After lurking dozens of years here on diyaudio , I decided to build my own riaa tube preamps.

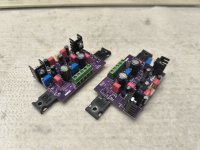

After retirement I recently picked up an old hobby, tubes and amps, combined with a renewed interest in playing vinyl , I acquired some pcb's on aliexpress. One board was based on the Mofi riaa mm/mc preamp, two dual opamps opa1652, two voltage regulators for symmetric psu ,+18V and -18V, and the split active low boost - passive high roll-off riaa network, ready in no time, and sounded quite nice, no hum, noise or other inconveniences, but not very satisfying to listen to.

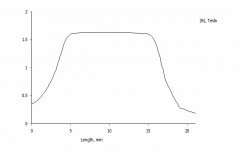

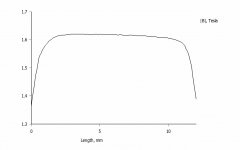

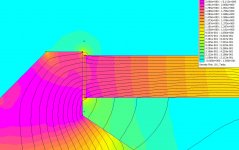

After some reading on the internet, I got interested in some tube based riaa preamps, in particular the ear384 which seems a shunt feedback design, the Joe Tritschler split passive high - shunt fb active low boost design with unobtainable tubes , and the JL Hood , originally solid state but translated to tubes-mosfet hybrid by me, split series feedback low boost and shunt fb high roll-off design. To that end I acquired two pcb's from aliexpress, one designed for the ear384 design and one for the shure M65 preamp. I wasn't very impressed with the sound of the Mofi ear384, it seemed to have more than twice the voltage output at 20kHz than at 20Hz. Measured with an inverse riaa filter , modelled after the design on Rod Elliot's webpages, with the 1k gain setting resistor altered to 590R , much closer to the original 604R from this design, with all inverse riaa components selected to be within 0.1% of the target values, this fed by a GFG-8015 function generator. So I changed that to the tube-mosfet hybrid JL Hood design:

A few errors , the 43R from the shunt feedback network is connected after the 3.3uF capacitor and the 590R isn't there.

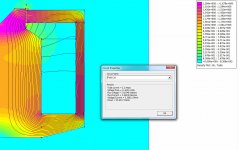

This was a lot better to my ears. Allso measurements with the inverse riaa filter seemed to indicate a much better riaa conformance , with deviations <0.2dB , and a slight roll of at 20kHz, depending on the actual value of the 81.5pF capacitor. The CCS loading the ecc83 is made out of a J112 jfet and a cpc3960 depletion mode mosfet with ca 1mA current. The active low boost riaa feedback network is targeted at around 4mA current. The capacitor parallel to the source resistor can be made into a rudimentary rumble filter. The 6J52P pentode can be anything , ef184 e280f e180f e186f e810f or 6j11p. This my not very tidy test model:

Two gas discharge tubes for ca. 289V stabilized HT and a LM317 for a stabilized 12.6V , the two 6J52P tubes here used run heaters in series, just like the single ecc83. Riaa componenets are selected to match between left and right channel. Because of the feedback design tube matching on gain is less relevant and left and rigt outputs match very nicely.

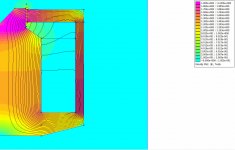

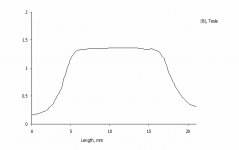

I allso read much regard for a completely passive design, so I used the shure M65 board to make a complete passive design:

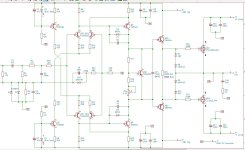

Again a hybrid design , with a 2sk117 jfet cascading into a 6BK7A triode , here cascoding the jfet and the triode would give higher gain, but I wanted to have a line level output voltage. Output is buffered by the ccs loaded mosfet source follower, whereafter the passive riaa network, the values shown gave me the best riaa conformance, though official calculations give sligtly different values. The second triode is ccs loaded with the "mu?" output used as the output. The 825R for the cathode, unbypassed, is to limit output voltage , a LM385Z-adj. would yield more gain, but I wanted to keep the output at approx. line level. This amp allso sounded very nice , though somewhat softer in tone , but absolute no listening fatigue, so much so I have to reconsider playing records because the cost of good needles is pretty inflating my household budget. This is the modified shur M65 pcb:

I couldn't decide which was the better of the above two designs, or the solid state mofi design. I find the tube designs more interesting to listen to, I think mainly because of the looks, with solid state there ain't much to look at, and , despite what people might say, looks count for the listening experience.

To listen to the tube riaa preamps , I allso decided to build an integrated power tube amp, consisting of the standard PP power amp, a tube based tone control, and a builtin riaa preamp.

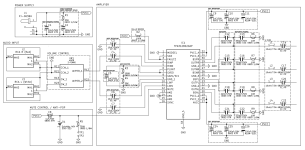

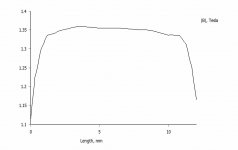

It's based om el86/6p43p tubes , with a 6BK7A based LTP phase splitter ,ccs in the tail to the -50V ,and a shared ecc83 input tube for L and R channels. The tone control is based on the ecc832 , the AU halve is used as the CF input with the AX halve serving as the actual tone control triode, baxandall type, so no gain in mid position. Both loaded with ccs's made of a J112 and a CPC3960, 4mA for the AU and 1.2mA for the AX , wherev the "mu" output is used for connecting to the power amp input. The riaa preamp is based on the Joe Tritschler passive -active shunt fb design, but with ecc83 tubes, a 2sk208 cascading into the the ecc83 as input, that is ccs loaded with 1.2mA , with the mu output loaded with the passive riaa high roll-of. It's cathode held at fixed voltage by two LM385Z-5 vref's that need only 10 micro A to work properly, and with 1Ohm dynamic resitance no capacitor for AC is needed. The second triode halve , allso ccs loaded with 1.2mA functions as the low boost shunt feedback amp and output to the volume pot. This riaa preamp allso sounds very good, albeit not as "clean" as the other two. The whole amp is fed by a smps , supposedly 300Watt, I got cheap from aliexpress. It's advertised to deliver 300V/600mA, 12.6V/?A , 6.3V/?A and -50V/100mA . Actual output voltages weren't that good. The 6.3V has it's own switcher to make the 6.3V from the 12.6V output. It gave under load only 5.9V and I had to change the feedback resistor value to the switcher to a slightly higher value, it's now 6.23V which seems close enough. The 12.6V was only 12.18V, after allso changing the feedback resitor to the calculated necessary value I got 12.54V , close enough, which allso brought the HT output from 278V to 283V, still quite some lower than the advertised 300V , but since I was using el86 tubes in standerd UL PP design, it was more than enough. Loaded with 5k OPT's , it delivers 18Watts per channel , constant tone test.

The amplifier has no appreciable hum or noise when line level inputs are selected and volume max with ear against speaker cone, but considerable hum when one of the riaa preamps is selected. The seperate riaa preamps have transformer psu's and sound more open than the built-in riaa preamp, but all have equal loud hum with volume at max. Might the smps be the reason for the less open sounding built-in riaa preamp ? I do see a lot of HF dirt on the several supply lines, in the 100kHz till 1MHz range. After changing the power supply input capacitor from the low quality 150uF 400V type to a brand quality 390uF 450V it was less, but still. From scope readings it seems to operate around the 115kHz region and is of the LLC resonant type. The output supply lines have no inductors , like you see in computer psu's. What would be usable types for this frequency and application? The tone control and power amp don't seem to suffer that much from the smps, but I have the idea the riaa preamp has. The tone control and riaa tubes are HT fed by a voltage regulator that brings down the 283V HT to 253V. I tried shielding the smps but that didn't had much effect. Allso, a signicant 50Hz ripple is present on the supply lines , as I understood from reading several papers, caused by the capacitor between the groundplanes of the power input and the supply output. Is there a preferred way of grounding this contraption. I now have a earthed power entry with HF filter to supress HF bleeding into the powerlines and at the supply side a bus ground connected to the power earth entry. Power ground is o.c. not connected. to any of earth or supply ground , except for the capacitor between the power ground and supply ground, which is there for safety reasons as I could make up of reading of the appropriate papers.

And the hum, how could I get most of the hum removed, when I connect the record player through the mofi solid state preamp, no hum at all, when I use one of the 3 tube riaa preamps lots of hum. I have to say that at the normal listening levels of the volume knob , there is no hum noticeable in listening position, only a bit with ear against speaker.

In the end I would say that all riaa preamps, when built to standards sound the same, with the fully active a bit more snappy and the fully passive a bit more airy , and the in-betweens , well , in between. The solid state preamp has no hum or noise issues whatsover, but is uninspiring and a bit flat sounding, probably mainly it doesn't look that good. The tube based riaa preamp are hummy at max volume, couldn't figure out where that comes from, grounding is exactly the same as with the solid state preamp. Noise is allso not a preblem for the tube preamps, though the smps fed riaa preamp seems to suffer a bit in cleanliness, hard to tell. I will at one point replace the smps with a transformer based psu, see how that goes. I am not sure if I hear that right, but smps seems to compress the audio a bit, but than again, might be completely subjective, knowing what you listen to might make you hear things that aren't there. Anyways, all the riaa preamps seem to perform quite well. The mofi ear384 and the shure M65 , the original designs for two of the pcb's I had bought sounded dreadful and very fatiguing, not recommended. I think I like the fully passive design best for acoustic/classical music and the JL Hood active series - active shunt design best for the electrified classic blues, blues-rock etc. music I like to listen to. Any comments on the designs would be appreciated. I am no electronics engineer so there might be a lot to comment on, all designs are cobbled together from bits and pieces I found lurking throught diyudio and the internet in general.

Thanks for reading this travel log into tubesland.

Systux