What is the point of using a AC chokes for tube equipment? None.If you google and look at the cache then I don't see anything about DC current, so based on that it would seem that you were naive.

DC chokes must have significant gap, compared to AC chokes (speaker xovers, or light ballasts).

Reason is magnetic core centerpoint is at offset (rated dc current)(~1/2 value of core saturation;~0,9T). Swings one "polarity" between zero up to max value.

AC chokes have less gap, they see only AC, and centerpoint is 0; magnetization swings between both max values- both "polarities" -like pp opt.

What happens when AC choke/ PP opt is used in DC circuit? Saturated core sounds crap, inductance is gone bye bye.

Last edited:

Hpeter, the point is that it is up to the diy designer as to where the choke BH operating point swings - a choke doesn't have to swing grossly into the saturation region just because there is DC current flowing (as you imply).

For example, a common flouro choke I have is fine for peak current swing to beyond 500mA - as such, I have used it with a few hundred mA of DC and a few hundred mA of AC swing, such that the peak AC+DC swing doesn't go significantly into the saturation region.

You may be aghast, or fixated, on why someone would use a choke designed for fluorescent light application, when a purpose made choke can be easily purchased for my amp application - the simple reason is that it is diy, and all about restoring and recycling old amps and parts rather than dumping parts that don't have the right aesthetic appeal for some. Similarly, if I have to buy a choke, then if the OP's choke was the cheapest available and suited my DC+AC swing application then I would purchase it, even if it wasn't advertised or specified for DC use.

If I were given the OP's purchased choke, because he didn't want it any more, then I would test its current swing versus saturation performance to get a good idea of opportunities for it in an amp.

Many parts are designed and specified for one application, but often get used in other applications - valves are a great example.

For example, a common flouro choke I have is fine for peak current swing to beyond 500mA - as such, I have used it with a few hundred mA of DC and a few hundred mA of AC swing, such that the peak AC+DC swing doesn't go significantly into the saturation region.

You may be aghast, or fixated, on why someone would use a choke designed for fluorescent light application, when a purpose made choke can be easily purchased for my amp application - the simple reason is that it is diy, and all about restoring and recycling old amps and parts rather than dumping parts that don't have the right aesthetic appeal for some. Similarly, if I have to buy a choke, then if the OP's choke was the cheapest available and suited my DC+AC swing application then I would purchase it, even if it wasn't advertised or specified for DC use.

If I were given the OP's purchased choke, because he didn't want it any more, then I would test its current swing versus saturation performance to get a good idea of opportunities for it in an amp.

Many parts are designed and specified for one application, but often get used in other applications - valves are a great example.

It´s ok, when we are talking about low value choke, where "internal gaps" between EI sheets will provide enough safety margin. (i used 36w lamp ballast ~0,9H for preamp duty)

But in case of high value(+high current chokes), additional gap is needed. If ignored, you get not what you paid for.

And this is the point of this thread.

1 Ampere turns vs Teslas; therefore i will not change my mind.

2 when i compare Lundahl datasheets (i get all info to make things done correctly), to various Poland iron manufacturers, then ..(oh crap there are none datasheets.. )

)

But in case of high value(+high current chokes), additional gap is needed. If ignored, you get not what you paid for.

And this is the point of this thread.

1 Ampere turns vs Teslas; therefore i will not change my mind.

2 when i compare Lundahl datasheets (i get all info to make things done correctly), to various Poland iron manufacturers, then ..(oh crap there are none datasheets..

What's the point of winding and selling a "choke" that has a wholly useless specification ("20H" but it's never 20H; 200mA but it's not good for 200mA of any kind of signal)?

The only reasonable uses I can think of: as a prewound primary (you-wind-it kits?), or as a saturable reactor (in which case, the spec they need to provide is saturation flux).

I should guess they don't sell many.

Tim

The only reasonable uses I can think of: as a prewound primary (you-wind-it kits?), or as a saturable reactor (in which case, the spec they need to provide is saturation flux).

I should guess they don't sell many.

Tim

What's the point of winding and selling a "choke" that has a wholly useless specification ("20H" but it's never 20H; 200mA but it's not good for 200mA of any kind of signal)?

It measures 20H at 5Vrms, and apparently 23H at 40Vrms - that's a choke. If you want to overlay other pre-conceptions then that indicates a level of naivety. The OP tried to clarify specs with the OEM - and has tried to do some testing (although I couldn't make head or tail of what the testing actually was) - so I reckon the jury is still out on what the choke performance really is at higher VAC, and at VAC+VDC.

TDS10/150 - Toroidal Choke 10H 150mA AC - Shop Toroidy.pl

TROBBINS Are you serious?

I do not see there RATED DC CURRENT, ONLY "NOMINAL AC CURRENT" (how do know, within what DC current range their inductance is valid? You don´t know, that´s the answer!

Those chokes are bloody useless, but you still keep repeating yourself.

Compare them to Hammond ,Sowter or Lundahl chokes! .

Hammond Mfg. - D.C. Filter Chokes - (153 - 159 Series)

Chokes for tube amp power supply or filament current supply ⋆ Lundahl Transformers

POWER SUPPLY FILTER AND PLATE CHOKES

TROBBINS Are you serious?

I do not see there RATED DC CURRENT, ONLY "NOMINAL AC CURRENT" (how do know, within what DC current range their inductance is valid? You don´t know, that´s the answer!

Those chokes are bloody useless, but you still keep repeating yourself.

Compare them to Hammond ,Sowter or Lundahl chokes! .

Hammond Mfg. - D.C. Filter Chokes - (153 - 159 Series)

Chokes for tube amp power supply or filament current supply ⋆ Lundahl Transformers

POWER SUPPLY FILTER AND PLATE CHOKES

As written: Unclear 150mADC is not OK before

"Inductance will drops during DC current flow."

Gap reduces DC saturation by linear law.

Gap reduces AC inductance by linear law.

Turns aggravate DC saturation by linear law.

Turns increase AC inductance by SQUARE LAW.

Henries made by turns hold the square law

advantage vs Henries made by not providing

sufficient gap.

Energy is stored in gap, not so much the iron.

Without gap, a core will saturate very easily.

Empty space is preferable to a saturated core of

equally low effectiveness. At least nothing won't

suffer a hysteresis loss or conduct eddys.

Wire loss, wire bulk, and poor flux confinement

are reasons we look to iron and related solutions.

Even as such cores impose limitations.

---

If you have two of those toroids, might still

be able to do something interesting. Perhaps

a magamp, blocking some higher frequency.

"Inductance will drops during DC current flow."

Gap reduces DC saturation by linear law.

Gap reduces AC inductance by linear law.

Turns aggravate DC saturation by linear law.

Turns increase AC inductance by SQUARE LAW.

Henries made by turns hold the square law

advantage vs Henries made by not providing

sufficient gap.

Energy is stored in gap, not so much the iron.

Without gap, a core will saturate very easily.

Empty space is preferable to a saturated core of

equally low effectiveness. At least nothing won't

suffer a hysteresis loss or conduct eddys.

Wire loss, wire bulk, and poor flux confinement

are reasons we look to iron and related solutions.

Even as such cores impose limitations.

---

If you have two of those toroids, might still

be able to do something interesting. Perhaps

a magamp, blocking some higher frequency.

Last edited:

What's the point of winding and selling a "choke" that has a wholly useless specification ("20H" but it's never 20H; 200mA but it's not good for 200mA of any kind of signal)?

The only reasonable uses I can think of: as a prewound primary (you-wind-it kits?), or as a saturable reactor (in which case, the spec they need to provide is saturation flux).

I should guess they don't sell many.

Tim

Hi Tim,

That was exactly my thought, and that of some people I spoke to regarding these chokes. When I asked them: how do you interpret the mA rating, all replies where: that is for DC current, isn't that taken for granted?

anyway, I think that a lot of audio products (chokes, OPTs, etc) end up in closets and are therefore never used, and when used, little will be actually measured.

i still have to reply to you in my other thread, about the "high power shunt". I agree with you that it is probably a waste, still I want to try it - will at least make good heaters for the winters

TDS10/150 - Toroidal Choke 10H 150mA AC - Shop Toroidy.pl

TROBBINS Are you serious?

I do not see there RATED DC CURRENT, ONLY "NOMINAL AC CURRENT" (how do know, within what DC current range their inductance is valid? You don´t know, that´s the answer!

Those chokes are bloody useless, but you still keep repeating yourself.

Compare them to Hammond ,Sowter or Lundahl chokes! .

Hammond Mfg. - D.C. Filter Chokes - (153 - 159 Series)

Chokes for tube amp power supply or filament current supply ⋆ Lundahl Transformers

POWER SUPPLY FILTER AND PLATE CHOKES

Hi!

They used to be rated for "nominal DC current", in post 33 you can see a printscreen I could make from google cache. When I wrote the producer, he changed the whole description of the chokes, including this information.

I am attaching what I actually built and measured. The primary of the power trafo was fed from a Variac. As I don't have seas of time to experiment, I did a test at low voltages - shouldn't matter for inductance - using 12,6V filaments as loads (12SN7 is 300mA, 12AT7 is 150mA) and some (measured) 47uF electrolytics.

After finding out that 450mA (12SN7 and 12AT7 in parallel) was over the top I kept the 12AT7, and lifted the Variac until I got about 12,6V DC across the filament, good for 150mA DC. With 20H the simulated ripple was minimal (5mV or so...) As I measured about 900mV, I decreased inductance until the simulated output was about this 900mV, ending up with 1H worth of inductance.

I did not have the time to test it in a choke input PS yet.

Attachments

Erik, thanks for expanding on the test you did. If you use a 1sec reporting delay in PSUD2 then the VC2 Max-Min=12.3-11.4=0.9Vpp, which is about 0.32Vrms (as harmonics are low). Perhaps you measured 0.9Vrms, not 0.9Vpp.

If choke inductance is tweaked to simulate 0.9Vrms on output for that PSUD circuit then inductance would be 0.4H.

If you used an 84 ohm resistive load (which would be more appropriate imho) with 150mADC, then inductance would need to be tweaked to 0.38H and VAC to 20V. Choke current varies from 110mA to 187mA.

For comparison, 40Vrms across that choke causes just 3mArms. So one observation from the test is that the core is pretty much fully saturated above about 110mApk, in which case the spec for 500mA (AC or DC) doesn't look right.

To get 500mArms AC only current through that choke (if it had 20H inductance), would for example require a 100Hz voltage across the choke of 6.2kV.

Did you ask the manufacturer to explain how the 500mA AC current spec was derived?

If choke inductance is tweaked to simulate 0.9Vrms on output for that PSUD circuit then inductance would be 0.4H.

If you used an 84 ohm resistive load (which would be more appropriate imho) with 150mADC, then inductance would need to be tweaked to 0.38H and VAC to 20V. Choke current varies from 110mA to 187mA.

For comparison, 40Vrms across that choke causes just 3mArms. So one observation from the test is that the core is pretty much fully saturated above about 110mApk, in which case the spec for 500mA (AC or DC) doesn't look right.

To get 500mArms AC only current through that choke (if it had 20H inductance), would for example require a 100Hz voltage across the choke of 6.2kV.

Did you ask the manufacturer to explain how the 500mA AC current spec was derived?

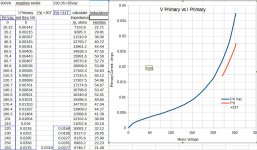

I posted a toroid transformer Iprimary vs Vprimary with the secondary open in another Thread.

In effect that is an inductance test.

Here is the diagram from excel/openoffice

Note that inductive reactance and inductance peak at ~110Vac. The peak will be between 110Vac and 115Vac.

Note how low the inductance is at the extremes of voltage. less than 50%

This is an AC test. It did not use DC to make the saturation worse.

This is typical for all continuous iron cores

They gain in inductance as the ampere turns increases

then as the core starts to saturate, the inductance begins to level off and then falls as saturaton becomes extreme.

If one wants an inductor that is impervious to flux saturation effects, then it must be air cored.

The next lower standard is to use a gapped core, or a core that includes microgaps (iron dust and similar types).

In effect that is an inductance test.

Here is the diagram from excel/openoffice

Note that inductive reactance and inductance peak at ~110Vac. The peak will be between 110Vac and 115Vac.

Note how low the inductance is at the extremes of voltage. less than 50%

This is an AC test. It did not use DC to make the saturation worse.

This is typical for all continuous iron cores

They gain in inductance as the ampere turns increases

then as the core starts to saturate, the inductance begins to level off and then falls as saturaton becomes extreme.

If one wants an inductor that is impervious to flux saturation effects, then it must be air cored.

The next lower standard is to use a gapped core, or a core that includes microgaps (iron dust and similar types).

Attachments

Last edited:

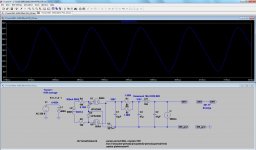

This is one of my active PSUs (300V, 200mA) simulation. I corresponds to the actual measurements.

The toroid transformer is capable up to 500W, secondary is 340V, 300mA (DCR:4R). The real rectifier tube is AX50 (mercury vapour).

As you can see, across the brutally large choke (Hammond 193J: 10H, 82R DCR) about 16Vpp sawthoot (on the 16.4V average DC) voltage.

The toroid transformer is capable up to 500W, secondary is 340V, 300mA (DCR:4R). The real rectifier tube is AX50 (mercury vapour).

As you can see, across the brutally large choke (Hammond 193J: 10H, 82R DCR) about 16Vpp sawthoot (on the 16.4V average DC) voltage.

Attachments

Erik, thanks for expanding on the test you did. If you use a 1sec reporting delay in PSUD2 then the VC2 Max-Min=12.3-11.4=0.9Vpp, which is about 0.32Vrms (as harmonics are low). Perhaps you measured 0.9Vrms, not 0.9Vpp.

If choke inductance is tweaked to simulate 0.9Vrms on output for that PSUD circuit then inductance would be 0.4H.

If you used an 84 ohm resistive load (which would be more appropriate imho) with 150mADC, then inductance would need to be tweaked to 0.38H and VAC to 20V. Choke current varies from 110mA to 187mA.

For comparison, 40Vrms across that choke causes just 3mArms. So one observation from the test is that the core is pretty much fully saturated above about 110mApk, in which case the spec for 500mA (AC or DC) doesn't look right.

To get 500mArms AC only current through that choke (if it had 20H inductance), would for example require a 100Hz voltage across the choke of 6.2kV.

Did you ask the manufacturer to explain how the 500mA AC current spec was derived?

I still wanted to thank you for that paper, I learned a couple things from it!

IIRC it was indeed 900mV pp (9 divisions at 0.1V setting), but that can be wrong.

My first question to the manufacturer was how he managed to get the whole range of chokes (from 5H@100mA to 20H@500mA) with the same size and weight, to which he replied that they all use the same core, it is only the wire diameter and nr of turns that change. So I imagine that the 500mA is the figure for max "standing current" in the wire.

Erik

Educational Opportunity

By the way, guys...

If you ever find yourself wondering if a ferrite bead would be useful somewhere, consider this:

They are rated precisely the same way.

They might give you an "inductance" spec (or rather, |Z| vs. freq), and a rated (i.e., DC power dissipation) rating.

They leave curiously absent, the case where both coincide...

In actual fact, in all cases, the inductance (or |Z| curve, or..) drops considerably for currents more than maybe 10% of Idc rating!

If you need a known impedance at high frequencies, and need DC capacity, consider an inductor, not a ferrite bead. Yes, the difference matters, and yes, they are marketed separately!

Ferrite beads are essentially only useful for small signal purposes, and some power filtering purposes as long as the DC current is very small. Why they're ever made in multiple amperes sizes, I have no idea. Another great deception.

The product in this thread, is little more than an absolutely enormous ferrite* bead.

*Technically correct, using the metallurgical meaning of "ferrite": the pure metallic alpha-iron phase.

Tim

By the way, guys...

If you ever find yourself wondering if a ferrite bead would be useful somewhere, consider this:

They are rated precisely the same way.

They might give you an "inductance" spec (or rather, |Z| vs. freq), and a rated (i.e., DC power dissipation) rating.

They leave curiously absent, the case where both coincide...

In actual fact, in all cases, the inductance (or |Z| curve, or..) drops considerably for currents more than maybe 10% of Idc rating!

If you need a known impedance at high frequencies, and need DC capacity, consider an inductor, not a ferrite bead. Yes, the difference matters, and yes, they are marketed separately!

Ferrite beads are essentially only useful for small signal purposes, and some power filtering purposes as long as the DC current is very small. Why they're ever made in multiple amperes sizes, I have no idea. Another great deception.

The product in this thread, is little more than an absolutely enormous ferrite* bead.

*Technically correct, using the metallurgical meaning of "ferrite": the pure metallic alpha-iron phase.

Tim

For decades, Ferroxcube have been providing extensive data manuals.

http://www.ferroxcube.com/FerroxcubeCorporateReception/datasheet/FXC_HB2013.pdf

Many applications have been accommodated over decades. For a newb it may be a bit daunting to find the right info, such as Fig 48 in the link for impact of DC current on impedance.

I've used beads for preamp inputs, when using low grid stopper value (eg. 10k) for noise. A balun type inductor is better suited though, as beads don't add too much impedance compared to 10k.

I've used beads on anode stoppers for 807's. A typical stopper is 10-100R, so that makes sense. Hopefully the local temp under the top-cap remains below 150C, cos thats when typical emi ferrite will hit a cliff.

http://www.ferroxcube.com/FerroxcubeCorporateReception/datasheet/FXC_HB2013.pdf

Many applications have been accommodated over decades. For a newb it may be a bit daunting to find the right info, such as Fig 48 in the link for impact of DC current on impedance.

I've used beads for preamp inputs, when using low grid stopper value (eg. 10k) for noise. A balun type inductor is better suited though, as beads don't add too much impedance compared to 10k.

I've used beads on anode stoppers for 807's. A typical stopper is 10-100R, so that makes sense. Hopefully the local temp under the top-cap remains below 150C, cos thats when typical emi ferrite will hit a cliff.

is there any update om this? I noticed that the Toroidy website

TDS10/250 - Toroidal Choke 10H 250mA DC - Shop Toroidy.pl

speaks of 250mA DC again....

after the summer I want to start with my KT88 SE amp, still need to buy the choke and the transformers and Toroidy looked like a good supplier for the lot.

TDS10/250 - Toroidal Choke 10H 250mA DC - Shop Toroidy.pl

speaks of 250mA DC again....

Technical data

Core type toroidal

Inductance L 10H

DC Resistance 45Ω

Nominal DC Current 250mA

Nominal voltage 400V

Dimensions 88 mm (OD) x 35 mm (h), weight: 1,3 kg

after the summer I want to start with my KT88 SE amp, still need to buy the choke and the transformers and Toroidy looked like a good supplier for the lot.

I asked Toroidy about this issue, and this was their response:

so it seems the issue is resolved now?Indeed a few months ago there was a problem with our core supplier.

All our products with inproper airgaps are now replaced.

Now, we're using properly airgapped cores for nominal DC current flow.

Problem is now fully fixed and our chokes withstands nominal DC current without any problems.

I asked Toroidy about this issue, and this was their response:

so it seems the issue is resolved now?

I just bought a bunch of 100 and 300mA chokes. Should arrive today.

Will confirm if the "problem" is solved of if they will return to Poland asap

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Warning about chokes by Toroidy