OK, OK. Even thou its my birthday i did the last essential drawing... the attached plus that the interior widrg is 280mm.

dave

Coincidentally I worked last night until 3AM to retrace everything on my modeling software and everything checked out very good. Now all I need to do is recheck everything with your latest schematic but I recon everything will be ok. I managed to squeeze the whole project into a 2500x1250 mm board, so you can make one enclosure from one sheet. Monday I'll go get the wood and start the work. Thank you and happy birthay!

*later edit*

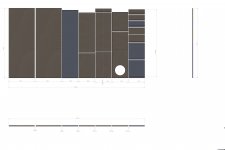

something like this picture. It's convenient if you buy the wood from some place that can only cut straight, then you can ask them to cut long pieces that you can fit in your vehicle. Then each piece can be sized into the corresponding parts. I left 1 cm between all parts so there's no problems if the initial cut isn't perfect. Units are in mm. The large sheet can be cut into 2 sheets of 450x1250 mm and 5 sheets of 280x1250mm. This way is easy to cary from the store and can be angle cut at home or somewhere else.

Attachments

Last edited:

OK, OK. Even thou its my birthday i did the last essential drawing... the attached plus that the interior width is 280mm.

dave

Happy birthday and thanks for this.

OK, OK. Even thou its my birthday i did the last essential drawing... the attached plus that the interior widrg is 280mm.

dave

Hi Dave, I hope you're having fun!

I rebuilt the speaker from your latest specs and I think there are 3 angles that don't fit right. First, the 45 degrees angle from the G piece should be 45.5 degrees, then F piece both angles should be 9.7 instead of 10.2 and 17.9 instead of 19. This way the H piece lines up parallel with the bottom part and almost all dimensions work out within 0.1mm from the schematic that you posted some time ago (the one with green writing, not the older one in red). Please correct me if I'm wrong thou. (after the party

...and I think there are 3 angles that don't fit right

Thanx for the QC. The angles on the G & F pieces i was working on were correct, the pieces were not correctly drawn. I fixed that and redimensioned and they now concur with your numbers. I have replaced the image in the earlier post.

In actual practise tenths of a degree are impractical to work with, but we might as well be as true to Ron's work as we can.

dave

Thanx for the QC. The angles on the G & F pieces i was working on were correct, the pieces were not correctly drawn. I fixed that and redimensioned and they now concur with your numbers. I have replaced the image in the earlier post.

In actual practise tenths of a degree are impractical to work with, but we might as well be as true to Ron's work as we can.

dave

You are right, hard to nail those angles when cutting/assembling. Thank you for your help, you made it easy for the rest of us to be confident in building this great enclosure!

Happy belated birthday Dave!

I'm so ready for the saw now. I think the angles will be tricky to get exact but I will try. It will be some time before the finished product as I live in an apartment and my wife doesn't exactly like saw dust everywhere for days on end. I promise pics will come when they're glued up.

I'm so ready for the saw now. I think the angles will be tricky to get exact but I will try. It will be some time before the finished product as I live in an apartment and my wife doesn't exactly like saw dust everywhere for days on end. I promise pics will come when they're glued up.

It's nice to see there's still intrest in the Dallas II design. It's been a long time since I built my pair but they still sound great and pass the WAF test.

I wanted to address a few questions asked in this thread.

Cutting the top off the design ? I did this to a lesser extent; I split the baffle just above the driver and tilted it back 18* , You may notice in this pic that Dave hosts on his site of my build. Ron Clarke commented negatively to my decision. He said the baffle size was a calculated part of the design. My change would raise the stage. Also, the larger baffle may help smooth the upper frequency response of the FE206E, which is a bit ragged and spikey.

Using the 206eN ? This Fostex model did not exist when Ron designed the Dallas II but the FE208 sigma did. Ron said the sigma could be used by adding a 3/4" thick section to the back of the compression chamber, reducing it's volume.

I wanted to address a few questions asked in this thread.

Cutting the top off the design ? I did this to a lesser extent; I split the baffle just above the driver and tilted it back 18* , You may notice in this pic that Dave hosts on his site of my build. Ron Clarke commented negatively to my decision. He said the baffle size was a calculated part of the design. My change would raise the stage. Also, the larger baffle may help smooth the upper frequency response of the FE206E, which is a bit ragged and spikey.

Using the 206eN ? This Fostex model did not exist when Ron designed the Dallas II but the FE208 sigma did. Ron said the sigma could be used by adding a 3/4" thick section to the back of the compression chamber, reducing it's volume.

Dave the thumbs here inrecent posts, are they downloadable somewhere?

Those aren't thumbs, they are full-screen snapshots.

They are downloadble from the posts. I need to do some more work before i can put it into a pdf.

dave

Thanks Dave for all the Dallas II drawings.

Is anybody building either speaker in this thread? It would be great to see some new build pics.

I have been modding the 206en's with felt and stiffening the basket. I like the phase guides from Steve Deckert...does anyone have opinion/experience with these?

Any other mods people have been trying?

Is anybody building either speaker in this thread? It would be great to see some new build pics.

I have been modding the 206en's with felt and stiffening the basket. I like the phase guides from Steve Deckert...does anyone have opinion/experience with these?

Any other mods people have been trying?

Totalcomfort, those Kirishimas look nice. I like the two-tone stain. Are those Cat-5 speaker wires? From the pictures they look short (compared to the doorframe). As others have pointed out, it may be hundreds of hours until they break in. Let us know your impressions.

Thanks I thought they turned out pretty good.

Speaker wire is standard white zip wire routed under carpet.

They do seem to sound a little better each time I play them,this my first pair of full range I have ever had.Compaired to my cornscala's they sound different,not better but not worse just different.I am still in the WOW!! stage with them and going to give myself some time before making final judgement.In love with them at this point!!

Ok, I still can't decide which of these to build. Both are acceptable for my room...I can sit minimum 12ft away. The build of the Dallas doesn't scare me at all. Like others, I'd like to extract the most bass. Has anyone built both? At the moment I'm enjoying my metronomes with a fleawatt amp with really holographic sound staging and what I'd like to achieve is an efficient (for the amp) speaker with similar but larger soundstage.

Totalcomfort, how's the bass out of the Kirishimas? Soundstage? I think Dave from P10 said they throw a really big soundstage. If you especially like Jazz or classical, I'd really like to hear some details.

...just want to keep the comparative critique going

Totalcomfort, how's the bass out of the Kirishimas? Soundstage? I think Dave from P10 said they throw a really big soundstage. If you especially like Jazz or classical, I'd really like to hear some details.

...just want to keep the comparative critique going

Wanting to keep this thread rolling along as I am awaiting some second hand fe208e's and assume the Dallas II would be the best design to extract the most out of these drivers?

I think I have enough info from the previous posts to do a draft 3d design and the cut out sheet.

May take me a couple of months to get the wood organised ,most likely marine ply.

Also with the outside top I might cover with a thin layer of ply wood that can bend and cover the angles so it looks round.

Sent from my XT925 using Tapatalk 2

I think I have enough info from the previous posts to do a draft 3d design and the cut out sheet.

May take me a couple of months to get the wood organised ,most likely marine ply.

Also with the outside top I might cover with a thin layer of ply wood that can bend and cover the angles so it looks round.

Sent from my XT925 using Tapatalk 2

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Dallas II vs Kirishima