Steppulley Noise measurement

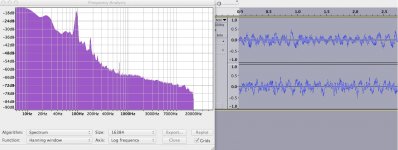

I did some measurements on a 124 Mk1 with worn steppulley bearings they produced some annoying noise .

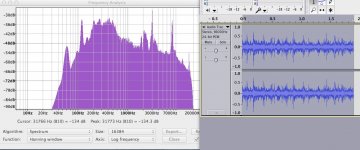

FFT with accellero meter from B@K on the chassis from the turntable .

Results speak for themselfs.

Volken

I did some measurements on a 124 Mk1 with worn steppulley bearings they produced some annoying noise .

FFT with accellero meter from B@K on the chassis from the turntable .

Results speak for themselfs.

Volken

Attachments

I did some measurements on a 124 Mk1 with worn steppulley bearings they produced some annoying noise .

FFT with accellero meter from B@K on the chassis from the turntable .

Results speak for themselfs.

Volken

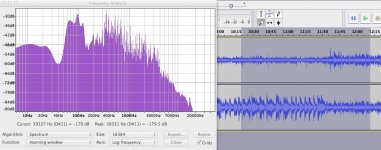

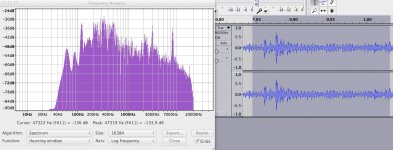

Volken, that's very interesting. I've got similar concerns with the steppulley bearings on my MKII. Take a look at the comparison photo I've attached and tell me if you think it's the same as what you experienced. This is the Thorens compared to same track on a Dual 1219. It's a spectorgram pulled using Audacity.

Attachments

Hallo Kevin,

you find the bearings on Ebay, always from the spanish seller.

http://www.ebay.de/itm/Thorens-TD-1...rd_Player_Turntable_Parts&hash=item3f2391f94c

Cheers

Maurizio

you find the bearings on Ebay, always from the spanish seller.

http://www.ebay.de/itm/Thorens-TD-1...rd_Player_Turntable_Parts&hash=item3f2391f94c

Cheers

Maurizio

Both very interesting. Some day I should get motivated to check my 124/II which actually had very low hours on it when I got it.

Volken where did you get the bearings for the step pulley? Not all bearings IMVLE are created alike..

These bearings came from Oillite bearings in the UK.

Volken, that's very interesting. I've got similar concerns with the steppulley bearings on my MKII. Take a look at the comparison photo I've attached and tell me if you think it's the same as what you experienced. This is the Thorens compared to same track on a Dual 1219. It's a spectorgram pulled using Audacity.

I"m note sure what I see on your spectrum plot the bearing frequence at my measurement is at about 400 Hz -500 Hz after replacement the noise is -20dB down on the 400 Hz level it runs quiet now .

Hallo Kevin,

you find the bearings on Ebay, always from the spanish seller.

<snip>

Cheers

Maurizio

I don't believe these are the bearings Volken is using which is why I asked specifically. I've found through direct experience and anecdotes from others that all bearings are not created equal which is why I asked.

Volken do you have a specific part number?

TNX...

I"m note sure what I see on your spectrum plot the bearing frequence at my measurement is at about 400 Hz -500 Hz after replacement the noise is -20dB down on the 400 Hz level it runs quiet now .

Volken - I took the spectrogram several months ago, but failed to take another one of just the silence, which would have let me identify the frequency, instead of just representing it as a "squiggle" in the silence prior to music start. I suspect though, that mine is in the 400 Hz - 500 Hz range too. Next time I hook up the Thorens I'll see if I can narrow it down.

When I first posted about this many months ago, I noted that it seemed as though I could see a mild oscillation in the top axle for the stepped pulley, but that I'd not been able to determine if it was the bearing or a bent axle. I bought a kit a month back that has several bearings in it (we think it originally came from Schopper) and I think one of them is for the stepped pulley. I need to confirm that and do the replacement so I see if that resolves the problem as it did for you

EDIT: Apologies. The pic I posted today is obviously the waveform, not a spectrogram. Foolish me for not pulling one at the time

Last edited:

TD 124/II spectrograms

My curiosity got the better of me, so I hooked up the Thorens to a preamp, recorded an album, and took screenshots from Audacity that show both the waveform and spectrogram for select portions of the recording. The screenshots I'm posting here are from John Coltrane Quartet - Ballads (ABC/Paramount Impulse!).

The recordings were done using the preamp's direct mode and no clamp or center weight was used, so this is pretty much what you hear is what you get.

I won't upload all the pics, but here's the run-down.

(1) the lead-in to track one.

(2) the silence between tracks one and two.

(3) a one minute segment of a track approximately 11 minutes in to side one.

(4) A sample of silence, de-clicked (ClickRepair) and amplified to -5 dB. This one I think shows the main issues most clearly.

As I reviewed the pics, I could see that the "squiggle" apparent in the waveform corresponds to the 100 Hz spike on the spectrogram. This was actually the second record I studied this way today. I decided to post the Coltrane shots because while the noise floor below 40 Hz moves up markedly to -48dB on this record, it was a lot worse on the other one.

While it's not apparent on the charts, there's also a lot of noise coming from the stepped pulley which may be related to the bearing, just not sure of that yet. Putting a mid of downward pressure on the belt eliminates this noise. Because this noise is pretty audible, I uploaded some videos to YouTube and will post links to those separately.

For background, at this point very little has been done to this turntable, besides a quick lube of the motor and spindle. My intent with these pics and vids is to establish a baseline. I will do the restoration/maintenance one step at a time and after each, pull similar charts so it'll be easy to tell when something I've done has made a difference (hopefully for the better). Any thoughts that come up while looking at the pics & vids, please post!

My curiosity got the better of me, so I hooked up the Thorens to a preamp, recorded an album, and took screenshots from Audacity that show both the waveform and spectrogram for select portions of the recording. The screenshots I'm posting here are from John Coltrane Quartet - Ballads (ABC/Paramount Impulse!).

The recordings were done using the preamp's direct mode and no clamp or center weight was used, so this is pretty much what you hear is what you get.

I won't upload all the pics, but here's the run-down.

(1) the lead-in to track one.

(2) the silence between tracks one and two.

(3) a one minute segment of a track approximately 11 minutes in to side one.

(4) A sample of silence, de-clicked (ClickRepair) and amplified to -5 dB. This one I think shows the main issues most clearly.

As I reviewed the pics, I could see that the "squiggle" apparent in the waveform corresponds to the 100 Hz spike on the spectrogram. This was actually the second record I studied this way today. I decided to post the Coltrane shots because while the noise floor below 40 Hz moves up markedly to -48dB on this record, it was a lot worse on the other one.

While it's not apparent on the charts, there's also a lot of noise coming from the stepped pulley which may be related to the bearing, just not sure of that yet. Putting a mid of downward pressure on the belt eliminates this noise. Because this noise is pretty audible, I uploaded some videos to YouTube and will post links to those separately.

For background, at this point very little has been done to this turntable, besides a quick lube of the motor and spindle. My intent with these pics and vids is to establish a baseline. I will do the restoration/maintenance one step at a time and after each, pull similar charts so it'll be easy to tell when something I've done has made a difference (hopefully for the better). Any thoughts that come up while looking at the pics & vids, please post!

Attachments

Last edited:

TD 124/II videos of stepped pulley noise

Here are the links to the videos I made showing the stepped pulley, idler wheel, etc. The pulley noise is pretty obvious, as is the fact the idler wheel's out of round. With respect to the pulley noise, mild downward pressure on the belt seems to eliminate it. Oddly, I didn't have this noise the last time I test ran the turntable. However, the 100 Hz spike was apparent then too.

I also did a video as I began recording, so if you're into Coltrane, enjoy what he sounds like coming out of a little laptop speaker, picked up by an iPhone! Apologies for not doing that one in landscape, but I really wasn't thinking about that at the time.

One thing I did before I began recording was an eddy current brake adjustment. When I first realized speed was off too much to adjust, my instinct was to move the magnet closer to the pulley. Eventually I sped the turntable up by hand, realized it was going too slow, not too fast, and made the right adjustment. I ran the turntable for over an hour and after about a 10 minute warmup, speed stayed pretty constant throughout.

Thorens TD-124/II test run - YouTube

Thorens TD-124/II stepped pulley - YouTube

Thorens test-idler wheel - YouTube

Here are the links to the videos I made showing the stepped pulley, idler wheel, etc. The pulley noise is pretty obvious, as is the fact the idler wheel's out of round. With respect to the pulley noise, mild downward pressure on the belt seems to eliminate it. Oddly, I didn't have this noise the last time I test ran the turntable. However, the 100 Hz spike was apparent then too.

I also did a video as I began recording, so if you're into Coltrane, enjoy what he sounds like coming out of a little laptop speaker, picked up by an iPhone! Apologies for not doing that one in landscape, but I really wasn't thinking about that at the time.

One thing I did before I began recording was an eddy current brake adjustment. When I first realized speed was off too much to adjust, my instinct was to move the magnet closer to the pulley. Eventually I sped the turntable up by hand, realized it was going too slow, not too fast, and made the right adjustment. I ran the turntable for over an hour and after about a 10 minute warmup, speed stayed pretty constant throughout.

Thorens TD-124/II test run - YouTube

Thorens TD-124/II stepped pulley - YouTube

Thorens test-idler wheel - YouTube

These bearings came from Oillite bearings in the UK.

Volken, I'm in the same situation as Kevinkr, so if you have part numbers from Oillite bearings, I would appreciate it if you'd let us know what they are. Thanks!

Volken, I'm in the same situation as Kevinkr, so if you have part numbers from Oillite bearings, I would appreciate it if you'd let us know what they are. Thanks!

Ok no problem AM0407-6 Oil Filled Bronze Plain Bush 4x7x6mm

Volken - I took the spectrogram several months ago, but failed to take another one of just the silence, which would have let me identify the frequency, instead of just representing it as a "squiggle" in the silence prior to music start. I suspect though, that mine is in the 400 Hz - 500 Hz range too. Next time I hook up the Thorens I'll see if I can narrow it down.

When I first posted about this many months ago, I noted that it seemed as though I could see a mild oscillation in the top axle for the stepped pulley, but that I'd not been able to determine if it was the bearing or a bent axle. I bought a kit a month back that has several bearings in it (we think it originally came from Schopper) and I think one of them is for the stepped pulley. I need to confirm that and do the replacement so I see if that resolves the problem as it did for you

EDIT: Apologies. The pic I posted today is obviously the waveform, not a spectrogram. Foolish me for not pulling one at the time

Schopper does not sell bearings for the steppulley , only a modification for the first steppulley where the bearing is on the top.

Replacement is not so easy because the fitting is tight same as for the motor bearings only at the steppulley you have a mounting extra .

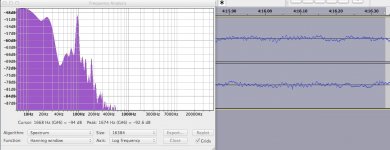

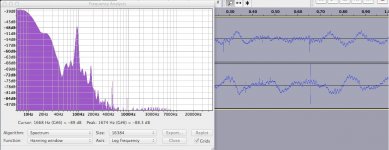

Thorens TD 124/II waveform using external mic

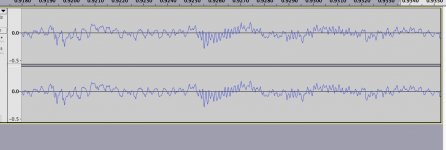

Last night I posted some screen grabs taken from a recording, focusing primarily on the silence between tracks. The idea was to create a baseline of noise, primarily from the stepped pulley, so I'd have something to compare as I renovated the turntable. Obviously by using as my sound source the silence between tracks, a lot of noise sources were included in addition to the noise I was trying to focus on - anything from the platter spindle, the tonearm gimbal, and the vinyl itself, but it was a start. I also posted some Youtube vids that let you hear what I was able to pick up with the iphone mic placed close to the pulley.

This morning, in an attempt to remove some of the other noise sources, I did a similar experiment, but this time recorded audio into Audacity via the mic built into my earbuds. The mic was taped to the inside of the chassis, a few inches from the stepped pulley. Once I'd captured the sound, it was amplified 40 dB to a -1dB. Without that amplification much of what the mic captured simply wouldn't render in the spectrogram. It did, however, amplify the noise to such a degree you'd think a freight train was going by on really bad tracks!

I've no idea what the frequency response is of the mic I used, but I'd guess it's been optimized for voice. Still, it picked up quite a bit on the low end, and as the primarily noise from the stepped pulley is quite audible, the mic did a reasonably good job.

As I did previously, there are a couple of YouTube vids, this time so you can see the waveform in Audacity while listening to the "freight train". I'm attaching some of the most relevant screen grabs to this post. As always, if there's something that comes to mind as you look through these, by all means let me know.

Here are the vid links.

Audio and waveform. Pulley noise - YouTube

Audio and waveform close-up - YouTube

Last night I posted some screen grabs taken from a recording, focusing primarily on the silence between tracks. The idea was to create a baseline of noise, primarily from the stepped pulley, so I'd have something to compare as I renovated the turntable. Obviously by using as my sound source the silence between tracks, a lot of noise sources were included in addition to the noise I was trying to focus on - anything from the platter spindle, the tonearm gimbal, and the vinyl itself, but it was a start. I also posted some Youtube vids that let you hear what I was able to pick up with the iphone mic placed close to the pulley.

This morning, in an attempt to remove some of the other noise sources, I did a similar experiment, but this time recorded audio into Audacity via the mic built into my earbuds. The mic was taped to the inside of the chassis, a few inches from the stepped pulley. Once I'd captured the sound, it was amplified 40 dB to a -1dB. Without that amplification much of what the mic captured simply wouldn't render in the spectrogram. It did, however, amplify the noise to such a degree you'd think a freight train was going by on really bad tracks!

I've no idea what the frequency response is of the mic I used, but I'd guess it's been optimized for voice. Still, it picked up quite a bit on the low end, and as the primarily noise from the stepped pulley is quite audible, the mic did a reasonably good job.

As I did previously, there are a couple of YouTube vids, this time so you can see the waveform in Audacity while listening to the "freight train". I'm attaching some of the most relevant screen grabs to this post. As always, if there's something that comes to mind as you look through these, by all means let me know.

Here are the vid links.

Audio and waveform. Pulley noise - YouTube

Audio and waveform close-up - YouTube

Attachments

Detach your tonearm from the deck, and use the pick-up to record noise. Make sure the tonearm board is fixed and stable, and that the tonearm can be swung over the deck.

Lower the needle on to the deck, close to where the wheel drives the platter to register its noise, and close to the engine, to register that.

Very effective way of localizing your readings.

Lower the needle on to the deck, close to where the wheel drives the platter to register its noise, and close to the engine, to register that.

Very effective way of localizing your readings.

Detach your tonearm from the deck, and use the pick-up to record noise. Make sure the tonearm board is fixed and stable, and that the tonearm can be swung over the deck.

Lower the needle on to the deck, close to where the wheel drives the platter to register its noise, and close to the engine, to register that.

Very effective way of localizing your readings.

Telemann - Thanks. I tend to forget that with this model what you're proposing isn't that difficult. Most other turntables I've worked on have tonearms that aren't meant to be removed.

About bushing replacements

Since I had the main platter off the turntable this morning, I thought it might be a good idea to test fit the replacement bushings I got as part of a kit. I thought they might be from Schopper, but based on comments here, that doesn't seem very likely.

They seem to slide over the spindle a little too easily for my taste. The spindle's in good shape, save for some scoring at the top and you certainly could feel that scoring as the bushing crossed over them. There also seems to be a bit of pitting on the inside of one of the replacements, so with all that in mind, I'm not comfortable using them.

I have a question. Does anyone know the precise diameter of the spindle and the clearance a proper bushing should have to match? If not, I'm considering finding someone with an accurate micrometer and having them determine the original spindle diameter by measuring the middle where there is no wear.

Since I had the main platter off the turntable this morning, I thought it might be a good idea to test fit the replacement bushings I got as part of a kit. I thought they might be from Schopper, but based on comments here, that doesn't seem very likely.

They seem to slide over the spindle a little too easily for my taste. The spindle's in good shape, save for some scoring at the top and you certainly could feel that scoring as the bushing crossed over them. There also seems to be a bit of pitting on the inside of one of the replacements, so with all that in mind, I'm not comfortable using them.

I have a question. Does anyone know the precise diameter of the spindle and the clearance a proper bushing should have to match? If not, I'm considering finding someone with an accurate micrometer and having them determine the original spindle diameter by measuring the middle where there is no wear.

Kevinkr - I have to thank you for one of your postings a long ways back. You'd gone through some of the most likely sources of noise related to the stepped pulley and idler wheel and made suggestions as to how to reduce or eliminate the noise by making height adjustments to the stepped pulley, among other things.

While I seem to remember having gone through some of your suggested fixes the first time I dealt with noise in this area, going through them again resolved a good part of it.

This time around the motor mounts and drive belt got replaced. The replacement mounts seem OK and certainly the motor's riding a little higher now. The replacement belt came with a couple of mild kinks in it, which I'm hoping will work themselves out. It also vibrates a bit, so unless I get all of that settled down, I'll go back to the original. The difference in diameter between the two seemed minimal.

While I seem to remember having gone through some of your suggested fixes the first time I dealt with noise in this area, going through them again resolved a good part of it.

This time around the motor mounts and drive belt got replaced. The replacement mounts seem OK and certainly the motor's riding a little higher now. The replacement belt came with a couple of mild kinks in it, which I'm hoping will work themselves out. It also vibrates a bit, so unless I get all of that settled down, I'll go back to the original. The difference in diameter between the two seemed minimal.

Kevinkr - I have to thank you for one of your postings a long ways back. You'd gone through some of the most likely sources of noise related to the stepped pulley and idler wheel and made suggestions as to how to reduce or eliminate the noise by making height adjustments to the stepped pulley, among other things.

While I seem to remember having gone through some of your suggested fixes the first time I dealt with noise in this area, going through them again resolved a good part of it.

This time around the motor mounts and drive belt got replaced. The replacement mounts seem OK and certainly the motor's riding a little higher now. The replacement belt came with a couple of mild kinks in it, which I'm hoping will work themselves out. It also vibrates a bit, so unless I get all of that settled down, I'll go back to the original. The difference in diameter between the two seemed minimal.

The best way to judge the noise from the step pulley is to remove the platter and idler wheel this way I made the measurements .

Mostly you can feel the axial play from the pulley in the bearing sometimes oil will do the trick but to keep it quiet better to replace the bearings.

Ok no problem AM0407-6 Oil Filled Bronze Plain Bush 4x7x6mm

I wasn't able to find this bushing on the Oilite product page. I did find an AAM 407-4 and an AAM407-8

- Home

- Source & Line

- Analogue Source

- Restoring and Improving A Thorens TD-124 MKII