2007 Maxon Motor Group Buy, Controller PCB and related parts is now closed, see below:

I decided to close the group buy now. Most of the changes are done by members already into the group. I have enough PCB, Motors and Parts kits to get the best price. Slightly more kits and I'll get just into more trouble, no quantity discount, etc...

So THIS GROUP BUY IS OFFICIALLY CLOSED

I'll start send you email requesting PayPal payment of what I have on file. I'll send you each your list of items and actual price.

Please pay this amount as rapidly as possible to my PayPal account.

I won't be able to order most of the stuff before you pay me since the amount of money is huge, and I don't want to get stuck with unsold item.

So delay in payment will delay the all group, production of parts and final delivery. Not counting my own work that may spread to months

Thanks you all for your interest and lets hope for the best

As I said I may have so PCB left at the end, but only the PCB, no parts, no motor, etc...

I decided to close the group buy now. Most of the changes are done by members already into the group. I have enough PCB, Motors and Parts kits to get the best price. Slightly more kits and I'll get just into more trouble, no quantity discount, etc...

So THIS GROUP BUY IS OFFICIALLY CLOSED

I'll start send you email requesting PayPal payment of what I have on file. I'll send you each your list of items and actual price.

Please pay this amount as rapidly as possible to my PayPal account.

I won't be able to order most of the stuff before you pay me since the amount of money is huge, and I don't want to get stuck with unsold item.

So delay in payment will delay the all group, production of parts and final delivery. Not counting my own work that may spread to months

Thanks you all for your interest and lets hope for the best

As I said I may have so PCB left at the end, but only the PCB, no parts, no motor, etc...

Custom Pulley Offer

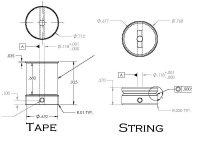

Hi Everyone. As you probably knew from the thread, to support both speeds, Mark Kelly controller needs a custom pulley with a diameter of about 17mm.

Following the Maxon GB 2007, Greg Nuspel is working on the custom pulley and will offer both designs, tape and/or string. Prices are not out yet but I asked him to match the Teres price of 25$ or better if possible, Greg will make a prototype for me to try before production.

See the included image for details.

Greg will do a production run of the pulleys, so I can supply you new pulleys if you want to use an other design than the original one supplied on this first Group Buy.

It will be made of aluminium T6 treated material to prevent oxidation and platter deposit. It also offers great strenght and it is light.

It will be manufactured to really thights tolerances, offer a thru hole and can be mounted using two opposite set screws as recommended by Vinyl-Addict. So it will be easy to remove without motor damage.

SO THE BIG QUESTION:

If Interested, you need to confirm me by email what pulley do you want the Tape OR String Pulley since this year pulley is not universal.

So reply by email with your choice and we will add you on the list for the custom Pulley.

Thanks...

Hi Everyone. As you probably knew from the thread, to support both speeds, Mark Kelly controller needs a custom pulley with a diameter of about 17mm.

Following the Maxon GB 2007, Greg Nuspel is working on the custom pulley and will offer both designs, tape and/or string. Prices are not out yet but I asked him to match the Teres price of 25$ or better if possible, Greg will make a prototype for me to try before production.

See the included image for details.

Greg will do a production run of the pulleys, so I can supply you new pulleys if you want to use an other design than the original one supplied on this first Group Buy.

It will be made of aluminium T6 treated material to prevent oxidation and platter deposit. It also offers great strenght and it is light.

It will be manufactured to really thights tolerances, offer a thru hole and can be mounted using two opposite set screws as recommended by Vinyl-Addict. So it will be easy to remove without motor damage.

SO THE BIG QUESTION:

If Interested, you need to confirm me by email what pulley do you want the Tape OR String Pulley since this year pulley is not universal.

So reply by email with your choice and we will add you on the list for the custom Pulley.

Thanks...

Attachments

Algar_emi said:Custom Pulley Offer

It will be manufactured to really thights tolerances, offer a thru hole and can be mounted using two opposite set screws as recommended by Vinyl-Addict. So it will be easy to remove without motor damage.

Thanks...

If you are going to use opposing set screws it is absolutely critical that the holesize be a very close slip fit with the motor shaft and concentric within 0.0002" The set screws are a very convenient feature but they will work against you if the holesize deviates more than 0.0002" since they are so close to the bottom of the pulley.

I would eliminate the shoulder on the tape pulley since it serves no purpose. It won't prevent the tape from walking and could cause damage to the tape as well. It is very hard to align the tape during the initial setup, at least that has been my greatest challenge since using tape so patience is crucial, however once you have it set up it is worth it.

Eric Weitzman said:I see there's no crown on the pulley. It's going to be VERY hard to keep the tape from riding up or down without a crown.

- Eric

Eric, crowning the pulley doesn't work for tape, although rubber belts work best using a crown. You have to adjust the "tilt" or angle of the motor pod to align the rotation of the tape with the platter. I see no up or down movement at all in my application. It does take patience initially to set up.

Well, let's call this a difference of opinion and not get too excited about it.

I've been using tape drive and have had three pulleys, two of them crowned. The belt was hardest to set up on the flat sided pulley and was nearly impossible to keep running true, which is one reason I changed over to crowned pulleys. My motor "pod" is bolted to the 600 lb plinth and doesn't move. I think the belt ran untrue on the flat pulley because of temperature changes and/or slip in the splice's adhesive.

- Eric

I've been using tape drive and have had three pulleys, two of them crowned. The belt was hardest to set up on the flat sided pulley and was nearly impossible to keep running true, which is one reason I changed over to crowned pulleys. My motor "pod" is bolted to the 600 lb plinth and doesn't move. I think the belt ran untrue on the flat pulley because of temperature changes and/or slip in the splice's adhesive.

- Eric

Eric Weitzman said:Well, let's call this a difference of opinion and not get too excited about it.

My motor "pod" is bolted to the 600 lb plinth and doesn't move. - Eric

Ha, Ha. I'm definitely not "too excited" Whatever works for you Eric. I machined several crowned pulleys for tape and none of them prevented the tape from conforming to the shape of the crown as it came in contact with the pulley. I didn't like that, obviously you find it acceptable.

The problem as I see it is your non-movable pod. I don't use a splice in any of my tape belts because the splice is the weakest link and a gap opens up over time due to stretching, then the adhesive is exposed and causes an annoying clicking sound with every rotation.

Your are correct -- I don't mind the tape conforming to the pulley's crown.

The motor distance/belt tension and tilt are changed during adjustment, then the "pod" bolts are tightened. I made an adjuster to tilt the motor axis with respect to the platter/bearing axis. The tilt adjuster was an afterthought. Experience is the best teacher...

What's your technique for forming a loop from the tape without splicing?

- Eric

The motor distance/belt tension and tilt are changed during adjustment, then the "pod" bolts are tightened. I made an adjuster to tilt the motor axis with respect to the platter/bearing axis. The tilt adjuster was an afterthought. Experience is the best teacher...

What's your technique for forming a loop from the tape without splicing?

- Eric

Just to let you know, previous members of this GB that I have from this year Maxon 2007 GB a few pulleys to sell. I have ONE custom Tape Pulley and TWO Custom String Pulleys. They are the perfect fit for MarK Kelly circuit and Maxon Motor. Fit and finish is superb. There won't be anymore once they are gone...

For anyone interested send me an email. Thanks.

For anyone interested send me an email. Thanks.

Algar_emi said:Just to let you know, previous members of this GB that I have from this year Maxon 2007 GB a few pulleys to sell. I have ONE custom Tape Pulley and TWO Custom String Pulleys. They are the perfect fit for MarK Kelly circuit and Maxon Motor. Fit and finish is superb. There won't be anymore once they are gone...

For anyone interested send me an email. Thanks.

Hello..

i'm interested..but i can't email (i'm new there), please..do you can contact me?

Grazie

Gianni

P.S.: Sorry for my English

problem with maxon motor and controller

Hello altogether,

I´ve a problem with my new maxon motor and the dc - speed controller - the system oscillate!

My turntable plate wights round about 15 kg or 33 pounds and I can handel a stable speed to the limit of 25 round per minutes. By faster settings the voltage rise up from 7,8 Volt to 8,4 for a secound and breaks then down to 1,5 Volt after that the voltage rise up to 8,4 Volt and so on.

So the hole system oscillate between 2 and 35 turns per minute.

Have anyone an idea what I have to do ?

Hoping to receive a favorable answer

Holger

Hello altogether,

I´ve a problem with my new maxon motor and the dc - speed controller - the system oscillate!

My turntable plate wights round about 15 kg or 33 pounds and I can handel a stable speed to the limit of 25 round per minutes. By faster settings the voltage rise up from 7,8 Volt to 8,4 for a secound and breaks then down to 1,5 Volt after that the voltage rise up to 8,4 Volt and so on.

So the hole system oscillate between 2 and 35 turns per minute.

Have anyone an idea what I have to do ?

Hoping to receive a favorable answer

Holger

Here is the link for the document for the controller. The previous site I had it posted on is gone.

http://basaudio.net/datasheets/TT Motor Controller_SB Doc_Ver 1.6.pdf

http://basaudio.net/datasheets/TT Motor Controller_SB Doc_Ver 1.6.pdf

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Group Buys

- Who is interested in a groupbuy of Mark Kelly's DC controller PCB and related parts