Does anyone have a cut sheet for the Lotus^2?

Thanks

Kris

Ask and you shall receive my friend. Have fun!

Attachments

Good work

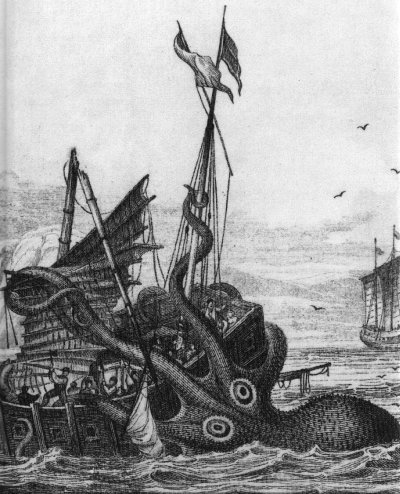

BTW, Chris has renamed this box the CHR-Ken (pronounced kri-ken).

dave

sorry 'bout that guys

is the teardrop sealed thing on top a tweeter?

real (OK, make that deaf above 12K) men don't need no

"what'sa come na go" tweeters

"what'sa come na go" tweetersThat new rev looks to be a design not suited to those with children or whom lack automatic weapons. Is the design related to the well known Kra-ken?

Excellent Steven. Instead of inserting an invisible i, we can insert invisible a...

Please ignore post 576, it is now CHR-Ken (pronounced kra-ken)

dave

Almost didn't have enough wood to finish them. Here they are all sanded after some wood filler and roundovers. Paint will come soon.

I was actually able to get the cutout for the drivers so exact that it could, in theory, work as a press fit. I wont use it that way but its nice to know that they'll be getting extra support on the flange rather than just the four small screws.

How are you getting on with these?

How are you getting on with these?

Last coat of paint didn't go so well. I'll be repainting if it's possible and then be done with them very soon. I first have to sand all the latex paint off.

I've been thinking on building two cabinets for CHR-70s..my plans are taken from markaudio.com, but with some changes. (The base from my plans is Toll70 CHR-70 Extended Bass Reflex)

The volume is now 12.26l (On winISD is ok)

The reason I've changed the plans are mainly for aspect and for an easy construction.

1. Does this modification change the sound for worse?

2. Do you guys have plans that you think would be better with the approximate effort and dimension?

If the sound will change, I I'm thinking in adding some more dampening as shown in picture (grey triangle)

This is my first diy project, so please be patient with me

The material used will be some MDF of at least 18mm (I'm thinking on 22mm) reinforced with bitumen (red line), and some acoustic foam of 20mm or so. (I like heavy stuff )

)

I've read the entire thread and this plan I think (noob also) will suit my needs best (SQ/dimension) what do you think?

The volume is now 12.26l (On winISD is ok)

The reason I've changed the plans are mainly for aspect and for an easy construction.

1. Does this modification change the sound for worse?

2. Do you guys have plans that you think would be better with the approximate effort and dimension?

An externally hosted image should be here but it was not working when we last tested it.

If the sound will change, I I'm thinking in adding some more dampening as shown in picture (grey triangle)

This is my first diy project, so please be patient with me

The material used will be some MDF of at least 18mm (I'm thinking on 22mm) reinforced with bitumen (red line), and some acoustic foam of 20mm or so. (I like heavy stuff

I've read the entire thread and this plan I think (noob also) will suit my needs best (SQ/dimension) what do you think?

Hi guys, I'm thinking about building some mMarS together with a friend. I want two for nearfield desktop listening, and my friend wants to build 5 for a home theater system. I realize the mMarS is probably the smallest possible enclosure for the CHR-70, and therefor also the least loud / least deep. Do you think he will be happy with 5 of these and some kind of sub under 100Hz (compared to high-end HTIBs for example)?

Also, in terms of needed material, these should be quite simple right? All I need is a CHR-70, two binding posts and some spare wire, some wool fiber and MPX (plywood)? Trying to make sure I don't forget something when I order.

Also, in terms of needed material, these should be quite simple right? All I need is a CHR-70, two binding posts and some spare wire, some wool fiber and MPX (plywood)? Trying to make sure I don't forget something when I order.

Oh dear.

Never fear, the paint finished out ok. I'll have a picture here in a bit.

mMarS is probably the smallest possible enclosure for the CHR-70, and therefor also the least loud / least deep. Do you think he will be happy with 5 of these and some kind of sub under 100Hz (compared to high-end HTIBs for example)?

For HT mains need only to hit 80 confortably, mMarS sims 80 Hz F3, 50 F10. mate with 1 or more subs and you have Toole's receipe for nirvana.

Also, in terms of needed material, these should be quite simple right? All I need is a CHR-70, two binding posts and some spare wire, some wool fiber and MPX (plywood)? Trying to make sure I don't forget something when I order.

With a milliSize box, especially if you add the holey brace, removable posts are required (you aren't getting a soldering iron into the box). I recommend ones with the smallest possible holes and with minimum metal (plastic nuts). It took some searching to find some we liked... see attached. I stock these & McBride (Q-components) sell them, everyone else sells the cup with the all metal posts.

Wool, polyfluff, fiberglass, 1/2" wool or cotton felt lining all work.

Good plywood is recommended.

The microTower HT Appendix has a number of variations on the mMarS for wall, in walls, etc.

dave

PS: for those with minimal woodworking kit we have flat-paks for a number of milliSize boxes including mMarS.

Attachments

Hi all,

Last year I bought a pair of Alpair10 (FR) and eventually I have built the Jaguars to house them - so far very impressed (apart from the first 2-3 hours). On the way to me is a pair of CHR70's which I will try in one of the Woden design boxes (I will sign up as a beta tester).

One of the problems I have found with mounting the Alpair10s and would seem to be a problem with the CHR70s is the lack of material into which to bolt the drive units - this is a problem especially with MDF.

So what I have been trying to design is a metal (alluminium) plate which would go across the width of the front panel and in height probably a few millimetres taller than the drive units. The drive units would bolt onto this plate - securely - and the plate would then be bolted onto the side walls. The ally plate could then be covered with timber (9-10mm deep) giving a flush looking installation.

This would allow the unit to be dismounted, and more critically re-mounted, without damage to the mounting holes. I will try this on my Jaguars to start off with and if it is OK with Scott I could try the same idea on say a beta version of the Maeshowe.

First off an email to Scott to join the betas.

Alan

Last year I bought a pair of Alpair10 (FR) and eventually I have built the Jaguars to house them - so far very impressed (apart from the first 2-3 hours). On the way to me is a pair of CHR70's which I will try in one of the Woden design boxes (I will sign up as a beta tester).

One of the problems I have found with mounting the Alpair10s and would seem to be a problem with the CHR70s is the lack of material into which to bolt the drive units - this is a problem especially with MDF.

So what I have been trying to design is a metal (alluminium) plate which would go across the width of the front panel and in height probably a few millimetres taller than the drive units. The drive units would bolt onto this plate - securely - and the plate would then be bolted onto the side walls. The ally plate could then be covered with timber (9-10mm deep) giving a flush looking installation.

This would allow the unit to be dismounted, and more critically re-mounted, without damage to the mounting holes. I will try this on my Jaguars to start off with and if it is OK with Scott I could try the same idea on say a beta version of the Maeshowe.

First off an email to Scott to join the betas.

Alan

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Mark Audio CHR-70 Application Thread