For my sins I am using a Linn LP12 whilst thinking about my 401. The LP12 has been in the original packing for 10 years in the loft. Fine when it came out. Recently it has wow! Very slow starting. Voltages fine ( 80 V ) coils fine at 2 x 4K4. One drip of the same oil as a Garrard in the motor bearings has cured it. Not odd except it worked at first. I have to say that Airpax motor is marginal. LP12 is far better than TD145 I also have ( same Denon DL 110 ). Not to the extent I agree with how it is engineered.

DL 110 is interesting. Almost as good as anything I know of considering the price. None will easilly know this as it is neither an ideal MC nor MM. It needs a special pre amp. Call it 1 mV and you will not be far wrong. An old slightly modified Quad 33 suits it fine ( M1 PCB changed from 470/220R to 560/130R ). The Quad is the most sillent pre amp I have every used. It must be better than it's modest 70 dB spec which I have degraded by >doubling the gain on the M1 setting. The Naim notably noisier although similar. Neither are very good designs by modern standards. The Quad far better than I thought. I have a hunch the 33 and DL110 do each other a favour.The Quad is known to have a lack of 20 kHz gain that results in an uptilt of the 75 uS. Looking for place to put in a 2 uS passive filter I see they beat me to it ( 5 uS ). As this is an MC it might just peak way above the 32 kHz roll off. Sounds very good. You will need to raise the gain if you want any punch. Very easy to do, 10 minutes work if the 33. M2 is unchanged. Shure M44 suits well for that. S1 can be used for CD if useful. Tape in H is ideal for CD as it is almost direct. If you want to upset people a TD124 Jelco DL110, 33/303 ESL 57's will do it. Spendor BC1 also. Klipshce Forte 2 I don't doubt also. Magneplanar SMGa is what I use.

DL 110 is interesting. Almost as good as anything I know of considering the price. None will easilly know this as it is neither an ideal MC nor MM. It needs a special pre amp. Call it 1 mV and you will not be far wrong. An old slightly modified Quad 33 suits it fine ( M1 PCB changed from 470/220R to 560/130R ). The Quad is the most sillent pre amp I have every used. It must be better than it's modest 70 dB spec which I have degraded by >doubling the gain on the M1 setting. The Naim notably noisier although similar. Neither are very good designs by modern standards. The Quad far better than I thought. I have a hunch the 33 and DL110 do each other a favour.The Quad is known to have a lack of 20 kHz gain that results in an uptilt of the 75 uS. Looking for place to put in a 2 uS passive filter I see they beat me to it ( 5 uS ). As this is an MC it might just peak way above the 32 kHz roll off. Sounds very good. You will need to raise the gain if you want any punch. Very easy to do, 10 minutes work if the 33. M2 is unchanged. Shure M44 suits well for that. S1 can be used for CD if useful. Tape in H is ideal for CD as it is almost direct. If you want to upset people a TD124 Jelco DL110, 33/303 ESL 57's will do it. Spendor BC1 also. Klipshce Forte 2 I don't doubt also. Magneplanar SMGa is what I use.

In case anyone needs a MKII chassis here is one that popped up on eBay today:

Thorens TD 124 MKII Turntable Chassis 100% Original and in super condition | eBay

Not a bargain in any sense of the word, but if you need one...

Thorens TD 124 MKII Turntable Chassis 100% Original and in super condition | eBay

Not a bargain in any sense of the word, but if you need one...

That seems an odd size for an Imperial measurement country to use way back in the '50s and '60s.

The TD-124 turntables are all metric, not imperial.

Thank you for the measurements. After a great deal of detective work, I found the lower shaft ball bearing. It fell off when putting the motor back together and found its way under the bronze bearing in the motor.

Evidently there is just enough clearance in there for the bearing to roll under if it comes out of the shaft.

I put a dab of grease to hold in in, reassembled and got her up and running. It is comes up to speed almost immediately and holding proper speed nicely.

The motor does seems much warmer than other turntables that I have. Is this normal for a Thorens TD-124? I will probably do a complete tear down of the motor soon with new bearings, felt washers etc.

Joe

Given the recent discussion of motor bushing issues here I would not replace the bushings unless you are absolutely certain they are badly worn. Replacing the felts is a good idea. Did you follow the procedure widely discussed in this thread to clean and re-impregnate the motor bearings with 20wt oil?

Useful links for future reference:

http://homepage2.nifty.com/pantone/t...overhaul_1.htm

E50 assy

In case anyone needs a MKII chassis here is one that popped up on eBay today:

Thorens TD 124 MKII Turntable Chassis 100% Original and in super condition | eBay

Not a bargain in any sense of the word, but if you need one...

Same seller has quite a few 124 parts up.

The LP12 is now fine. I had a hunch as the same motor in Regas had trouble when Airpax used the wrong oil. Said that a Belgian employee was lazy and used motorcar oil. A year or so later black gunge resulted and stuck motors. I used the SAE30 I use for TD124's and all is bliss. The difference is a subtle as a bent stylus. Even now the motor takes for ever to start the platter. I have been spoilt by 124's and 401's. A 124 is not unlike a LP12 except it has more verve.

Hi all,

I've been lurking around this thread for a while, and having read about the first half of it by now. There's still a lot to of useful stuff to process here, so my questions might be already answered somewhere... I also know it's a lot of questions, so I would be very grateful for any suggestions.

I'm planning to restore a TD 124 MK I (Serial No 28283) and do some upgrades:

- cleaning the chassis, pulleys, oiling the spindles, etc

- oiling the spindle/main bearing

- see how the old belt performs after a talc treatment

- dismantling and oiling the motor, and changing the coils to Simone Lucchetti's product

- adding the MK II type motor suspension rods and grommets

- adding new rubber mushrooms

I have only a bare minimum experience with electronic technology, but the descriptions here and the step by step photo galleries of rebuild projects available elsewhere make it look pretty straightforward and doable even for lay folks with some diy sense and basic soldering skills. Am I correct? Is there anything above where I can seriously mess up and should ask a professional technician to do it instead of doing it myself?

I still have a bunch of questions before I get going:

- The enamel chassis shows a slight discoloration (UV and nicotine I guess): what is the best way of getting it back to its lighter original color? I was thinking of doing it the way they polish vintage cars: wash, clay, polish, and wax. Maybe there is a more simple, yet safe and efficient method.

- Because of the smoking ex owner, it is covered with a brownish nicotine film (both the underside and the inside parts like the idler). What cleaning method would you recommend to clean up this mess? I'm especially concerned about the idler and the belt as I don't want to damage them in the process.

- I've seen people mentioning that polishing the pulleys makes a big difference. What materials / methods should I use for it? To what extent do you polish it?

- While rebuilding the motor, how do I know whether or not I should change the bushings to new ones?

- The bearing well seemed empty on first impression, however the spindle was clean, shiny, slightly lubed and it doesn't show wear. Shall I clean the bushings and bearing well, or just add some oil? If I need to clean it, what's the best way of going about it?

- The spindle had a couple of very-very-very tiny marks (maybe the previous owner wasn't too careful when he put it back in the bearing). Is it necessary to get it polished?

- I've got a Thorens TP-14 arm that came with the table that needs a bit of fixing (sagging counterweight), but seems to be in OK shape. I've heard conflicting opinions of this arm, so I decided that I will give it a go before shelling out more money on an upgrade.

What is a good sounding, affordable cart that is also a good match with this arm? I have a Van Den Hul MM-1, a Shure V-15 Type III, and a Shure M-95 ED at home, but if there is a better fit, I would be willing to get it.

Thank you for your advice in advance.

I've been lurking around this thread for a while, and having read about the first half of it by now. There's still a lot to of useful stuff to process here, so my questions might be already answered somewhere... I also know it's a lot of questions, so I would be very grateful for any suggestions.

I'm planning to restore a TD 124 MK I (Serial No 28283) and do some upgrades:

- cleaning the chassis, pulleys, oiling the spindles, etc

- oiling the spindle/main bearing

- see how the old belt performs after a talc treatment

- dismantling and oiling the motor, and changing the coils to Simone Lucchetti's product

- adding the MK II type motor suspension rods and grommets

- adding new rubber mushrooms

I have only a bare minimum experience with electronic technology, but the descriptions here and the step by step photo galleries of rebuild projects available elsewhere make it look pretty straightforward and doable even for lay folks with some diy sense and basic soldering skills. Am I correct? Is there anything above where I can seriously mess up and should ask a professional technician to do it instead of doing it myself?

I still have a bunch of questions before I get going:

- The enamel chassis shows a slight discoloration (UV and nicotine I guess): what is the best way of getting it back to its lighter original color? I was thinking of doing it the way they polish vintage cars: wash, clay, polish, and wax. Maybe there is a more simple, yet safe and efficient method.

- Because of the smoking ex owner, it is covered with a brownish nicotine film (both the underside and the inside parts like the idler). What cleaning method would you recommend to clean up this mess? I'm especially concerned about the idler and the belt as I don't want to damage them in the process.

- I've seen people mentioning that polishing the pulleys makes a big difference. What materials / methods should I use for it? To what extent do you polish it?

- While rebuilding the motor, how do I know whether or not I should change the bushings to new ones?

- The bearing well seemed empty on first impression, however the spindle was clean, shiny, slightly lubed and it doesn't show wear. Shall I clean the bushings and bearing well, or just add some oil? If I need to clean it, what's the best way of going about it?

- The spindle had a couple of very-very-very tiny marks (maybe the previous owner wasn't too careful when he put it back in the bearing). Is it necessary to get it polished?

- I've got a Thorens TP-14 arm that came with the table that needs a bit of fixing (sagging counterweight), but seems to be in OK shape. I've heard conflicting opinions of this arm, so I decided that I will give it a go before shelling out more money on an upgrade.

What is a good sounding, affordable cart that is also a good match with this arm? I have a Van Den Hul MM-1, a Shure V-15 Type III, and a Shure M-95 ED at home, but if there is a better fit, I would be willing to get it.

Thank you for your advice in advance.

SHINDO

This might be an unmodified Shindo 301 bearing? It is longer than standard and uses a ball thrust. There is no sign of any wear so a very good job done. The small group of six balls resesmble those of cheap turnatables. A mystery. Perhaps it has a centering action or decouples?

If you go on the Loricraft Facebook page you will see how a ceramic ball has ruined a shaft. Full marks Shindo to get this right. The Garrard 501 looks very similar. Interesting as we never saw the Shindo before. The 501 is standard Garrard principle with money thrown at it.

The Shindow has a very heavy platter. It is debatable if this works. More bass, less timing if a Linn fan? 301 will beat a Linn on Linn's special qualities so worth being careful.

This Shindo came to Loricaft for repair. Someone has painted the platter to match the deck. That someone painted the drive rim !!!!! As 14 inch lathes are rare that will be a problem. We adapted our Colcester to do that so maybe. We are writting to Shindo for guidance.

I don't work for Loricraft these days. I have returned to my 1990 status of friend of. I was there yesterday to cut out my baffles for my 4 x 2 speakers. Met with Brian Mortimer who's dad designed the 301 and RC1 ( and many more ). All autochange turntables refer to the Monty's patent. Brian is 75 and was head of quality control at Garrard. What I didn't know is Monty was always friendly with rival BSR. In retirement he did all the safety approvals for BSR. BSR historically were the worlds largest producer. We are talking 6 million a year if I remember correctly. We are assembling a team of ex Garrard people for a project. One is a very famous racing car deigner, he was part of the Zero 100 team when young. Hope he says yes. Call it pride of Swindon if you like. I am nearing 60 and by far the youngest.

Got my belts from audiosilente (he sends 2 belts, very good deal). They are slightly shorter in length and slightly not as wide than the one that came with my table. Much longer than the 12.1" I got from another ebay vendor. Put it on and started it up. Could not get the strobe to adjust the speed. had to adjust the eddy current brake out. Finally got it to adjust properly. I'll let it run for awhile, might have to adjust it later. One thing I did notice is it dropped the noise level, I think most of what I am hearing now when I turn the volume way up is record surface noise. Last thing to do now is get the motor re-built.

Highend Bearings (TD-124/Garrard-401 etc. ) : Sometimes I wonder if multi ball bearing may have some advantage. Single ball will have single point and if platter is heavy would exert enormous pressure. While as multiball bearing would share the weight. If multiball bearing is stable, one can loose the second lower bushing in the shaft as well, to lessen the noise even further. Icing on the cake would be to put repelling magnets, so somewhat less pressure is on them. Not sure though, may be experienced members could chime in.

As I have Technics TT, to measure noise I put small heavy wood piece (approx. ½" x 1") on TT, move tonearm over it and gently put stylus on it with same pressure as we put on record. Normaly I hear motor and other noise at around 1 o'clock position. Once I had cheap Philips Idler wheel TT. The noise started just a little bit earlier than the level of Technics. Interesting thing is while Technics the noise started gradually, on philips it was sudden.

Regards.

As I have Technics TT, to measure noise I put small heavy wood piece (approx. ½" x 1") on TT, move tonearm over it and gently put stylus on it with same pressure as we put on record. Normaly I hear motor and other noise at around 1 o'clock position. Once I had cheap Philips Idler wheel TT. The noise started just a little bit earlier than the level of Technics. Interesting thing is while Technics the noise started gradually, on philips it was sudden.

Regards.

This shows the problem with the conventional bearings type. The contact area. The 6 ball bearing seem not to reduce the load! They seem only to reduce centering problems? I am told Shindo is no longer. Mr Miguchi of Sound Box might help us. I put up this picture hoping someone might know? What we might do is machine the bottom part in nylon that has been water treated. The piece taken out of the lathe as few times as possible so as to have an accurate centre. We have failed to centre this bearing and doubt the whole idea. The nylon would damp vibration. Tufnol might be ideal. There is a chance this is a clone part and not the work of Mr Shindo?

Papst motor with three phase powersupply in TD124

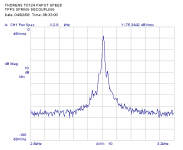

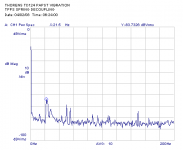

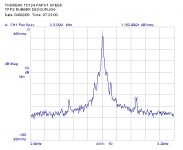

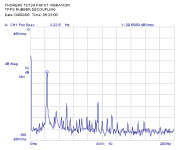

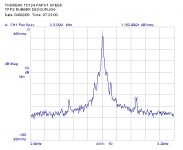

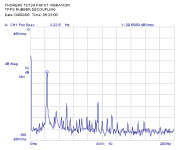

Finally the first results from my new three phase powersupply for the Papst and EMT930 motor.

The measurements are done without brake .

Freq.from powersupply is 46,94 hz voltage 220 volt.

The powersupply is connected by a 7 wire shielded cable for independent neonlamp power and swithing the three phase supply on with the speed switch on the turntable.

Measurements are quite spectacular the speed stabilty is the best I measured so far on idler turntables a very sharp peak .

Thorens supplied with the Papst modification also other softer rubbers I have used them in the first measurements seen the own motor freq.22,5 hz at -39 db and statorvibration 94 hz at -66db.

After replacing the rubbers by springs the own motor freq.vibration goes to -63 db and 94 hz stator vibration -78 db

Finally the first results from my new three phase powersupply for the Papst and EMT930 motor.

The measurements are done without brake .

Freq.from powersupply is 46,94 hz voltage 220 volt.

The powersupply is connected by a 7 wire shielded cable for independent neonlamp power and swithing the three phase supply on with the speed switch on the turntable.

Measurements are quite spectacular the speed stabilty is the best I measured so far on idler turntables a very sharp peak .

Thorens supplied with the Papst modification also other softer rubbers I have used them in the first measurements seen the own motor freq.22,5 hz at -39 db and statorvibration 94 hz at -66db.

After replacing the rubbers by springs the own motor freq.vibration goes to -63 db and 94 hz stator vibration -78 db

Attachments

- Home

- Source & Line

- Analogue Source

- Restoring and Improving A Thorens TD-124 MKII