It seems only to be a problem if I don't allow things to settle for a few seconds before reading the value. I was just a bit surprised.

The Ortofon arrived with a friend today and allows me to easily measure tracking force and does so in a manner that allows me to account for the interaction between the iron platter on the 124 (which is magnetic) and the strong fields generated by these cartridges.

The Ortofon is needlessly expensive IMHO, and I resisted getting one for a long while, the other was under $15 IIRC a couple of years ago..

Given the clearances involved the Ortofon just works better for my general needs. It is also a bit better behaved than the cheaper unit I have on hand.

The Ortofon arrived with a friend today and allows me to easily measure tracking force and does so in a manner that allows me to account for the interaction between the iron platter on the 124 (which is magnetic) and the strong fields generated by these cartridges.

The Ortofon is needlessly expensive IMHO, and I resisted getting one for a long while, the other was under $15 IIRC a couple of years ago..

Given the clearances involved the Ortofon just works better for my general needs. It is also a bit better behaved than the cheaper unit I have on hand.

It seems only to be a problem if I don't allow things to settle for a few seconds before reading the value. I was just a bit surprised.

The Ortofon arrived with a friend today and allows me to easily measure tracking force and does so in a manner that allows me to account for the interaction between the iron platter on the 124 (which is magnetic) and the strong fields generated by these cartridges.

The Ortofon is needlessly expensive IMHO, and I resisted getting one for a long while, the other was under $15 IIRC a couple of years ago..

Given the clearances involved the Ortofon just works better for my general needs. It is also a bit better behaved than the cheaper unit I have on hand.

Good evening Kevin, and happy DST to you.

Back in my earlier days of trying to set up and measure tracking force on LT arms I was having all kinds of trouble. The Ortofon plastic balance giveaway was utterly useless and the Harborfreight electronic scales was way too thick to allow reading with it positioned on the TT platter. I could set up a platform off to the side of the platter and use that but that was far too much trouble. So I settled for the following subterfuge. With a spinning record on the platter I adjusted the counterweight so that the stylus was just grazing the tops of the grooves but not following them. Then I weighed out a small pea of plumbers putty to the force I wanted and placed it on the headshell. I have been using 1.8 to 2.0 grams. My arm and ADC cart will actually track at 1.5g or even a bit less but I like the overall performance and sound better with the 2g weight. You might try this as a cross check on what you are doing.

Rgds,

BillG

Tracking force issue has been resolved with the new scale, its design makes slipping it in under the stylus very easy with the arm properly set up.

The other news of note is in a moment of insanity or inspiration I stuffed one of my hollow titanium arm tubes completely full of cork. (This is NOT reversible!) Quite laborious, and yet surprisingly effective, for a gram or so of additional mass the HF sibilance on some material has been killed deader than dead. Playing the worst case vinyl now and not a peep.

A friend and I are planning to make some new arm wands in various materials for evaluation.

I got to play with a TT-3 at the Salon Audio show in Montreal yesterday, quite interesting arm that exhibits many of the same strengths and weaknesses as my much older Southers. Overall I liked it quite a lot. (It's a lot more refined)

The other news of note is in a moment of insanity or inspiration I stuffed one of my hollow titanium arm tubes completely full of cork. (This is NOT reversible!) Quite laborious, and yet surprisingly effective, for a gram or so of additional mass the HF sibilance on some material has been killed deader than dead. Playing the worst case vinyl now and not a peep.

A friend and I are planning to make some new arm wands in various materials for evaluation.

I got to play with a TT-3 at the Salon Audio show in Montreal yesterday, quite interesting arm that exhibits many of the same strengths and weaknesses as my much older Southers. Overall I liked it quite a lot. (It's a lot more refined)

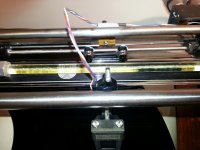

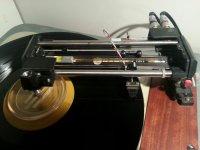

A couple of pix as the SLA-3 currently stands. Next I am going to replace the wiring. I noticed on the TT-3 that the arm cable goes directly to the RCA jacks which is I think I am going to do, it eliminates the intermediate connector but retains the RCA jacks which I find convenient.

Attachments

Kevin,

What tonearm wire are you going to use? The original cable on my SLA-3 is starting to fray and may eventually fail. I've looked at the Cardas Clear and may order some to try.

I see you still have the wire cable guard installed. It could be another source of unwanted resonance. You should try removing it. Mine came off very easily.

Regards,

David

What tonearm wire are you going to use? The original cable on my SLA-3 is starting to fray and may eventually fail. I've looked at the Cardas Clear and may order some to try.

I see you still have the wire cable guard installed. It could be another source of unwanted resonance. You should try removing it. Mine came off very easily.

Regards,

David

Hi Dave,

Given my fumbled fingeredness I figured I would leave the sleeving alone and set this cable aside at some point soon. I assume you are talking about the very flexible heat shrink tubing on the cartridge end of the cable.

I have a Clear Audio super cable that I will try with a 4 pin header before I proceed with further wiring modifications which will require new wire.

My understanding is that Clear Audio can provide replacement wiring for these arms, that said I have not found the U.S. distributor to be particularly helpful. Might have better luck talking to an authorized dealer who might have some pull with the distributor.

I am still looking for appropriate wire actually. Cardas no longer makes the super skinny stuff some people were using some years back. 38 - 42 awg magnet wire has been suggested amongst other things. There may be some decent options on eBay particularly from U.K. or German sellers.

I'm surprised that your original cable has held up this long, the net is rife (well sort of ) with stories of cable failures over some unspecified time interval.

) with stories of cable failures over some unspecified time interval.

Given my fumbled fingeredness I figured I would leave the sleeving alone and set this cable aside at some point soon. I assume you are talking about the very flexible heat shrink tubing on the cartridge end of the cable.

I have a Clear Audio super cable that I will try with a 4 pin header before I proceed with further wiring modifications which will require new wire.

My understanding is that Clear Audio can provide replacement wiring for these arms, that said I have not found the U.S. distributor to be particularly helpful. Might have better luck talking to an authorized dealer who might have some pull with the distributor.

I am still looking for appropriate wire actually. Cardas no longer makes the super skinny stuff some people were using some years back. 38 - 42 awg magnet wire has been suggested amongst other things. There may be some decent options on eBay particularly from U.K. or German sellers.

I'm surprised that your original cable has held up this long, the net is rife (well sort of

Hello Kevin,

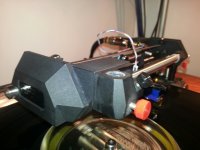

Here are some pictures of my SLA-3. Sorry about the size. I couldn't figure out how to size them correctly. The third pictures shows my arm with the optional thick plastic cover. In the second picture, you can see the thin metal rod laying across the top of the arm, which Souther calls the cable guide. I took it off because it added resonance. It was simple to remove on my arm. You may want to try it out yourself.

Also shown are the two holes I drilled to add lead shot into the two metal tubes. I tapped them and used screws to seal them. This mod added a bit of mass to the arm and I believe this mod reduced resonance further. You can see the one shot I removed to show its size. You can fill these rods with anything you want even sand or glass beads.

The first picture is a picture that I got from the Souther dealer when I bought my arm. I don't know much about it, but I think it was an attempt my Lou Souther to design the arm to be actively driven by the chain mechanism that you see. Any guess on how it would work?

Regards,

David

Here are some pictures of my SLA-3. Sorry about the size. I couldn't figure out how to size them correctly. The third pictures shows my arm with the optional thick plastic cover. In the second picture, you can see the thin metal rod laying across the top of the arm, which Souther calls the cable guide. I took it off because it added resonance. It was simple to remove on my arm. You may want to try it out yourself.

Also shown are the two holes I drilled to add lead shot into the two metal tubes. I tapped them and used screws to seal them. This mod added a bit of mass to the arm and I believe this mod reduced resonance further. You can see the one shot I removed to show its size. You can fill these rods with anything you want even sand or glass beads.

The first picture is a picture that I got from the Souther dealer when I bought my arm. I don't know much about it, but I think it was an attempt my Lou Souther to design the arm to be actively driven by the chain mechanism that you see. Any guess on how it would work?

Regards,

David

Attachments

Hi Dave,

The size of those photos is just fine. Great detail actually which is helpful in my on going mod plan.

My Tri-Quartz is heavily modified with many of the things you have approached from a different angle. The metal tubes on that are are filled with a mixture of sand and what appears to be acquaplas - not sure will ask the guy who gave it to me. This arm has a third large metal rod added as you may have noticed from pictures for additional stiffness - this was done at Souther's suggestion.

The SLA-3 has only some very minor modifications to date, but I will make some additional changes soon. I like the idea of lead shot or similar in the support tubes. The big change was damping a hollow titanium arm tube internally with cork - this has largely killed the sibilance issues I was having, careful adjustment of azimuth, overhang and VTA have helped with the rest.

I am also thinking about adding the third quartz rod found on the Tri-Quartz, although this really makes bearing replacement a pain in the butt.

Talking about bearings, the ones recommended earlier in this thread despite being lubricated are a substantial improvement over even the bearings in the NIB SLA-3. Since installing these bearings I have not had any instances of severe LF mistracking or midrange distortion in either arm. They seem to behave no differently in terms of friction than what they replaced, and run more smoothly.

I like the simple thick plastic top plate and am thinking about getting a couple made for both my arms.

I ordered two sets of KAB super flexible 34ga litz tone arm wire, and some Cardas tags, it was cheap enough so that if it does not work well I will just use it for something else in the future. My plan is to wire directly to the RCA jacks as Clear Audio has done in the TT-3. My cartridge has a source impedance of 2 ohms so I am hoping to avoid adding excessive dcr in the signal path.

This will be the first major mod I undertake on the SLA-3, and I plan to install a new set of RCA jacks on the Tri-Quartz and do the same thing.

The source impedance of the Per Windfeld is low, and to my considerable surprise my expedient choice of unshielded interconnect works fine, no discernible hum pick up issue, at this point adding ground lift switches on the input of the SUT would give me balanced operation - something I will add shortly when I have time to order the appropriate switches.

The size of those photos is just fine. Great detail actually which is helpful in my on going mod plan.

My Tri-Quartz is heavily modified with many of the things you have approached from a different angle. The metal tubes on that are are filled with a mixture of sand and what appears to be acquaplas - not sure will ask the guy who gave it to me. This arm has a third large metal rod added as you may have noticed from pictures for additional stiffness - this was done at Souther's suggestion.

The SLA-3 has only some very minor modifications to date, but I will make some additional changes soon. I like the idea of lead shot or similar in the support tubes. The big change was damping a hollow titanium arm tube internally with cork - this has largely killed the sibilance issues I was having, careful adjustment of azimuth, overhang and VTA have helped with the rest.

I am also thinking about adding the third quartz rod found on the Tri-Quartz, although this really makes bearing replacement a pain in the butt.

Talking about bearings, the ones recommended earlier in this thread despite being lubricated are a substantial improvement over even the bearings in the NIB SLA-3. Since installing these bearings I have not had any instances of severe LF mistracking or midrange distortion in either arm. They seem to behave no differently in terms of friction than what they replaced, and run more smoothly.

I like the simple thick plastic top plate and am thinking about getting a couple made for both my arms.

I ordered two sets of KAB super flexible 34ga litz tone arm wire, and some Cardas tags, it was cheap enough so that if it does not work well I will just use it for something else in the future. My plan is to wire directly to the RCA jacks as Clear Audio has done in the TT-3. My cartridge has a source impedance of 2 ohms so I am hoping to avoid adding excessive dcr in the signal path.

This will be the first major mod I undertake on the SLA-3, and I plan to install a new set of RCA jacks on the Tri-Quartz and do the same thing.

The source impedance of the Per Windfeld is low, and to my considerable surprise my expedient choice of unshielded interconnect works fine, no discernible hum pick up issue, at this point adding ground lift switches on the input of the SUT would give me balanced operation - something I will add shortly when I have time to order the appropriate switches.

I definitely have seen pictures of this particular arm before, I've never seen it in person though and have no idea what might have happened to it.

I assume there is a threaded lead screw hidden somewhere on the arm, but don't see evidence of it. I don't see how this could work, ever. Given its entirely passive nature and no defined groove pitch for LPs I don't see how it could maintain tangency to the groove over even a portion of the record being played.

I'm wondering if it wasn't just a humorous chain pull by Souther.

I assume there is a threaded lead screw hidden somewhere on the arm, but don't see evidence of it. I don't see how this could work, ever. Given its entirely passive nature and no defined groove pitch for LPs I don't see how it could maintain tangency to the groove over even a portion of the record being played.

I'm wondering if it wasn't just a humorous chain pull by Souther.

Attachments

Tri-Quartz Rewire

I purchased some Kab super flexible tone arm wire which is 34 awg per for conductor. I was not entirely sure that it would work, but it turns out that 4 conductors of this are much more flexible than the rather stiff wire I had on the arm.

I also installed a set of RCA jacks on the arm, undoing one of the mods done by the previous owner.

I didn't really have a great feel for the dimensions of the wire and made it a bit too long to be honest. It doesn't look that great, but works fine. I would leave off the tubing I slipped over the clips as this and the thicker wire adds significant mass which may not be a good thing in some instances. (Here it does not hurt)

It is a vast improvement over what it replaced subjectively speaking (and to my surprise) - perhaps eliminating a couple of solder joints helped. The RCA jacks are Tiffany which just fit. (Pretty much nothing else did.)

I purchased some Kab super flexible tone arm wire which is 34 awg per for conductor. I was not entirely sure that it would work, but it turns out that 4 conductors of this are much more flexible than the rather stiff wire I had on the arm.

I also installed a set of RCA jacks on the arm, undoing one of the mods done by the previous owner.

I didn't really have a great feel for the dimensions of the wire and made it a bit too long to be honest. It doesn't look that great, but works fine. I would leave off the tubing I slipped over the clips as this and the thicker wire adds significant mass which may not be a good thing in some instances. (Here it does not hurt)

It is a vast improvement over what it replaced subjectively speaking (and to my surprise) - perhaps eliminating a couple of solder joints helped. The RCA jacks are Tiffany which just fit. (Pretty much nothing else did.)

Attachments

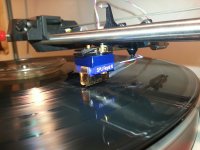

Figured out a better way to route the tonearm wiring.. Involved a wee bit of double sided sticky tape that I pressed the sleeve into the tape. This is a pretty major improvement over the kludged wiring I used previously.

This stuff is extremely flexible, it's also a bit heavy and created an issue with setting the tracking force which required the addition of an additional counterweight. In this case the additional mass is a benefit. This particular Benz model will never have great bass unfortunately, but otherwise performs quite well.

This stuff is extremely flexible, it's also a bit heavy and created an issue with setting the tracking force which required the addition of an additional counterweight. In this case the additional mass is a benefit. This particular Benz model will never have great bass unfortunately, but otherwise performs quite well.

Attachments

Quick recap on changes and lessons learned

Cartridges:

- I've replaced the original Souther unlubricated bearings in both arms with lubricated bearings sourced from McMaster Carr. Despite the advice to the contrary these bearings seem to work much better than even NIB Souther OEM bearings. The endemic bearing chatter is eliminated and I have not observed any side effects due to possibly increased drag. (No evidence of a significant increase with these bearings.) See this post for details: http://www.diyaudio.com/forums/anal...er-linear-tonearm-td-124-a-3.html#post4616478

- I have rewired both arms with KAB super flexible 34ga litz wire. It really is flexible - more so than any of the replacements made specifically for this arm. This cable sounds better than the original or any of the replacements. (It eliminates multiple solder joints and contacts, but I find in general I prefer litz wire in very low level applications anyway.)

- Set it up carefully, and exactly as Souther recommends until you are good enough at it to use some short cuts.

- The arm should work properly when perfectly leveled and parallel to the record surface. No slope should be necessary ever and will result in a changing VTA as the record plays. Fix whatever is causing the arm to mis-track - it should not need to travel downhill ever.. There may be a VTF component (too low by cartridge design) to this problem or excessive bearing drag.

- Keep it clean! Use only distilled water for wiping down the rods and do it regularly.

- VTA setting can be quite critical with some cartridges, in particular those with line contact type styli, a mistake here can make things quite unlistenable.

- Cartridges in the 5 - 11gm range will work well

- The hollow arm wands suck, don't use them if possible. IMO they are only appropriate with lightweight, low VTF, high compliance MM types.

- If you have to use a hollow arm wand, partial to full stuffing with cork helps tame the HF resonances in these tubes.

- Cartridges with a lateral compliance of 8 - 16 CU seem to work. Where compliances are broken out separately a low horizontal compliance may be the way to go.

- Recommend cartridges with rated VTF of 2 - 3gms

- Tone arm wire dress is important in order to minimize resistance to carriage movement during play.

Cartridges:

- Benz Ebony H - best arm match I have heard with this cartridge. Bass is a bit wooly and tubby, but is worse on any other arm I have tried it with. Otherwise wonderful.

- Ortofon Royal N - Strangely this one works better than anything else I have tried so far. Sounds very good, no mis-tracking or other odd behaviors.

- Ortofon Per Windfeld - Problematic and not recommended at this point in time. Very promising, some of the best and worst sound depending on vinyl. Very unforgiving of VTA, azimuth and overhang settings. Substantial issues with sibilance, more sensitive to arm wand material and condition of carriage bearings than any other cartridge tried so far.

hi Kevin, the Souther is a great arm. I own 2 and I have described the mod.s I made to mine in an earlier thread.

http://www.diyaudio.com/forums/anal...nearms-no-airpump-no-servo-2.html#post3848913

One problem I was not able to solve was yawing with eccentric records. The bearings are not locked in tight on the quart rod, and I have observed a twisting of the arm as it tracks off-centre records - the arm should move left and right with each revolution of the record, staying parallel to the groove. But the cartridge gets dragged left to right ahead of the arm, ever so slightly, in effect twisting the arm around the bearing point (s). In practice I never heard that this upsetting the sound (which remained superb) but it is unsettling to watch.

Right now I am using an MG-1 air bearing arm. Of course this introduces the complications of an air ump, and much heavier arm. But this bearing will eliminate all twisting with off-centre records.

Advanced Analog Audio - MG-1 MK1 AIR BEARING OPERATE LINEAR TRACKING TONEARM

But if all your records are centred then the Souther is close to perfect IMHO. (with my mod.s of course )

)

http://www.diyaudio.com/forums/anal...nearms-no-airpump-no-servo-2.html#post3848913

One problem I was not able to solve was yawing with eccentric records. The bearings are not locked in tight on the quart rod, and I have observed a twisting of the arm as it tracks off-centre records - the arm should move left and right with each revolution of the record, staying parallel to the groove. But the cartridge gets dragged left to right ahead of the arm, ever so slightly, in effect twisting the arm around the bearing point (s). In practice I never heard that this upsetting the sound (which remained superb) but it is unsettling to watch.

Right now I am using an MG-1 air bearing arm. Of course this introduces the complications of an air ump, and much heavier arm. But this bearing will eliminate all twisting with off-centre records.

Advanced Analog Audio - MG-1 MK1 AIR BEARING OPERATE LINEAR TRACKING TONEARM

But if all your records are centred then the Souther is close to perfect IMHO. (with my mod.s of course

I went through the other thread and all of the mods you've done are on one of my arms. My Tri-Quartz has 3 rods as suggested by Lou Souther himself, the SLA-3 will get one relatively soon. The TQ is also full of lead shot, aqua-plas and sand.

Both are completely rewired and no plastic covers in sight.

One of our fellow members pointed to a replacement bearing that he thought would be a suitable replacement for the originals - seem to work better despite the presence of lubricant. Installed on both arms.

I put the support block I got with the TQ on the SLA-3 since that is the arm that went on the better table. The TQ was a complete salvage job.

I may or may not add the third quartz rod found on the TQ to the SLA-3, it creates maintenance nightmares (bearing service) and I am not convinced it is doing a lot.

On the carriage thing I use fairly heavy MC cartridges, tracking at 2 - 3gms and have tweaked the bearings and I haven't observed the rocking motion described to anything like the extent described, but I will watch for it.

Strangely enough a little blu-tac judiciously applied to key areas on the carriage seems to improve the HF behavior considerably. (Possibly I have deluded myself into believing this.. lol)

Late in life Souther started to recommend using heavier low compliance cartridges on his arms which seemed a bit strange to me, but I can report that the Ortofon Royal N with a compliance of 8 cu tracking at 3gms works really well, and will get moved to the TQ shortly. (The Windfeld went back on the SLA-3 last night and is working better than previously, although I think the custom arm wand when ready will be a better match to this cartridge.)

Both are completely rewired and no plastic covers in sight.

One of our fellow members pointed to a replacement bearing that he thought would be a suitable replacement for the originals - seem to work better despite the presence of lubricant. Installed on both arms.

I put the support block I got with the TQ on the SLA-3 since that is the arm that went on the better table. The TQ was a complete salvage job.

I may or may not add the third quartz rod found on the TQ to the SLA-3, it creates maintenance nightmares (bearing service) and I am not convinced it is doing a lot.

On the carriage thing I use fairly heavy MC cartridges, tracking at 2 - 3gms and have tweaked the bearings and I haven't observed the rocking motion described to anything like the extent described, but I will watch for it.

Strangely enough a little blu-tac judiciously applied to key areas on the carriage seems to improve the HF behavior considerably. (Possibly I have deluded myself into believing this.. lol)

Late in life Souther started to recommend using heavier low compliance cartridges on his arms which seemed a bit strange to me, but I can report that the Ortofon Royal N with a compliance of 8 cu tracking at 3gms works really well, and will get moved to the TQ shortly. (The Windfeld went back on the SLA-3 last night and is working better than previously, although I think the custom arm wand when ready will be a better match to this cartridge.)

kevinkr,

Fist off, thanks for all your contributions to the diy commumity over the years.

Being a hobby machinist /audiophile for many years I would like to give some observations about mechanical linear arms in general. Most people concentrate on the bearing quality, which is essential, however IMHO whether the arm that rides inside a glass tube or on top of a rod the tube or the rod gets the least amount scrutiny. The bearing mfgr's can give precise specs and tolerances to their products as can most glass tube/ rod mfg's but the rods/tubes being used for linear tonearms are simply not precise enough. Unless the glass/quatrz rods/ tubes are precision ground they will have many minute imperfections such as dips, peaks, out of round, and not to mention... bent to a small degree. All of these imperfections adds up to tonearm "quirks" such as sticking, twisting, mistracking etc. Not all the problems are the rod/tubes fault of course, but some are---the ones that can't be casually explained.

I realize all tonearms are built to a price/ performance point, however a clever (many here) diy person can make improvements that the mfg's can't or will not do.

I have purchased several glass/quartz tubes/rods from several suppliers over the last couple of years and have been VERY disappointed-----once I measured them !!!

I have spun these rods and tubes on a high precision Hardidge lathe and center jigs to measure the run out using .0001" indicators and have been made almost sea sick from looking at the amount of indicator movement !!!! Some of the rods would only be good for mixing drinks!!!

Most people don't have the luxury of having precision measuring equipment, so what can be done ?

For the Souther arm, you could buy precision ground tungsten carbide rods on EBAY, MSC etc. which is super hard, durable, in any diameter you need and not too expensive. The precision glass/quartz option will almost for sure be more expensive. The odds of getting 2 identical mass produced glass/quartz rods is near impossible. Without precise tube/rods linear tonearms will never realize its full potential. The only question is how far you want to go for maximum arm performance. Just my 2 cents.

Fist off, thanks for all your contributions to the diy commumity over the years.

Being a hobby machinist /audiophile for many years I would like to give some observations about mechanical linear arms in general. Most people concentrate on the bearing quality, which is essential, however IMHO whether the arm that rides inside a glass tube or on top of a rod the tube or the rod gets the least amount scrutiny. The bearing mfgr's can give precise specs and tolerances to their products as can most glass tube/ rod mfg's but the rods/tubes being used for linear tonearms are simply not precise enough. Unless the glass/quatrz rods/ tubes are precision ground they will have many minute imperfections such as dips, peaks, out of round, and not to mention... bent to a small degree. All of these imperfections adds up to tonearm "quirks" such as sticking, twisting, mistracking etc. Not all the problems are the rod/tubes fault of course, but some are---the ones that can't be casually explained.

I realize all tonearms are built to a price/ performance point, however a clever (many here) diy person can make improvements that the mfg's can't or will not do.

I have purchased several glass/quartz tubes/rods from several suppliers over the last couple of years and have been VERY disappointed-----once I measured them !!!

I have spun these rods and tubes on a high precision Hardidge lathe and center jigs to measure the run out using .0001" indicators and have been made almost sea sick from looking at the amount of indicator movement !!!! Some of the rods would only be good for mixing drinks!!!

Most people don't have the luxury of having precision measuring equipment, so what can be done ?

For the Souther arm, you could buy precision ground tungsten carbide rods on EBAY, MSC etc. which is super hard, durable, in any diameter you need and not too expensive. The precision glass/quartz option will almost for sure be more expensive. The odds of getting 2 identical mass produced glass/quartz rods is near impossible. Without precise tube/rods linear tonearms will never realize its full potential. The only question is how far you want to go for maximum arm performance. Just my 2 cents.

Good point, not sure of the quality of the rods typically supplied on the Souther arms. In this specific case I was referring to the center rod on the Tri-Quartz which is there to stiffen the whole assembly.

I have a metal working lathe and dial indicators so I could spin rod, but I am wondering whether I could achieve sufficient accuracy with the equipment on hand to do a meaningful measurement. (Probably not)

I have a metal working lathe and dial indicators so I could spin rod, but I am wondering whether I could achieve sufficient accuracy with the equipment on hand to do a meaningful measurement. (Probably not)

kevinkr,

It would be very difficult to reliably measure a thin glass/ quartz rod in a lathe except in a precision collet, however you can see by eye if the rod is any good when you turn the lathe on. The easiest way is to manually turn the rod between v blocks on a surface plate using a dial indicator. Sometimes you can roll the rods on a mirror a find the out of spec rods by eye.

That is why I suggested the ground tungsten carbide rod--most are accurate to .0005" or less.

It would be very difficult to reliably measure a thin glass/ quartz rod in a lathe except in a precision collet, however you can see by eye if the rod is any good when you turn the lathe on. The easiest way is to manually turn the rod between v blocks on a surface plate using a dial indicator. Sometimes you can roll the rods on a mirror a find the out of spec rods by eye.

That is why I suggested the ground tungsten carbide rod--most are accurate to .0005" or less.

What is the drag compared to a quartz glass rod? There is quite a lot of lore surrounding the original design process for the Souther arm, the glass was a deliberate choice I understand.

Neither of these arms have problems with skipping, HF mistracking can be a big problem with the hollow arm tubes even when internally damped. I won't use them in the future, and the arm wands a friend and I are getting ready to make will use a variety of solid rods.

Some things to note:

**The SLA-3 carriage and the Tri-Quartz carriages differ significantly.**

**Arm Wands and Weights**

Neither of these arms have problems with skipping, HF mistracking can be a big problem with the hollow arm tubes even when internally damped. I won't use them in the future, and the arm wands a friend and I are getting ready to make will use a variety of solid rods.

Some things to note:

**The SLA-3 carriage and the Tri-Quartz carriages differ significantly.**

- The vertical bearing and mount on the SLA-3 has a round hole designed for 3/32" O.D. arm tubes only. Both solid rod and hollow tube arm wands were available.

- The vertical bearing and mount on the Tri-Quartz has a rhombus shaped hole and will accommodate both the older 3/32" (0.094") and the later solid 0.105" diameter rod based wands.

**Arm Wands and Weights**

- Hollow and solid arm tubes differ in length, with the solid arm tubes being slightly longer.

- Hollow wands are rather light at ~1.4gms

- Solid wands are much heavier at 4.5 - 5.0gms.

- IMLE the solid wands perform much better.

- Weights are typically approximately 2, 4, 6 gms, a single 10gm weight would in many cases be useful with modern MC cartridges.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Souther Linear Tonearm on A TD-124