Mike, you could dispense with one of the rear glass rods and run the bearing on the top of the rod. The front rail is effectively your alignment in that case. I'd be concerned that if front and rear rails aren't absolutely perfectly aligned, or if there's any friction in the end float of the bearings, one or more will be trying to climb the wall of the rod.

Thanks Carlo, i will keep on the development route as its encouraging enough to be worthwhile!Great improvement, Mike.

On mine better a symmetrical friction on both sides, and just gravity for self centring, but I understand well that 3 bearings are better than 4.

Do a quick test, put a steel ball on a L profile, and try to hold it still: you will see that often a level is not enough. Then do the same test with a ball bearing cart. That's why I like non-recirculating: better there are only the sophisticated solutions developed by Niffy.

5000 years ago the Egyptians were already making very fast battle carts, with spoked wheels on greasy bearings, but to move the blocks of the pyramids they used non-recirculating: a matter of friction.

carlo

microphony: not clear what's happening. remember that CF is conductive

Microphony, i mean as Warren responds below, interestingly there is less from the carriage movement more from tapping the MDF mounts, its physical conducting the noise through and i know getting rid of this on conventional set ups is well beneficial. i shall experiment.

They are glass rods Warren so i can only really damp the aluminium mount, but its not really very tolerant of mishandling and i may well move towards a Carlo recirc balls route, however i am still not sure how one gets them to stay in the correct location........dont you keep needing to reset them?This will be normal to some extent. My rail is damped to the point where if I tap it with a pencil I get a dull thud through the speakers. But I can hear when I move the carriage by hand on the rail.

If I were you I would damp the rail. If you used glass tube fill the tube with epoxy. I then epoxied carbon fibre between the rods and rail. My rail uses carbide rods. For your next rail you could use linear rails. I have a set of 6mm round linear rods I was going to use but went 4mm.

My Vernier says they are 100% parallel and they look the same as the carriage rides from one end to the other, but you are correct, its a tolerance issue and sensitive as well which i don't like and i am sure at microscopic level they will be wrong, so a three wheel tolerant solution that maintains VTF if it self centres is sought............Mike, you could dispense with one of the rear glass rods and run the bearing on the top of the rod. The front rail is effectively your alignment in that case. I'd be concerned that if front and rear rails aren't absolutely perfectly aligned, or if there's any friction in the end float of the bearings, one or more will be trying to climb the wall of the rod.

I played some more records now and its quite good, in many ways at least pleasant in comparison to my proprietary arm etc, but now after playing more records i find it skips back/repeats occasionally, the two wheeled version didn't do that so i wonder if its the increased friction of the third bearing or its torque effect behind the radial rail.

I need to fix that next before further listening and experiments.

BTW my VTA is not adjustable, cartridge top is just flat to the record, is that ok?

so i could try as Apace suggests a top of rail position for the third bearing or start on a different route. In that context i have some 12mm ball bearings i guess they are much too big and heavy...............mike

I need to fix that next before further listening and experiments.

BTW my VTA is not adjustable, cartridge top is just flat to the record, is that ok?

so i could try as Apace suggests a top of rail position for the third bearing or start on a different route. In that context i have some 12mm ball bearings i guess they are much too big and heavy...............mike

Corkscrew - radial rail

The only example of using a flex strip bearing in a linear turntable that I've seen is this aborted kickstarter project with a servo tonearm, except the flex strip is placed front to back instead of sideways.Since the back strip is fixed position and the front strip can flop up and down so it's really a pivoting bearing without the rigidity of traditional pivot arms.

I played some more records now and its quite good, in many ways at least pleasant in comparison to my proprietary arm etc, but now after playing more records i find it skips back/repeats occasionally, the two wheeled version didn't do that so i wonder if its the increased friction of the third bearing or its torque effect behind the radial rail.

I need to fix that next before further listening and experiments.

BTW my VTA is not adjustable, cartridge top is just flat to the record, is that ok?

so i could try as Apace suggests a top of rail position for the third bearing or start on a different route. In that context i have some 12mm ball bearings i guess they are much too big and heavy...............mike

Check wiring, mine will miss track if the wiring is pulling on the carriage. Also someone mentioned using a single rod on the rear rail, I think this a good idea. If the rails are out even a few 10ths it will increase starting torque. This should be alleviated with the single rod and bearing running flat on top.

I wouldn't worry about VTA at this point get the arm working then see if VTA make a difference. I know in my pivoting arm which has VTA on the fly of 8mm I can hear no difference between full up and full down. Do I think VTA is a myth - no I think if the COM is above or below the pivot VTF varies with stylus height.

The only example of using a flex strip bearing in a linear turntable that I've seen is this aborted kickstarter project with a servo tonearm, except the flex strip is placed front to back instead of sideways.Since the back strip is fixed position and the front strip can flop up and down so it's really a pivoting bearing without the rigidity of traditional pivot arms.

That's the one I couldn't remember, with the "spring steel" mounting.

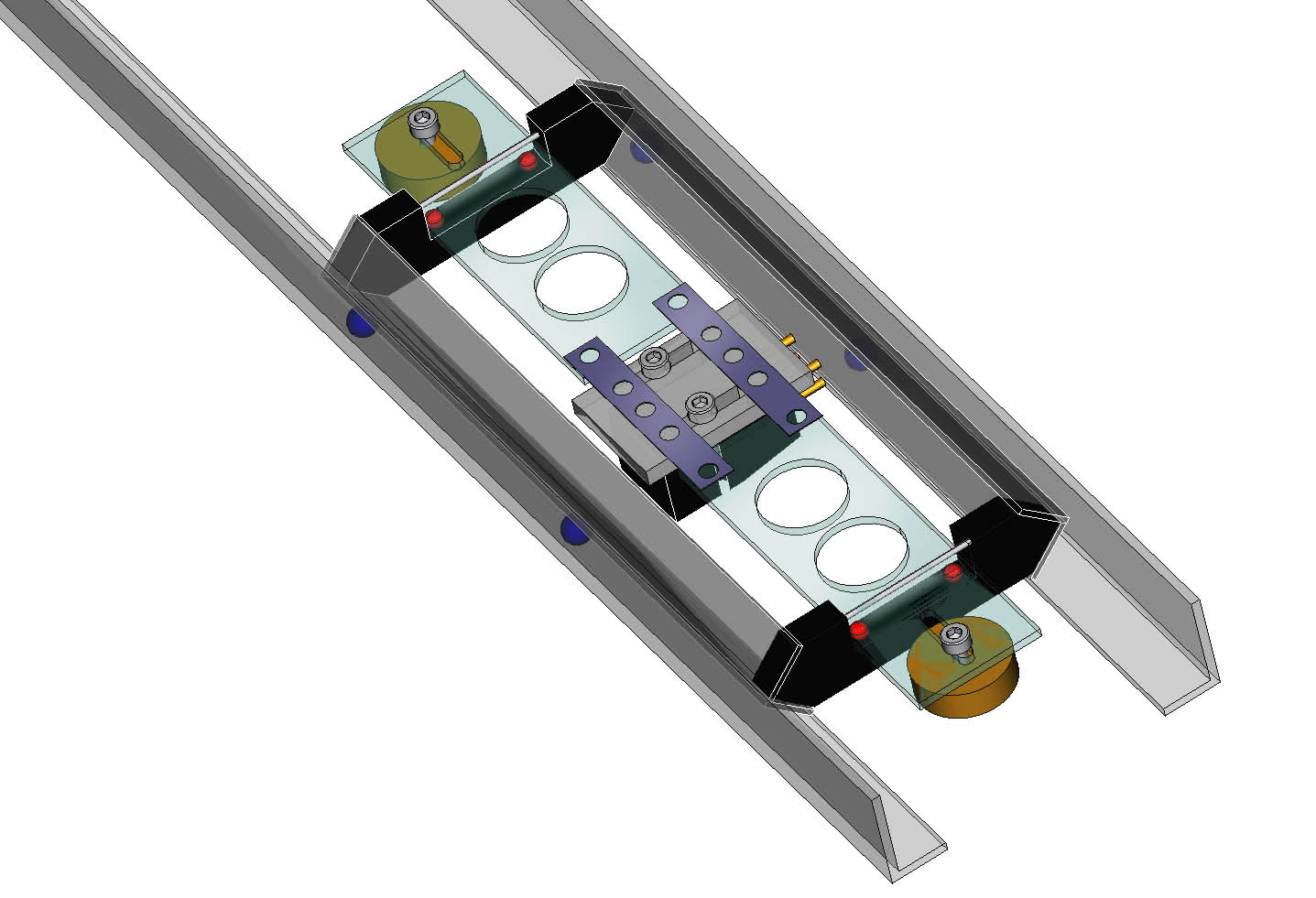

Let's start designing: some numbers and evaluations about the "Corkscrew Cart" radial rail.

Compared to A, solution B allows greatly reduced weight of the moving masses, while increasing the vert. eff. mass (thus improving the vert. vs hor. ratio*). This at the price of a greater (0,78 vs 0,28) hinge bending. (less consistent VTF?)

The extremely tight measures of unwanted movements are very promising, but the overall weight of the carriage must be kept as low as possible. (materials, dimensions)

Hi Dd, glad to hear you again. At personal level - remembering all precious hints you gave me in the past - and since you know well what's new and what's not in TAs design.

If you look at this present attachment you'll notice that i'm trying not to use the flex hinge for the articulation (just a 0,28 bent). But that solution seems attractive, even if it lets imagine great VTF variations. Do you know something more?

carlo

* this is an interesting point to think about: in fact a rigid radial rail, which eliminates the disadvantages of the mobile one - starting from the famous parallelogram - brings us back to a situation very similar to a normal LTA: hor eff mass much greater than the vertical, and vertical articulation through one or 2 short arms.

Now one of the advantages of the LC, according to authoritative opinions, is precisely the elimination of the arm (= resonances) and, according to others less authoritative (mine), to have a better ratio of V/H masses, and no chattering, by grounding the cartridge directly to the mass of the rail.

So, at the end, which one will sound better ?

Compared to A, solution B allows greatly reduced weight of the moving masses, while increasing the vert. eff. mass (thus improving the vert. vs hor. ratio*). This at the price of a greater (0,78 vs 0,28) hinge bending. (less consistent VTF?)

The extremely tight measures of unwanted movements are very promising, but the overall weight of the carriage must be kept as low as possible. (materials, dimensions)

Hi Dd, glad to hear you again. At personal level - remembering all precious hints you gave me in the past - and since you know well what's new and what's not in TAs design.

If you look at this present attachment you'll notice that i'm trying not to use the flex hinge for the articulation (just a 0,28 bent). But that solution seems attractive, even if it lets imagine great VTF variations. Do you know something more?

carlo

* this is an interesting point to think about: in fact a rigid radial rail, which eliminates the disadvantages of the mobile one - starting from the famous parallelogram - brings us back to a situation very similar to a normal LTA: hor eff mass much greater than the vertical, and vertical articulation through one or 2 short arms.

Now one of the advantages of the LC, according to authoritative opinions, is precisely the elimination of the arm (= resonances) and, according to others less authoritative (mine), to have a better ratio of V/H masses, and no chattering, by grounding the cartridge directly to the mass of the rail.

So, at the end, which one will sound better ?

Attachments

Last edited:

Lil Casey prism mk3

here my usual measurements, performed the same way as the previous ones, to which refer for the method - already widely discussed - and comparisons.

Measurements confirm a behavior extremely close to that of the LC Carbon. There is a certain worsening on the vertical joint due the increase in weight, and an unexpected improvement in hor. friction, thanks to the new double vee carriage: now i'm very near the 1mN threshold. But this doesn't seem to have changed visibly the previous tracking, even under the severe crash test conditions.

.

Conclusions: no "outstanding" improvement on the previous one, if not to avoid the comments of some audiophile friend: "yes, it sounds great.... but that T cart on a round rail, may tilt".

So it's probably the best (and my last) of the LCs, at the cost of a greater constructive commitment for the double Vee. A carbon version would spare a lot of lightening work, if you like an hitech look.

ciao - carlo

The mp4 videos are zip compressed - The sine bar data are very close to #3528 #3562 prototype tests, so not reported.

here my usual measurements, performed the same way as the previous ones, to which refer for the method - already widely discussed - and comparisons.

Measurements confirm a behavior extremely close to that of the LC Carbon. There is a certain worsening on the vertical joint due the increase in weight, and an unexpected improvement in hor. friction, thanks to the new double vee carriage: now i'm very near the 1mN threshold. But this doesn't seem to have changed visibly the previous tracking, even under the severe crash test conditions.

.

Conclusions: no "outstanding" improvement on the previous one, if not to avoid the comments of some audiophile friend: "yes, it sounds great.... but that T cart on a round rail, may tilt".

So it's probably the best (and my last) of the LCs, at the cost of a greater constructive commitment for the double Vee. A carbon version would spare a lot of lightening work, if you like an hitech look.

ciao - carlo

The mp4 videos are zip compressed - The sine bar data are very close to #3528 #3562 prototype tests, so not reported.

Attachments

Check wiring, mine will miss track if the wiring is pulling on the carriage. Also someone mentioned using a single rod on the rear rail, I think this a good idea. If the rails are out even a few 10ths it will increase starting torque. This should be alleviated with the single rod and bearing running flat on top.

I wouldn't worry about VTA at this point get the arm working then see if VTA make a difference. I know in my pivoting arm which has VTA on the fly of 8mm I can hear no difference between full up and full down. Do I think VTA is a myth - no I think if the COM is above or below the pivot VTF varies with stylus height.

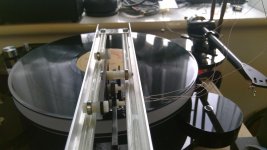

Good news and bad news, running the third bearing on top of one rail was an easy enough adjustment, i just respaced it on its bolt and although this affects VTA, steeper by a degree or two as the bearing is higher than the others it seemed to work, got past the previous sticky bit but then stuck at a new one later on the same side which the two bearing one tracked no problem.................all (simple!) ideas very welcome, mike

Attachments

Good news and bad news, running the third bearing on top of one rail was an easy enough adjustment, i just respaced it on its bolt and although this affects VTA, steeper by a degree or two as the bearing is higher than the others it seemed to work, got past the previous sticky bit but then stuck at a new one later on the same side which the two bearing one tracked no problem.................all (simple!) ideas very welcome, mike

Hi Mike and all!

This thread is very interesting and inspiring, even though I never even considered getting into tone-arm stuff (yet)...

My little 2c on your picture above:

I think you should use a little block or a „Aluminium-angle“ at the end of the arm—this „platelet“ may be good for keeping the inner distance, but I would doubt it is vertically stiff enough...

I hope you see what I try to describe?

Hi Mike and all!

This thread is very interesting and inspiring, even though I never even considered getting into tone-arm stuff (yet)...

My little 2c on your picture above:

I think you should use a little block or a „Aluminium-angle“ at the end of the arm—this „platelet“ may be good for keeping the inner distance, but I would doubt it is vertically stiff enough...

I hope you see what I try to describe?

I think i agree completely, there remain many inadequacies, its not refined like other work you see on this thread, i am just trying to get something working before doing that sort of work!

Which is a good method to make progress [emoji1303]I ... just trying to get something working before doing that sort of work!

Good news and bad news, running the third bearing on top of one rail was an easy enough adjustment, i just respaced it on its bolt and although this affects VTA, steeper by a degree or two as the bearing is higher than the others it seemed to work, got past the previous sticky bit but then stuck at a new one later on the same side which the two bearing one tracked no problem.................all (simple!) ideas very welcome, mike

Well, my Kludge proto is all a bit sensitive in my view, it tracked the second glitch cleanly now by moving the centre of the wiring towards the centre of record and a touch more tracking weight, towards the max recommended of 2g now.

It wont ever be a viable entertainer that way so I will have to improve it further, occasional repeats are not really a viable level are they?

However i enjoy listening to music on something i didn't believe i could build which is the whole idea! - it sounds OK, and that makes it worthwhile, several of you said, just build something and i have and that's fun, thankyou all so far, and i look forward to the benefit of your expertise in the future!

Mylar hinges to replace BB's on my parallelogram?

I mocked up a Mylar hinge from 1.5mm grp plate and heavy drafting Mylar.

this bit of 20mm long plate sags 2mm under its own weight so empirically i feel it wont be a big VTF variance in warp. the hinge is really play free in the plane perpendicular to the hinge plane....should be better than the bag of nails BB's?

Any thoughts before i do a complete mock up failure please?!

mike

I mocked up a Mylar hinge from 1.5mm grp plate and heavy drafting Mylar.

this bit of 20mm long plate sags 2mm under its own weight so empirically i feel it wont be a big VTF variance in warp. the hinge is really play free in the plane perpendicular to the hinge plane....should be better than the bag of nails BB's?

Any thoughts before i do a complete mock up failure please?!

mike

Attachments

Good news and bad news, running the third bearing on top of one rail was an easy enough adjustment, i just respaced it on its bolt and although this affects VTA, steeper by a degree or two as the bearing is higher than the others it seemed to work, got past the previous sticky bit but then stuck at a new one later on the same side which the two bearing one tracked no problem.................all (simple!) ideas very welcome, mike

It'll be the rail. Also try scraping a razor blade along the rail in case there is glue on it.

My first LTA used 6mm pyrex tubes and they are not perfectly round or concentric. I bought 20 tubes and have a granite surface plate I rolled all of them on to find the best 2 for my rail. If I were starting again with what I know now I would use 6mm linear rods, these are pretty straight, hardened and smooth.

Hi Mike, that photo of a 100mg weight was posted to visualize this kind of problems: the flexibility of the hinge (or the joint frictions) should be always lower than that of the elastomer of the cartridge; a 100mg force starts to have visible effects, nasty over 200 .

Many years ago I made two pivoted TAs with an elastic vertical articulation: the first had a 1mm lexan flat wand, the second rotated horizontally on a 0.8 piano wire which, due its flexure, gave the vertical joint too, . They sounded very good*, but consider that their hinge flexed only thanks to the 22.5 cm lever.

On your parallelogram, with 4 hinges and just a lever of 4-5 cm. you need a really thin Mylar.

carlo

*I abandoned those ideas because the VTF adjustment changed with the thickness of the disc, on the warps and .... with the seasons! (>more C° >more flexure)

If you don't have a 100mg weight - simply cut a 35mm square of office paper

Many years ago I made two pivoted TAs with an elastic vertical articulation: the first had a 1mm lexan flat wand, the second rotated horizontally on a 0.8 piano wire which, due its flexure, gave the vertical joint too, . They sounded very good*, but consider that their hinge flexed only thanks to the 22.5 cm lever.

On your parallelogram, with 4 hinges and just a lever of 4-5 cm. you need a really thin Mylar.

carlo

*I abandoned those ideas because the VTF adjustment changed with the thickness of the disc, on the warps and .... with the seasons! (>more C° >more flexure)

If you don't have a 100mg weight - simply cut a 35mm square of office paper

Last edited:

Hi Mike, that photo of a 100mg weight was posted to visualize this kind of problems:

On your parallelogram, with 4 hinges and just a lever of 4-5 cm. you need a really thin Mylar.

carlo

I shall definitely follow this one a bit more because its cheap and easy with no tools as well, i understand those limitations you explain, it probably depends how thin Mylar behaves.

Meanwhile, i am going to try and sort out my rail rods, i have a nice glass table to test them on, which is at least optically flat to the eye! - i will try some polishing methods on scrap rod as well, perhaps the fine diamond paper?

mike

Hi, Mike56

Came across these computer fan bearings on ebay--ABEC-9 grade. This may help you and others looking for high precision bearings.

Computer Fan Ball Bearings For PC Cooling Case Fan Repair 3*8*4 mm | eBay

Get yourself a pair of 12" tungsten carbide rods. These are rigid, hard (92 Rockwell), precision ground, and have an approximate 600 grit finish. You can gain about 10% less friction. They are also cheap, These are the rods Niffy and I use. You can get a cheap set of diamond polishing compounds ( ebay ) and further polish the rods if you wish.

Carbide Rod – Centennial Carbide: Carbide Blanks, Rod and End Mills

Hope this helps you and others out. Jewel V, pin bearings are the best but Clearaudio makes some very nice linear tonearms using ball bearings, so it can be done. Good luck

Joe

Came across these computer fan bearings on ebay--ABEC-9 grade. This may help you and others looking for high precision bearings.

Computer Fan Ball Bearings For PC Cooling Case Fan Repair 3*8*4 mm | eBay

Get yourself a pair of 12" tungsten carbide rods. These are rigid, hard (92 Rockwell), precision ground, and have an approximate 600 grit finish. You can gain about 10% less friction. They are also cheap, These are the rods Niffy and I use. You can get a cheap set of diamond polishing compounds ( ebay ) and further polish the rods if you wish.

Carbide Rod – Centennial Carbide: Carbide Blanks, Rod and End Mills

Hope this helps you and others out. Jewel V, pin bearings are the best but Clearaudio makes some very nice linear tonearms using ball bearings, so it can be done. Good luck

Joe

Thanks All as always,

I "ground/polished" my rails along the contact points with fine diamond paper, starting with 1500 and going down to whatever the finest one is, i think 3 micron foil and also emery cloth.

I have no idea which did what, but when I played the slightly tricky record from previously (Oscar Peterson 4, If you could see me now, piano, bass, guitar, drums - an old favorite) and it looks and sounds better, no visual stiction now and sounds rock solid, bass particularly. I think i have taken off a few microhills(!) from each rail and where previously i could see slightly lumpy rotation of carriage bearings even when it didn't skip, now that seems much better.

So now i can listen a bit and see what i think of the sound whilst considering what i might do next

mike

I "ground/polished" my rails along the contact points with fine diamond paper, starting with 1500 and going down to whatever the finest one is, i think 3 micron foil and also emery cloth.

I have no idea which did what, but when I played the slightly tricky record from previously (Oscar Peterson 4, If you could see me now, piano, bass, guitar, drums - an old favorite) and it looks and sounds better, no visual stiction now and sounds rock solid, bass particularly. I think i have taken off a few microhills(!) from each rail and where previously i could see slightly lumpy rotation of carriage bearings even when it didn't skip, now that seems much better.

So now i can listen a bit and see what i think of the sound whilst considering what i might do next

mike

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm