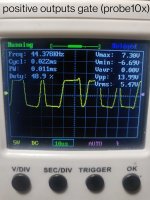

Finally is some data done at various volume levels but not calibrated, so is simply -20dB and -10dB. I can confirm that -10dB was pushing the excursion limits to around the 4mm Xmax of the Mark Audio drivers. My own Tenacious 7 CF is +/- 2.7mm to 82% BL, and +/- 3.5mm to 70% BL, so not quite as far. These measurements where taken nearfield.

^^^ Tenacious 7 CF @ -20dB

^^^ Mark Audio Pluvia 7 Gen 1 @ -20dB

^^^ Tenacious 7 CF @ -10dB

^^^ Mark Audio Pluvia 7 Gen 1

I could be wrong, but I can't seem to find any other 3D printed speaker drivers which are this close at competing with off the shelf drivers?

For clarity, the speaker cone, surround, spider, chassis and front fascia are all 3D printed components and designed by myself. The magnet motor is also my own design, not borrowing from any other design. In fact, the motor is removeable and can be reused for other designs and driver sizes.

Any questions / critiques etc, please fire away. I have been working on this 6 years now and I am doing what I can to improve my work

Thanks for checking out this long post!

Paul - Polymate3D