200W to 300W of amplifier power would be ideal for a 500VA toroid.

Is that 2in² (sqin) core capable of 500VA?

I thought the formula for predicting VA is

31 * (core area)² * Flux = 31*2*2*1.6 = 200VA?

Toroids can fit about twice as much copper in them as EI cores. that's why there are no rule of thumb formulas.

Toroids can fit about twice as much copper in them as EI cores. that's why there are no rule of thumb formulas.

agreed, formulas are just that, formulas....

and if your formula says 300w, that doesn't mean the traffo is unusable at 301w,

there are a lot more to consider.....i tend to favor the practical side of things...

and if the acceptable toroid flux is 1.6T, whereas the EI is limited to around 0.8T, you will find that the half area core with twice the copper comes out as being the same, i.e. the standard formula predicting VA works for both types.

without knowing the true quality of the irons on hand, all this talk serves no piratical purpose...

Another question arise!

Given that data, How to determine the turn/volt of this toroid transformer?

I cannot use the turn ratio unless We know one value i.e. primary or secondary number of windings

below is the generic formula for calculating the number of turns:

#turns = V / (4.44 x CA x f x CS )

where: V = voltage across the terminal winding, in volts

4.44 = constant for sine wave

CA = cross-sectional area of core, in square meter

f = frequency, in Hz

CS = core saturation, in tesla

say for example:

for primary winding V = 230v, f = 60Hz,

for torroid CA = 2 sq.in or 0.00129 sq.m.

since we do not know the core saturation, we will assume 0.9T for calculation purposes...

therefore,

#turns (primary) = 230 / (4.44 x 0.00129 x 60 x 0.9) = 744

turns per volt = 744 / 230 = 3.2 turns per volt

above is only an illustration, so the result may not be correct for your actual core.

there was one member at Elab.ph who rewound his torroid this way...

he weighed in the primary copper, got the same size and weight copper and started winding,

once done, he then wrapped several turns of wire for a temporary secondary to

confirm the turns per volt data and used that data to wind the secondary winding...

very practical isn't it?

he weighed in the primary copper, got the same size and weight copper and started winding,

once done, he then wrapped several turns of wire for a temporary secondary to

confirm the turns per volt data and used that data to wind the secondary winding...

very practical isn't it?

Thank you so much jaagut!

When I started winding transformer (way back in my high school days with EI cores ) I used to use that same method.

) I used to use that same method.

When I find transformers with no label that are still working and I cannot see the specifics on the table that was provided by my high school teacher. I used to dismantle the core and wound up few turns and then assemble it. Measuring the voltage across that, then I would know the turn/volt..

When I started winding transformer (way back in my high school days with EI cores

When I find transformers with no label that are still working and I cannot see the specifics on the table that was provided by my high school teacher. I used to dismantle the core and wound up few turns and then assemble it. Measuring the voltage across that, then I would know the turn/volt..

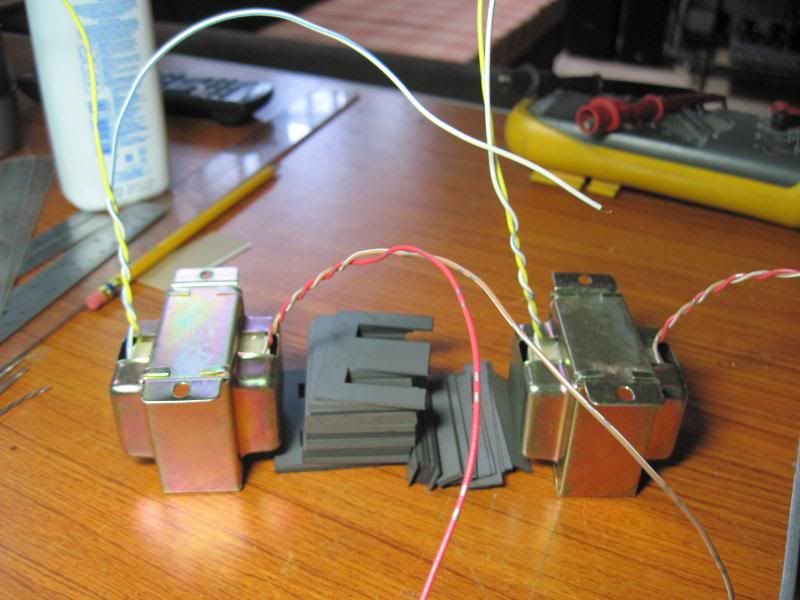

freshly baked traffos...

finished this in just a week....the hot Manila sun cures the varnish very quick...'D

left to right, traffos set for an upcoming 829b SET amp,

2 x 25 volts 270 va traffo for gainclone amp,

2 x 38 volts 500 va traffo for my 2nd honey badger build,

2 x 52 volts 750 va traffo for a 6 pair Leach Lo-TiM amp...

finished this in just a week....the hot Manila sun cures the varnish very quick...'D

left to right, traffos set for an upcoming 829b SET amp,

2 x 25 volts 270 va traffo for gainclone amp,

2 x 38 volts 500 va traffo for my 2nd honey badger build,

2 x 52 volts 750 va traffo for a 6 pair Leach Lo-TiM amp...

Attachments

Tony

What is the largest wire diameter you have had to use winding trannies for audio purposes ?

Reason I ask is I am trying to pick up a secondhand winder from Germany and the guy selling the machines has asked me that question. As I haven't actually wound one yet I am not too sure. Some of the stuff you have wound for heater trannies uses quite thick wire ?

What is the largest wire diameter you have had to use winding trannies for audio purposes ?

Reason I ask is I am trying to pick up a secondhand winder from Germany and the guy selling the machines has asked me that question. As I haven't actually wound one yet I am not too sure. Some of the stuff you have wound for heater trannies uses quite thick wire ?

Tony

What is the largest wire diameter you have had to use winding trannies for audio purposes ?

Reason I ask is I am trying to pick up a secondhand winder from Germany and the guy selling the machines has asked me that question. As I haven't actually wound one yet I am not too sure. Some of the stuff you have wound for heater trannies uses quite thick wire ?

AWG #8 magnet wire....

yes for heater wires, sometimes 2 strands of #14 wire for filaments....

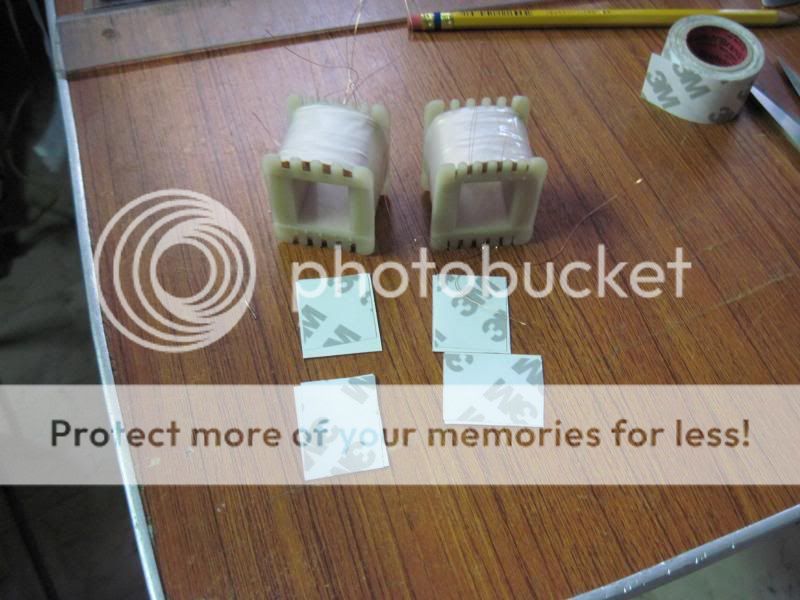

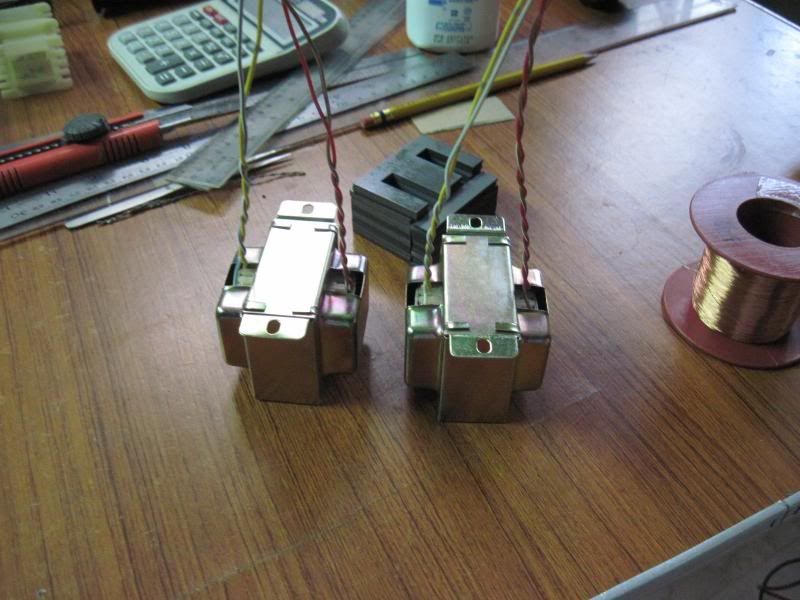

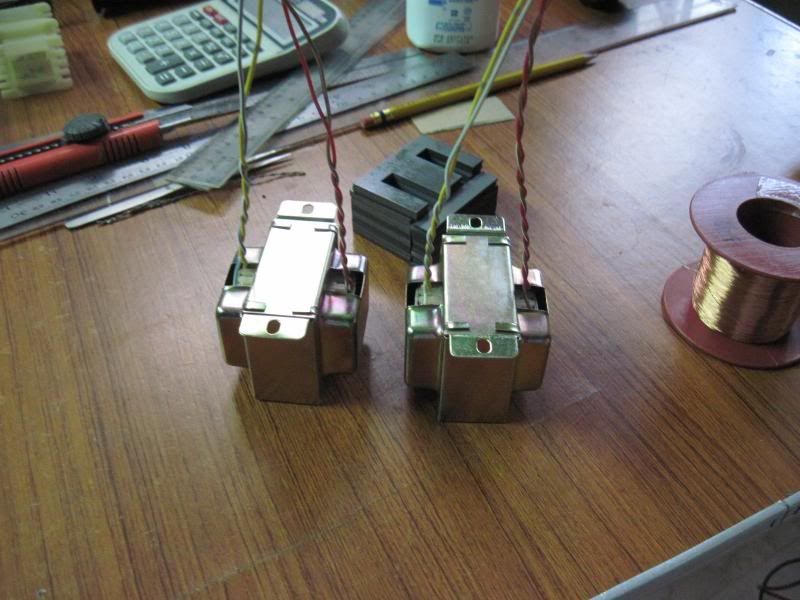

output transformer for a 6J5 preamp ala Jack Elliano...

turns ratio is 5:1, 5k primary to 200 ohm secondary...

on Z11 3/4 inch cores.....

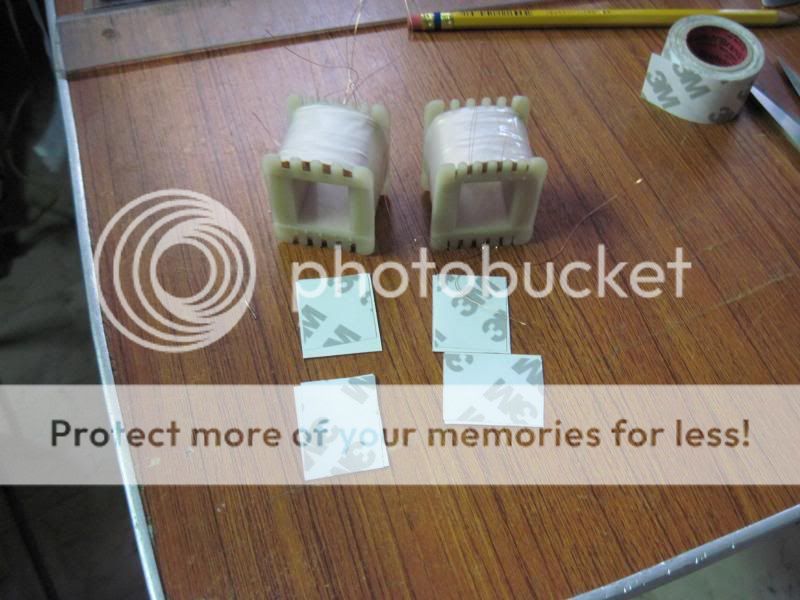

3M double sided tapes come in handy...

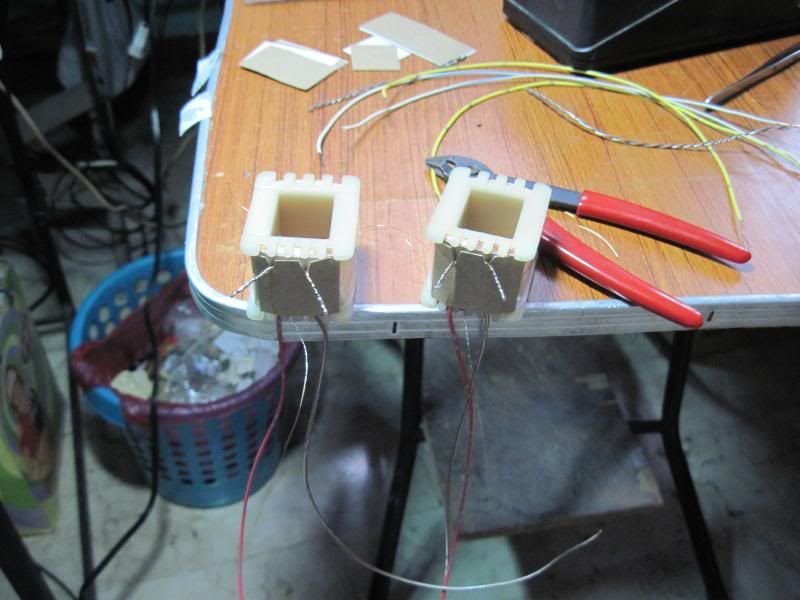

terminating primary leads...

primary leads terminated....

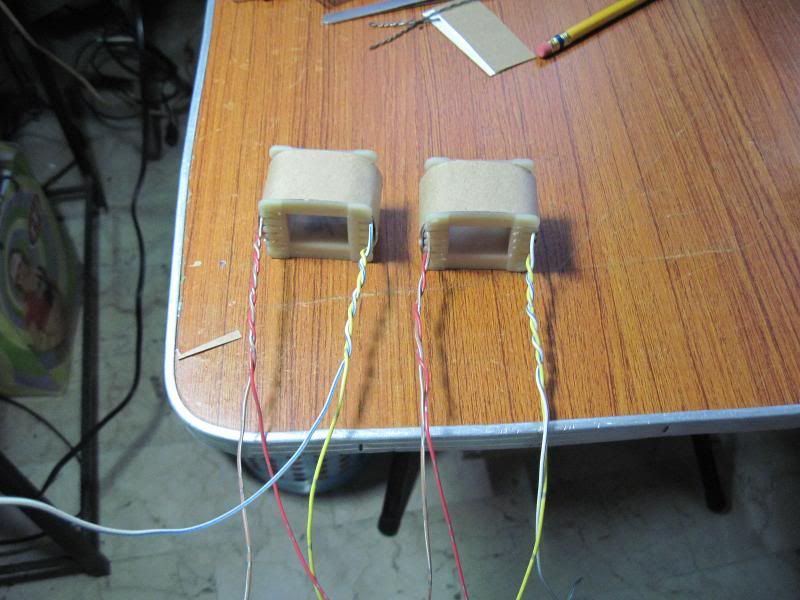

secondary leads terminated...

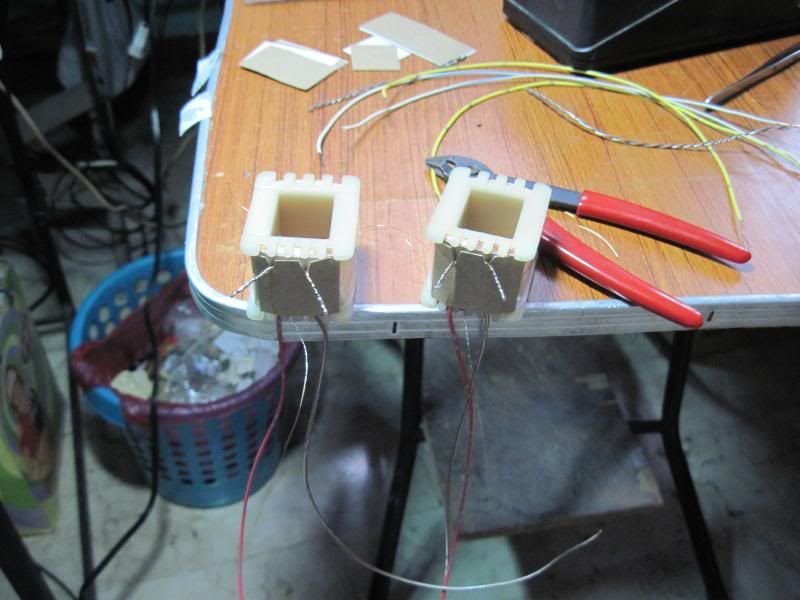

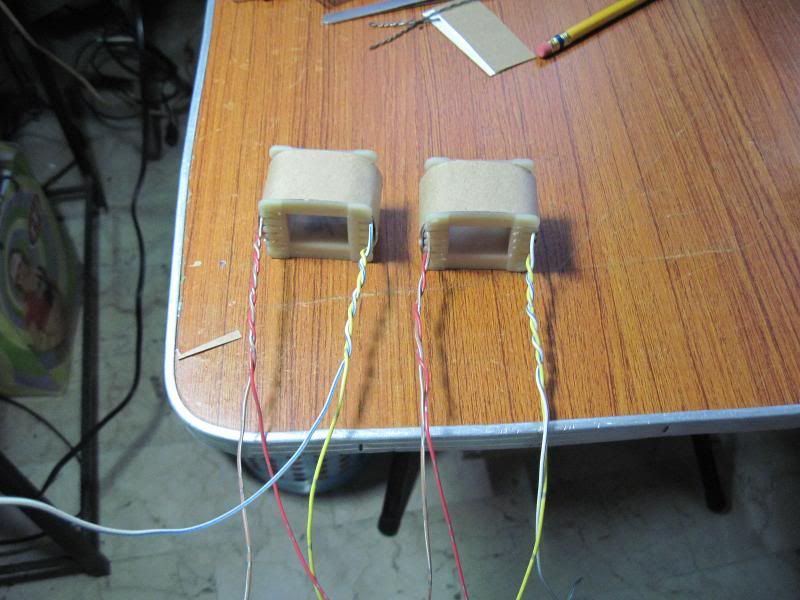

both primary and secondary leads secured...

coil outer wrap completed, cores come in next..

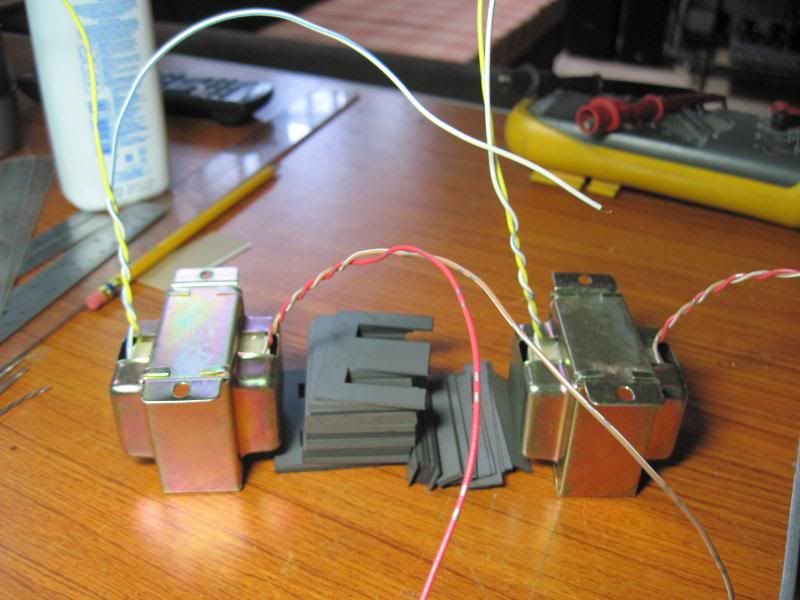

some left-over cores to be used on next build....

a pair of output trafffos finished and ready for a dip in varnish...

i took me about 3 to 4 hours from start to finish.....

in case you are wondering, that talcum powder is for my sweaty hands...

turns ratio is 5:1, 5k primary to 200 ohm secondary...

on Z11 3/4 inch cores.....

3M double sided tapes come in handy...

terminating primary leads...

primary leads terminated....

secondary leads terminated...

both primary and secondary leads secured...

coil outer wrap completed, cores come in next..

some left-over cores to be used on next build....

a pair of output trafffos finished and ready for a dip in varnish...

i took me about 3 to 4 hours from start to finish.....

in case you are wondering, that talcum powder is for my sweaty hands...

- Home

- Amplifiers

- Power Supplies

- Tony's latest traffo DIY build