So indeed, three wheels on the wagon it will be, i have splashed out on the bearing! - may take a few days, but i will start looking at the rails because i have lots of glass and aluminium.

i will start by mounting the current kit on the modified wagon so that i learn one thing at a time.

I just remembered i will have to drill the carbon again.............

Best, mike

i will start by mounting the current kit on the modified wagon so that i learn one thing at a time.

I just remembered i will have to drill the carbon again.............

Best, mike

I have been refining the LTA and have found a few small errors. I put the whole bridge on the granite surface plate and found the rail with a 0.4mm bow up in the middle, this has been corrected to about 0.1mm. 1 wheel is slightly eccentric but not by much, I'm not going to fix this.

I also found the COM of the carriage was too high. VTF was decreasing 0.9g with a 3mm increase in stylus height. I have no idea how Niffy got his COM at the pivot I was unable to get it this low and I have raised the rail 3mm. VFT now decreases 0.1g over 3mm, I will have to live with this.

Also redistributed mass, moving the CW backwards away from the pivot. Ran the HFN test LP vertical and horizontal resonance test and have V 16Hz and H 18Hz. The higher compliance 881s would have the resonance well above 20Hz this could be the reason for the inability to track with this cartridge.

Tracking with the EPC205 is better than ever, although I can still hear very slight distortion occasionally on some tracks.

I also found the COM of the carriage was too high. VTF was decreasing 0.9g with a 3mm increase in stylus height. I have no idea how Niffy got his COM at the pivot I was unable to get it this low and I have raised the rail 3mm. VFT now decreases 0.1g over 3mm, I will have to live with this.

Also redistributed mass, moving the CW backwards away from the pivot. Ran the HFN test LP vertical and horizontal resonance test and have V 16Hz and H 18Hz. The higher compliance 881s would have the resonance well above 20Hz this could be the reason for the inability to track with this cartridge.

Tracking with the EPC205 is better than ever, although I can still hear very slight distortion occasionally on some tracks.

Interesting thought...........Maybe time to invest in a small mill/drill. I couldn't live without my lathe and mill now.

Is a Dremel on a drill stand any good or waste of money? - to what level do you need to go for precision please?

mike

Carlo,The ideal would be the stylus tip no more than 1 cm under.

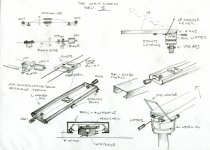

I see and like the simplicity, light weight, small levers but, to get the stylus <1cm under the rail height the cartridge top must be between the rails because the cartridge plus warp accommodation must fit and that must be about 2cm. So the rails would have to spread apart at least the length of the cartridge plus wiring?- is that a nasty geometry? - unless the back, third wheel, steadying rail was higher than the front one......

For now i will implement the simple same level steadying rail and see how it works!

knife blade joint (i like sharp knifes) allows rotation on a steady pivot, without the wire should slide (arc is longer than the chord) movement will be just +-2mm. But thre is a mistake - the wire attachment must be under the blade, not over

c

And he draws beautiful freehand as well!!

no more unfortunately, i'm too old. but i was product photographer in a graphic studio, so no merit

c

And he draws beautiful freehand as well!!

no more unfortunately, i'm too old. but i was product photographer in a graphic studio, so no merit

Last edited:

what a dumb: no mistake, it works as represented. fortunately

the problem is another: how stiff must be the piano wire ? and how will behave with resonances? 10 years ago i made a pivoted one with piano wire as vert articulation, but it was a completely different situation

c

the problem is another: how stiff must be the piano wire ? and how will behave with resonances? 10 years ago i made a pivoted one with piano wire as vert articulation, but it was a completely different situation

c

That makes sense Carlo, part of me likes the simplicity and apparent lack of play, part of me worries about resonances, which after all is what piano wire is there for! Another part says it will be quite stiff in bend........

Easy answer for me, mod. 1 which is underway will retain the CP (Carlo parallelogram which i borrowed from the LC outboard end)

Working on it now, should be running Wednesday

best

mike

Easy answer for me, mod. 1 which is underway will retain the CP (Carlo parallelogram which i borrowed from the LC outboard end)

Working on it now, should be running Wednesday

best

mike

If you are worried about resonances, throw away all the ball bearings (starting from those claimed 0 play): a can full of nails from the point of view of the stylus tip and its micro movements that like to shake unloaded balls inside. For it a 0,5 piano wire may be instead like an old oak tree for us.

c

piano wires+ headshell mass is a resonating compound that should be calculated, as on every arm

c

piano wires+ headshell mass is a resonating compound that should be calculated, as on every arm

Last edited:

Many thanks Carlo, i understand the point completely! - However i am where i am just now and restarting at a different point must probably wait a bit. I also find iterative progress more interesting and compelling than binning the current set up! Cant wait to listen to records with an LTA i made myself, even though i have quite a nice conventional arm sitting there......

So, like you, all ideas intrigue me, and may resurface later!

My pair of rails are now complete, just awaiting another (ball!) bearing.

best

Mike

So, like you, all ideas intrigue me, and may resurface later!

My pair of rails are now complete, just awaiting another (ball!) bearing.

best

Mike

And he draws beautiful freehand as well!!

Right you are Mike.

Carlo must somehow be related to Leonardo da Vinci....

Thanks Koldby, I'm moved: it's surely because even none of Leonardo's "inventions" has ever worked: planes that didn't fly, tanks that didn't move, bridges that collapsed ....

Today's proof- a quick test with the piano wire shows that it cannot work: if it is rigid enough to support the cartridge, it is too rigid to have the necessary sensitivity on the warps.

carlo

the only thing that makes me feel close to that sublime painter (this is what really makes him immortal) is to live 20 km from Vinci.

Today's proof- a quick test with the piano wire shows that it cannot work: if it is rigid enough to support the cartridge, it is too rigid to have the necessary sensitivity on the warps.

carlo

the only thing that makes me feel close to that sublime painter (this is what really makes him immortal) is to live 20 km from Vinci.

Hi Warren

The resonance frequency falls with increasing compliance so the 881s resonance should be lower if its compliance is higher. The V 16Hz and H 18Hz figures are really a bit high, and suggests the moving mass of your carriage + cartridge is low. I assume low moving mass and low friction are required to follow an unmodulated groove but too low a compliance or too low a mass puts the resonance close to the music low frequencies. It seems that the right choice of cartridge is crucial. I have not read the entire thread, so my concerns may have been addressed previously. I wonder if this (non?) issue is solved by the servo approach? This brings a whole other level of complexity though. Not usually within the reach of diyers.

Ran the HFN test LP vertical and horizontal resonance test and have V 16Hz and H 18Hz. The higher compliance 881s would have the resonance well above 20Hz this could be the reason for the inability to track with this cartridge.

Tracking with the EPC205 is better than ever, although I can still hear very slight distortion occasionally on some tracks.

The resonance frequency falls with increasing compliance so the 881s resonance should be lower if its compliance is higher. The V 16Hz and H 18Hz figures are really a bit high, and suggests the moving mass of your carriage + cartridge is low. I assume low moving mass and low friction are required to follow an unmodulated groove but too low a compliance or too low a mass puts the resonance close to the music low frequencies. It seems that the right choice of cartridge is crucial. I have not read the entire thread, so my concerns may have been addressed previously. I wonder if this (non?) issue is solved by the servo approach? This brings a whole other level of complexity though. Not usually within the reach of diyers.

Last edited:

Hi Bon,

I probably shouldn't write after a couple glasses of RED. What I actually meant to say was. I increased (larger CW) and moved the COM of the carriage lower and away from the vertical pivot increasing effective mass of the carriage lowering the resonant frequency under 20Hz. With Fr above 20Hz this is probably why the 881 struggled.

I read a paper written by Poul Ladegaard (see linked PDF) where the measurements and conclusion he made should put arm/cart resonance in 15-18Hz range. This was based on sidebands generated by having Fr lower.

For me getting Fr in this rage was pure luck.

http://www.cieri.net/Documenti/Misu...esonances in Turntables (AN17-233 - 1977).pdf

I probably shouldn't write after a couple glasses of RED. What I actually meant to say was. I increased (larger CW) and moved the COM of the carriage lower and away from the vertical pivot increasing effective mass of the carriage lowering the resonant frequency under 20Hz. With Fr above 20Hz this is probably why the 881 struggled.

I read a paper written by Poul Ladegaard (see linked PDF) where the measurements and conclusion he made should put arm/cart resonance in 15-18Hz range. This was based on sidebands generated by having Fr lower.

For me getting Fr in this rage was pure luck.

http://www.cieri.net/Documenti/Misu...esonances in Turntables (AN17-233 - 1977).pdf

Thanks Koldby, I'm moved: it's surely because even none of Leonardo's "inventions" has ever worked: planes that didn't fly, tanks that didn't move, bridges that collapsed ....

Today's proof- a quick test with the piano wire shows that it cannot work: if it is rigid enough to support the cartridge, it is too rigid to have the necessary sensitivity on the warps.

Carlo

the only thing that makes me feel close to that sublime painter (this is what really makes him immortal) is to live 20 km from Vinci.

Maestro, i enjoyed the quality and content of your drawing as you know, even more than the certainty your CAD work implies.

Thought for today, and being aware of your hate for the bag of nails of 7 ball bearings i will have in my first proto, low angle parallelogram hinges might be Mylar film or similar, no idea how to make them, but for sure no chatter?

Jewels for all of them doesn't seem to fit my ethos of low cost.

mike

I think I have seen something like your idea, but done with "spring steel".Thanks Koldby, I'm moved: it's surely because even none of Leonardo's "inventions" has ever worked: planes that didn't fly, tanks that didn't move, bridges that collapsed ....

Today's proof- a quick test with the piano wire shows that it cannot work: if it is rigid enough to support the cartridge, it is too rigid to have the necessary sensitivity on the warps.

carlo

the only thing that makes me feel close to that sublime painter (this is what really makes him immortal) is to live 20 km from Vinci.

That is the Danish word for it. Thin springy steel plate used in , as example, watch springs.

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm