Hello all,

First post, long time lurker. I've been building for about 12 years with varying amounts of success. I started out with trying the different types of enclosures from sealed/ported to some quarterwave and OB stuff. Then I found out about miniDSP and fell down the active rabbit hole for like 7 years.

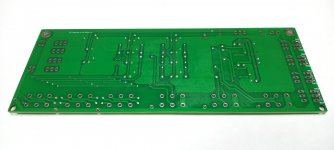

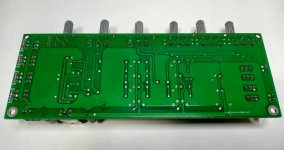

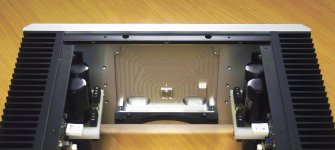

Here are some pictures of one of my builds. Recently the GR Research youtube channel got me interested in actual passive crossover design and measurements and that's pretty much where I am now. I converted some of my active builds to passive using measurements and software for the first time. Then did some other upgrades to speakers for some friends.

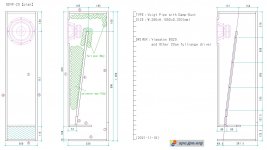

Recently I decided I would try to make a small bookshelf speaker that could come-to-market as an exercise, not an actual goal. This being my first post and all, I want to stress that I'm fully aware a speaker I'm making isn't going to show up in stores, ever. I'm not even trying to sell this pair, I'm giving them to my cousin. Anyway, here was my attempt at making a cheap (sub $1000 MSRP), small, bookshelf speaker. The project kind of snowballed and ended up not being very cheap after getting the MDF CNC'd on the second attempt and adding a second passive radiator. The drivers are the SB Acoustics

SB13PFC25R-08 5" Paper Cone Woofer and the

SB29RDNC-C000-4 Neo Magnet, Ring Dome Tweeter.

I used .5" MDF on the prototype and a single passive radiator (rear mounted). The bass wasn't very extended and the cabinet had a good bit of vibration on the sides, despite having a brace between the tweeter and woofer that touched 4 walls.

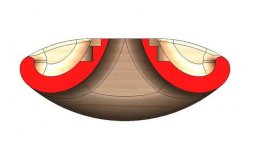

I moved to .75" MDF and two passive radiators to hopefully boost the low end a little bit (I'm guessing this sounds funny to better designers). I didn't succeed with the bass extension in the end. When selecting the woofers I wasn't sure if I should trust the low frequency part of the plot, but after completion I believe I have my answer.

The front baffle is 3D printed and bonded to the MDF with resin. Printing allowed way more freedom in angles and features since I'm not very good at woodworking. They were printed at 25% infill and weigh just under 500g each. On a small build like this, I would definitely 3D print again.

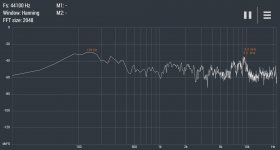

How do they sound? I was very surprised at how detailed and accurate these things turned out. These $35 woofers are an insane value and I will definitely be using more SB Acoustics drivers in future builds as a result. I really enjoy the tight bass that they are able to produce. They only reach down to 60Hz, but there is noticeable drop-off below 100Hz. Bass strings are very articulate. They are fun to listen to after a healthy bit of bass boost on the amplifier side. Imaging and transparency are very good. I really like the sound of this tweeter and it's small faceplate.

Specs:

60-20,000Hz +-2.5dB

~91dB efficiency (this seemed high to me, and I haven't measured this before so I may have done it wrong. I used my o-scope to set Vrms to 2.83v at 1000Hz and did a sweep at that level)

8ohm nominal, 5.3ohm minimum

Internal volume: 9L

External dimensions: 8" wide, 11.25" tall, 11" deep

Material costs:

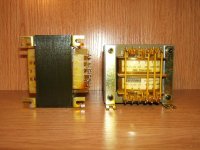

Drivers: 71.60x2 + 34.70x2 + 35.70x4 = $355

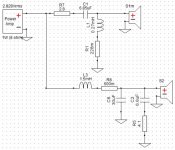

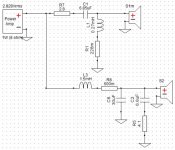

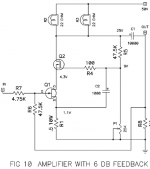

Crossovers: $111

3D Print material: $15

MDF: $25 (can be cut from 1 quarter sheet)

Total: $506

Takeaways:

- They are a good speaker, probably my best so far in terms of natural sound. BUT, I'm not sure anyone would want it in the $1000 range without more bass extension.

- It's hard to make a cheap speakers without auditioning a bunch of drivers and prototyping a lot of enclosures.

- Passive radiators sound really good but add a large percentage of cost, duh.

- It's even harder to make a cheap speaker when they have to look good. These look OK in the pictures, but could not be sold in mass market they way they are.