Hi Jim.

It's been quite a while since last we messaged, I've looked in at your air bearing arm every now and again. Very interesting.

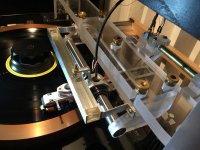

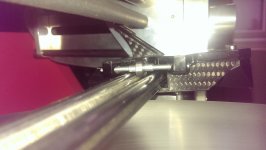

If you remember from Colin,s diy linear tonearm thread I designed my arm for maximum rigidity in order to push the arms fundamental bending resonance above the audio bandwidth. This made a very chunky short arm. Quite different from a souther in appearance. The rail passes through the carriage, ie the carriage has structural members that pass both above and below the rail. There is only a fraction of a millimetre clearance between the rail and the carriage on all sides so it is absolutely impossible to derail. See photo.

I originally designed the carriage for pin bearings but could not make them or the wheels accurately enough so I adapted to ball race bearings. I have since improved my skills and have high hopes that the new version will work, they measure much better and that's just the first, low grade materials version.

As the ball race bearings worked I stuck with them whilst I built the rest of the deck. Now the deck is finished I'm revisiting the bearings.

Hi hottattoo

Exiting news. I have a couple of rail/wheel combinations that I want to try, using glass rods to fine tune the design, then I'll rebuild with the tungsten rods and jewel bearings and will of course keep you posted, good results or bad. The rails are quite Labour intensive to build so progress is frustratingly slow. I've just taken the latest version out of the oven. Hopefully I'll have it finished and fitted sometime early next week. Touch wood.

Niffy

It's been quite a while since last we messaged, I've looked in at your air bearing arm every now and again. Very interesting.

If you remember from Colin,s diy linear tonearm thread I designed my arm for maximum rigidity in order to push the arms fundamental bending resonance above the audio bandwidth. This made a very chunky short arm. Quite different from a souther in appearance. The rail passes through the carriage, ie the carriage has structural members that pass both above and below the rail. There is only a fraction of a millimetre clearance between the rail and the carriage on all sides so it is absolutely impossible to derail. See photo.

I originally designed the carriage for pin bearings but could not make them or the wheels accurately enough so I adapted to ball race bearings. I have since improved my skills and have high hopes that the new version will work, they measure much better and that's just the first, low grade materials version.

As the ball race bearings worked I stuck with them whilst I built the rest of the deck. Now the deck is finished I'm revisiting the bearings.

Hi hottattoo

Exiting news. I have a couple of rail/wheel combinations that I want to try, using glass rods to fine tune the design, then I'll rebuild with the tungsten rods and jewel bearings and will of course keep you posted, good results or bad. The rails are quite Labour intensive to build so progress is frustratingly slow. I've just taken the latest version out of the oven. Hopefully I'll have it finished and fitted sometime early next week. Touch wood.

Niffy

Hi Niffy!

I understand it now. It is a clever design. Your table looks stunning. I bet it must sound as good as it looks.

I have been updating my air bearing arms for a while. I just got a part from someone in UK. He is very kind and did the part on his CNC machine. I will try to assembly it this weekend.

Jim

I understand it now. It is a clever design. Your table looks stunning. I bet it must sound as good as it looks.

I have been updating my air bearing arms for a while. I just got a part from someone in UK. He is very kind and did the part on his CNC machine. I will try to assembly it this weekend.

Jim

Hi hottattoo

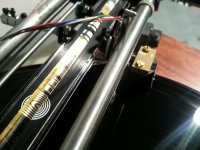

The glass isn't to difficult, the. Real pta is the end mounting blocks. The latest rail assembly consists of 12 components of different materials glued and bolted together with additional damping material in the support bars. Rigid and totally dead. It took about 2 full days to build, and it isn't quite finished yet. I have 2 sets of bearings, 1 full zirconium ceramic and 1 silicon nitride hybrid. They seem to have similar friction and sound very similar. The hybrid sound just a little better to my ears. I think that this is due to silicon nitride being less dense than zirconium oxide. This makes the balls lighter and store less energy reducing chatter. That's my guess though I'm open to other theories. At least discussing how different bearing materials sound is less of topic than we have been.

Hi Jim

I'll definitely be checking your thread. A work of art.

Niffy

The glass isn't to difficult, the. Real pta is the end mounting blocks. The latest rail assembly consists of 12 components of different materials glued and bolted together with additional damping material in the support bars. Rigid and totally dead. It took about 2 full days to build, and it isn't quite finished yet. I have 2 sets of bearings, 1 full zirconium ceramic and 1 silicon nitride hybrid. They seem to have similar friction and sound very similar. The hybrid sound just a little better to my ears. I think that this is due to silicon nitride being less dense than zirconium oxide. This makes the balls lighter and store less energy reducing chatter. That's my guess though I'm open to other theories. At least discussing how different bearing materials sound is less of topic than we have been.

Hi Jim

I'll definitely be checking your thread. A work of art.

Niffy

Hi niffy,

Tungsten carbide rods are here !!! They look beautiful-- and are they STIFF. This should help your project along. You have my email so send me your shipping address and the rods will be shipped today !!

kevinkr,

Since you served as the "instigator" of this fine topic, I am offering you also a pair of tungsten carbide rods ( ground and polished ) of the size required to replace the glass rods of your Souther arm ( if you like) as an experiment for the benefit of everybody who has an interest in this project. Let me know the size you need. Hope this is enough on topic !!!!

Tungsten carbide rods are here !!! They look beautiful-- and are they STIFF. This should help your project along. You have my email so send me your shipping address and the rods will be shipped today !!

kevinkr,

Since you served as the "instigator" of this fine topic, I am offering you also a pair of tungsten carbide rods ( ground and polished ) of the size required to replace the glass rods of your Souther arm ( if you like) as an experiment for the benefit of everybody who has an interest in this project. Let me know the size you need. Hope this is enough on topic !!!!

super10018,

Your tonearm is stunning !!! i followed your entire arm project with great interest. I am torn between making an air bearing and a mechanical linear arm knowing full well the advantages and disadvantages of both. I have an older Souther arm on an Oracle delphi mk2 turntable in storage that I have not looked at in many years. I will have to break it out when I get time.

Your tonearm is stunning !!! i followed your entire arm project with great interest. I am torn between making an air bearing and a mechanical linear arm knowing full well the advantages and disadvantages of both. I have an older Souther arm on an Oracle delphi mk2 turntable in storage that I have not looked at in many years. I will have to break it out when I get time.

Hi Kevin

I am probably largely responsible for the drift off topic. Sorry about that. What is on topic or off topic is dependent on what the purpose of this thread actually is. If it is an investigation into how the souther arm can be improved then discussion of different bearings and alternative materials is relevant. The first part of my rather long post, #106, was relevant as it describing some of the limitations of the bearings that are an important part of the souther. The second half of the post was I admit a bit off topic. How off topic is dependent upon how much modification to the original arm is possible and.how much is possible before it ceases to be a souther and becomes something different.

A title for a splinter thread could be "alternative bearings for passive linear tracking tonearm"

Niffy

I am probably largely responsible for the drift off topic. Sorry about that. What is on topic or off topic is dependent on what the purpose of this thread actually is. If it is an investigation into how the souther arm can be improved then discussion of different bearings and alternative materials is relevant. The first part of my rather long post, #106, was relevant as it describing some of the limitations of the bearings that are an important part of the souther. The second half of the post was I admit a bit off topic. How off topic is dependent upon how much modification to the original arm is possible and.how much is possible before it ceases to be a souther and becomes something different.

A title for a splinter thread could be "alternative bearings for passive linear tracking tonearm"

Niffy

In looking things over if we moved all of the stuff to a new thread the only participant at this point would be me, so I'm going to leave those posts. Anything that might be relevant to Souther style arms (yours sort of qualifies here) is OK, didn't really have the heart to proceed since I've learned some useful stuff here in the past few days. Next post will be the day's project.

<snip>

kevinkr,

Since you served as the "instigator" of this fine topic, I am offering you also a pair of tungsten carbide rods ( ground and polished ) of the size required to replace the glass rods of your Souther arm ( if you like) as an experiment for the benefit of everybody who has an interest in this project. Let me know the size you need. Hope this is enough on topic !!!!

I am definitely interested and will post the details for rods I can use soon. I will have to make a new rail plate to use them on, I'm not going to modify the existing ones as that would render the arm scrap if something went wrong. lol

Many thanks..

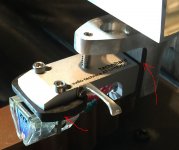

First homebrew arm wand

All of the bits and pieces finally got here, and last night I spent some time cleaning up my little machine shop. This is probably the most ambitious I have been in a couple of years.

I used 6 inches of 3/32" stainless steel rod and bronze rectangular bar stock of 0.1875" x 0.75" cut to 0.50" for the head shell (cartridge mounting block).

Based on previous experiments that seemed to indicate that the cartridge was happier with rather high mass, previously close to 40gms in the horizontal plane I decided to go a relatively high overall mass. I ended up with 43gms with counterweights, and cartridge all set to go. The arm with cartridge came to roughly 29gms, and 14gms of counter weight mass was the right combination of weight. I believe 12gms - 14gms is the optimum range and I make a tellurium copper counter weight sometime in the next week or so. This wand works better than any of the Souther wands, although the ones I have modified with solid rod work much better than the hollow OEM wands with the cartridges I have on hand.

All of the bits and pieces finally got here, and last night I spent some time cleaning up my little machine shop. This is probably the most ambitious I have been in a couple of years.

I used 6 inches of 3/32" stainless steel rod and bronze rectangular bar stock of 0.1875" x 0.75" cut to 0.50" for the head shell (cartridge mounting block).

Based on previous experiments that seemed to indicate that the cartridge was happier with rather high mass, previously close to 40gms in the horizontal plane I decided to go a relatively high overall mass. I ended up with 43gms with counterweights, and cartridge all set to go. The arm with cartridge came to roughly 29gms, and 14gms of counter weight mass was the right combination of weight. I believe 12gms - 14gms is the optimum range and I make a tellurium copper counter weight sometime in the next week or so. This wand works better than any of the Souther wands, although the ones I have modified with solid rod work much better than the hollow OEM wands with the cartridges I have on hand.

Attachments

I should mention my machining skills are nascent, this is the first attempt at precision machining I have attempted. I'm surprised I have the patience, I set things up quite carefully, and am discovering having the right tools for the job results in much better results. I have a feeling I will be doing a lot more of it..

I am slowly adding tools and machines to my little shop which due to various challenges sat unexplored and unused for several years even while I continued to acquire tools. (For a while I thought I would never be well enough again to embark down the road of learning how to use all of this stuff.. lol)

I didn't quite do a perfect job, but the critical dimensions are right, and the cartridge is perpendicular to the arm wand in the horizontal plane which is not of trivial importance.

Edit: I think I need more space!

I am slowly adding tools and machines to my little shop which due to various challenges sat unexplored and unused for several years even while I continued to acquire tools. (For a while I thought I would never be well enough again to embark down the road of learning how to use all of this stuff.. lol)

I didn't quite do a perfect job, but the critical dimensions are right, and the cartridge is perpendicular to the arm wand in the horizontal plane which is not of trivial importance.

Edit: I think I need more space!

Attachments

Be careful, making cool stuff can be highly addictive.

A couple of questions. Are the new arm components being built for a specific cartridge? I was wondering if the incompatibility you've found with the windfeld may have been due to insufficient vertical effective mass. Is this mod aimed at resolving this issue?

Tellurium copper? What are your reasons for choosing this material for your counterweight?

Have fun building.

Niffy

A couple of questions. Are the new arm components being built for a specific cartridge? I was wondering if the incompatibility you've found with the windfeld may have been due to insufficient vertical effective mass. Is this mod aimed at resolving this issue?

Tellurium copper? What are your reasons for choosing this material for your counterweight?

Have fun building.

Niffy

Hi Niffy,

Yes I built this wand specifically to work with the Windfeld, it did not seem to be just an issue of insufficient effective vertical mass, but something more. The cartridge apparently couples rather a lot of HF energy into the arm, and generated a lot of sibilance, and generally sounded bad on material with demanding HF content. I found that the more damping (not just mass) that I applied to the arm the better it worked, but not quite enough. That big block of bronze seems to be the key.

The tellurium copper rod was chosen because it has quite high mass per unit volume and is quite dense. A friend of mine with some background in material science indicated in a casual conversation that it might be one of the better materials to make counterweights out of due to be well damped. I also have a bronze alloy which is also high mass per unit volume. I'm just experimenting and looking for combinations that work.

What I can say from listening for a few hours is that this wand actually works well with the Windfeld - shot in the dark, but I may now be able to use this on the Tri-Quartz at least. (The Benz sounds so good on the SLA-3 that I'm leaving it there)

I've modified several of the original arm wands, fitting them with stainless steel or bronze rod in place of the titanium thin walled tubing originally provided. In all cases the improvement was audible.

Yes I built this wand specifically to work with the Windfeld, it did not seem to be just an issue of insufficient effective vertical mass, but something more. The cartridge apparently couples rather a lot of HF energy into the arm, and generated a lot of sibilance, and generally sounded bad on material with demanding HF content. I found that the more damping (not just mass) that I applied to the arm the better it worked, but not quite enough. That big block of bronze seems to be the key.

The tellurium copper rod was chosen because it has quite high mass per unit volume and is quite dense. A friend of mine with some background in material science indicated in a casual conversation that it might be one of the better materials to make counterweights out of due to be well damped. I also have a bronze alloy which is also high mass per unit volume. I'm just experimenting and looking for combinations that work.

What I can say from listening for a few hours is that this wand actually works well with the Windfeld - shot in the dark, but I may now be able to use this on the Tri-Quartz at least. (The Benz sounds so good on the SLA-3 that I'm leaving it there)

I've modified several of the original arm wands, fitting them with stainless steel or bronze rod in place of the titanium thin walled tubing originally provided. In all cases the improvement was audible.

Hi Kevin,

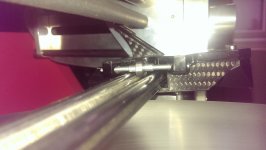

I wouldn’t probably use copper for head shell. It is a bit too heavy. Personally, I like Audio Technica Technihard head shell very much and bought two. In your case, I would suggest to use magnesium for head shell or 2024 aluminum with wood shim. Magnesium is a very well damped material. For me, I have made all different kind of shim for cartridge. I use two 1.5 mm carbon fiber shim and glue them together. I also did carbon fiber with different woods and magnesium. The woods I have tried are african black wood, snake wood and lignum vitae. I think African black wood has most even density and sounds most natural. Please see the photo. In the photo, where the red arrow points to is a piece of African black wood. For the head shell, it is two 1.5 mm carbon fiber glued together. For different cartridge, I use different shim to reduce resonance. The windfeld has stainless steel case. You definitely need to a piece of wood shim to isolate the resonance between metal case and metal head shell. In fact, since your arm wand is metal too. I probably try all wood head shell. African black wood is my choice for the wood.

Jim

I wouldn’t probably use copper for head shell. It is a bit too heavy. Personally, I like Audio Technica Technihard head shell very much and bought two. In your case, I would suggest to use magnesium for head shell or 2024 aluminum with wood shim. Magnesium is a very well damped material. For me, I have made all different kind of shim for cartridge. I use two 1.5 mm carbon fiber shim and glue them together. I also did carbon fiber with different woods and magnesium. The woods I have tried are african black wood, snake wood and lignum vitae. I think African black wood has most even density and sounds most natural. Please see the photo. In the photo, where the red arrow points to is a piece of African black wood. For the head shell, it is two 1.5 mm carbon fiber glued together. For different cartridge, I use different shim to reduce resonance. The windfeld has stainless steel case. You definitely need to a piece of wood shim to isolate the resonance between metal case and metal head shell. In fact, since your arm wand is metal too. I probably try all wood head shell. African black wood is my choice for the wood.

Jim

Attachments

Last edited:

Hi Jim,

The copper is just for the counterweights, the head shells will be aluminum or bronze, noting that the bronze is rather heavy so those shells will be shorter in order to keep the weight down.

I have been thinking about a wood head shell for one or more of the wands and will have a look at African black wood.

The Windfeld is much happier on the new wand than it was on any of the originals or the Schick.

The copper is just for the counterweights, the head shells will be aluminum or bronze, noting that the bronze is rather heavy so those shells will be shorter in order to keep the weight down.

I have been thinking about a wood head shell for one or more of the wands and will have a look at African black wood.

The Windfeld is much happier on the new wand than it was on any of the originals or the Schick.

Tellurium Copper

Tellurium is added to copper to improve its machinability. Because Tellurium is rare, Tellurium copper costs more.

Sincerely,

Ralf

The tellurium copper rod was chosen because it has quite high mass

Tellurium is added to copper to improve its machinability. Because Tellurium is rare, Tellurium copper costs more.

Sincerely,

Ralf

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Souther Linear Tonearm on A TD-124