A belt drive is not like a geared or toothed drive.It's curious that all the files so far are fast. What's going on there?

A belt drive cannot be designed to an exact speed.

The mains is not an exact speed.

This combination will give speed errors.

One cannot compensate for mains frequency errors. That would need a new generator locked to it's own precision frequency.

A belt drive has both slip that varies with loading and has a compensation factor that takes account of belt thickness and stiffness.

Change the belt slightly and the belt drive speed will change.

Something like that, +/- 0.5% or similar IIRC. However, in practice it doesn't shift very far very fast, otherwise something at the generator end really would go BANGMains in UK is only allowed to vary +/-1%, Suspect where George is will not be any different as bad things tend to happen.

I just watched the UK mains frequency shift about 0.1% from near perfect 50.000Hz over the span of a few minutes....... another 2 minutes of my life I'll never get back...............

So long as frequency deviation isn't much, such slow changes are inaudible by most mortals and motor speed variation seldom shows up on polar plots over the course of a few revolutions. Certainly masked by other big factors, such as eccentricity/centering and warp IME. Mains will always normalise to 50.000Hz over a long enough period, for sure.

LD

Last edited:

A belt drive cannot be designed to an exact speed.

<snip>

A belt drive has both slip that varies with loading and has a compensation factor that takes account of belt thickness and stiffness.

Change the belt slightly and the belt drive speed will change.

Both my big belt driven TT's, a Thorens TD 320 and a Dual CS 5000, don't show any speed errors. The first one due to it's heavy platter and careful design, using a BLDC motor with X-tal referenced speed control, the 2nd one with a similar motor and a speed control that grasps it's actual speed information directly from the platter.

My smaller Dual's, two 1237A and a 1239, feature synchronous motors with rpm's directly synchronized to mains frequency, which is very stable here. In addition the platter speed may be adjusted by hand in the range of ± half a semitone.

Best regards!

Best regards!

Even if a platter rotates with zero error, there will still be significant playback pitch variation due to the effects of cart-arm instability, spindle centering, vertical run-out, and warp, etc etc.Both my big belt driven TT's, a Thorens TD 320 and a Dual CS 5000, don't show any speed errors.

Such effects typically dwarf any motor or platter drive speed variation in TTs, unless there is a drive fault IME No matter what drive and what platter.

Long term there well may be zero speed error, but the audibility of short term variations dominates typical pitch errors, for most people in most cases. That is perhaps very counter-intuitive, but if one cares about pitch stability the TT platter/drive is seldom the place to apply effort, IME.

LD

Last edited:

I didn't mean stability, that another matter. Just wondering why all the samples so far have been fast. Never slow, never varying over the course of many plays, just fast.

There are many ways to adjust TT speed, strobes, tones - there are even smart phone apps. I used to use a stop watch and count turns over 3 minutes. Tedious, but I assume accurate. Maybe not. I do remember that we ran them slightly fast in radio, said to be a standard practice at the time.

I used to use a stop watch and count turns over 3 minutes. Tedious, but I assume accurate. Maybe not. I do remember that we ran them slightly fast in radio, said to be a standard practice at the time.

There are many ways to adjust TT speed, strobes, tones - there are even smart phone apps.

Something like that, +/- 0.5% or similar IIRC. However, in practice it doesn't shift very far very fast, otherwise something at the generator end really would go BANG

I just watched the UK mains frequency shift about 0.1% from near perfect 50.000Hz over the span of a few minutes....... another 2 minutes of my life I'll never get back...............

LD

I rather enjoy looking at gridwatch. But that is more due to my current project than merely geeky fascination...honest

Even if a platter rotates with zero error, there will still be significant playback pitch variation due to the effects of cart-arm instability, spindle centering, vertical run-out, and warp, etc etc.

Such effects typically dwarf any motor or platter drive speed variation in TTs, unless there is a drive fault IME No matter what drive and what platter.

LD

Killjoy. I was eyeing up a CS5000 to add to the stable.

Killjoy. I was eyeing up a CS5000 to add to the stable.

There's more to TT/platter sound than pitch stability though.........and a little instability of the right sort is probably euphonic........ so don't let me put you off

I think I have a test file recording for one of the Dual belt drives in the archive, I'll fetch it out.

LD

Last edited:

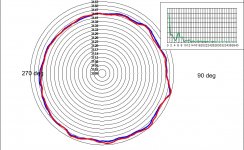

Thank you LuckyHere's the first of the analysis polar plots. It's the S1 T10 3150Hz tone.

The TT is running fast, and there's a strong 'once per revolution' variation that mimics eccentricity. Could be centering or vertical run-out, or bent spindle or something like that ? This effect is so bad that it's likely to mask anything else, and that shows up in the inset spectrum...

Neither centering or vertical run-out at least that strong as I could see.

Not a good rotating platter but judging from the spectrum inset, IMO a very good arm.

George

The RB300 is a very good arm. I would have one now were it not for getting offered a good deal on an SME 20 years ago. The audiomods upgrade kits Audiomods tonearms and tonearm kits to the RB250 do temp me but you still end up with an arm with no azimuth adjustment. Not sure anyone has tried a cut and shut to make the arm able to rotate...

Noob Query. I am learning to read polar plots. The wavy plot denote speed variation. the centering of plot denotes eccentricity. What does inset spectrum graph denotes ?Thank you Lucky

Neither centering or vertical run-out at least that strong as I could see.

Not a good rotating platter but judging from the spectrum inset, IMO a very good arm.

George

Thanks and regards.

Inset in Lucky's words

George

The inset is intended to provide a spectrum view of whatever is FM modulating the test tone. It's just the result of an FFT of the demodulator output, sampled around the revolution. The y axis is auto-scale-to-fit linear level of demod output. For the purpose of identifying contributing sources that's fine. And the x axis is simply modulating frequency in Hz.

In the scheme of things, the FM modulating action is all at low frequencies, one can see that a number of ways. There's no energy for it to be otherwise, when you think about it....... but hey, that's for another thread !

LD

George

The audiomods upgrade kits

I barely had set the cart on the arm. The combo left the house without giving me time to record the other test tracks.

Oracle Delphi V + Audiomods + DL-103 (VTF 2.5gm)

HFN S1 T6 300Hz +12dB

Dropbox - Oracle+Audiomods+DL-103_HFN S1 T6.wav

George

Attachments

Hi Luckydog,

I ripped two 3150 Hz tracks today. Would you please do plots for me?

I have a 6 lbs outer ring. One track is with the outer ring and another is without outer ring. The outer ring is heavy and I would like to see if it has any impact on the stability of the turn table.

My table is SME20, diy air bearing arm and Denon DL-103r cartridge.

Dropbox - 3150 with outer ring.wav

Dropbox - 3150 without outer ring.wav

Thank you!

Jim

I ripped two 3150 Hz tracks today. Would you please do plots for me?

I have a 6 lbs outer ring. One track is with the outer ring and another is without outer ring. The outer ring is heavy and I would like to see if it has any impact on the stability of the turn table.

My table is SME20, diy air bearing arm and Denon DL-103r cartridge.

Dropbox - 3150 with outer ring.wav

Dropbox - 3150 without outer ring.wav

Thank you!

Jim

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Turntable speed stabilty