.... and the kirishima on the sketchup repositories

been done for sometime.

And i have a big lead on getting Dallas into Sketchup, given the vector drawing i took a snapshot of ... email meif you want that.

dave

Attachments

I'm looking forward to the final design on this. It may lend itself to a "hybrid" lamination on my CNC machine for two of the corners that are most visible externally.

For example, the two tight curves -- cut as stacked pieces -- won't take much more material than the three panels that must be cut to form the bends.

I would probably cut the "bends" out of some 1 inch MDF I have and the flat panels out of 3/4" plywood.

For example, the two tight curves -- cut as stacked pieces -- won't take much more material than the three panels that must be cut to form the bends.

I would probably cut the "bends" out of some 1 inch MDF I have and the flat panels out of 3/4" plywood.

Attachments

I'm looking forward to the final design on this. It may lend itself to a "hybrid" lamination on my CNC machine for two of the corners that are most visible externally.

For example, the two tight curves -- cut as stacked pieces -- won't take much more material than the three panels that must be cut to form the bends.

I would probably cut the "bends" out of some 1 inch MDF I have and the flat panels out of 3/4" plywood.

looking at the radius of all the curves, you could realistically do the outer shell with a unibody design. i can get aeronautical grade ply @ 1.8mm thick for a decent price. if you made the template you could just build up the glued layers into your own 18mm ply. imagine correct choice of adhesive might also go a long way to increasing the dampening properties of the thing.

Hi diyaudio and everybody in diyaudio

My name is Kha(Le Mai Kha)I'm come from Viet Nam.My favourist is hear the sound of spearker and power of amply,but in Viet Nam,we don't have much chance(if buy one speaker is too expenssive and it not too good to hear).and now,I want to assk you,is anyone can help me.I want buy 4 lower speaker of JBL about 30mm just the secondhand.anh 2 horn of Electro_voice and I want make a speaker like JBL 6600.please help me.please contact me with mail is le.mai.kha@gmail.com.thanks for all help.and this speaker I will use in my house

My name is Kha(Le Mai Kha)I'm come from Viet Nam.My favourist is hear the sound of spearker and power of amply,but in Viet Nam,we don't have much chance(if buy one speaker is too expenssive and it not too good to hear).and now,I want to assk you,is anyone can help me.I want buy 4 lower speaker of JBL about 30mm just the secondhand.anh 2 horn of Electro_voice and I want make a speaker like JBL 6600.please help me.please contact me with mail is le.mai.kha@gmail.com.thanks for all help.and this speaker I will use in my house

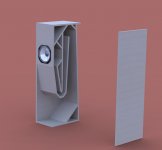

I decided to finish the Dallas II project so I began redrawing from the bits that were left online. I had access to a computer with SolidWorks software so I began drawing each piece and then assemble them together. I only encountered two minor problems and it may be that it was late and I was tired. I finished the 3D model and have each piece modeled separately but they are in the solidworks format. I could export them to dxg I think, have to search a bit for that thou. I attached some pictures with the problem areas but I think that could be very easily fixed. I may try the next week to correct. If interest is shown I could export all individual parts in dxf and archive them.

Attachments

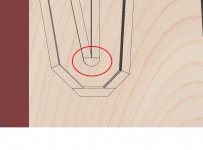

Forgot to mention that if you have all the pieces cut perfectly than you just connect one to the other, you don't need any reference points but the middle inside piece. That has to be constructed with some dimensions into account. If someone could tell me the reference points and dimensions I'd appreciate. To illustrate what I mean I attached a comparison picture to show how the center arrangement can move. I had no reference for it in my modeling software so I set it by eye when I took the screenshot.

Also there's one piece that I can't see how to easily manufacture, it's the turning edge on the lower pass. It's round and thick. I may make that from a 18mm thick piece and round it by sanding or some other means.

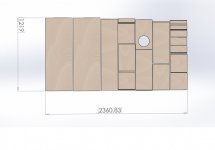

I also made a rough arrangement of all the parts included for one speaker and it seems that they would all fit into a 2500x1250mm plywood sheet with minimum loses.

Also there's one piece that I can't see how to easily manufacture, it's the turning edge on the lower pass. It's round and thick. I may make that from a 18mm thick piece and round it by sanding or some other means.

I also made a rough arrangement of all the parts included for one speaker and it seems that they would all fit into a 2500x1250mm plywood sheet with minimum loses.

Attachments

I will proper finish the project into CAD and arrange the bad angles (IF they are bad and it wasn't a mistake on my behalf) and then post the whole project (individual pieces with angles).The good part is that all pieces are 18mm thick and 280mm width (minus the side panels but those are easy). So all that's needed are the lenght and angles. It isn't the easiest but I read that it is very rewarding. I cannot find another project for fe206eN given my room size with proper bass. The Kirishima is too big for what I need so I'm left with this design. As I recall Dallas II is for fe206e and I have fe206en. I wonder if it would work the same...

Trileru,

IIRC diyAudio member Puffin built the FE208E Sigma cabinet and installed FE206en and got good results in his room (10' x 11' or slightly larger)... not a particularly easy build though requiring five 8' x 4' boards and many pieces. All straight cuts - no angles, that's the good thing.

Dallas II looks nicer though, and people who've built them say that it performs very well.

IIRC diyAudio member Puffin built the FE208E Sigma cabinet and installed FE206en and got good results in his room (10' x 11' or slightly larger)... not a particularly easy build though requiring five 8' x 4' boards and many pieces. All straight cuts - no angles, that's the good thing.

Dallas II looks nicer though, and people who've built them say that it performs very well.

I will proper finish the project into CAD and arrange the bad angles

The picture in post #11 is a snap from a CAD drawing i must have done... that means i have plans at least mostly finished.

dave

The picture in post #11 is a snap from a CAD drawing i must have done... that means i have plans at least mostly finished.

dave

I trust you in this matter more than I trust myself

waiting for the whole project

Regarding the Dallas II plans: It seems that the thread is dead. I am waiting for the other shoe to drop. Dave, is there anything more to see? I really like what you've done with the other drawings and I think they're enough to go on but if there's more, I'm more than eager to see.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Dallas II vs Kirishima