I recently decided to try to upcycle a microwave oven transformer into an output transformer with roughly a 2500:24 ohm impedance ratio. I chose a turns ratio of 1500:150 merely because those are round numbers. I didn't want to make this any more complicated than strictly necessary since I've never tried it before. It took a fair amount of time and patience, but I have both. Microwave iron is so readily available that I figure that someone else may have a need to know how this turned out for me. I challenge anyone to try the same instead of sending yet another dead microwave oven to the landfill. I am not claiming that this experimental transformer is "just as good" as any factory made transformer. That is entirely subjective in my opinion. It does sound great to my unqualified ear though.

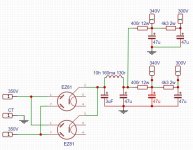

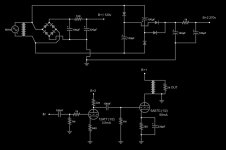

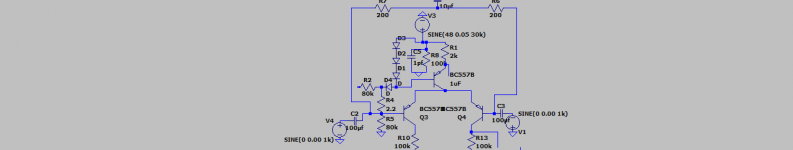

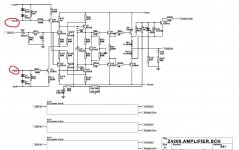

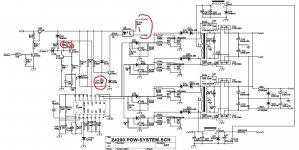

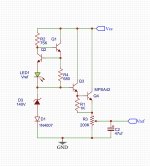

I put together a test setup consisting of a 12AT7 gain stage coupled to a 6AS7G dual power triode for the output stage, given that it has such low output impedance. I take it that the 6AS7G has much lower "technical" Z than 2500 ohms, but I got far and away the best results with what I have here. The transformer that I compared this one to is an Edcor GSXE10-2.5k - 16ohm since that's the closest match that I have on hand. I intend to try this with smaller iron in the future for a headphone amplifier.

The microwave iron is freakishly huge for that purpose, but it's still in the experimental stage and it was easier to wind, given it's large size. The microwave iron that I have is already in an E-I configuration, and the "E" and "I" were bead welded together. I cut the welds with a grinder and pryed the "I" off, exposing the factory windings. I removed all three of those, along with the shunts. On one piece of iron, I ground the middle leg of the "E" down by a couple of mm to increase the air gap, but didn't notice any improvement over leaving it alone. I 3d-printed a bobbin for the new iron out of Nylon, and put it on a hand-cranked jig to wind it.

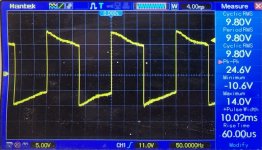

On my first attempt, I wound the primary and the secondary both in one large go each, laying the secondary entirely on top of the primary. I used 28awg magnet wire for both, since I have a large amount of it that's been salvaged from shaded pole electric motors, and isolated the windings from each other using Kapton tape. The results of that one were mixed. I wasn't overly careful with getting the turns very neat and even, and the result was a square wave output that had a considerable amount of rolloff. That is, the "corners" of the waveform were rounded on all frequencies. Not sure of "rolloff" is the correct term for that, but there it is.

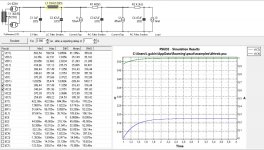

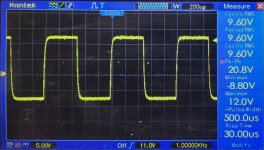

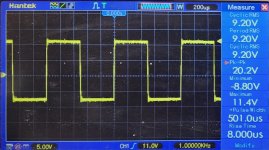

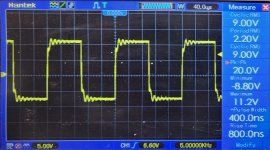

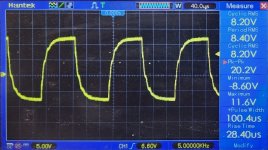

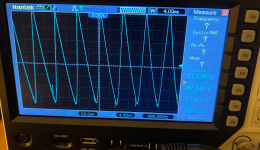

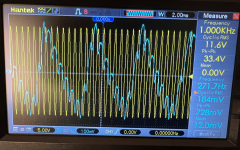

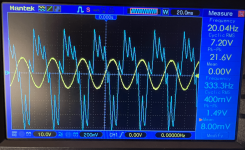

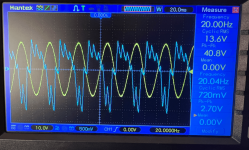

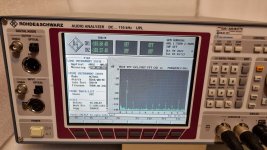

On the second attempt, I carefully wound four layers of the primary, then one layer of the secondary, then another four of the primary, etc until finished. I then spliced the segments together. I again isolated the primary and secondary at all transitions with Kapton tape. I fed a square wave into the amp at several frequencies and documented the output on a scope. I don't yet know how to calculate THD, so I apologize for not including that data. I observed near-identical performance at low frequencies. The edges of the waveform were somewhat rounded off on the DIY transformer at high frequencies though. Not so much that I found it unpleasant to the ear. I really like it in fact, and am excited that it worked anywhere near as well as it did. The trebel is nice and clear, but it's not as sharp and piercing here as I've seen with some other setups.

So anyway, there it is. The iron on the DIY trafo is a little janky looking, but one would be surprised what a little sandpaper and spray paint can do to remedy that. There's certainly room for improvement overall, but it's workable and I think that's pretty awesome.